High-solids ethylene-vinyl acetate latex

A technology of vinyl acetate and ethylene, which is applied in the field of high solid content ethylene-vinyl acetate dispersion, and can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

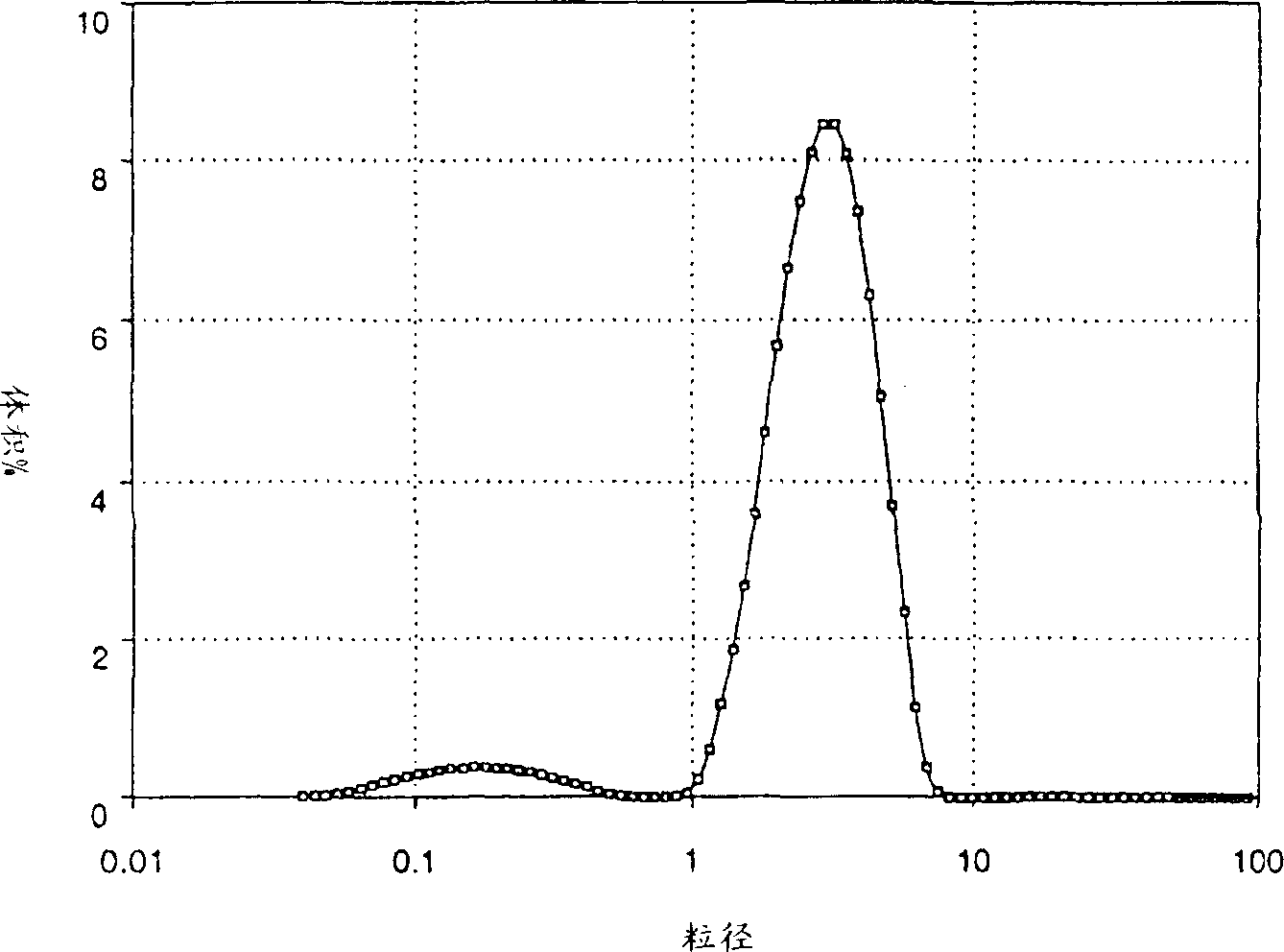

Image

Examples

Embodiment 1

[0029] An aqueous solution was prepared by adding 378 g of AIRVOL 203 (Air Products) to 1260 g of cold deionized water while stirring. The mixture was heated at 85°C for 1 hour. Once cooled, 1 g of sodium bicarbonate, 2 g of formaldehyde sulfoxylate (sodium formaldehyde sulfoxylate), 21 g of a 1% aqueous solution of ferrous sulfate, 21 g of a 1% aqueous solution of Versene (ETDA complexing agent) and 341 g of 25-1808 (National Starch and Chemical Company), an ethylene-vinyl acetate seed latex (55% solids, 12 / 88 ethylene / vinyl acetate stabilized with 5 parts polyvinyl alcohol). The solution was stirred and the pH was adjusted to 3.9-4.1 with phosphoric acid. It was then added to a 12L stainless steel reaction vessel and the inlet was rinsed with 200g of deionized water.

[0030] The reaction vessel was purged by pressurizing to 7 bar twice with nitrogen and once with ethylene to 7 bar. Empty the vessel between purges.

[0031] The reaction vessel was then evacuated and 5764...

Embodiment 2

[0041] This example was prepared using the same method as described in Example 1, but with the water partition changed. The initial reactor charge had 1860 g of deionized water, while each initiator solution contained 353 g of deionized water. The resulting polymer had a solids content of 68.25%, a viscosity of 2550 mPa.s, and a glass transition temperature of 16.3°C.

Embodiment 3

[0043] Example 3 was synthesized as described in Example 1, but without introducing the seed latex into the aqueous phase. The resulting polymer had a solids content of 68.84%, a viscosity of 3450 mPa.s, and a Tg of 11.2°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com