Copper-based chromium-niobium electrical contact material and preparation method thereof, copper-based electrical contact and air-type high-voltage isolating switch

An electrical contact, copper-based technology, applied in the direction of electrical switches, electrical components, contacts, etc., can solve the problems of large contact resistance, loose electrical contacts, easy to generate heat, etc., achieve small difference in thermal elastic modulus, and prevent loosening or fall off, the effect of strong heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

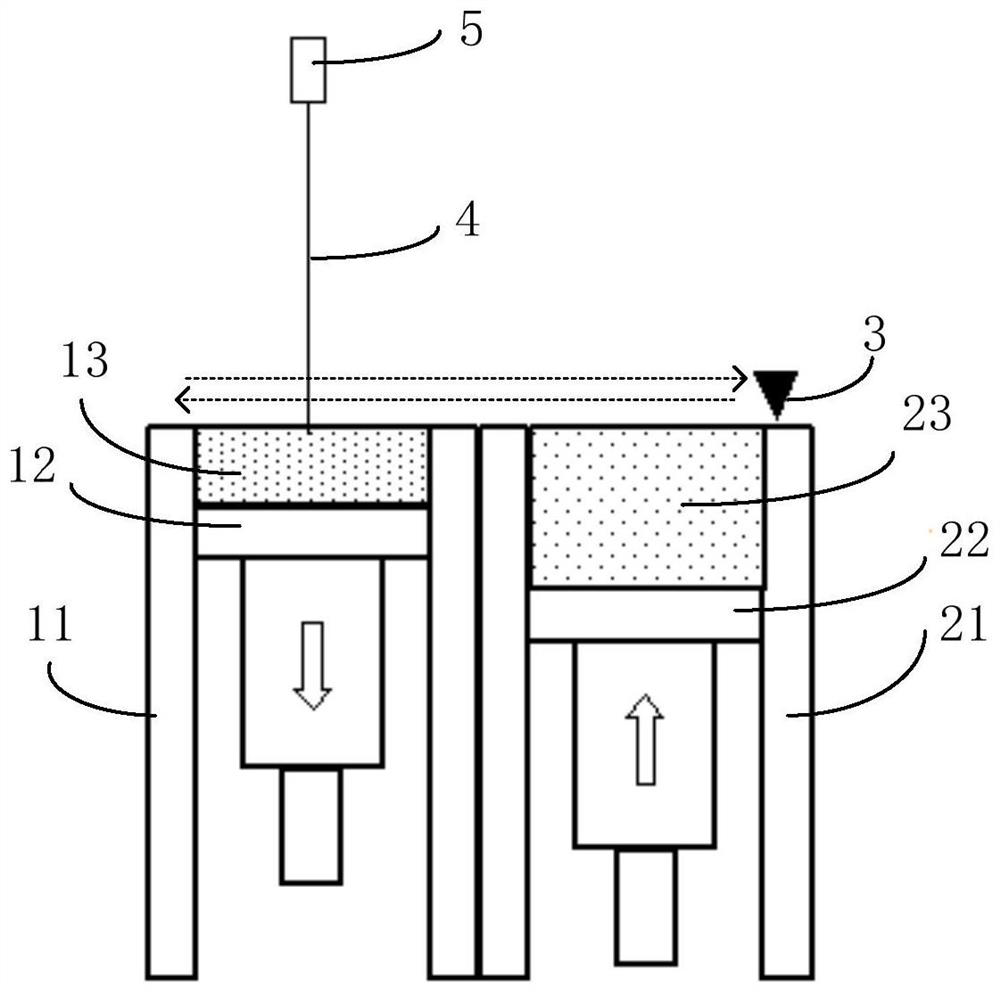

[0055] The embodiment of the present invention also provides a preparation method of the copper-based chromium diniobium electrical contact material, which is characterized in that it includes:

[0056] A variety of Cu powder, Cr powder, and Nb powder with different weight ratios are provided, and the Cu powder, Cr powder, and Nb powder of each weight ratio are printed and formed by 3D printing technology in turn to obtain the composite layer, wherein, The composite layer is formed on the pure copper substrate by layer-by-layer printing with the total content of Cr powder and Nb powder from low to high.

[0057] The preparation method of the copper-based chromium niobium electrical contact material provided by the embodiment of the present invention uses 3D printing technology to prepare Cu powder, Cr powder and Nb powder with different weight ratios to obtain Cu and Cr 2 The copper-based chromium-niobium electrical contact material with the mass percentage of Nb in a gradient...

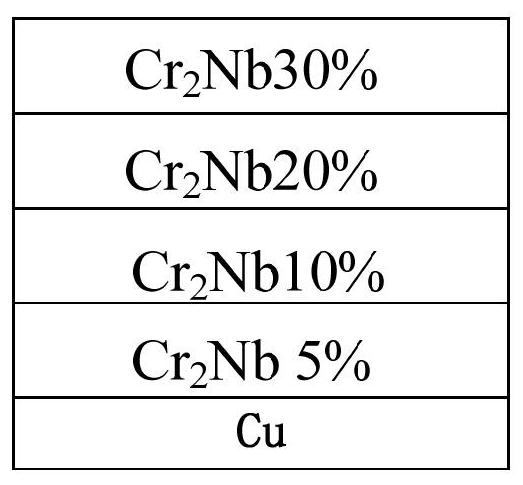

Embodiment 1

[0075] S00, provide 4 kinds of Cu powder, Cr powder, Nb powder with different weight proportions, recorded in mass percentage, respectively: 70% Cu powder, 15.84% Cr powder and 14.16% Nb powder, 80% Cu powder, 10.56% % Cr powder and 9.44% Nb powder, 90% Cu powder, 5.28% Cr powder and 4.72% Nb powder, 95% Cu powder, 2.64% Cr powder and 2.36% Nb powder. The purity of the Cu powder, Cr powder and Nb powder are all greater than or equal to 99.95%, and the particle diameters are all less than 50 μm.

[0076] S10, 4 kinds of Cu powder, Cr powder, and Nb powder with different weight ratios were fully mixed in a three-dimensional powder mixer for 3 hours to obtain 4 kinds of mixed powders.

[0077] S20, placing 0.05mm thick pure copper as a substrate on the first lifting platform 12, and then putting the mixed powder of 95% Cu powder, 2.64% Cr powder and 2.36% Nb powder into the powder cylinder of the 3D printer 21, the mixed powder is placed on the second lifting platform 22.

[00...

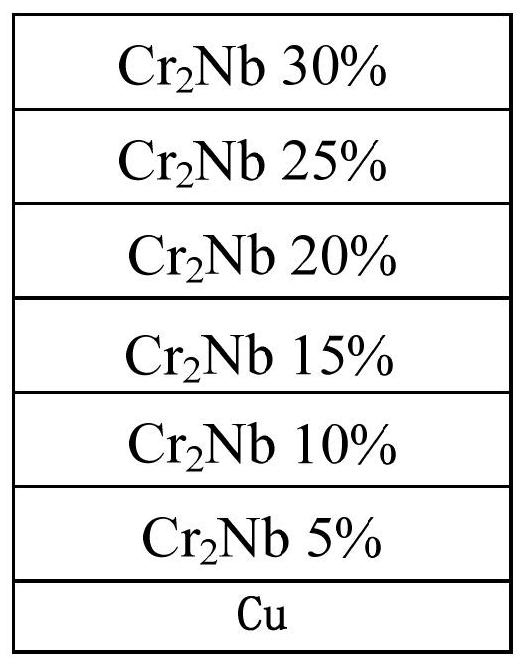

Embodiment 2

[0081]S00 provides 6 kinds of Cu powder, Cr powder and Nb powder with different weight ratios, recorded in mass percentage, respectively: 70% Cu powder, 15.84% Cr powder and 14.16% Nb powder, 75% Cu powder, 13.2% % Cr powder and 11.8% Nb powder, 80% Cu powder, 10.56% Cr powder and 9.44% Nb powder, 85% Cu powder, 7.92% Cr powder and 7.08% Nb powder, 90% Cu powder, 5.28% Cr powder and 4.72% %Nb powder, 95% Cu powder, 2.64% Cr powder and 2.36% Nb powder. The purity of the Cu powder, Cr powder and Nb powder are all greater than or equal to 99.95%, and the particle diameters are all less than 50 μm.

[0082] S10, 6 kinds of Cu powders, Cr powders, and Nb powders with different weight ratios were fully mixed in a three-dimensional powder mixer for 3 hours to obtain 6 kinds of mixed powders.

[0083] S20, placing a 0.05mm thick pure copper substrate as the substrate on the first lifting platform 12, and then putting the mixed powder of 95% Cu powder, 2.64% Cr powder and 2.36% Nb pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com