Electroplating roller for sheet parts

A technology of sheet parts and electroplating drums, which is applied in the electrolysis process and electrolysis components, etc., can solve the problems of low work efficiency of operators, uneven coating of the plated objects, difficulty in taking out the plated objects, etc., and achieve the goal of discharging and replacing The electrode is convenient, the coating is uniform, and the plating quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

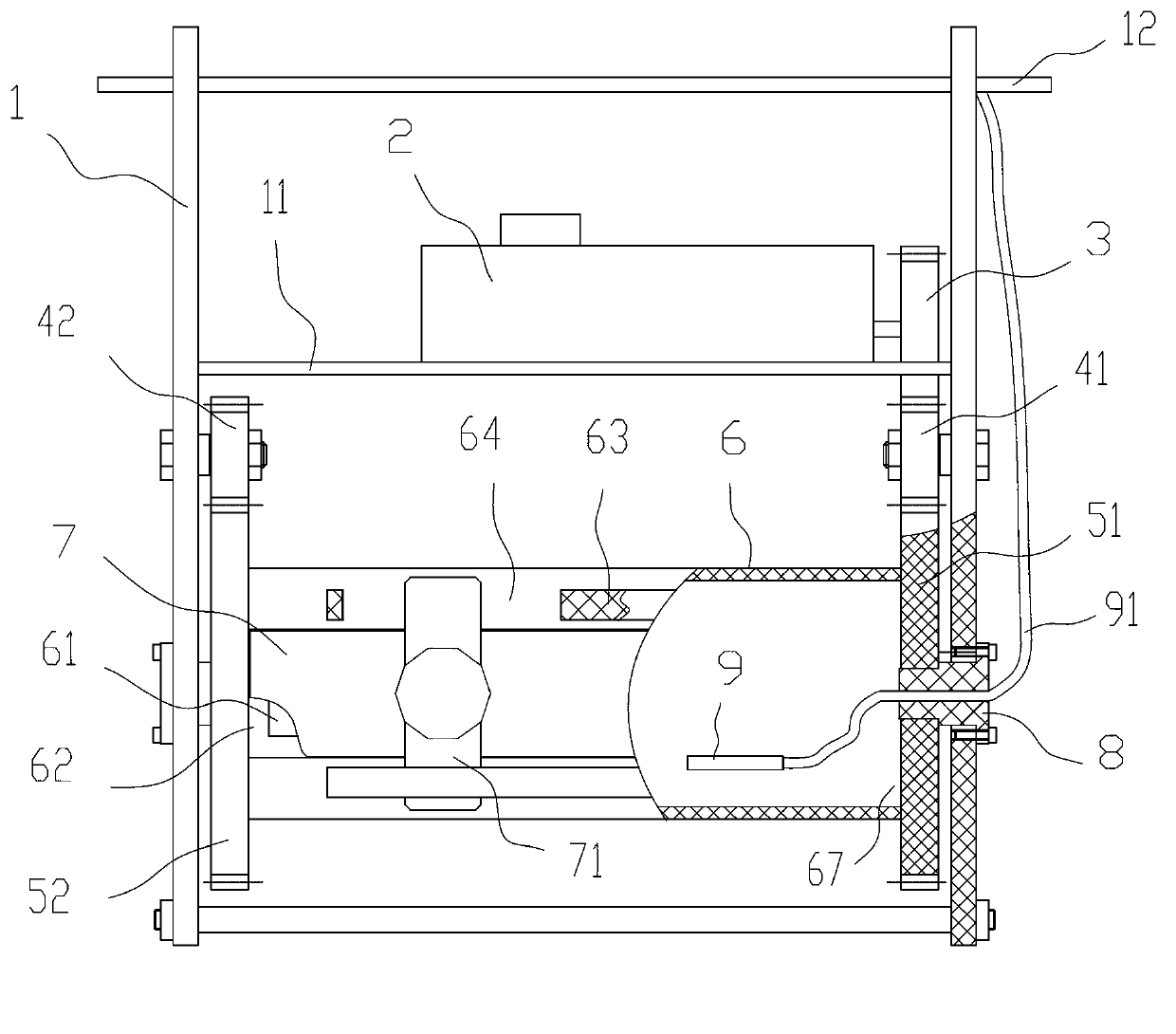

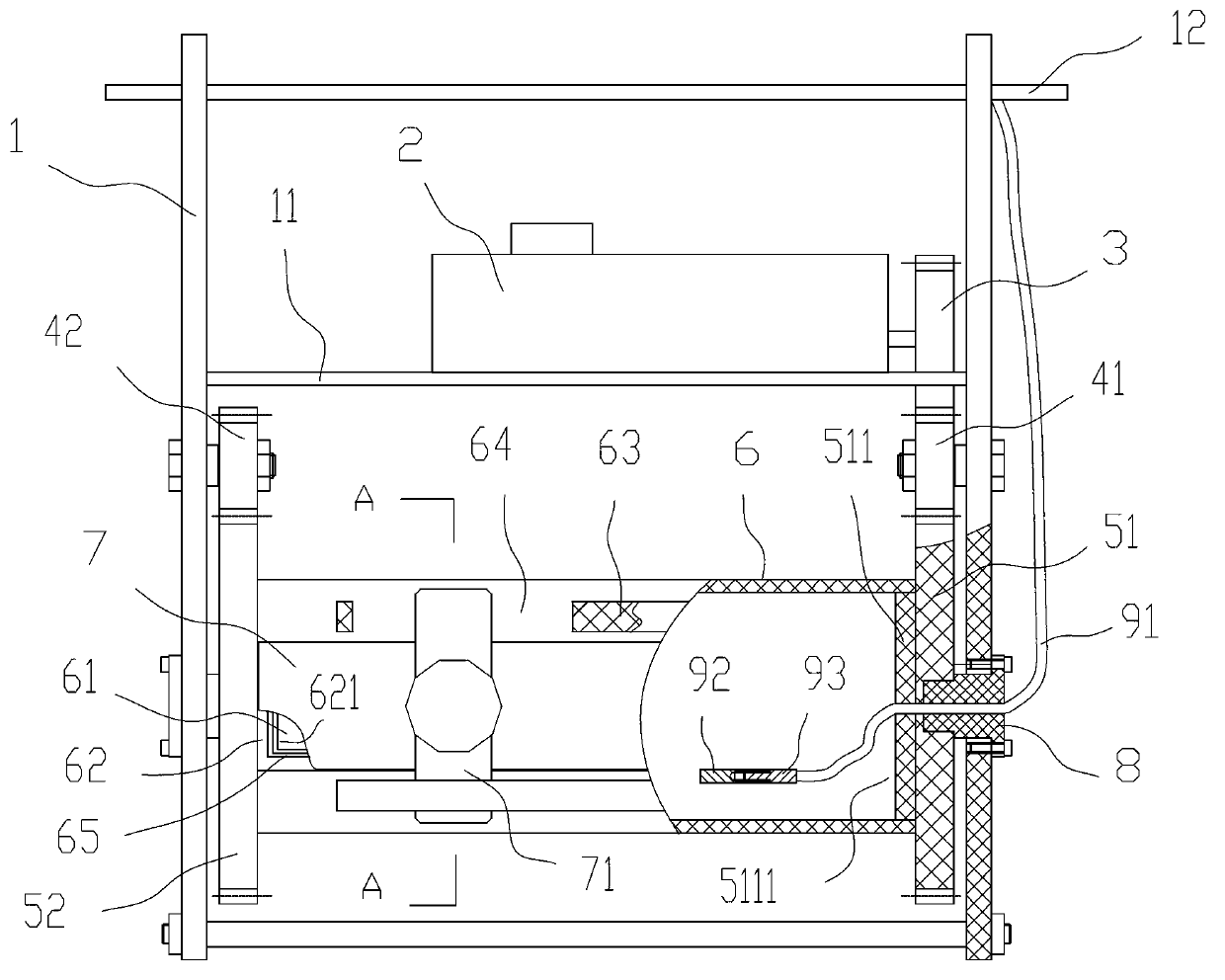

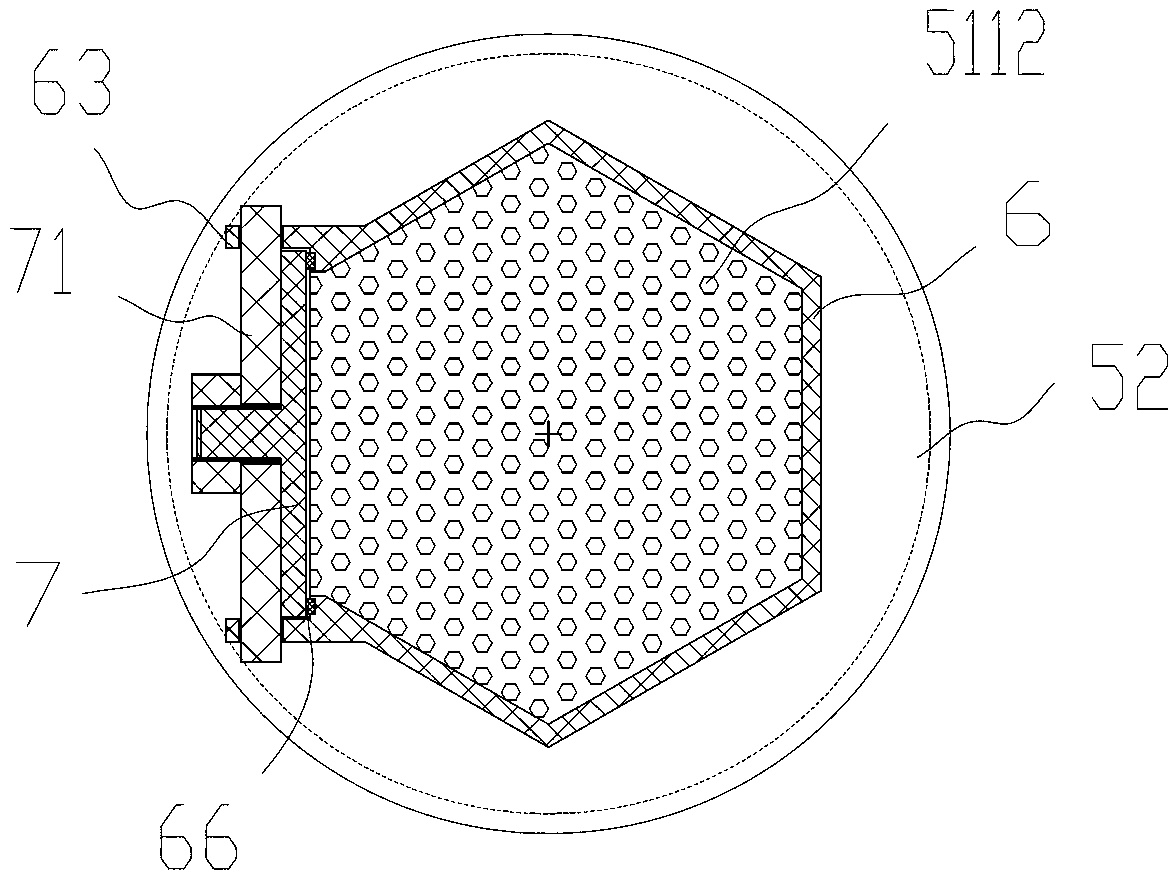

[0013] Such as figure 2 with image 3 As shown, the cylinder is composed of a cylinder 6 with a hexagonal cross section and gear discs 51, 52 arranged at both ends of the cylinder. The cylinder 6 wall is provided with holes for the passage of the electroplating solution. One side wall of the cylinder 6 There is an entrance 61 for placing the object to be plated and a dodge door 7 installed at the entrance 61. There is a stepped door frame 62 matching the edge of the dodge door 7 around the entrance 61; the dodge door 7 is provided with a rotatable latch 71 The outer wall of the cylinder body 6 at the upper and lower ends of the inlet 61 is provided with a protruding door bolt fixing frame 63, and the fixing frame 63 is provided with a slot 64 for screwing in the end of the door bolt 71. Place the movable door 7 in the door frame 62 , and then rotate the two ends of the door bolt 71 into the upper and lower slots 64 , so that the movable door 7 can be fixed on the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com