Ethylene-propylene-diene monomer(EPDM) rubber heat-insulating material with ceramifiable ablation carbon layer

A technology of EPDM rubber and thermal insulation materials, which is applied in the field of porcelainization, can solve the problems of mechanical erosion, reduce the ablation resistance and erosion resistance of EPDM thermal insulation materials, and fall off in flakes, so as to reduce the escape of combustibles. Out, improve the anti-ablation and erosion ability, reduce the effect of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

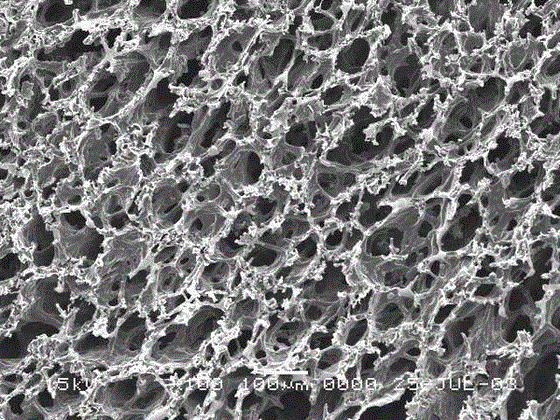

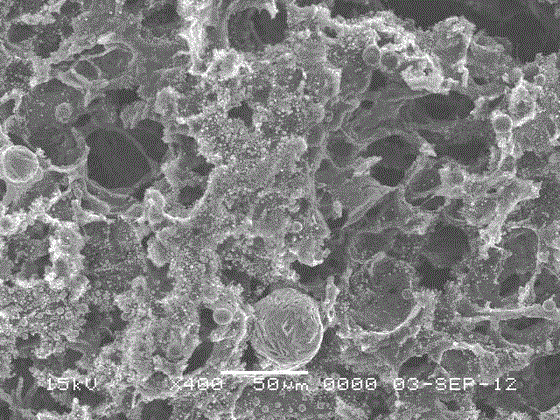

Image

Examples

Embodiment 1

[0040] Embodiment 1 (comparative example)

[0041] (1) Raw material preparation: according to the proportioning ratio of embodiment 1 in table 1, raw material preparation.

[0042] (2) Mixing: according to EPDM thin pass 3 times → aramid PA → ZnO, SA → SiO 2 →LPO, SMOS→TR→APP, MoO 3 → RD, MMg → DCP → Thin-pass 10-pass sheet-out sequence to refine EPDM thermal insulation materials.

[0043] (3) Sample preparation: prepare a 2mm thick film for testing mechanics, density and smoke signal; prepare 5 ablation pieces of Ф30mm×10mm for testing ablation performance; vulcanization system: 160℃×30min.

[0044] (4) Performance test: Test the performance of the insulation material in accordance with the corresponding standards and specifications. See Table 2 and Table 3 for specific results.

[0045] Table 1 adds the embodiment formula of OMMT

[0046]

Embodiment 2- Embodiment 11

[0048] (1) Prepare materials: Prepare materials according to the proportioning of Example 2-Example 11 in Table 1.

[0049] (2) Mixing: according to EPDM thin pass 3 times → aramid PA → ZnO, SA → SiO 2 , OMMT→LPO, SMOS→TR→APP, MoO 3 → RD, MMg → DCP → Thin-pass 10-pass sheet-out sequence to refine EPDM thermal insulation materials.

[0050] (3) Sample preparation: prepare a 2mm thick film for testing mechanics, density and smoke signal; prepare 5 ablation pieces of Ф30mm×10mm for testing ablation performance; vulcanization system: 160℃×30min.

[0051] (4) Performance test: Test the performance of the insulation material in accordance with the corresponding standards and specifications. See Table 2 and Table 3 for specific results.

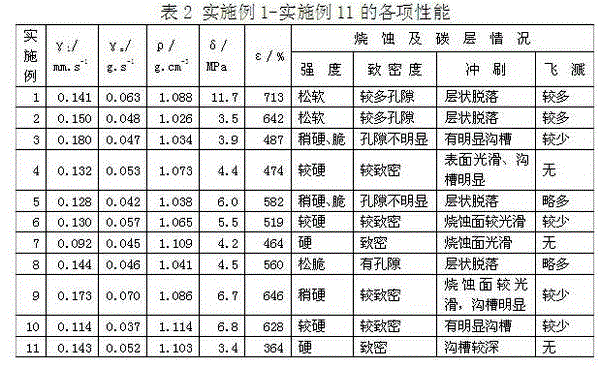

[0052] Table 2 Various performances of embodiment 1-embodiment 11

[0053]

[0054] Note: The ablation and carbon layer are all visual inspection, the same as Table 5 below.

[0055] It can be seen from the results and data in Table 2 that af...

Embodiment 12- Embodiment 16

[0062] (1) Raw material preparation: according to the proportioning preparation of embodiment 12-embodiment 16 in table 4.

[0063] (2) Mixing: according to EPDM thin pass 3 times → aramid PA → ZnO, SA → SiO 2 , Mica→LPO, SMOS→TR→APP→RD, MMg→DCP→Thin Pass 10-pass sequential refining of EPDM thermal insulation materials.

[0064] (3) Sample preparation: prepare a 2mm thick film for testing mechanics, density and smoke signal; prepare 5 ablation pieces of Ф30mm×10mm for testing ablation performance; vulcanization system: 160℃×30min.

[0065] (4) Performance test: Test the performance of the insulation material according to the corresponding standards and specifications. See Table 5 for the specific results.

[0066] Like OMMT, Mica is also a silicate substance, and its melting point is about 100°C lower than OMMT. From the result data in Table 5, it can be seen that Mica can also ceramize the carbonized layer of EPDM thermal insulation material, making it have a carbon layer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com