Solvent, method and application for preparing high-performance metal halide perovskite thin film

A perovskite and perovskite precursor technology, applied in the field of microelectronics, can solve problems such as unfavorable development and commercialization of perovskite devices, general perovskite film quality, and increased production costs, and achieve appropriate solvent volatility. , easy to control, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

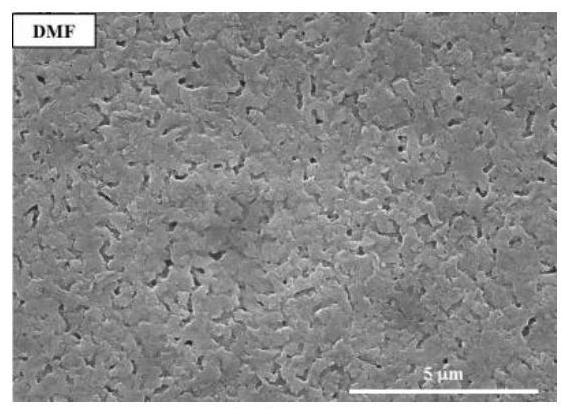

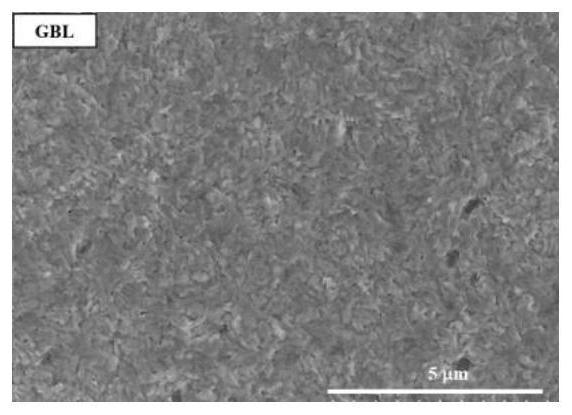

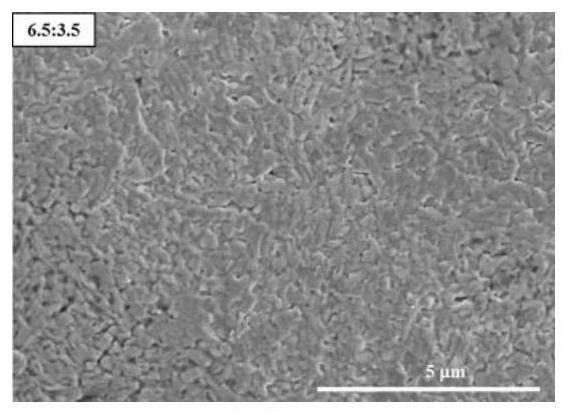

[0031] DMF and GBL are two organic solvents with quite different properties. The boiling point of DMF is relatively low at 153 °C, and the polarity is relatively large at 6.40 D. The ability to form hydrogen bonds and coordinate with metals is very strong. GBL has a relatively high boiling point of 204 °C and a relatively low polarity of 4.12 D, which can form hydrogen bonds, but its coordination ability with metals is relatively weak. The quality of perovskite films directly depends on the type of solvent, the properties of the solvated intermediates, and the interaction between the solvent and the solvated intermediates, and the above two solvents have defects in the preparation of perovskite films by themselves.

[0032] In this example, scanning electron microscopy (SEM) and ultraviolet-visible spectroscopy (UV-Vis) were performed on perovskite films prepared from perovskite precursor solutions with different solvent ratios. like Figure 1a , Figure 1b and Figure 1c A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com