Method for measuring silicon base body and membrane base combination intensity

A technology that combines strength and silicon substrates. It is applied in the direction of measuring devices, semiconductor/solid-state device testing/measurement, and special data processing applications. It can solve problems such as complex construction, limited measurement accuracy, and inability to take into account the influence of liquid compression errors. Eliminate cumbersomeness and avoid the effect of carrier compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

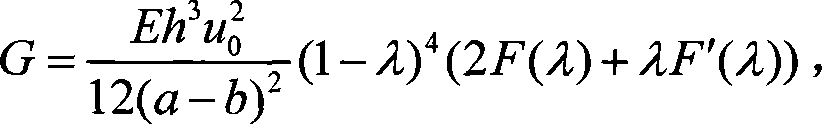

[0025] Below in conjunction with the embodiment of the present invention is described in detail: this embodiment is implemented under the premise of the technical solution of the present invention, has provided detailed implementation and process, but protection scope of the present invention is not limited to following embodiment.

[0026] This embodiment is implemented under the following implementation conditions and technical requirements:

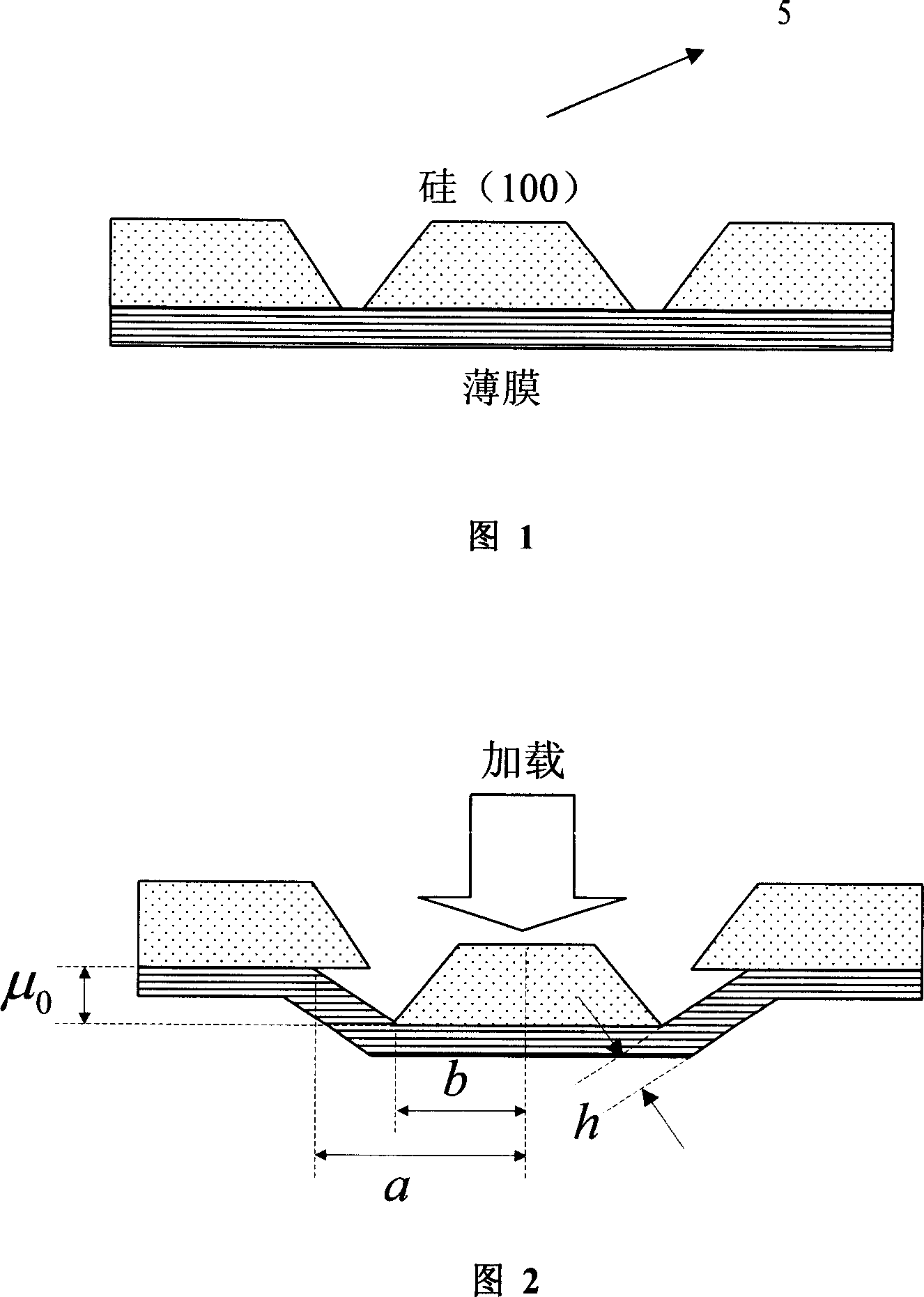

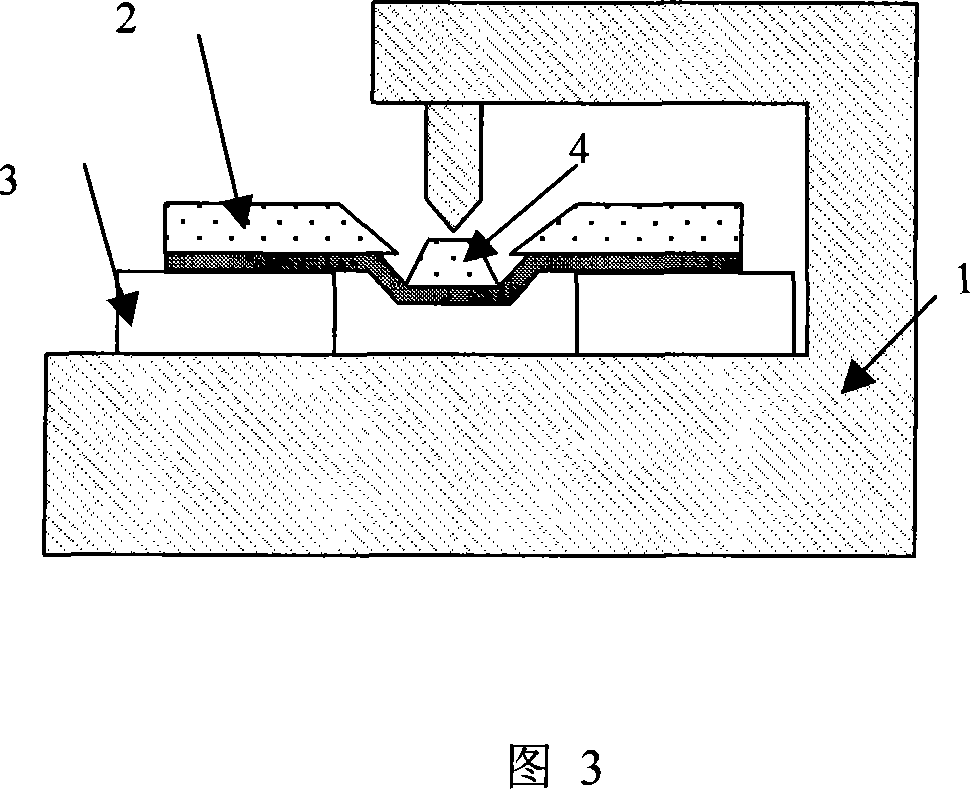

[0027] The first step is the pretreatment of the parts to be tested. The components to be tested include: a single crystal silicon substrate and a silicon nitride film with a film thickness of 1 μm.

[0028] Or use the current very mature photolithography technology to make patterns on the silicon substrate on the back of the component to be tested. The pattern is designed as a circle.

[0029] Or use a wet etching method: transfer the pattern to the photoresist through the mask plate, after exposure and development, etched by hydrof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com