Conducting ring, power supply device based on conducting ring and electroplating jig based on power supply device

A technology for power supply devices and electroplating fixtures, applied in current conduction devices, circuits, electrolysis processes, etc., can solve the problems of different wafer coating thicknesses, current density indexing deviations, etc., to ensure consistency and uniformity, reduce Frequency, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

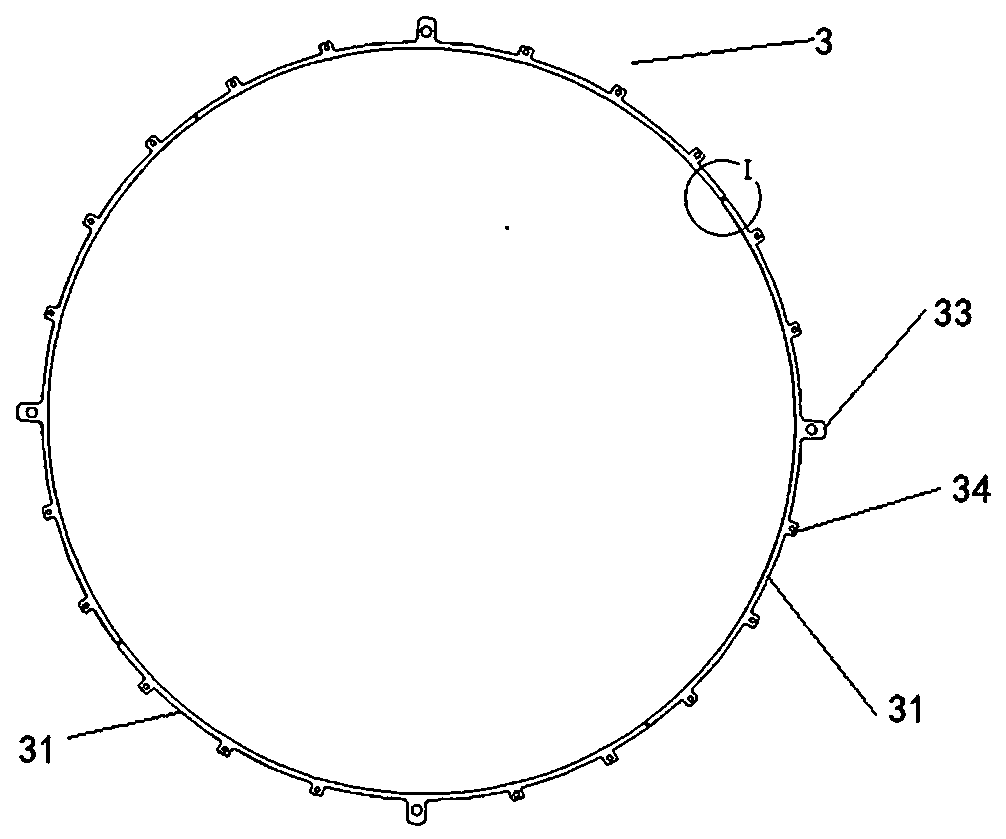

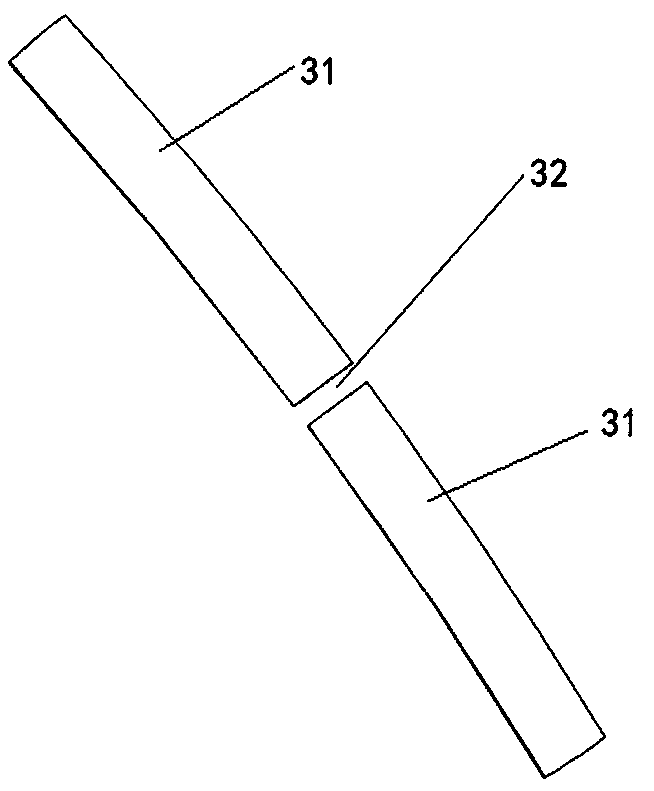

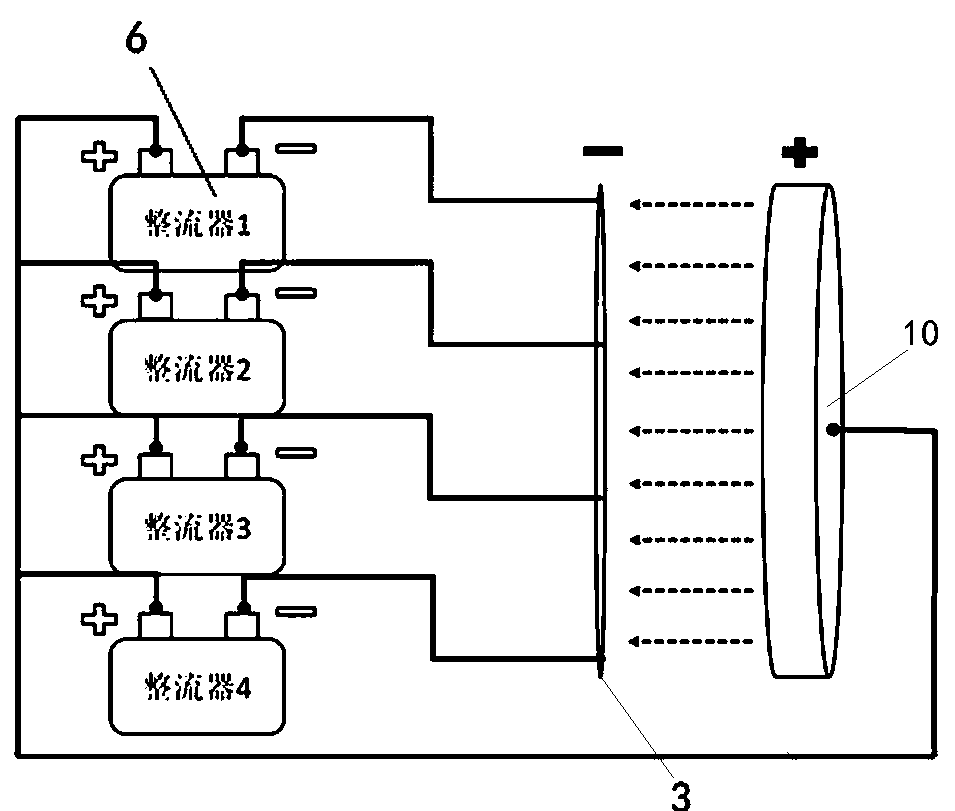

[0026] see Figure 1-2 , the conductive ring provided by the present invention includes a conductive ring body 3, the conductive ring body is distributed in a segmented structure, and is composed of a plurality of conductive segments 31; the opening 32 between every two adjacent conductive segments is filled The insulating glue is separated by the insulating glue layer; the surface of the conductive ring body is wrapped with an insulating glue layer; and the conductive ring body is provided with at least one electrode 33 and at least one supporting foot 34 .

[0027] In this embodiment, the outer surface of the conductive ring body 31 is sequentially provided with a nickel-plated layer and a silver-plated layer from inside to outside, and the silver-plated layer is placed between the nickel-plated layer and the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com