A kind of preparation method of bicomponent ceramic modified carbon/carbon composite material

A carbon composite material and two-component technology, applied in the field of composite materials, can solve the problems of ZrC micropowder density, equipment pollution, long production cycle, etc., and achieve excellent high-temperature erosion resistance, excellent mechanical properties, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] (2) Preparation of low-density carbon / carbon composite material: using methane or propane as a carbon source, put the fiber preform into a high-temperature deposition furnace for chemical vapor deposition to obtain the low-density carbon / carbon composite material Body;

[0027] (3) Glue configuration: use polycarbosilane / xylene solution and zirconium carbide precursor xylene solution as modification solution, use ultrasonic oscillation method to mix the solutions, and use this mixed solution to vacuum the fiber preform Dipping;

[0028] (4) Vacuum impregnation: Use the prepared impregnation glue to vacuum impregnate the above-mentioned low-density carbon / carbon composite material.

[0029] (5) Pyrolysis: put the fiber prefabricated body that has been vacuum-impregnated into a high-temperature cracking furnace, and perform high-temperature cracking under vacuum;

[0030] (6) repeat step (4) and step (5) glue impregnation-pyrolysis, until the weight after the completion...

Embodiment 1

[0039] (1) Material preparation:

[0040] a. Using carbon felt as a fiber reinforcement to prepare a fiber preform

[0041] b. Prepare SiC and ZrC ceramic precursor solutions.

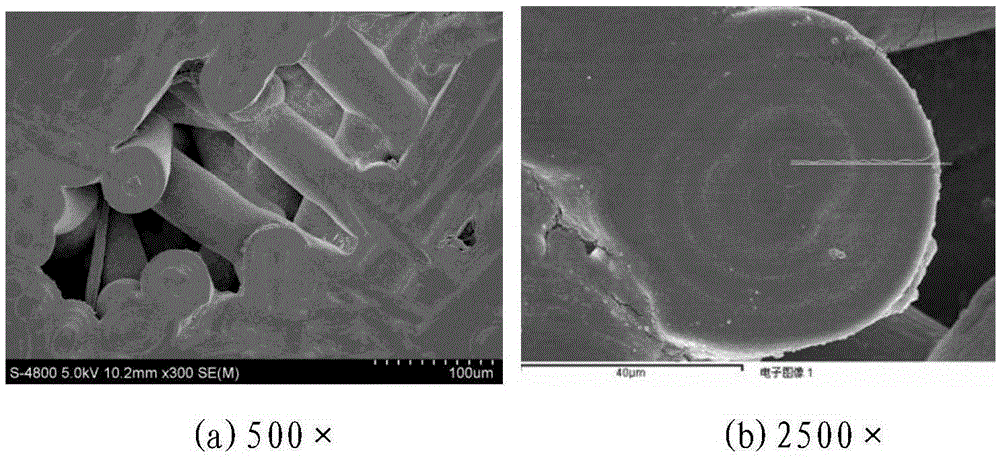

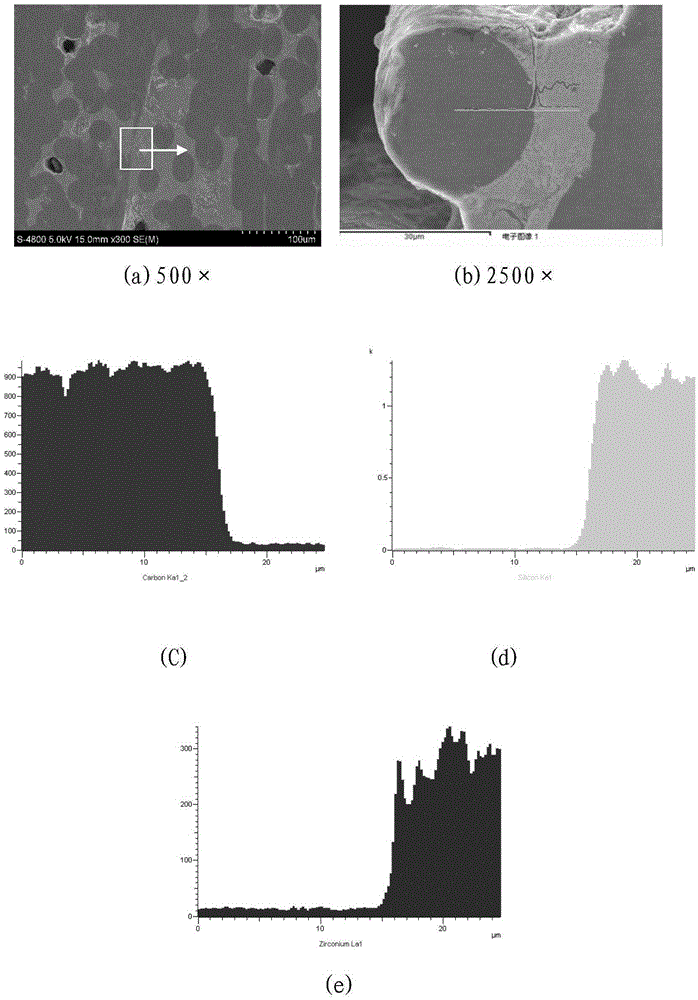

[0042] (2) Preparation of low-density carbon / carbon composite material: using propane as a carbon source, put the fiber prefabricated body into a high-temperature deposition furnace for chemical vapor deposition to obtain the low-density carbon / carbon composite material green body ; The chemical vapor deposition process conditions are: propane as the carbon source, the flow rate is 800ml / min; the dilution gas is high-purity nitrogen, the flow rate is 800ml / min; the deposition temperature is 1000°C, the deposition pressure is 0.5KPa, and the deposition time is 100h. The resulting low-density carbon / carbon composite material has a density of 1.2g / cm3 .Analyze the microstructure of low-density carbon / carbon composites, the scan photos are as follows figure 1 (a), (b) shown. From figure 1 It can be see...

Embodiment 2

[0053] A kind of preparation method of ZrC / SiC two-component modified carbon / carbon composite material of the present invention, comprises the following steps:

[0054] (1) Material preparation:

[0055] a. Using carbon felt as a fiber reinforcement to prepare a fiber preform

[0056] b. Prepare SiC and ZrC ceramic precursor solutions.

[0057] (2) Preparation of low-density carbon / carbon composite material: using propane as a carbon source, put the fiber prefabricated body into a high-temperature deposition furnace for chemical vapor deposition to obtain the low-density carbon / carbon composite material green body ; The chemical vapor deposition process conditions are: propane as the carbon source, the flow rate is 1000ml / min; the dilution gas is high-purity nitrogen, the flow rate is 1000ml / min; the deposition temperature is 1100°C, the deposition pressure is 1.5KPa, and the deposition time is 120h. The resulting low-density carbon / carbon composite material has a density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com