Two-in-one trivalent chromium blue white passivation solution for passivation and sealing and use process thereof

A technology of passivation solution and trivalent chromium, which is applied in the coating process of metal materials, etc., can solve the problems of increased passivation cost, more waste water, and increased cost of waste water treatment, and achieve good corrosion resistance and heat resistance, waste water Ease of handling, effect of improving plating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

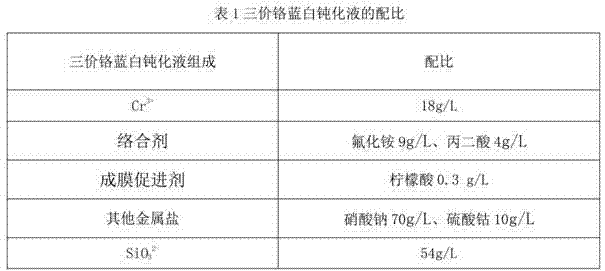

[0032] See Table 1 for the formula of passivation and sealing two-in-one trivalent chromium blue-white passivation solution.

[0033]

[0034] Among them, Cr 3+ Provided by chromium sulfate; SiO 3 2- Provided by sodium silicate with the balance being water.

[0035] Adopt the above-mentioned passivation and sealing two-in-one trivalent chromium blue-white passivation solution to carry out passivation and sealing treatment to the workpiece after electroplating treatment, which includes the following steps:

[0036] 1) Pre-plating treatment;

[0037] 2) Potassium chloride galvanizing;

[0038] The galvanized layer adopts Sanfu's SF-522 low-foaming / non-foaming potassium chloride galvanizing additive acid zinc coating (coating thickness ≥ 8um), and its basic operation process is as follows:

[0039] Potassium chloride 180 g / L

[0040] Zinc chloride 50 g / L

[0041] Boric acid 30 g / L

[0042] SF-522 Brightener 1ml / L

[0043] SF-522 softener 25ml / L

[0044] p...

Embodiment 2

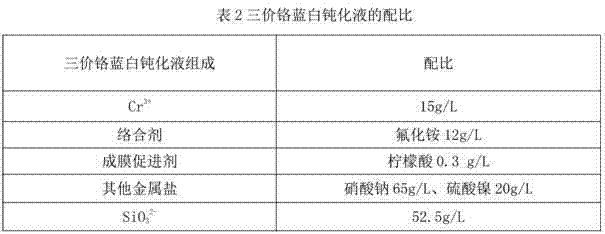

[0062] See Table 2 for the formula of passivation and sealing two-in-one trivalent chromium blue-white passivation solution.

[0063]

[0064] Among them, Cr 3+ Provided by Chromium Nitrate, SiO 3 2- Provided by potassium silicate, the balance is water.

[0065] Adopt the above-mentioned passivation and sealing two-in-one trivalent chromium blue-white passivation solution to carry out passivation and sealing treatment to the workpiece after electroplating treatment, which includes the following steps:

[0066] 4) Pre-plating treatment;

[0067] 5) Potassium chloride galvanizing;

[0068] The galvanized layer adopts Sanfu's SF-522 low-foaming / non-foaming potassium chloride galvanizing additive acid zinc coating (coating thickness ≥ 8um), and its basic operation process is as follows:

[0069] Potassium chloride 200 g / L

[0070] Zinc chloride 60 g / L

[0071] Boric acid 33 g / L

[0072] SF-522 brightener 2 ml / L

[0073] SF-522 softener 30ml / L

[0074] pH 5...

Embodiment 3

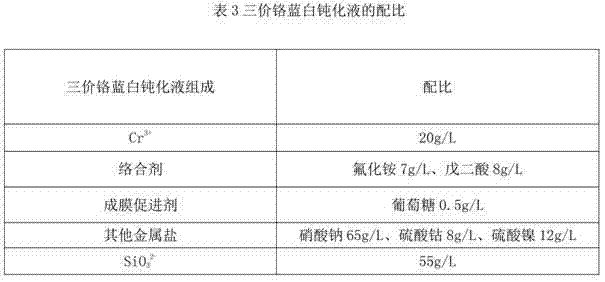

[0092] See Table 3 for the formula of passivation and sealing two-in-one trivalent chromium blue-white passivation solution.

[0093]

[0094] Among them, Cr 3+ Provided by Chromium Chloride, SiO 3 2- Provided by lithium silicate with the balance being water.

[0095] Adopt the above-mentioned passivation and sealing two-in-one trivalent chromium blue-white passivation solution to carry out passivation and sealing treatment to the workpiece after electroplating treatment, which includes the following steps:

[0096] 7) Pre-plating treatment;

[0097] 8) Potassium chloride galvanizing;

[0098] The galvanized layer adopts Sanfu's SF-522 low-foaming / non-foaming potassium chloride galvanizing additive acid zinc coating (coating thickness ≥ 8um), and its basic operation process is as follows:

[0099] Potassium chloride 230 g / L

[0100] Zinc chloride 70 g / L

[0101] Boric acid 35 g / L

[0102] SF-522 brightener 3 ml / L

[0103] SF-522 softener 35ml / L

[0104]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com