Chain belt electroplating supporting frame and electroplating equipment using the same

A technology for chain belts and chain teeth, which is applied in applications, clothing, sliding fastener components, etc. It can solve problems such as no arbitrary bending, failure to ensure electrical contact, and damage to the electroplating reaction interface, and achieve high-quality electroplating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

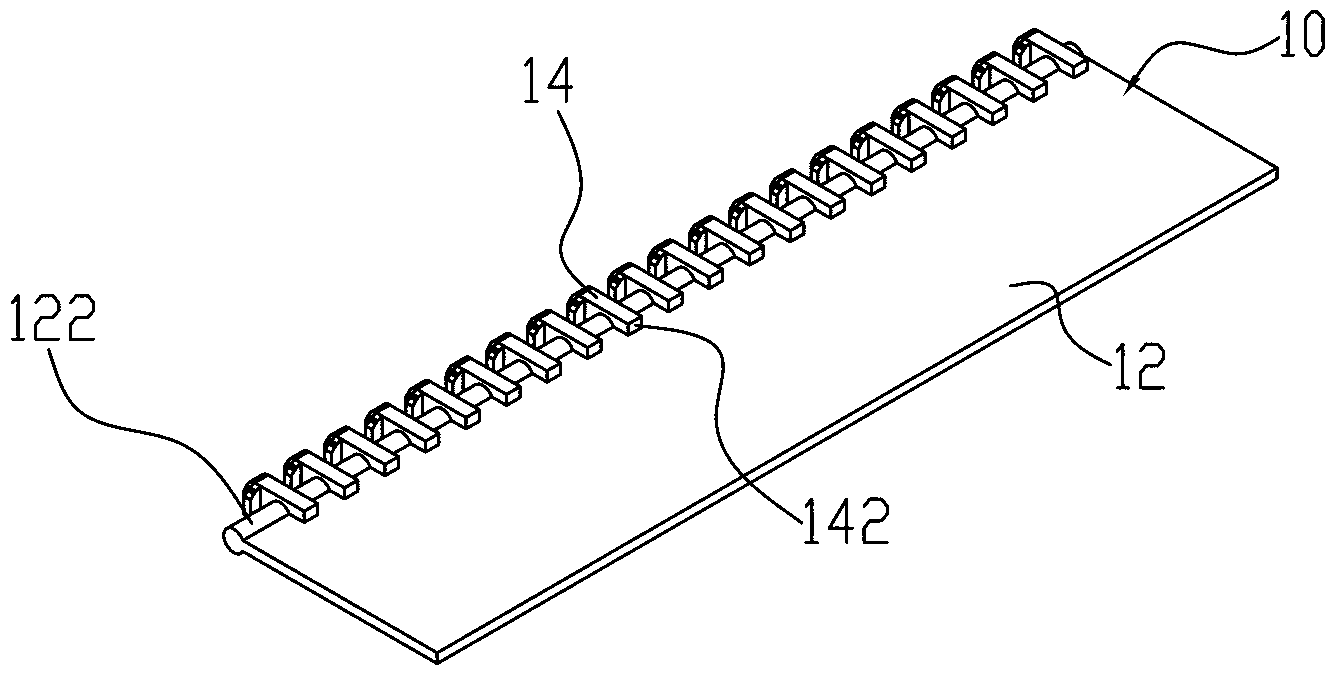

[0016] see figure 1 , figure 1 Shown is a perspective view of the zipper stringer 10 to be electroplated in the present invention. The chain belt 10 includes a fabric belt 12 and a plurality of metal fastener elements 14 disposed on the fabric belt 12 at intervals. Each metal fastener element 14 includes two legs 142 . The fabric belt 12 is provided with a fabric rib 122 on one side thereof, and the legs 142 of the metal fastener elements 14 are fixed on the fabric belt 12 by engaging the fabric rib 122 . The cloth tape 12 has a certain stretching elasticity along the stretching direction of the cloth tape 12 .

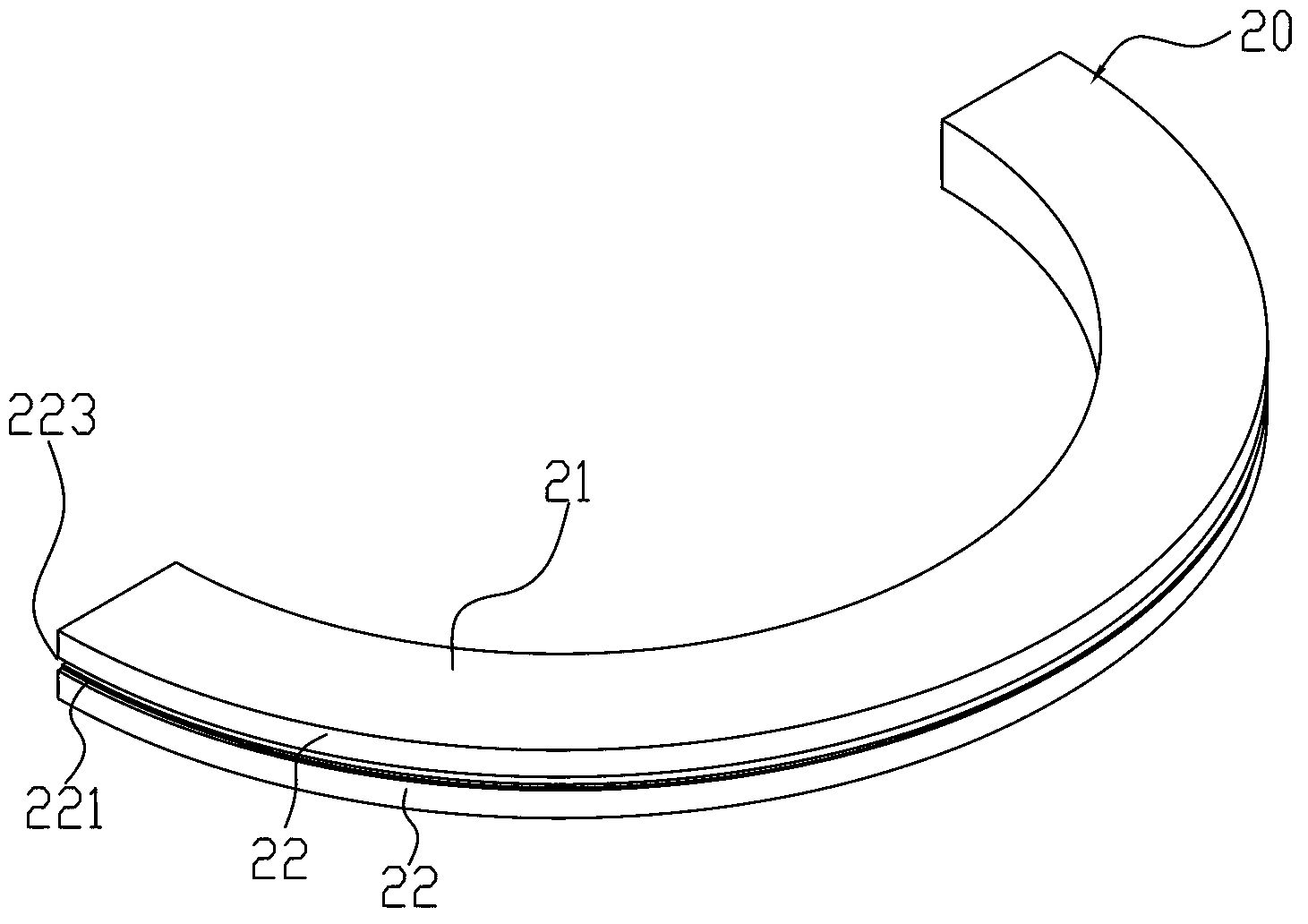

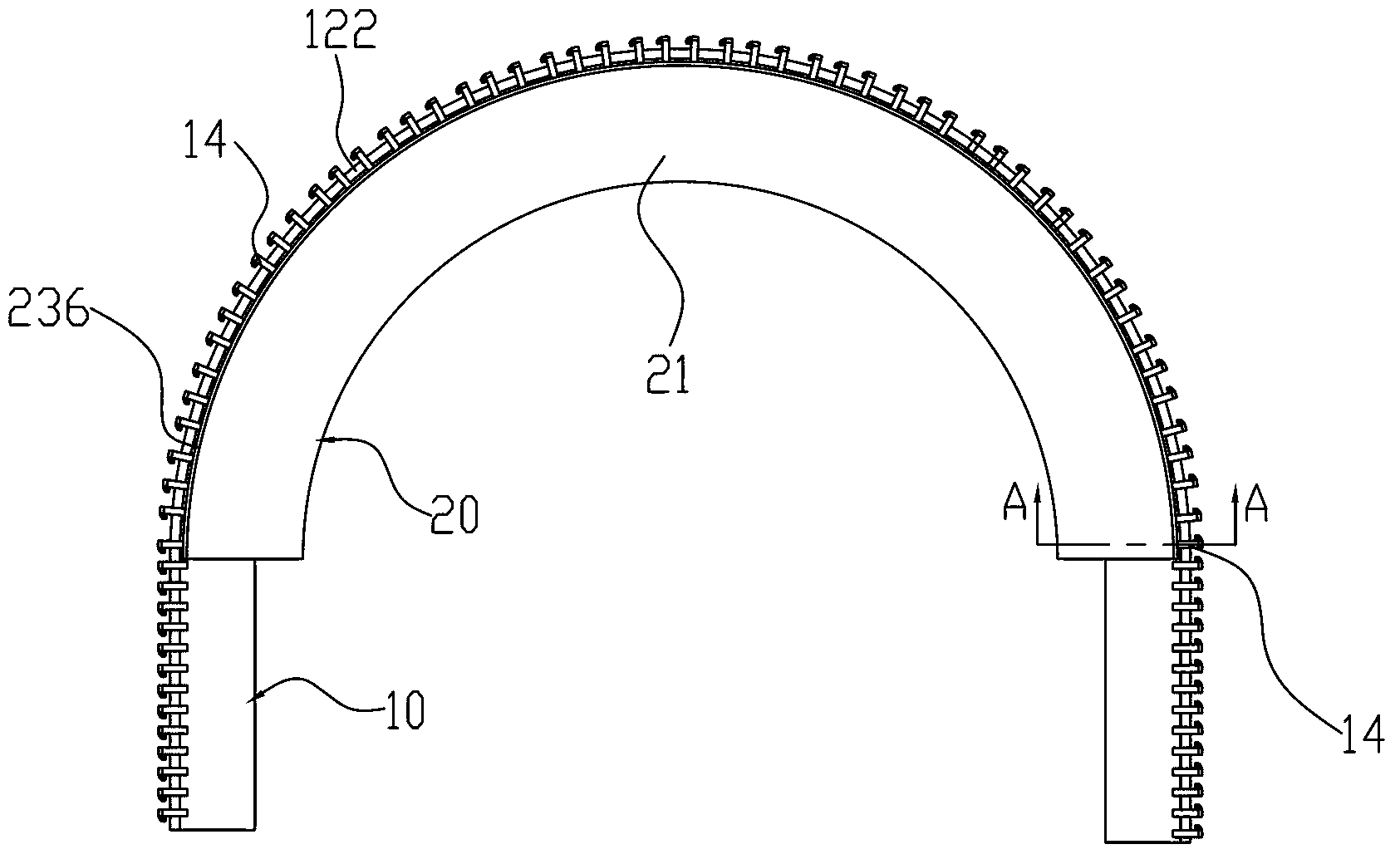

[0017] Please refer to figure 2 and Figure 5 , The chain belt electroplating bracket 20 of the first embodiment of the present invention includes a bracket body 21 and a chain belt traction mechanism, and the chain belt traction mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com