Patents

Literature

32results about How to "Moderate solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel phosphor nitrogen composite combustion inhibitor

InactiveCN1807552AModerate solubilitySimple processFireproof paintsPaper/cardboardPhosphateFireproofing

This invention discloses the preparing method for a new kind of phosphorus-nitrogen composite flame retardant, especially for pyroammonium phosphate flame retardant. The pyroammonium phosphate flame retardant is synthesized mainly with commercial phosphoric acid and urea; cool to proper temperature after the reaction; adjust reaction by adding appropriate neutralization agent; cool crystallize; centrifuge to get the product. The pyroammonium phosphate flame retardant contains pyromonoammonium phosphate, pyrodiammonium phosphate, pyrotriammonium phosphate and pyrotetroammonium phosphate. Its phosphor content exceeds 25% and nitrogen content exceeds10%. Its non-aqueous solubility is moderate. It is highly effective and nontoxic, so it is broadly used in fireproofing coatings, flame-retardant platics, flame-retardant fibres, flame-retardant textiles, wood goods, and so on.

Owner:朱凯琴

VOC (volatile organic compound)-free epoxy modified water-borne PU (polyurethane) finish paint and preparation method thereof

The invention discloses VOC (volatile organic compound)-free epoxy modified water-borne PU (polyurethane) finish paint and a preparation method thereof. The finish paint comprises: 1) a host formed by even mixing of 80-95 parts of a high-solid-content epoxy modified PU-polyacrylate micro-emulsion, 0.3-2.5 parts of an assistant and 3-6 parts of dodecanol ester by mass; and 2) a curing agent which is a multi-silicon-hydroxyl or multi-siloxy-group compound with the amount of 10-40% of the mass of the host. The epoxy modified water-borne PU finish paint has excellent gloss uniformity, adhesive force, hardness, transparency, fullness, hand feeling and the like. The PU finish paint is widely applicable to decoration and protection of surfaces of various wood products such as wooden furniture, plywood, solid wood floors and the like.

Owner:SHAANXI UNIV OF SCI & TECH

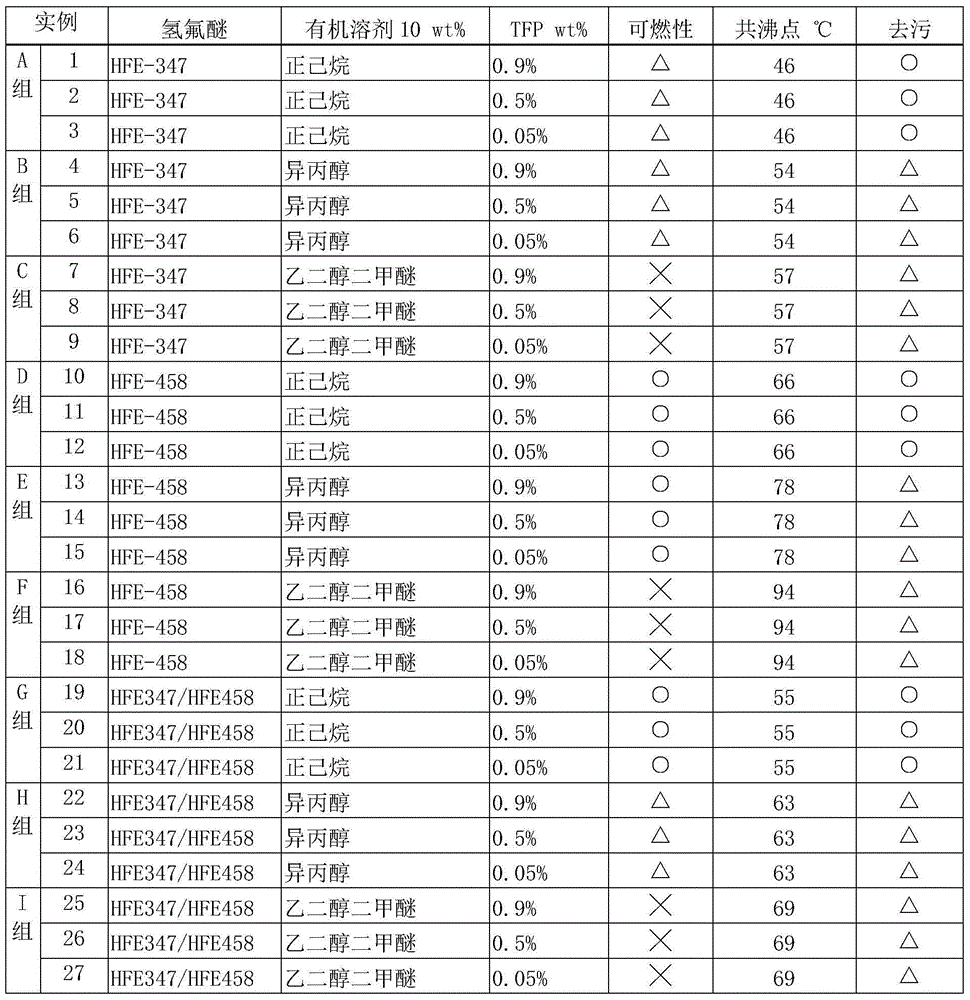

Electronic element cleaning agent and application method thereof

InactiveCN105524748AModerate solubilityGood choiceOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsOrganic solventHydrofluoroether

The invention provides a cleaning agent used on electronic elements. The cleaning agent comprises hydrofluoroether, fluoroalcohol and an organic solvent different from hydrofluoroether and fluoroalcohol. With the total weight of the cleaning agent as a reference, the content of fluoroalcohol is higher than 0wt% and lower than 1wt%. The invention also provides a method for applying the cleaning agent.

Owner:TAIWAN FLUORO TECH

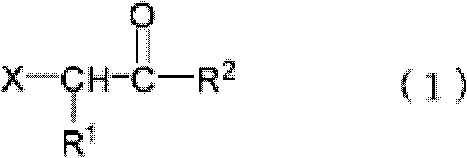

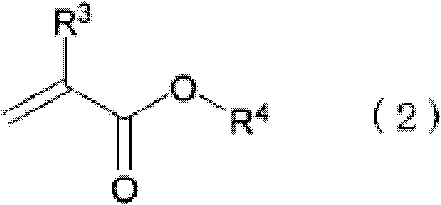

Antifouling coating composition, antifouling coating film formed from the composition, coated object having the coating film on surface, and method of antifouling treatment by forming the coating film

InactiveCN102369250AExcellent long-term storageHigh viscosityAntifouling/underwater paintsPaints with biocidesCarbon numberHydrogen atom

The present invention provides an antifouling coating material which can be used to form an antifouling coating film excellent in long-term antifouling performance and physical properties, and which is excellent in long-term storage stability. The present invention provides an antifouling coating composition containing a copolymer [A] obtained by copolymerizing a monomer represented by a general formula (1) (wherein, X represents acryloyloxy, methacryloyloxy, crotonoyloxy, or isocrotonoyloxy, R1 represents a hydrogen atom or methyl, and R2 represents an alkyl group having a carbon number of 1 to 6), and a polymerizable monomer represented by a general formula (2) (wherein, R3 represents a hydrogen atom or methyl, R4 represents an alkyl group having a carbon number of 1 to 10, or an alkyl group having a carbon number of 2 to 5 to which an alkoxy group having a carbon number of 1 to 4 is bonded.).

Owner:NITTO KASEI CO LTD

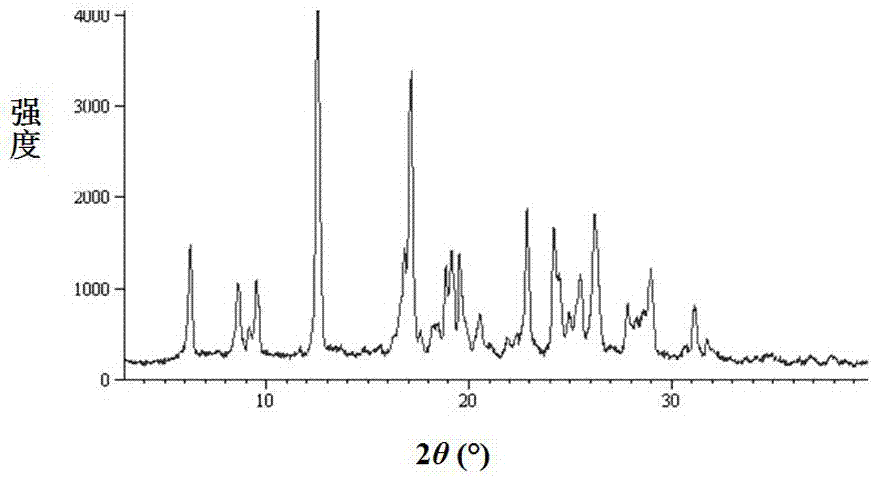

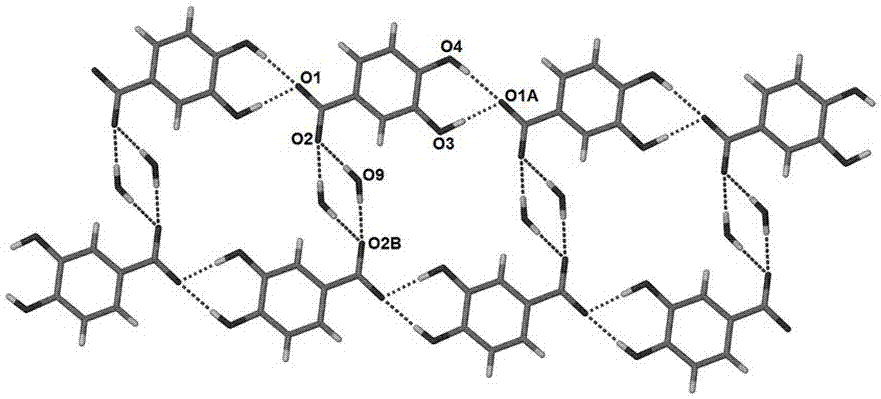

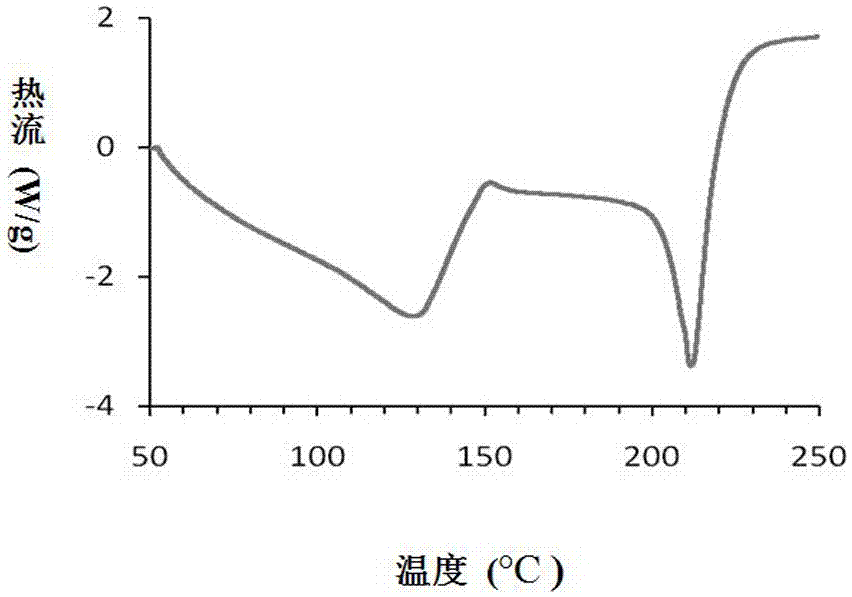

Non-hygroscopicity protocatechuic acid berberine monohydrate having crystal form

ActiveCN107188890AEasy to prepareClear crystal structureOrganic chemistry methodsCarboxylic compound separation/purificationSolubilityBerberine hydrochloride

The present invention discloses a non-hygroscopicity protocatechuic acid berberine monohydrate having a crystal form, and belongs to the technical field of drug crystallization. According to the present invention, berberine hydrochloride, protocatechuic acid and sodium hydroxide are dissolved in an ethanol aqueous solution according to a certain ratio to form the protocatechuic acid berberine monohydrate crystal; the preparation method has characteristics of simpleness, easy performing, low cost, and high crystal yield; and the prepared protocatechuic acid berberine monohydrate crystal does not have the hygroscopicity, has the moderate solubility in water, can be rapidly dissolved, and can be used in cardiovascular diseases and anti-cancer.

Owner:MINJIANG UNIV

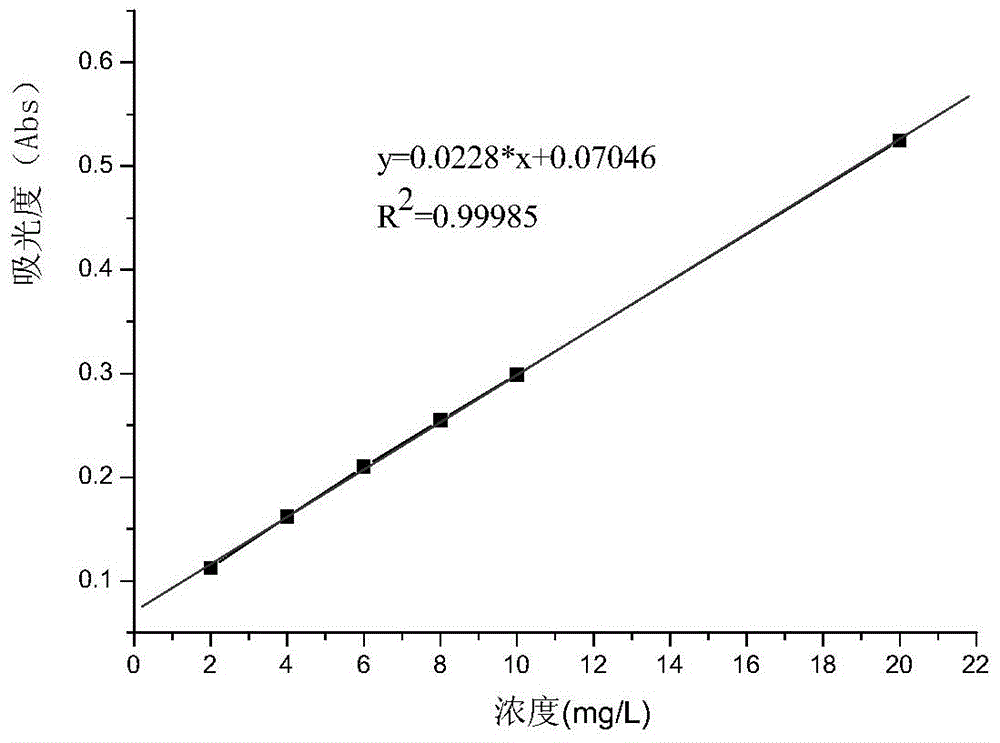

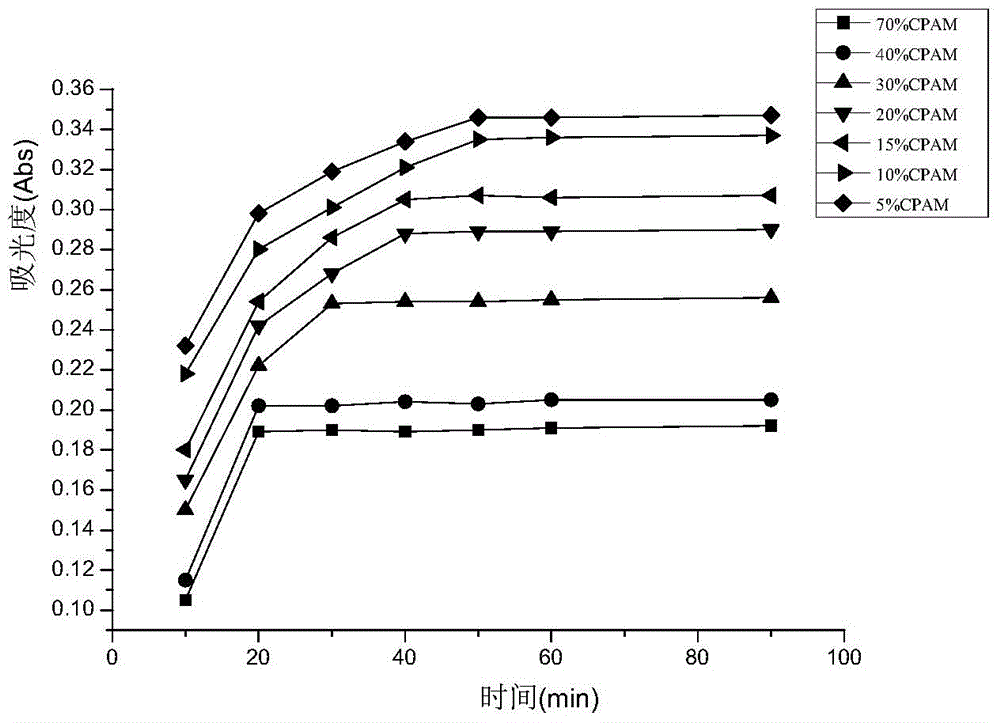

Method for detecting residual acrylamide monomer in cationic polyacrylamide

ActiveCN104977268AElasticModerate solubilityColor/spectral properties measurementsChemistryStandard curve

The invention discloses a method for detecting a residual acrylamide monomer in cationic polyacrylamide. The method comprises the following steps: preparing a 0.01-0.15g / mL mixture from a polyacrylamide sample with the cationic degree being 5-70% and an extractant; extracting the residual acrylamide monomer by using ultrasonic waves to obtain an extracting solution; filtering supernate of the extracting solution, diluting, and measuring the absorbancy of the diluted supernate on an ultraviolet spectrophotometer; and calculating the content of the residual acrylamide monomer in the cationic polyacrylamide by combining an acrylamide standard curve. The method can be used for extracting and detecting the residual acrylamide monomer in water treatment agents, namely the polyacrylamide, with different cationic degrees, and formed colloid has the elasticity; the extracting solution is clear; the extracting of the residual acrylamide monomer is complete and fast; and the content detection is accurate, needed devices are simple, energy is saved, the extracting method is simple and convenient, short in time, and high in extracting efficiency, and requirements on the detection of the residual acrylamide monomer in the polyacrylamide with the different cationic degrees in different sludge-sewage industries can be met.

Owner:浙江友联化学工业有限公司

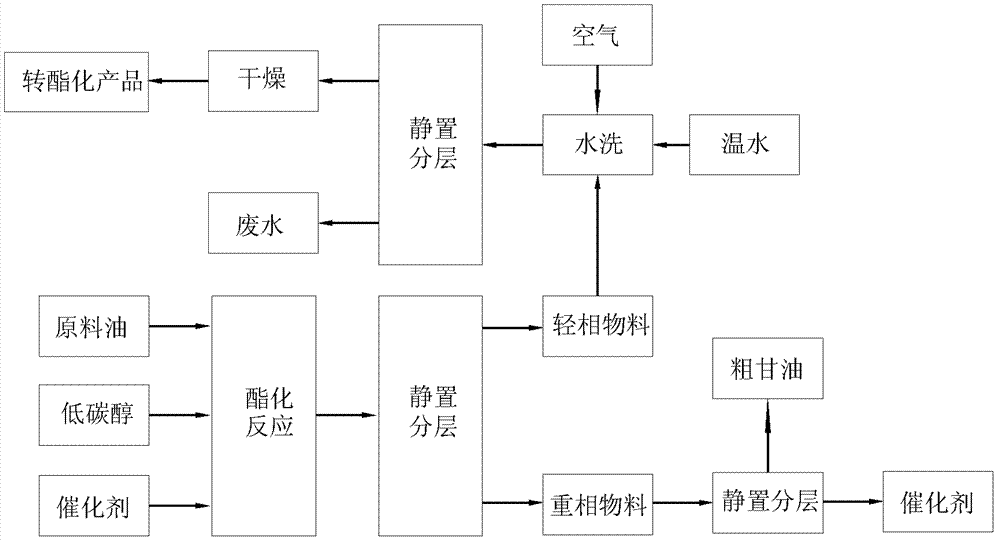

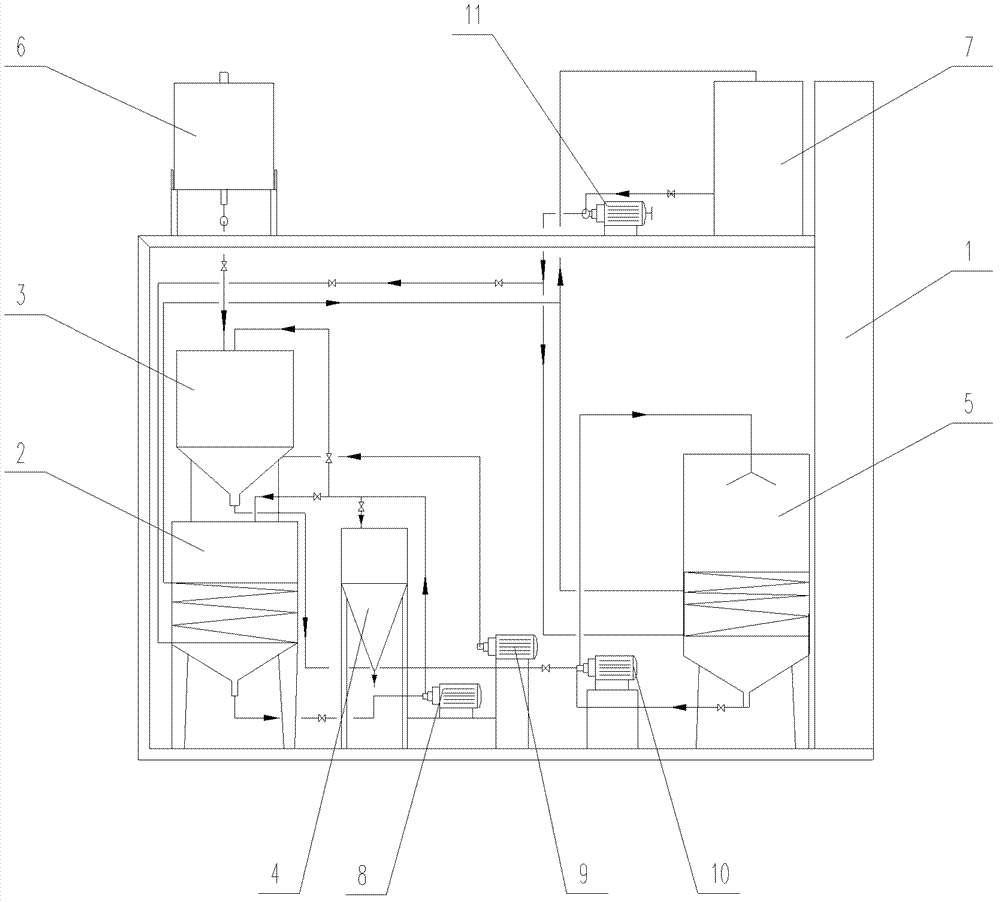

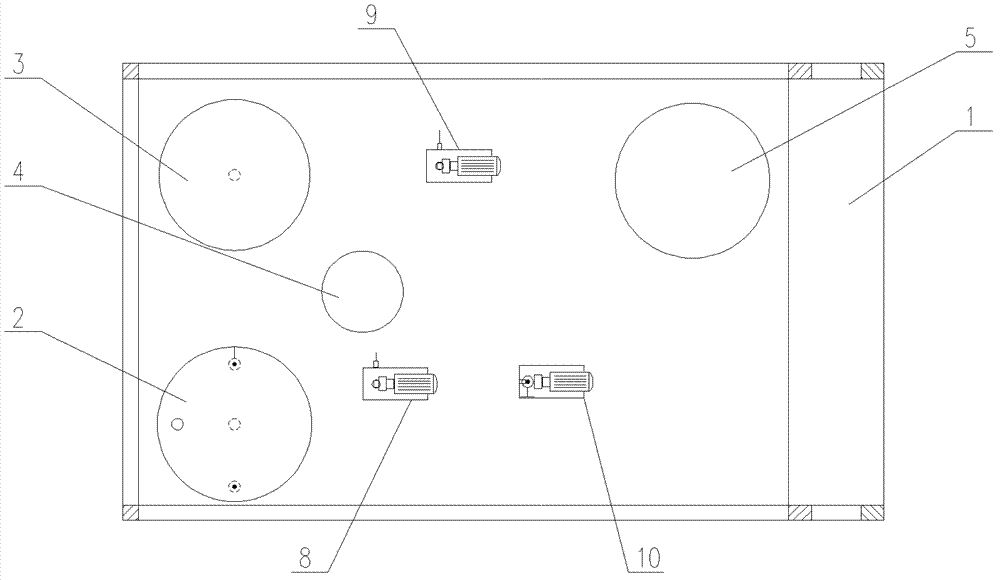

Production device and production method for distribution type plant oil transesterification

InactiveCN102492560BEasy to recycleShort process routeFatty acid esterificationFatty-oils/fats refiningHeat conductingWarm water

The invention discloses a production device and a production method for distribution type plant oil transesterification. The production device comprises an equipment frame, a reaction kettle, a washing tank, a catalyst recovering tank, a drier, a warm water storage tank, a heat conducting oil heating tank, a reaction circulating pump, an air pump, a material pump and a heat conducting oil pump. The production method comprises the following steps of: heating and stirring a mixture of plant fat raw material oil, low-carbon alcohol and a pyridyl trifluoromethanesulfonate ion liquid catalyst to react for 3-5 hours; standing so that reaction materials are divided into a light phase and a heavy phase, and separating the light phase from the heavy phase; standing the heavy-phase material and naturally cooling, so that the catalyst is precipitated to the bottom, and the rest is crude glycerol containing alcohol; adding warm water to the light-phase material for washing, and then standing so that the light phase and the heavy phase are formed again; and pumping the light-phase material into the drier for drying, so as to obtain the plant oil. The production method disclosed by the invention can achieve homogeneous catalysis and different-phase separation through process integration, and the yield of the plant oil is improved; and the production device disclosed by the invention is handy and simple, and is convenient for real-time processing of a dispersed raw material.

Owner:SOUTH CHINA UNIV OF TECH

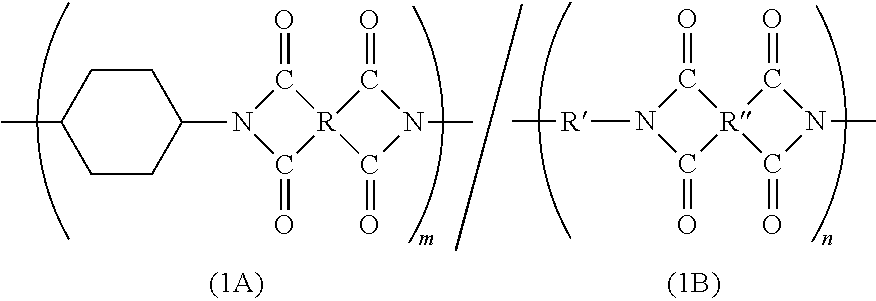

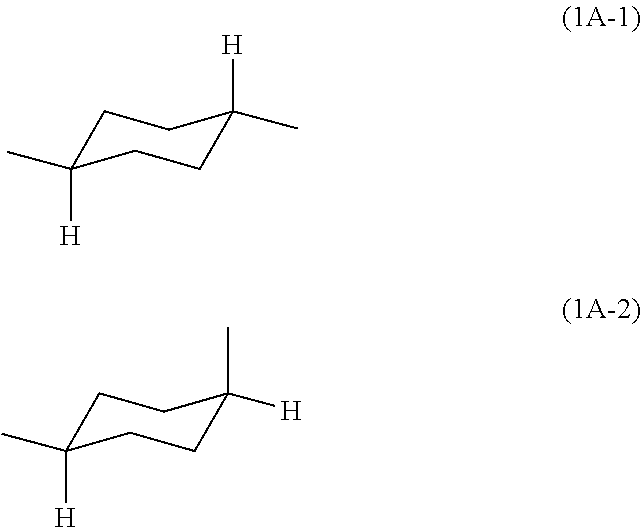

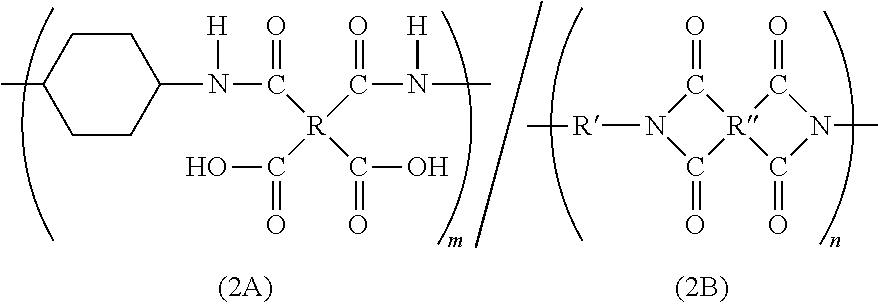

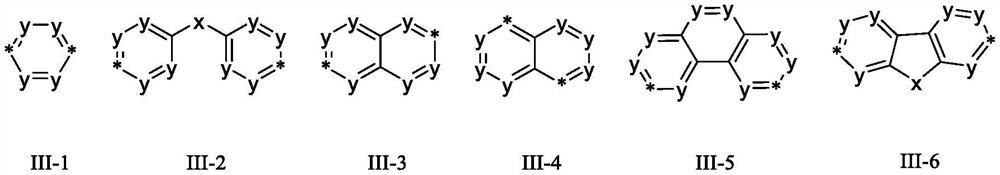

Block polyimide, block polyamide acid imide and use thereof

InactiveUS20160075830A1High transparencyLow CTEOptical articlesPrinted circuit manufactureImideSolubility

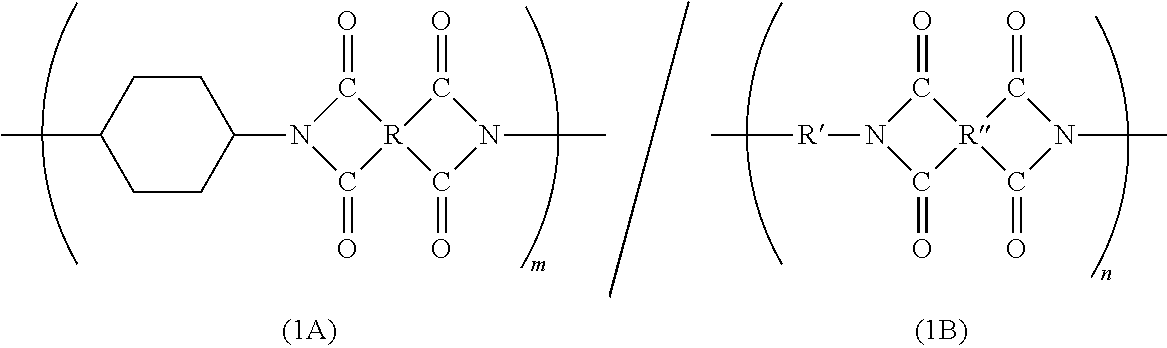

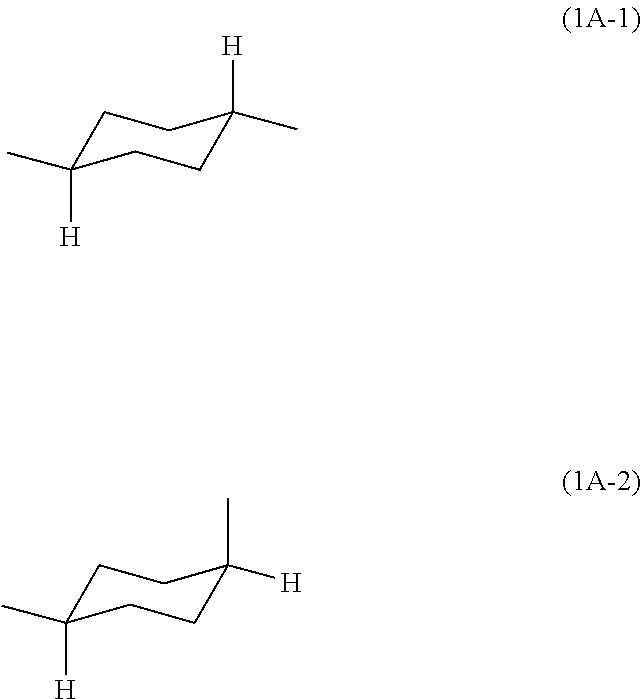

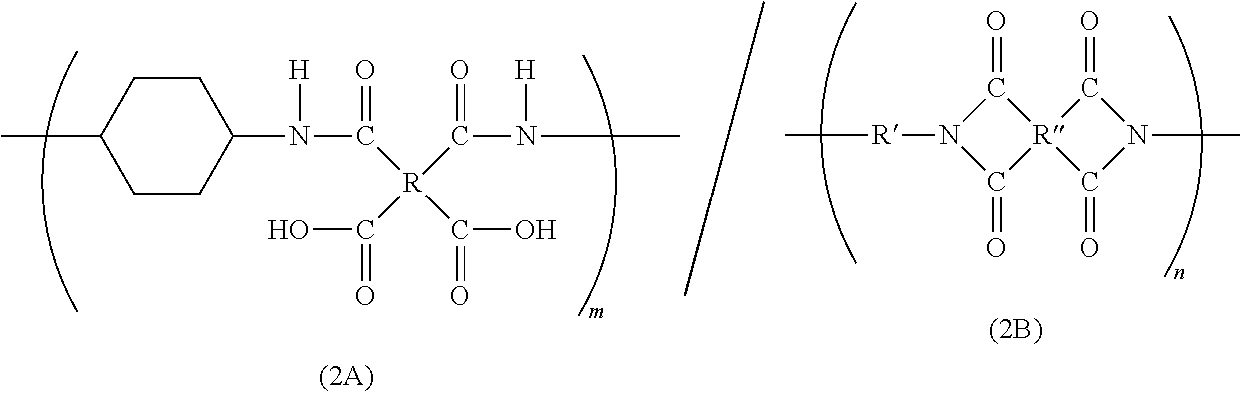

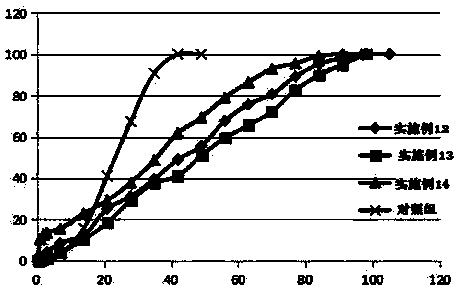

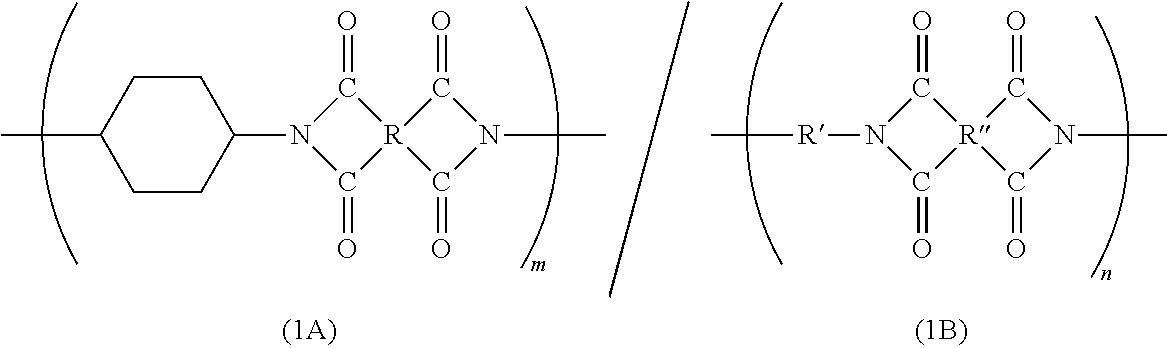

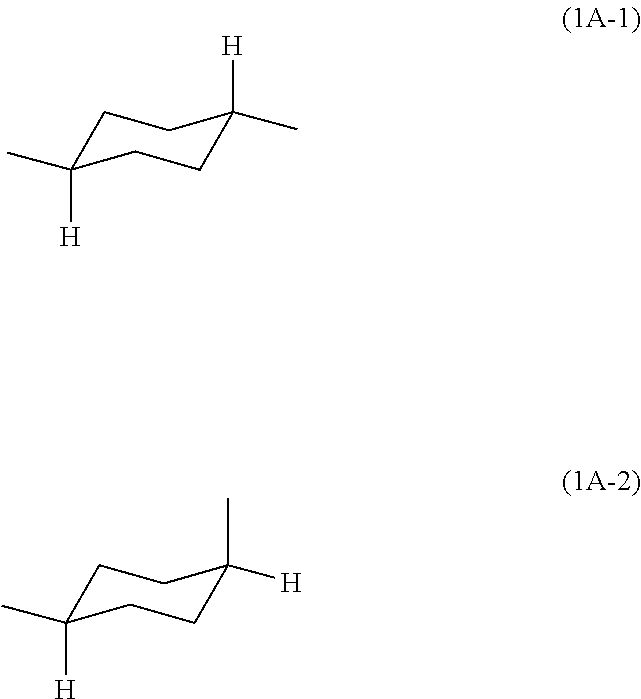

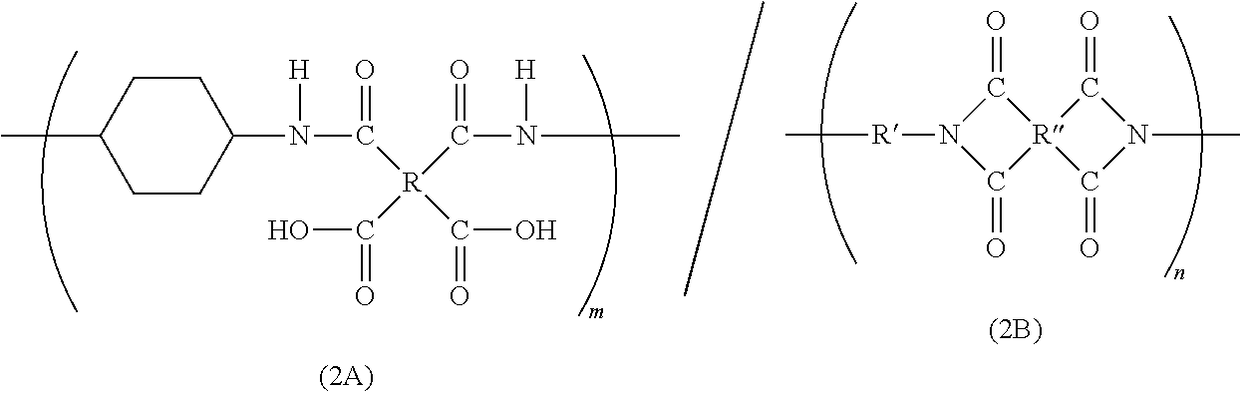

The purpose of the present invention is to provide a block polyamide acid imide having an appropriate solubility in aqueous alkaline solutions, and block polyimides that are obtained using same and have high transparency and a low coefficient of linear thermal expansion (low CTE). This block polyimide comprises blocks configured from repeating structural units represented by formula (1A) and blocks configured from repeating structural units represented by formula (1B).

Owner:MITSUI CHEM INC

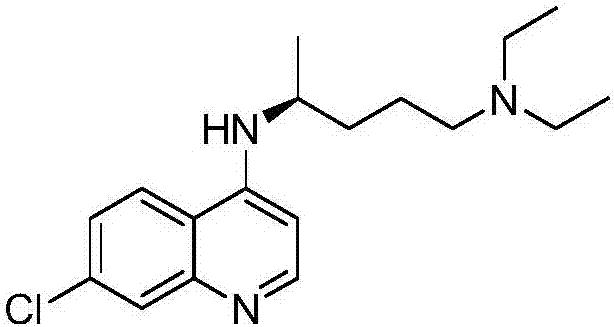

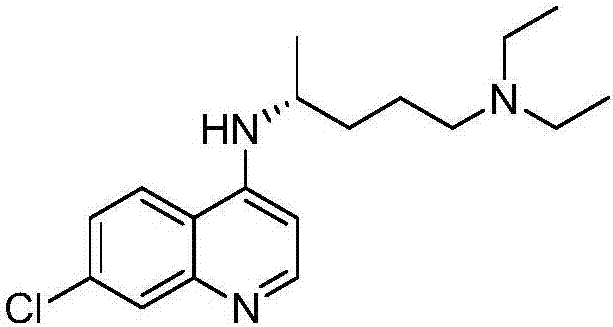

A kind of asymmetric synthetic method of optically pure (r)/(s)-chloroquine

ActiveCN105693605BHigh yieldHigh selectivityOrganic chemistrySynthesis methodsEnantioselective synthesis

The invention discloses an asymmetric synthesis method of optically pure (R) / (S)-chloroquine. 4-amino-7-chloroquinoline and 5-diethylin-2-pentanone are taken as starting raw materials and are subjected to an asymmetric reductive ammoniation reaction under the catalysis of chiral acid, optically pure chloroquine is obtained, and the spatial configuration of a product is controlled through spatial configuration of the chiral acid. The method adopts simple steps, the raw materials are easy to obtain, the yield is higher, the stereoselectivity is good, the chiral construction cost is relatively lower, the operation is simple, and the method is environment-friendly and suitable for large-scale production.

Owner:大连润生康泰医学检验实验室有限公司

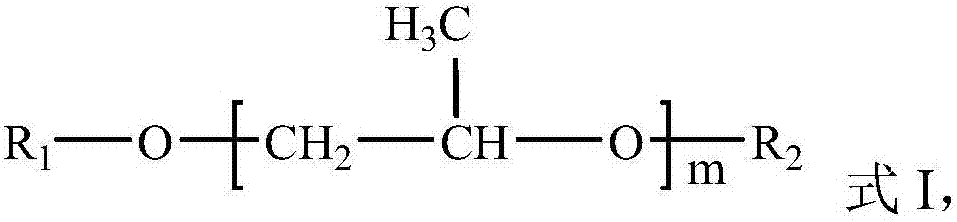

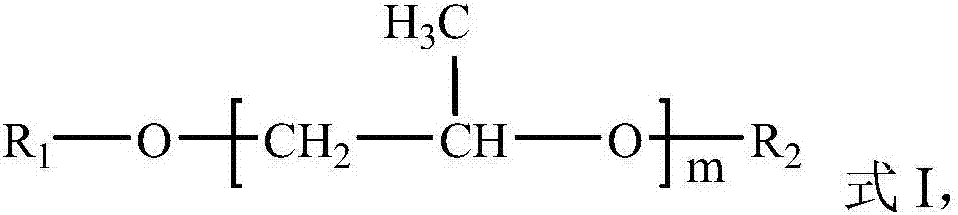

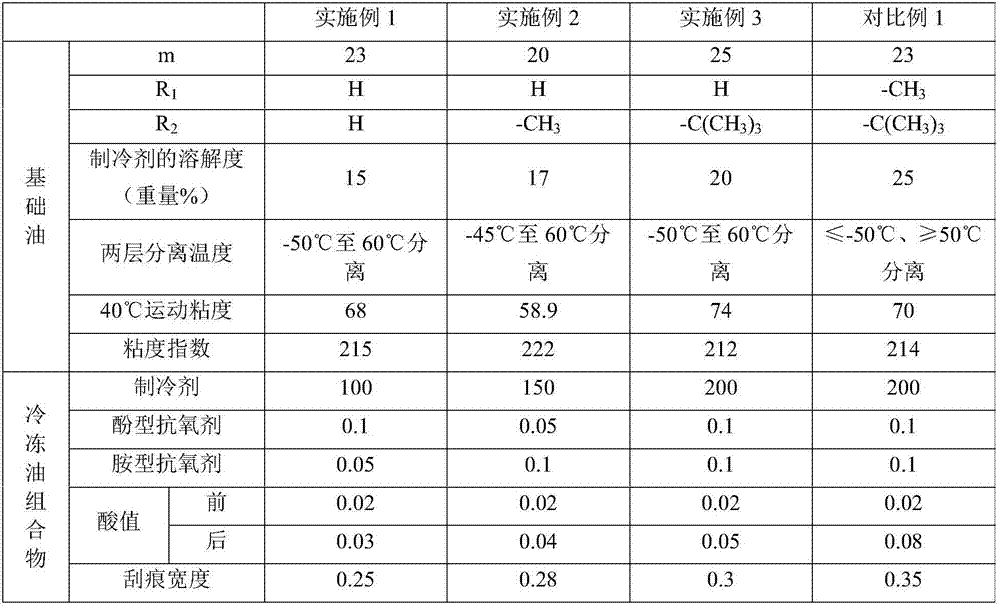

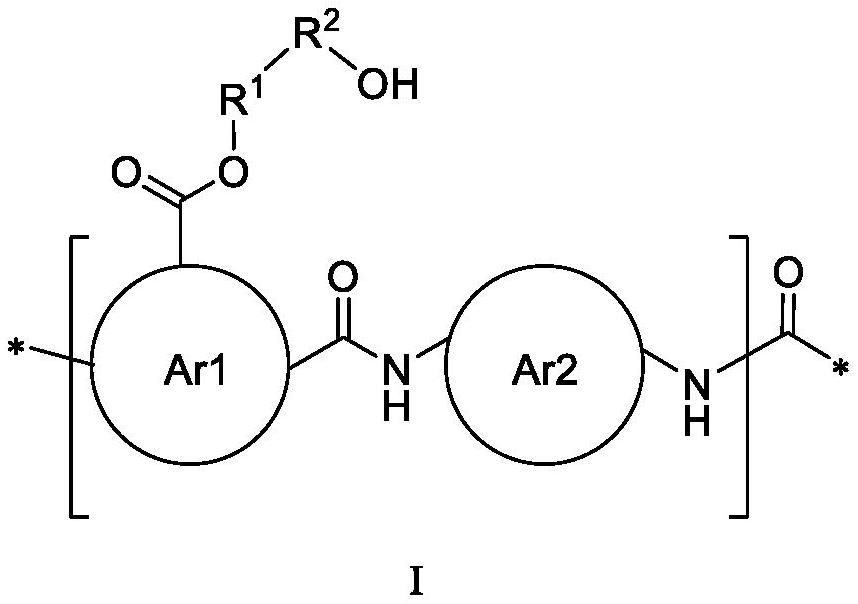

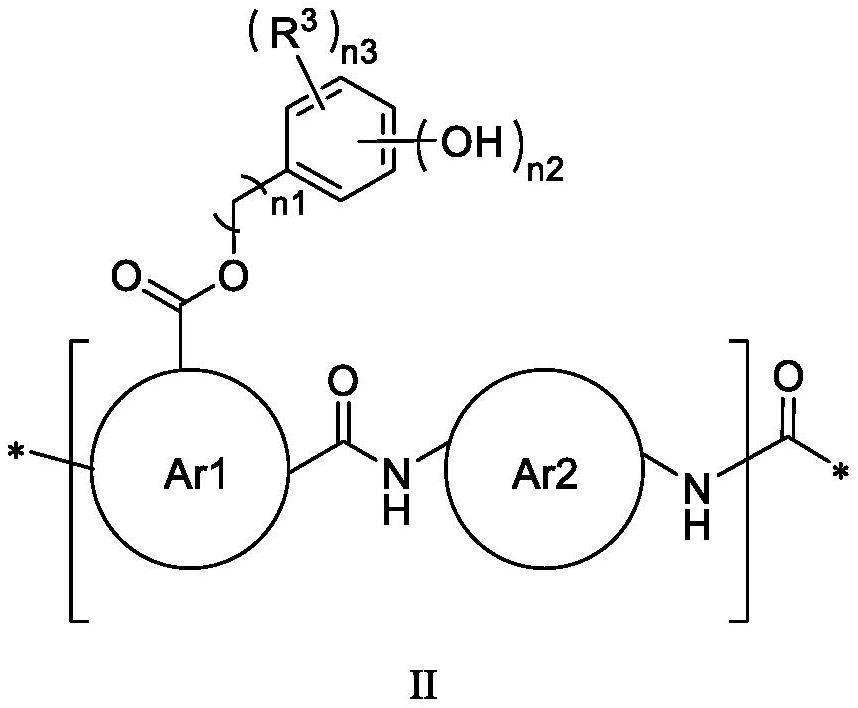

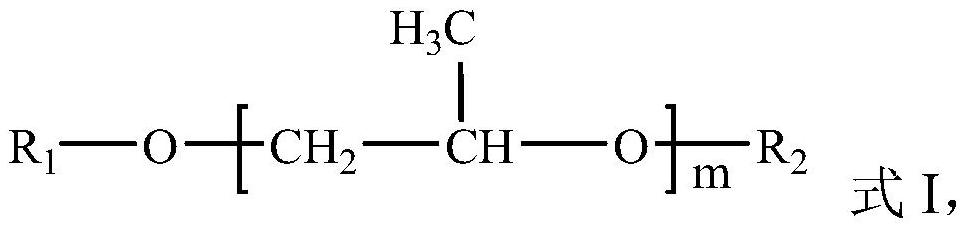

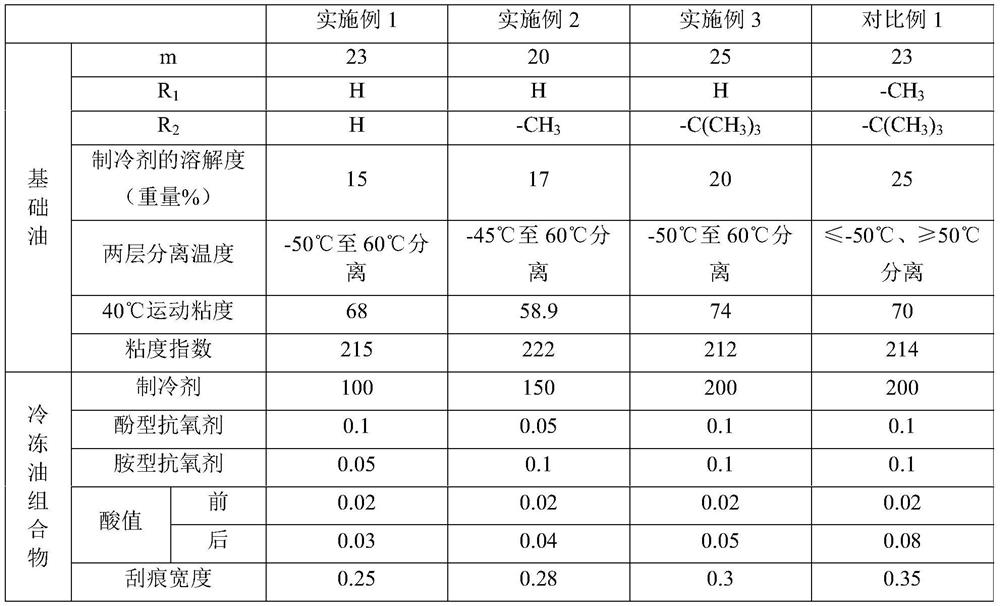

Refrigerant oil composition and application thereof

ActiveCN107353983AModerate solubilityImprove the lubrication effectLubricant compositionLiquid systemRefrigerant

The invention relates to the field of refrigeration equipment and discloses refrigerant oil composition and an application thereof. The refrigerant oil composition comprises base oil and a refrigerant, wherein the refrigerant is propane; the base oil contains a compound shown as formula I in the description, in the formula I, R1 is H, R2 is H or C1-C18 alkyl, and m is an integer larger than or equal to 1. The invention further discloses a compressor with the refrigerant oil composition serving as a circulating cooling liquid system as well as a refrigerating circulating device. The base oil and the refrigerant propane have good solubility, the lubricity is good, so that sufficient cooling can be also realized even when the dosage of the refrigerant is lower, and the safety is guaranteed while the cooling effect is guaranteed.

Owner:GUANGDONG MEIZHI COMPRESSOR

Silicate fertilizer and its preparing method

The present invention discloses silicate fertilizer and its preparation process. The silicate fertilizer has silicate content not less than 10 % and its saturated leached liquid has pH value not greater than 6.5. It is prepared with sodium silicate or calcium silicate material, and through neutralizing with acid to prepare silicic acid colloid solution, precipitating, filtering, washing, neutralizing, drying and crushing. The silicate fertilizer has the features of high silicate content, fast and long acting, silica utilizing rate up to 100 %, moderate solubility, capacity of greatly raising the yield of crop, etc.

Owner:张至德

Polymer, photoresist, photoresist layer and photoetching process

PendingCN114539518AModerate solubilitySolubility EquilibriumPhotosensitive material processingPolymer scienceLithography process

The invention relates to the technical field of photoetching materials, in particular to a polymer, photoresist, a photoresist layer and a photoetching process. The polymer shown in the formula I is adopted as the photoresist raw material, the weight-average molecular weight of the polymer is limited to be within a certain range, compared with traditional phenolic resin and other resin raw materials, the polymer has better heat resistance and stability, and the prepared photoresist layer can be suitable for more harsh device processing conditions; according to the present invention, the solubility in the alkaline developing solution is moderate, the solubility in the common photoresist solvent is good, the solubility can be well balanced, and compared with the traditional technology, the imaging is good and fine, and the production efficiency is high.

Owner:苏州理硕科技有限公司

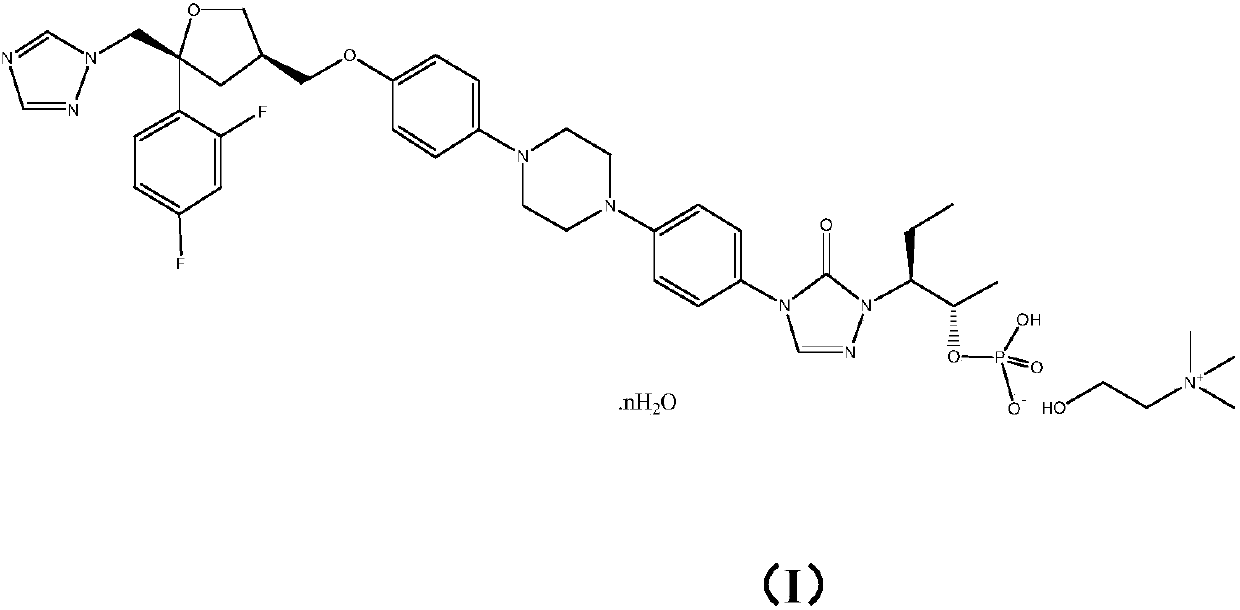

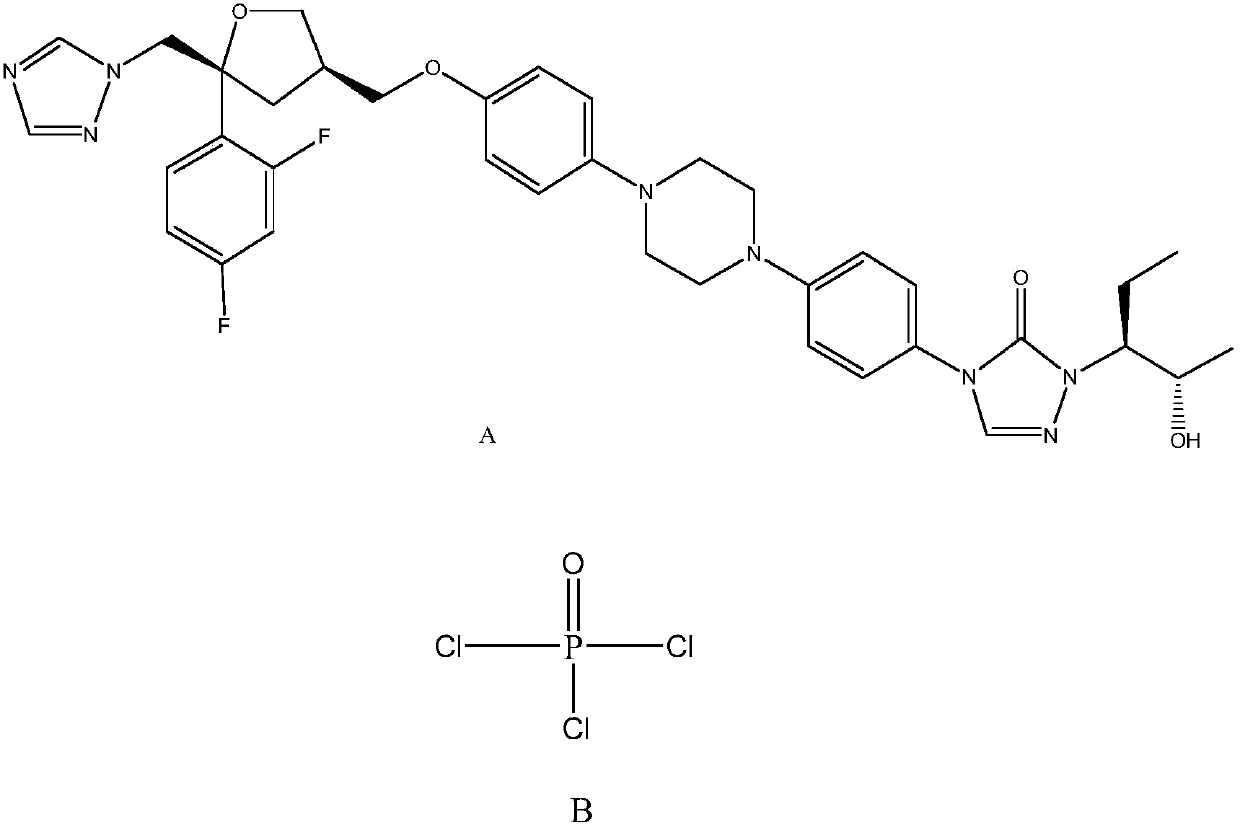

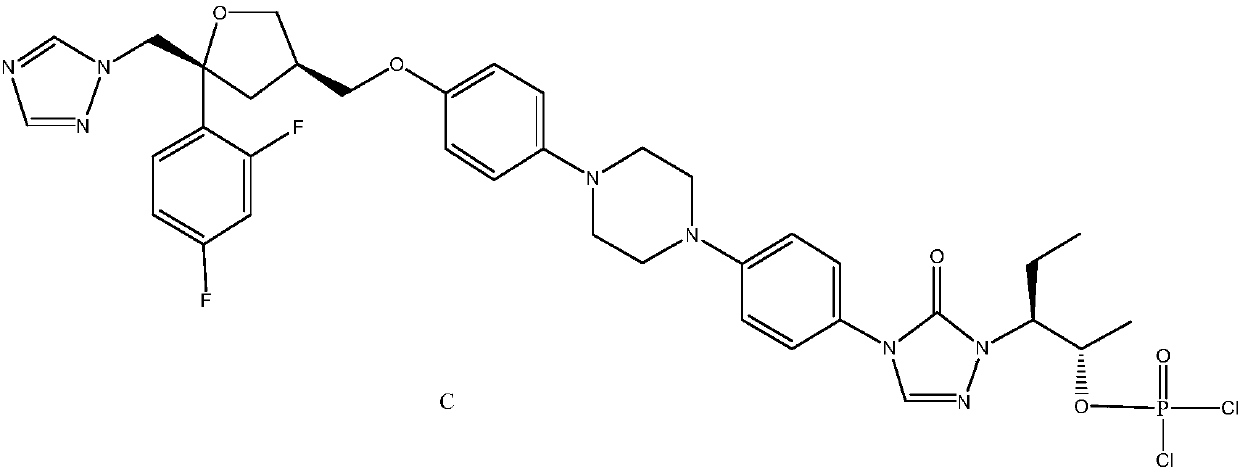

Monocholine salt of posaconazole phosphate, preparation method and applications thereof

ActiveCN110938093AImprove solubilityImprove stabilityOrganic active ingredientsAntimycoticsPhosphoric Acid EstersPhosphate

The invention relates to a monocholine salt of posaconazole phosphate, a preparation method and applications thereof, wherein the monocholine salt of posaconazole phosphate has a structure representedby a formula (I), and n is an integer of 0-12, preferably an integer of 0-8, more preferably an integer of 0-6.

Owner:HC SYNTHETIC PHARMA CO LTD

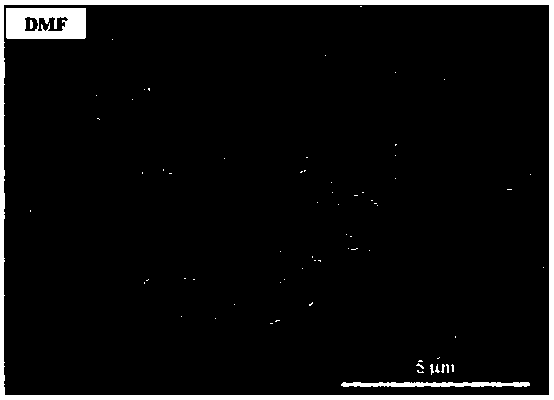

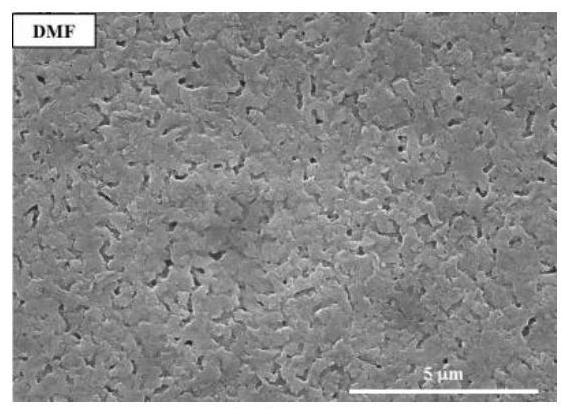

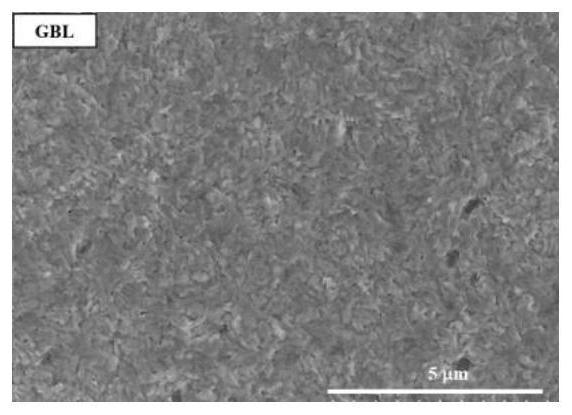

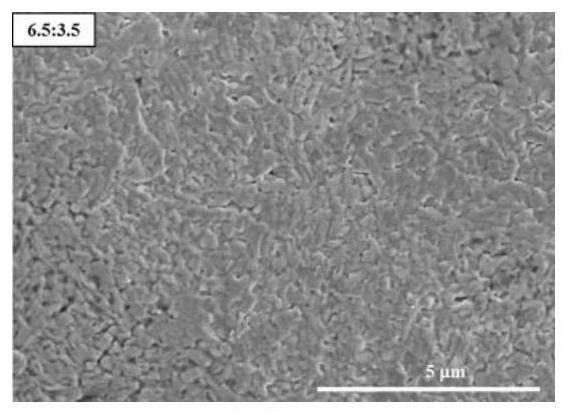

Solvent and method for preparing high-performance metal halide perovskite film, and application

ActiveCN109920939AProper volatilityIncrease coverageThermoelectric device manufacture/treatmentSolid-state devicesSolventMetal halides

The invention discloses a solvent and a method for preparing a high-performance metal halide perovskite film, and an application, and belongs to the technical field of microelectronics. The solvent for preparing the high-performance metal halide perovskite film comprises the following components in parts by volume: 3 parts of DMF and 1-2 parts of GBL. The solvent can effectively control the morphology of the perovskite film, so that the performance, efficiency and stability of a device are improved; and the solvent is used for industrial production and has the characteristics of simple and feasible method, low cost, strong controllability and the like.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

Method for recycling waste TPO skin material

PendingCN112140407ALow flexural modulus requirementImprove solubilityPlastic recyclingBLENDER/MIXERFender

The invention discloses a method for recycling a waste TPO skin material, and relates to the technical field of material recycling. The method comprises the following steps of sorting, clearing and removing impurities from scrapped workpieces containing TPO skin materials, crushing the scrapped workpieces into material blocks, pouring the material blocks into a stirrer, adding a swelling agent aqueous solution, heating, stirring, degumming, and separating to obtain TPO material blocks; and cleaning and drying the TPO material blocks, putting the TPO material blocks into a high-speed mixer, adding an extracting agent, stirring, feeding into a double-screw extruder through a forced feeding machine, extruding, defoaming, granulating, cooling, drying and dicing. The method solves the problem of resource waste caused by landfill treatment of the scrapped workpieces containing the waste TPO skin materials in the prior art, and recovered TPO particles can be used as a toughening agent of modified PP or soft products with low flexural modulus requirements, such as automobile wheel covers and fenders.

Owner:广西鑫深科技有限公司

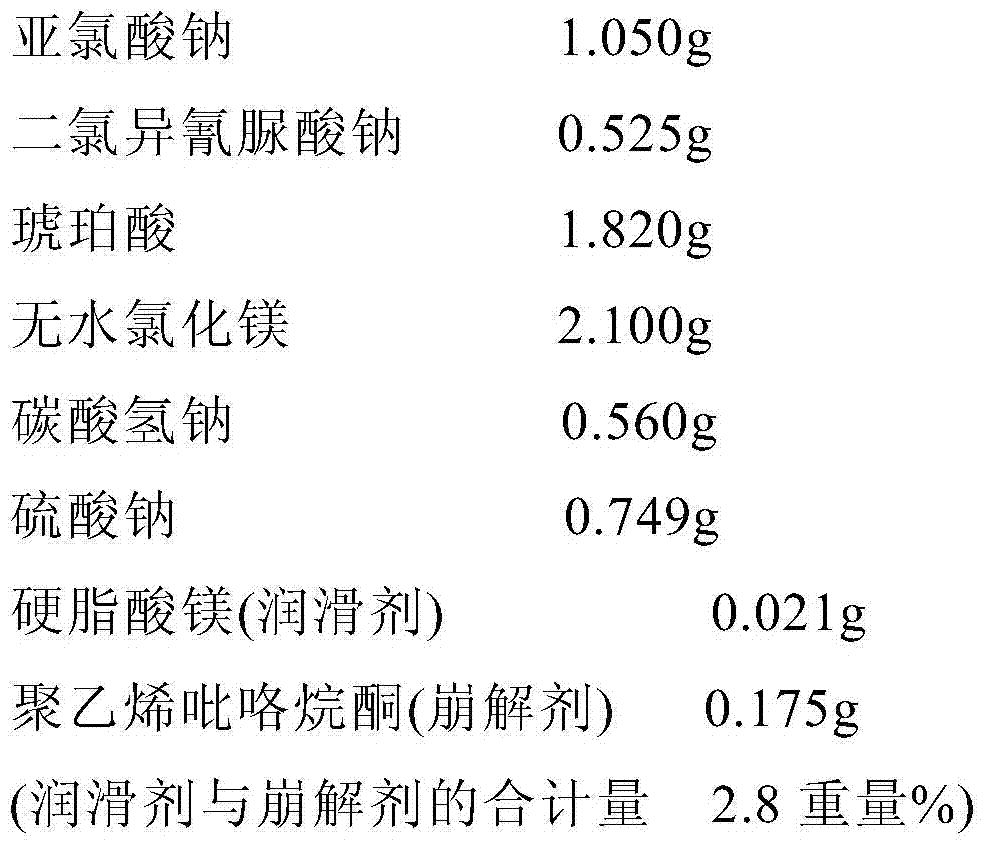

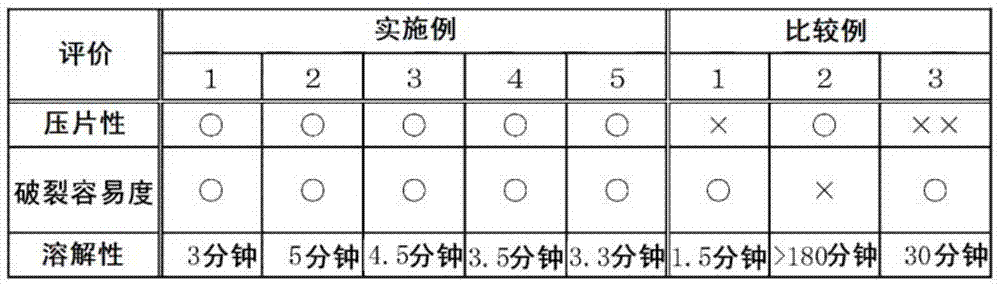

Tablets for the preparation of solutions of chlorine dioxide

ActiveCN104995133BEfficient manufacturingModerate solubilityAntibacterial agentsBiocideChlorine dioxideSolid acid

A tablet containing metal chlorite, a chlorine-releasing compound that releases chlorine when in contact with water, a solid acid source, a stearic acid metal salt, and a polymer-based disintegrating agent, and a stearic acid metal salt and a polymer-based disintegrant The total amount of the decomposing agent is 0.3 to 10% by weight relative to the whole tablet. Regardless of the scale of the facility to be treated, this tablet can generate chlorine dioxide at a sufficient concentration within a practical time, and has the advantages of being transported. Sufficient strength that does not cause breakage during handling, packaging, etc., and high productivity.

Owner:OSAKA SODA CO LTD

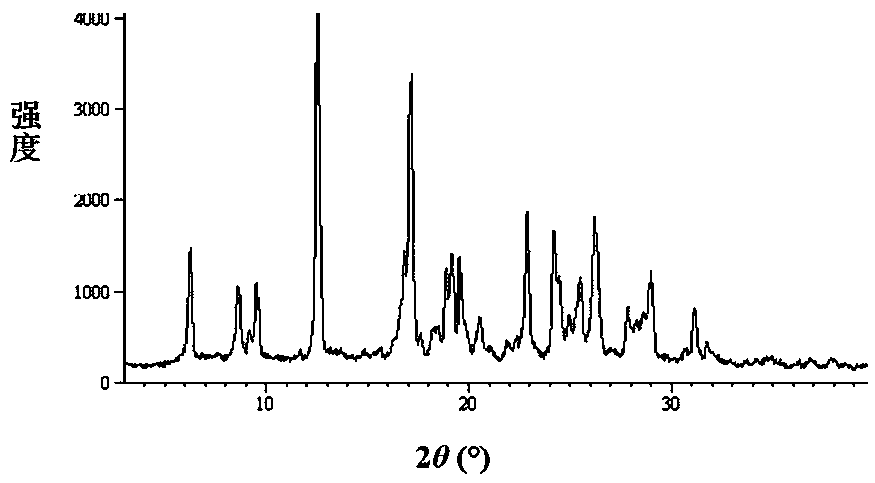

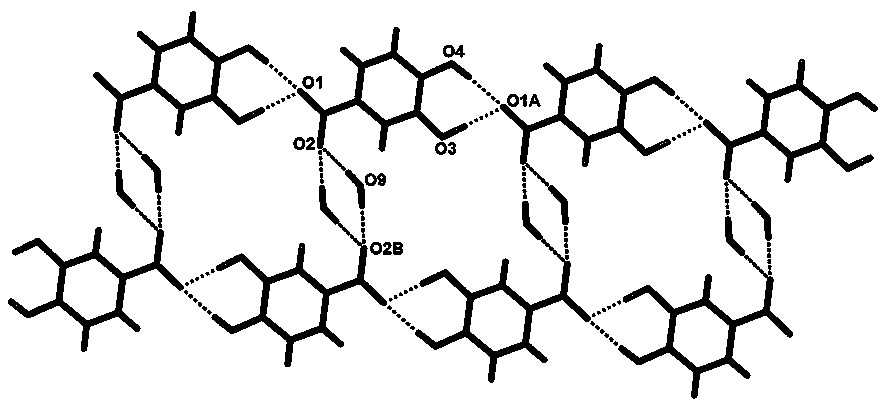

A crystalline form of non-hygroscopic protocatechin berberine monohydrate

ActiveCN107188890BEasy to prepareClear crystal structureOrganic chemistry methodsCarboxylic compound separation/purificationAqueous ethanolBerberine hydrochloride

The present invention discloses a non-hygroscopicity protocatechuic acid berberine monohydrate having a crystal form, and belongs to the technical field of drug crystallization. According to the present invention, berberine hydrochloride, protocatechuic acid and sodium hydroxide are dissolved in an ethanol aqueous solution according to a certain ratio to form the protocatechuic acid berberine monohydrate crystal; the preparation method has characteristics of simpleness, easy performing, low cost, and high crystal yield; and the prepared protocatechuic acid berberine monohydrate crystal does not have the hygroscopicity, has the moderate solubility in water, can be rapidly dissolved, and can be used in cardiovascular diseases and anti-cancer.

Owner:MINJIANG UNIV

Libricant and media for coolant compressed refrigeration circulator

InactiveCN1224686CReduce fillingModerate compatibilityCompression machines with non-reversible cycleHeat-exchange elementsSolubilityHalogen

To obtain a lubricating oil for a refrigerant compression type refrigerating cycle apparatus, which has proper compatibility with and solubility in a 2-4C hydrocarbon refrigerant having no halogen atom, keeps viscosity not to impair lubricating properties, reduces the amount of the refrigerant filled and has excellent lubricating properties, stability, etc., and a working fluid. In the lubricating oil for refrigerant compression type refrigerating cycle apparatus with which the 2-4C hydrocarbon refrigerant containing no halogen atom is used, the lubricating oil comprises an ether compound represented by general formula R1-A-OR2(R1and R2are each a 1-4C alkyl group; A is a polymerization chain consisting of m oxyethylene groups and n oxypropylene groups; m is an integer of 0-50; n is an integer of 2-50; m / n is <=1) as a main component and has 10-100 mm2 / s viscosity at 40[deg.]C. The working fluid for the refrigerant compression type refrigerating cycle apparatus comprises the 2-4C hydrocarbon refrigerant containing no halogen atom and the lubricating oil.

Owner:JAPAN ENERGY CORP

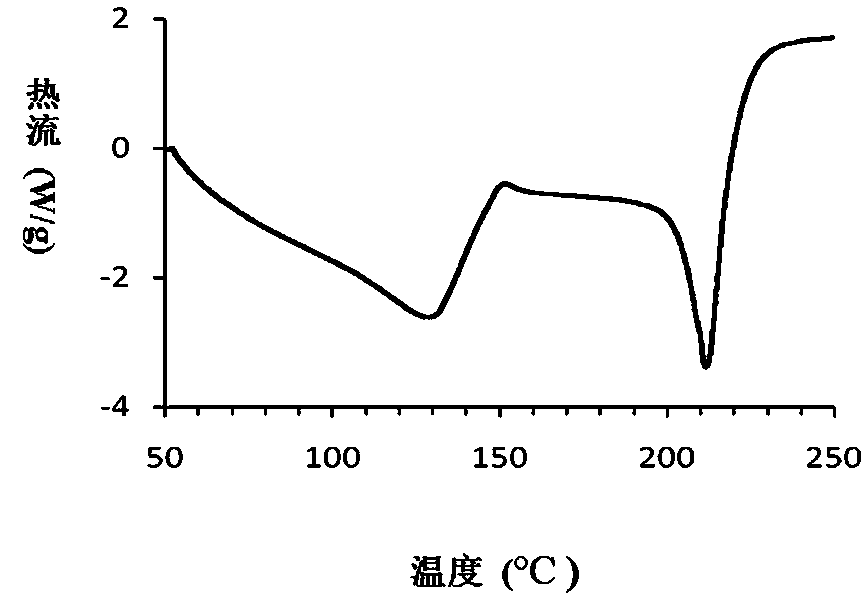

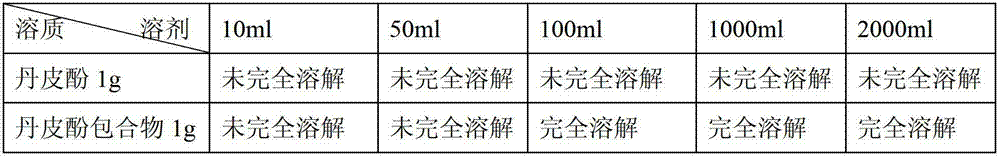

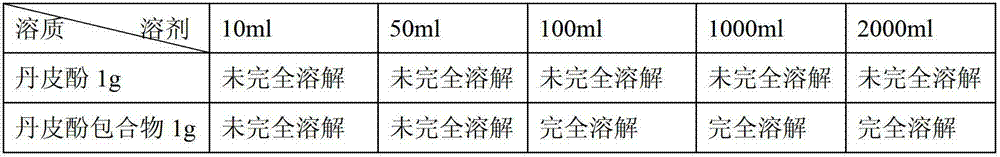

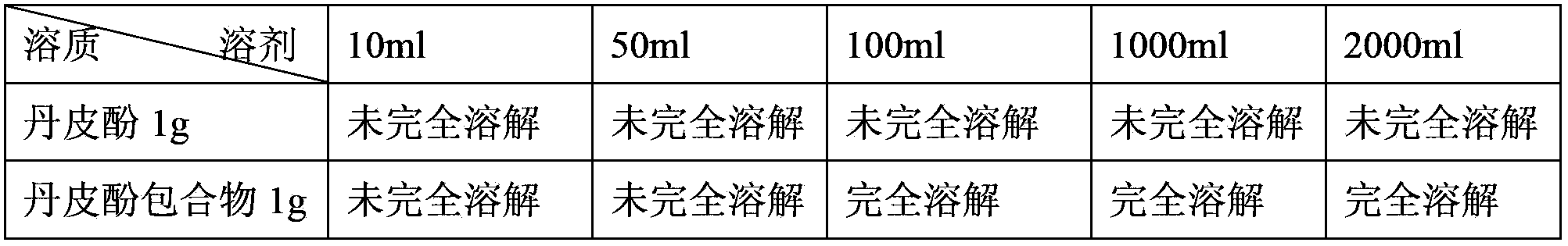

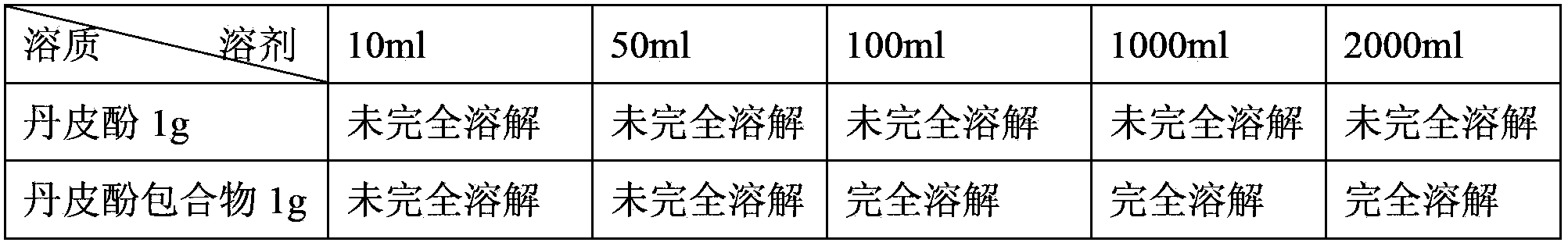

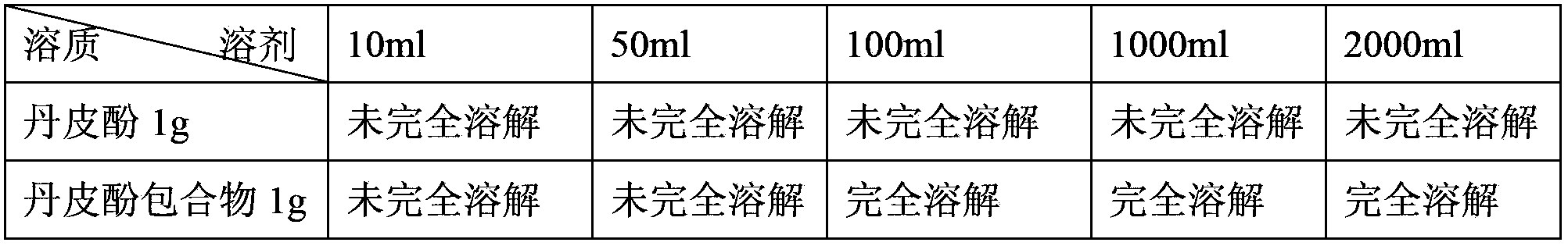

Paeonol inclusion compound and preparation method thereof

ActiveCN102784131AHydrophilicGood water solubilityAntibacterial agentsCosmetic preparationsWater solubleBeta-Cyclodextrins

The invention provides a paeonol inclusion compound. A compound agent is a mixture of beta-cyclodextrin and hydroxypropyl beta-cyclodextrin; the molar ratio of the beta-cyclodextrin to the hydroxypropyl beta-cyclodextrin is (10:1)-(1:1); and the molar ratio of paeonol to the compound agent is (1:12)-(1:10). The paeonol inclusion compound has greatly increased water-solubility, good stability, difficulty in separation, and an excellent taste masking effect; and the compound rate can reach to more than 80 percent.

Owner:HUBEI TIANSHENG PHARMA

Silicic acid fertilizer and preparation technology thereof

The invention relates to a silicic acid fertilizer and a preparation technology thereof. The content of silicic acid in the silicify fertilizer is higher than 10%, and the pH value of a saturation extract is lower than 6.5. The silicic acid fertilizer is prepared by the following steps: sodium silicate or material blocks containing calcium silicate are used as raw materials, raw materials are neutralized with acid, a silicic acid colloidal solution is prepared, a deposition treatment is carried out, after filtering, washing, neutralization, drying and crushing, a finished product is obtained. The prepared silicic acid fertilizer has the following characteristics: the silicic acid content is high; after the fertilizer is applied to fields, the soil does not cake and deteriorate; the fertilizer is long-term effective, wherein utilization rate of silica is 100%; the solubility is moderate and the fertilizer efficiency is high, and the fertilizer can be used as a base fertilizer and an additional fertilizer; outputs of crops can be greatly increased; the fertilizer can be prepared into a complex fertilizer with a nitrogenous fertilizer, a phosphate fertilizer, a potash fertilizer and other common fertilizers, and usage of the fertilizer is convenient; the preparation technology is simple, investment is low and production cost is low.

Owner:宋淑芹

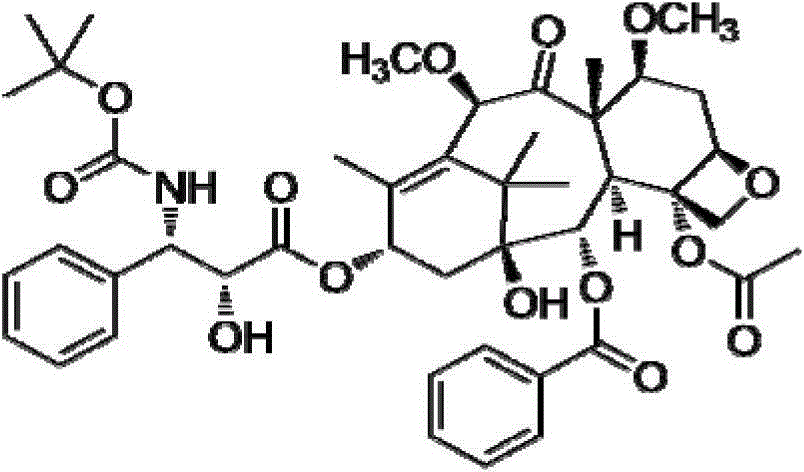

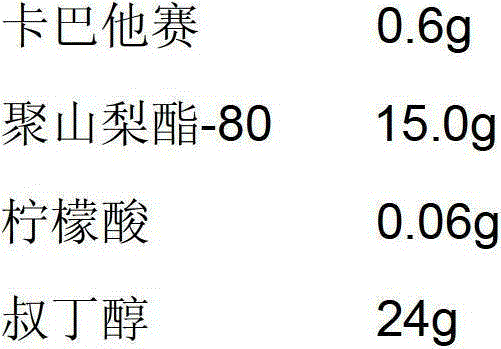

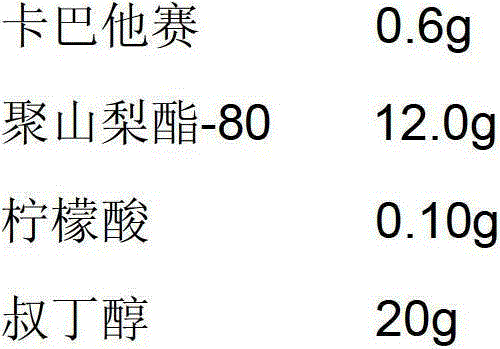

A kind of injection composition containing cabazitaxel and its preparation method

InactiveCN103961345BSimple production processEasy to operate industriallyOrganic active ingredientsPharmaceutical delivery mechanismCabazitaxelFiltration

The invention provides a Jevtana-containing injection composition and a preparation method thereof. A mass ratio of Jevtana, polysorbate to citric acid in the Jevtana-containing injection composition is 1: 20-30: 0.05-0.25 and a tert-butyl alcohol residual quantity ratio is less than 0.5%. The preparation method utilizes tert-butyl alcohol as a solvent and a mass ratio of Jevtana to tert-butyl alcohol is 1: 20-45. The preparation method comprises the following steps of adding polysorbate-80 and citric acid into tert-butyl alcohol, carrying out stirring for dissolution, adding Jevtana into the solution for dissolution, carrying out sterilization filtration, carrying out split charging and carrying out vacuum removal of tert-butyl alcohol.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Block polyimide, block polyamide acid imide and use thereof

Provided are a block polyamide acid imide having an appropriate solubility in aqueous alkaline solutions, and block polyimides that are obtained using same and have high transparency and a low coefficient of linear thermal expansion (low CTE). The block polyimide comprises blocks configured from repeating structural units represented by defined formula (1A) and blocks configured from repeating structural units represented by defined formula (1B).

Owner:MITSUI CHEM INC

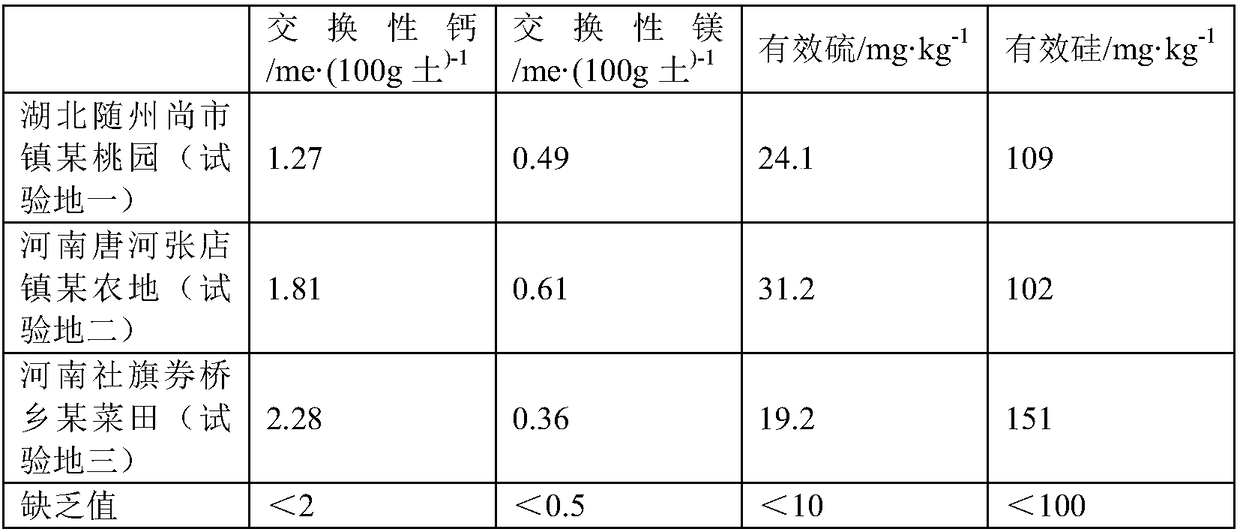

Technology for producing medium element fertilizer by using phosphogypsum

PendingCN108752141AImproved soilTargetedCalcareous fertilisersFertilizer mixturesSpecific gravityFertilizer

The invention relates to the technical field of a medium element fertilizer, and especially relates to a technology for producing the medium element fertilizer by using phosphogypsum. The technology comprises the following steps: performing phosphogypsum pretreatment, mixing phosphogypsum and a soil conditioner, performing fragmentation and granulation on a mixture to obtain the granular-fertilizer, and performing steps of primary drying, primary cooling, secondary drying, and secondary cooling to obtain a product. The free water proportion in the pre-treated phosphogypsum is 12-15%, the granular-fertilizer is heated to 75-85 DEG C while primary drying, the proportion of the free water in the granular-fertilizer is reduced to 10-13%, the temperature of the granular-fertilizer after primarycooling is reduced to 65 DEG C, the granular-fertilizer after secondary drying is heated to the temperature of 75-80 DEG C, and the proportion of the free water in the granular-fertilizer is reducedto lower than 8%, A granulation step is carried out under normal temperature without addition of water, and is cold condition waterless granulation. The by-product realizes reasonable utilization, theproblem of soil acidifying and salinization in our country can be solved, and the technology perform active effects for reducing crops fertilizer damage and increasing the crops quality.

Owner:宜城市农丰化工有限公司

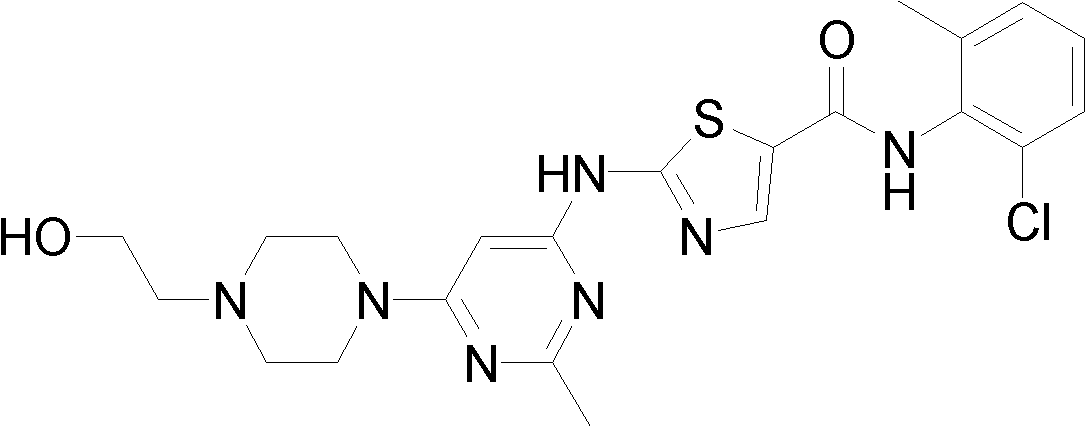

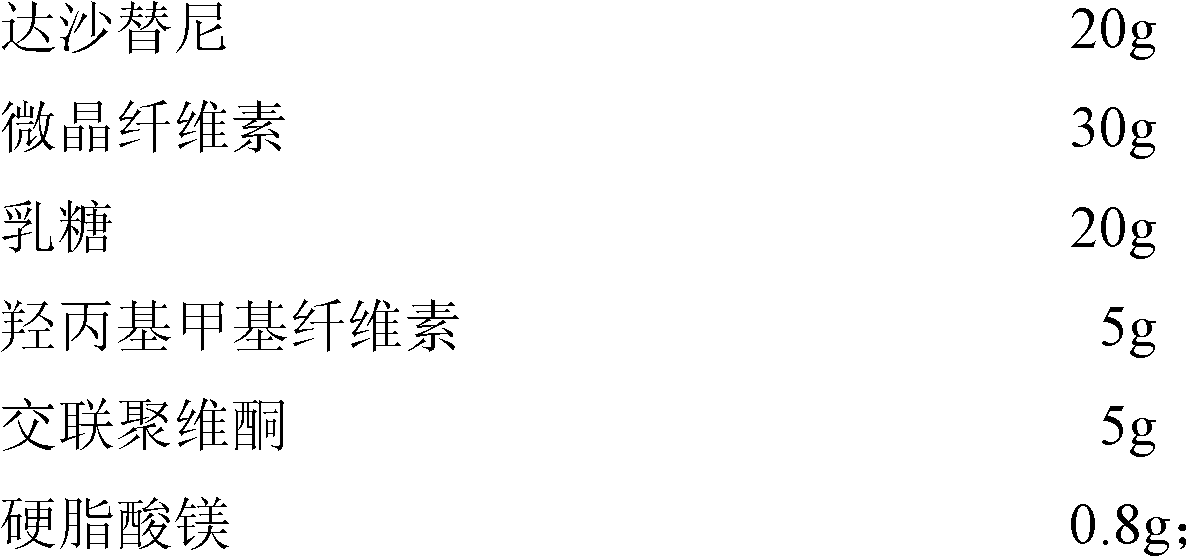

Method for preparing large particle size dasatinib

The invention discloses a method for preparing large particle size dasatinib, which comprises the following steps of: adding dasatinib into an organic solvent to obtain slurry; heating until backflow to obtain a clear solution; cooling the solution to decrease the temperature by 5-15 DEG C to obtain a suspension; cooling the suspension for 5-15 h to room temperature; and filtering the suspension, and vacuum-drying the obtained solid at 40-60 DEG C. Large particle size dasatinib with particle sizes D (0.1)=3.0 to 10 mum, D (0.5)=15 to 60 mum and D (0.9)=100 to 150 mum can be obtained by using the preparation method provided by the invention. Experiments prove that dasatinib obtained in the invention has good flowability and compressibility and moderate solubility and is beneficial to making of qualified preparations and lowering the production cost of raw materials and preparations, and the requirement of industrial production can be satisfied.

Owner:SHANGHAI ACEBRIGHT PHARMA CO LTD +1

Paeonol inclusion compound and preparation method thereof

ActiveCN102784131BHydrophilicGood water solubilityAntibacterial agentsCosmetic preparationsWater solubleBeta-Cyclodextrins

The invention provides a paeonol inclusion compound. A compound agent is a mixture of beta-cyclodextrin and hydroxypropyl beta-cyclodextrin; the molar ratio of the beta-cyclodextrin to the hydroxypropyl beta-cyclodextrin is (10:1)-(1:1); and the molar ratio of paeonol to the compound agent is (1:12)-(1:10). The paeonol inclusion compound has greatly increased water-solubility, good stability, difficulty in separation, and an excellent taste masking effect; and the compound rate can reach to more than 80 percent.

Owner:HUBEI TIANSHENG PHARMA

Refrigeration oil composition and its application

ActiveCN107353983BModerate solubilityImprove the lubrication effectLubricant compositionCooling effectEngineering

The invention relates to the field of refrigeration equipment and discloses refrigerant oil composition and an application thereof. The refrigerant oil composition comprises base oil and a refrigerant, wherein the refrigerant is propane; the base oil contains a compound shown as formula I in the description, in the formula I, R1 is H, R2 is H or C1-C18 alkyl, and m is an integer larger than or equal to 1. The invention further discloses a compressor with the refrigerant oil composition serving as a circulating cooling liquid system as well as a refrigerating circulating device. The base oil and the refrigerant propane have good solubility, the lubricity is good, so that sufficient cooling can be also realized even when the dosage of the refrigerant is lower, and the safety is guaranteed while the cooling effect is guaranteed.

Owner:GUANGDONG MEIZHI COMPRESSOR

Cooling engine oil for hydrocarbon refrigerant

InactiveCN1268725CReduce fill volumeReduced insulation performanceHeat-exchange elementsAdditivesSolubilityPolyol

To provide a refrigerating machine oil which has appropriate compatibility with and solubility in a hydrocarbon refrigerant, can maintain a viscosity which does not adversely affect its lubricity, can reduce the filling amount of the refrigerant and, in addition, has excellent lubricity, electrical insulating properties, stability and the like. The refrigerating machine oil for a hydrocarbon refrigerant comprises an ester of one or more kinds of a 5-10C neopentyl polyol with one or more kinds selected from a 5-9C linear or branched monovalent fatty acid as the major component.

Owner:JAPAN ENERGY CORP

Solvent, method and application for preparing high-performance metal halide perovskite thin film

ActiveCN109920939BProper volatilityIncrease coverageThermoelectric device manufacture/treatmentSolid-state devicesThin membraneMetal halides

Owner:XIAN JIAOTONG LIVERPOOL UNIV

A micro-block polymer for long-acting sustained-release preparations and its preparation method and use

ActiveCN107698747BRegulate drug releaseModerate degradation ratePharmaceutical delivery mechanismPharmaceutical non-active ingredientsSolubilityP-dioxanone

The invention discloses a micro-block polymer for long-acting sustained-release preparations and a preparation method thereof. The micro-block polymer includes a glycolide block and A with a weight ratio of 1-5:4-8 Component block; the A component is lactide, caprolactone, trimethylene carbonate or p-dioxanone; the molecular weight of the micro-block polymer is 5000~500000; glycolide block The average sequence length of glycolide in the segment is 3 to 5; the micro-block polymer used for long-acting sustained-release preparations of the present invention adjusts the microstructure of the entire polymer by adjusting the segment sequence length and distribution of glycolide The degradation rate and solubility of the long-acting sustained-release preparation can be adjusted accordingly; the LGG used in this application is between 3 and 5, the structure of the polymer is regular, the degradation rate is moderate, and there will be no sudden release of the drug , and the blockiness of the polymer is moderate, the solubility in most organic solvents is good, and it is suitable for the preparation process of most pharmaceutical preparations.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Block polyimide, block polyamide acid imide and use thereof

ActiveUS20170240705A1High transparencyLow CTEOptical articlesPrinted circuit manufactureSolubilityImide

Provided are a block polyamide acid imide having an appropriate solubility in aqueous alkaline solutions, and block polyimides that are obtained using same and have high transparency and a low coefficient of linear thermal expansion (low CTE). The block polyimide comprises blocks configured from repeating structural units represented by defined formula (1A) and blocks configured from repeating structural units represented by defined formula (1B).

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com