Improved discharging spark plug electrode structure along the surface

An electrode structure and creeping discharge technology, applied in the field of spark plugs, achieves the effects of strong firing power, accelerated combustion speed, and avoiding the danger of early ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

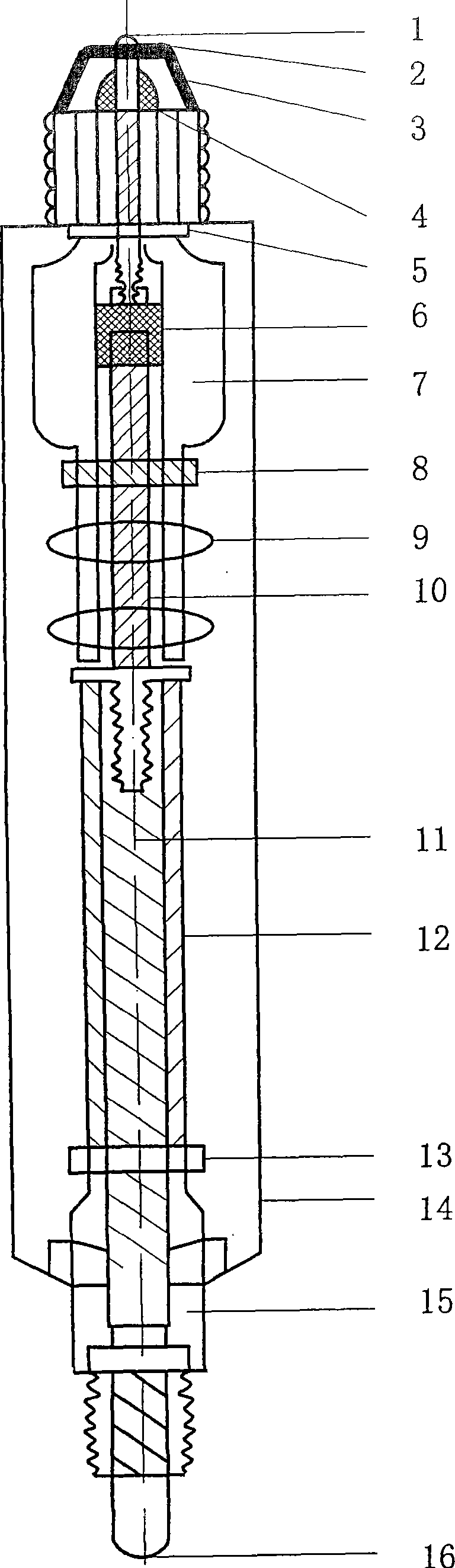

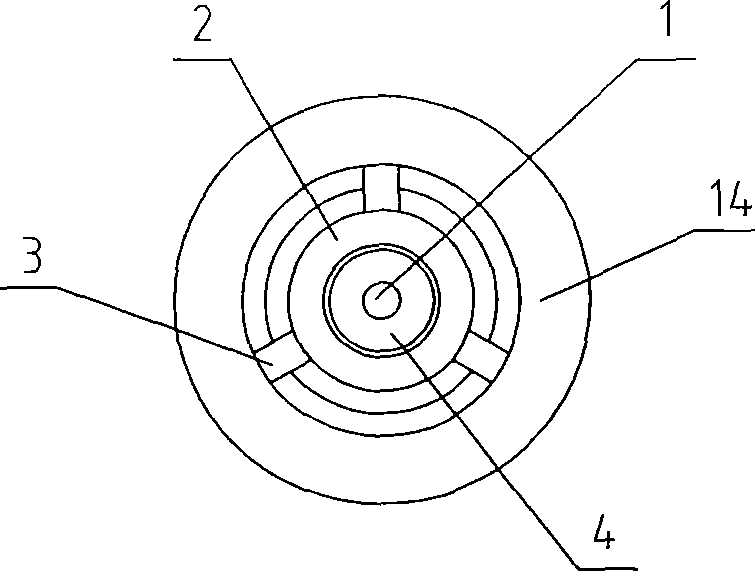

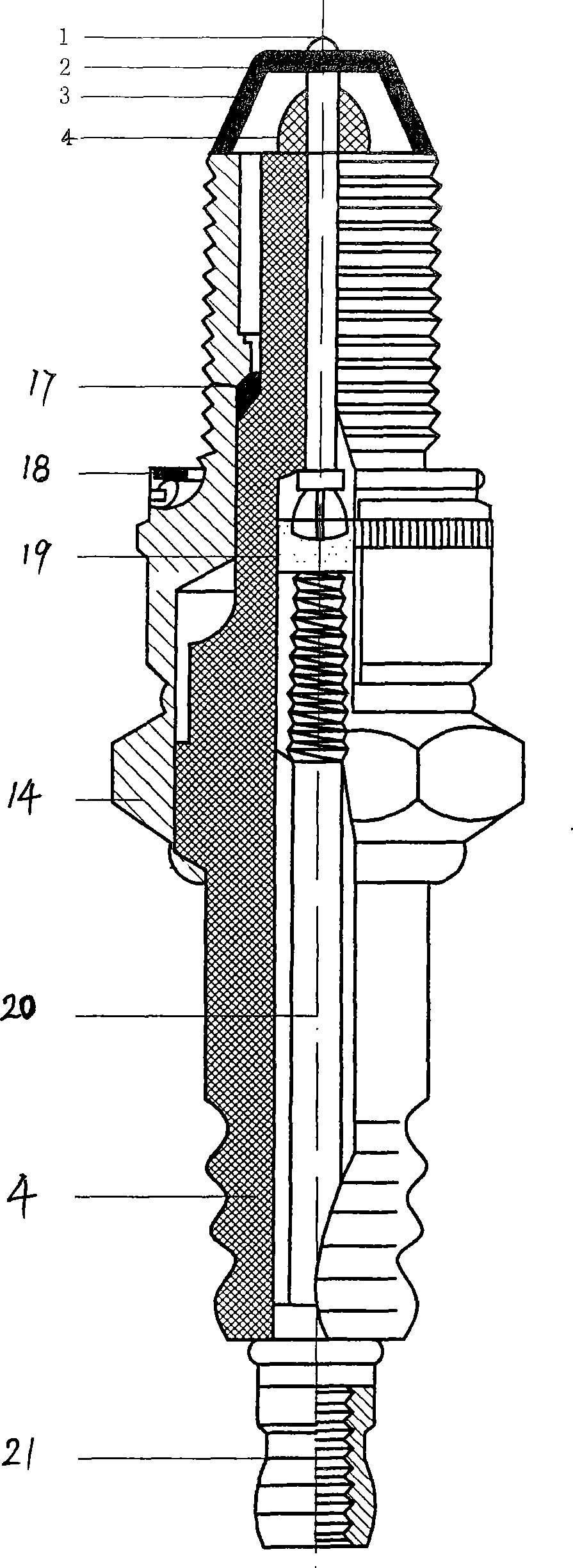

[0012] figure 1 , figure 2 Shown is a spark plug for a power generation internal combustion engine, including a center electrode 1 installed in a metal shell 14 and insulated from the metal shell 14. The metal shell 14 is electrically connected to the side electrode 2, and there is a spark between the center electrode 1 and the side electrode 2 gap. The side electrode 2 is in the shape of a ring, and a support frame 3 is provided between the side electrode 2 and the top of the metal shell 14, so that the side electrode 2 is separated from the top of the metal shell 14. The support frame 3 is composed of three sheet metal bodies, Evenly distributed between the outer edge of the side electrode 2 and the outer edge of the top end of the metal case 14 . The metal shell 14 is an iron pipe, the lower end of the center electrode 1 is embedded in the insulating magnetic piece 7 placed on the top of the metal shell 14, and the upper part of the insulating magnetic piece 7 is sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com