Barrel plating current intensity real-time online testing device

A technology of current density and online testing, which is applied in the direction of current density measurement, electrolytic process, electrolytic components, etc., can solve the problems that affect the quality of electroplating and cannot realize microcomputer control, etc., and achieve the effect of improving the quality of electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The device and method for on-line testing of the barrel plating current density will be further described below in conjunction with the accompanying drawings.

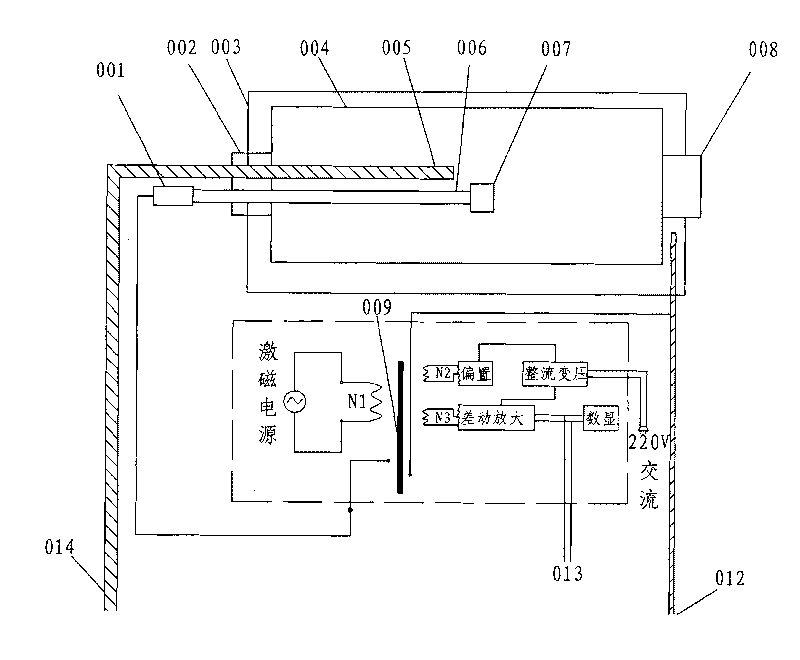

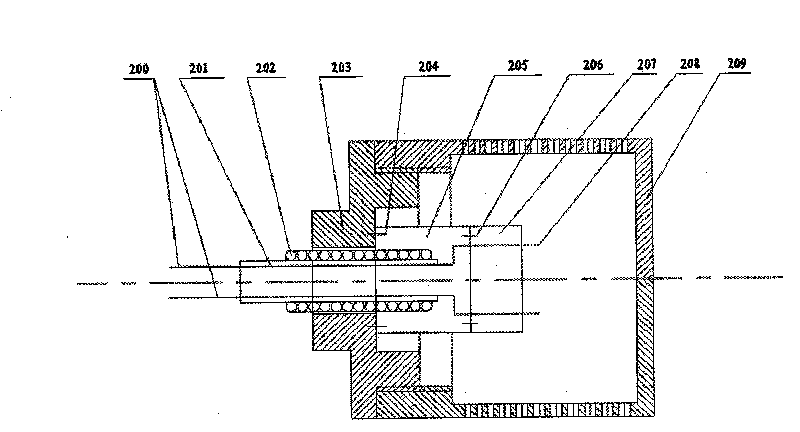

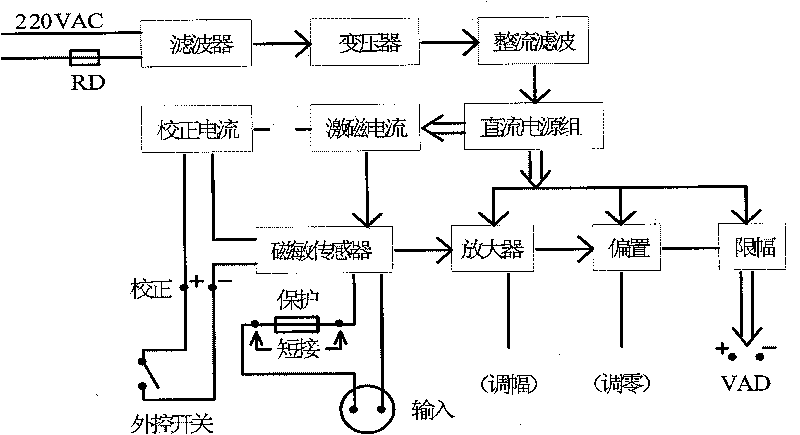

[0037] Such as figure 1 As shown, in the barrel plating current density on-line test device, firstly open the barrel cover, put the measuring needle part 007 into the center of the barrel, and then pass the spring-wrapped transmission wire 006 and pole lead wire 005 through the barrel After the wire 006 protrudes from the center hole of the rotating shaft 002 from the drum rotating shaft 008, connect the multi-strand copper wires to the switch 001 respectively, and the other interface of the switch 001 is connected to a single-strand copper wire with an insulating jacket. Connect to the magnetic sensitive element 009 of the test device, as the anode of the input signal, and the other pole of the input signal of the measuring device is connected to the cathode of the nearby electroplating power supply. During ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com