Method for detecting residual acrylamide monomer in cationic polyacrylamide

A technology of acrylamide monomer and polyacrylamide, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of shortening pretreatment time, long pretreatment time, cumbersome steps, etc., and achieve ideal extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

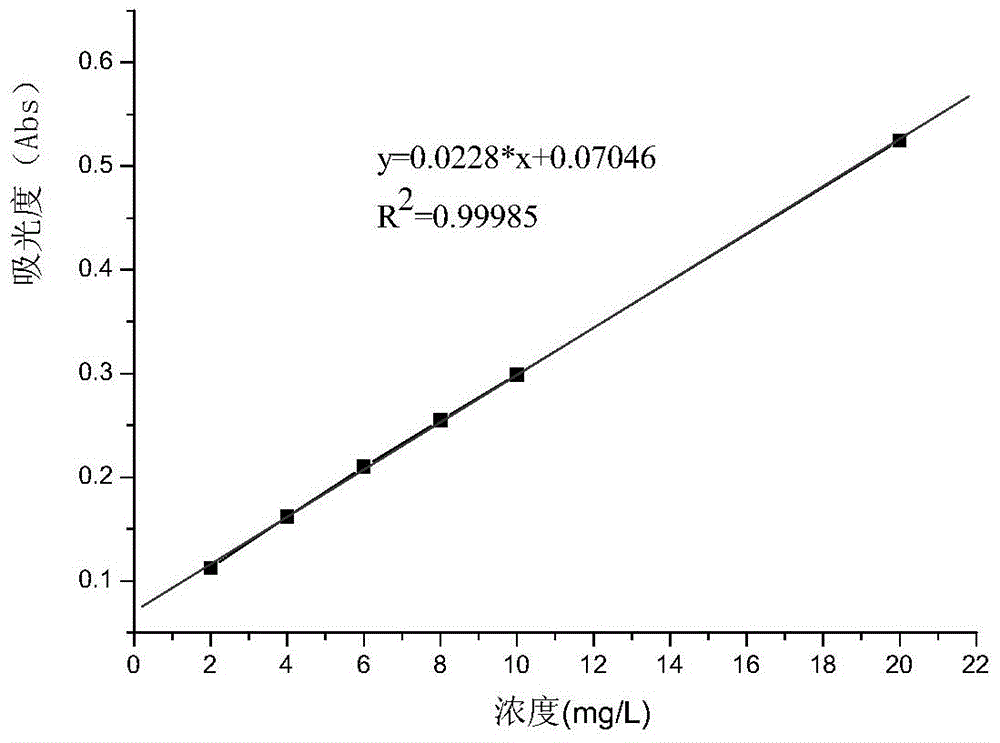

[0046] Take about 5g of cationic polyacrylamide samples with cationic degrees of 5%, 10%, 15%, 20%, 30%, 40%, and 70%, respectively, and dissolve them in 50mL of mixed solvents of ethanol and water with different volume ratios. extraction, the results are shown in Table 1:

[0047] Table 1

[0048]

[0049]

[0050] It can be seen from Table 1 that in the extractant of CPAM with a cationic degree of 5-10%, when the volume ratio of ethanol to water is 0-65:100-35, the solubility of polyacrylamide in the extract is increased due to the large proportion of water. The increase makes the colloid viscous and difficult to extract; when the volume ratio of ethanol to water is 71-100:29-0, the solubility of polyacrylamide in the extraction solution decreases due to the large proportion of ethanol, resulting in the colloid being hard on the outside and soft on the inside. , the sample is not completely swollen, the residual acrylamide monomer is not completely extracted, and the ...

Embodiment 2

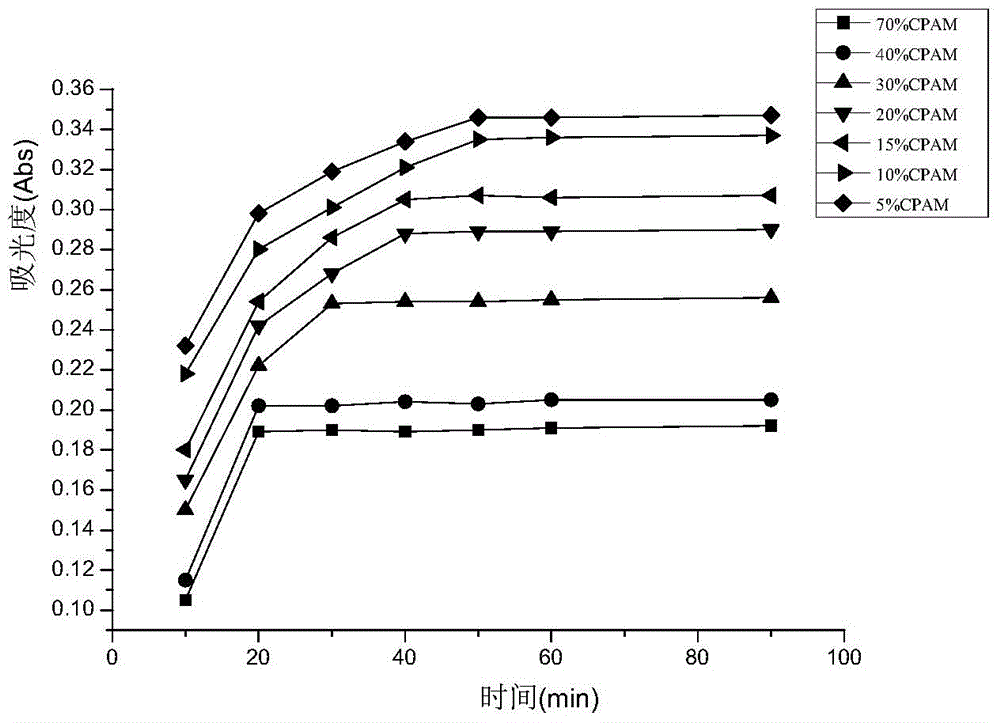

[0071] Take by weighing cationic degree is respectively 5%, 10%, 15%, 20%, 30%, 40%, 70% CPAM sample 2g left and right, with the optimal extractant 20mL (ethanol and water) of corresponding cationic degree among the embodiment 1 ) to prepare a polyacrylamide mixture, put the 7 mixtures in an ultrasonic cleaner, adjust the ultrasonic power to 0-50W, and ultrasonicate for 60min, 90min, and 120min respectively, then filter the supernatant, dilute it 10 times, and place it at room temperature for 30min. , measure its absorbance at 220nm place of ultraviolet spectrophotometer, and measured result is as shown in table 4:

[0072] Table 4

[0073]

[0074] Again, the CPAM sample 2g that takes by weighing cation degree is respectively 5%, 10%, 15%, 20%, 30%, 40%, 70% is about, and the optimum extractant 20mL (ethanol) of corresponding cation degree among the embodiment 1 and water) to prepare a polyacrylamide mixture, and ultrasonically extract the 7 mixtures in an ultrasonic clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com