Loading method of ZIFs on silicon substrate, silicon substrate material and application of silicon substrate material

A matrix material and matrix technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of controllable thickness, large selection randomness, and good load uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

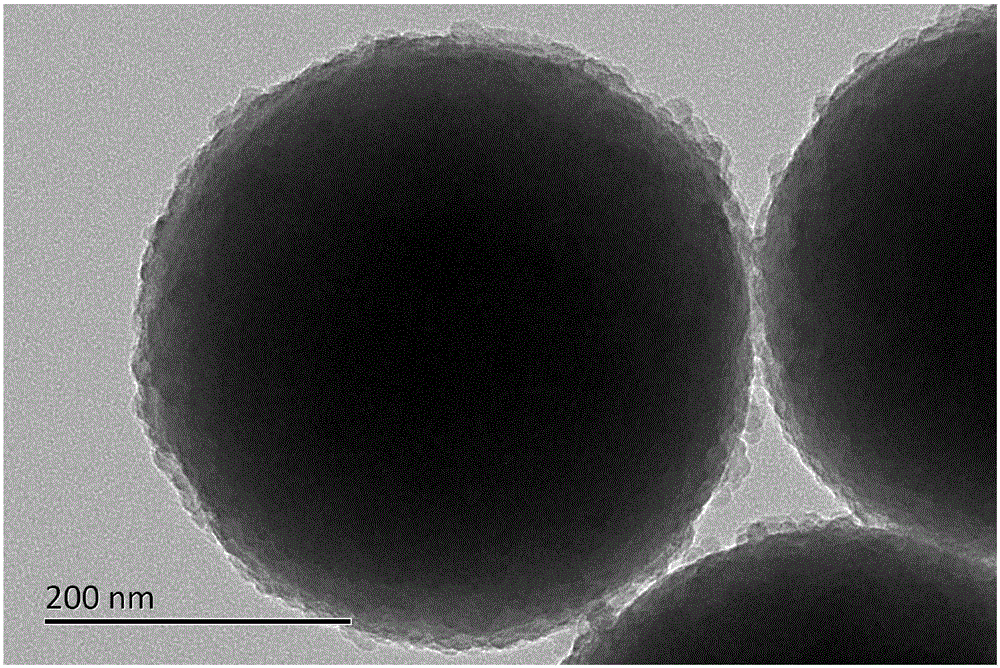

[0029] Prepare solid silicon spheres with a diameter of 400 nm by the Stober method, weigh 1 g of silicon spheres in a 100 mL round-bottomed flask, add 40 mL of HCl with a mass concentration of 10%, reflux at 95 ° C for 8 h, filter with suction, water and dry Wash with water and ethanol until neutral, and dry at 100°C for 24 hours for later use.

[0030] Add 1 g of vacuum-dried acidified silicon spheres to a 100 mL three-necked flask, add 40 mL of dry toluene and 1 mL of N-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole , after ultrasonic or vacuum degassing, at N 2 Reflux reaction at 109°C for 24 hours under the protection of the protection, suction filtration, first wash with dry toluene 3 times, wash with acetone and acetonitrile once, and vacuum dry at 60°C overnight to obtain derivatized silicon spheres.

[0031] Prepare 0.168mol / L methanol solution of zinc nitrate and 1.21mol / L methanol solution of 2-methylimidazole.

[0032] Weigh 0.4g of derivatized silicon spheres i...

Embodiment 2

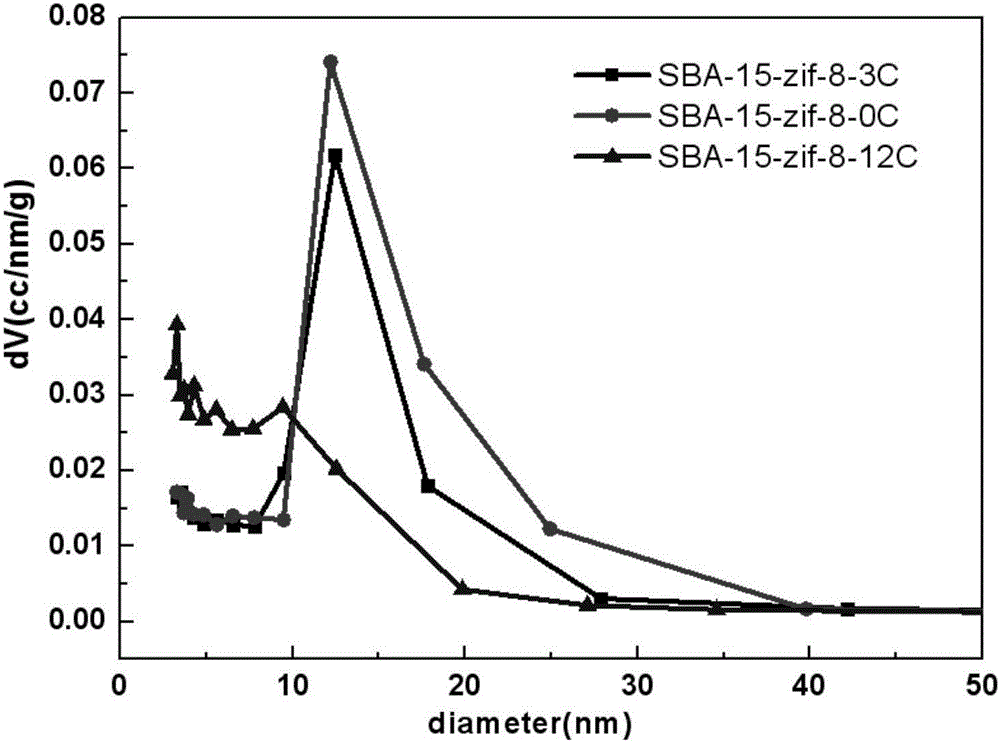

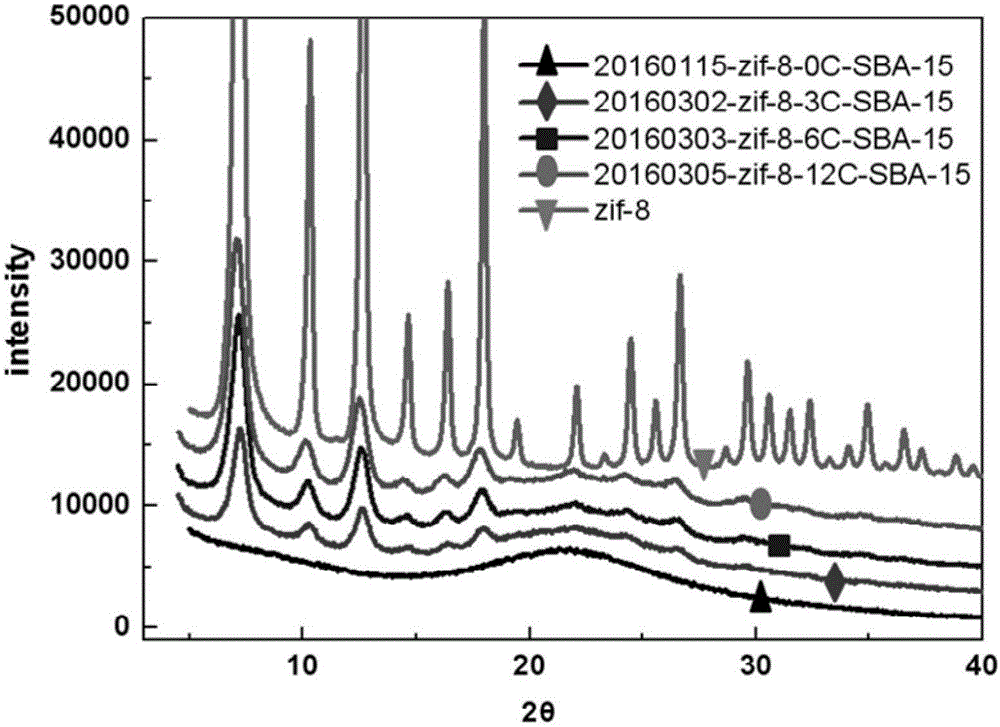

[0035] Prepare SBA-15 with a pore diameter of about 15 nm by adding n-hexane as a pore-enlarging agent, weigh 1 g of SBA-15 in a 100 mL round bottom flask, add 50 mL of 10% HCl and reflux at 95 °C for 8 h , filtered with suction, washed with water and absolute ethanol until neutral, and dried at 100°C for 24h.

[0036] Add 1 g of activated SBA-15 dried in vacuum to a 100 mL three-necked flask, add 40 mL of dry toluene and 1 mL of N-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole, After ultrasonic or vacuum degassing, in N 2 Reflux reaction at 109°C for 24h under the protection of the protection, suction filtration, washing with dry toluene 3 times, and washing with acetone and acetonitrile once respectively, and vacuum drying at 60°C overnight to obtain the derivatized SBA-15.

[0037] Prepare 0.168mol / L methanol solution of zinc nitrate and 1.21mol / L methanol solution of 2-methylimidazole.

[0038] Weigh 0.2g of derivatized SBA-15 and a 50mL round bottom flask, add 10mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com