Electroplating device for lead wire framework

A technology of lead frame and electroplating device, which is applied in the direction of jewelry, etc., can solve the problems of affecting the quality of lead frame electroplating, low production efficiency, easy to cause pollution, etc., and achieve the effect of avoiding burning phenomenon, high yield rate and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

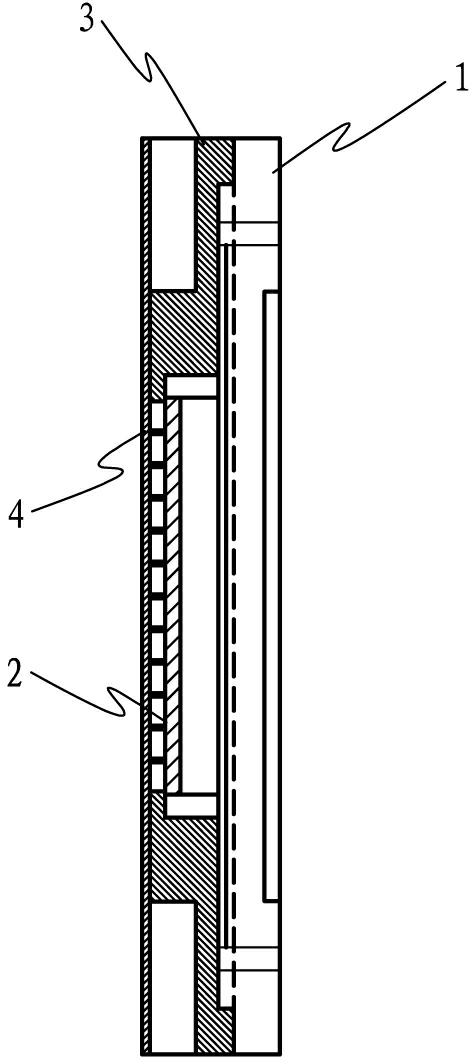

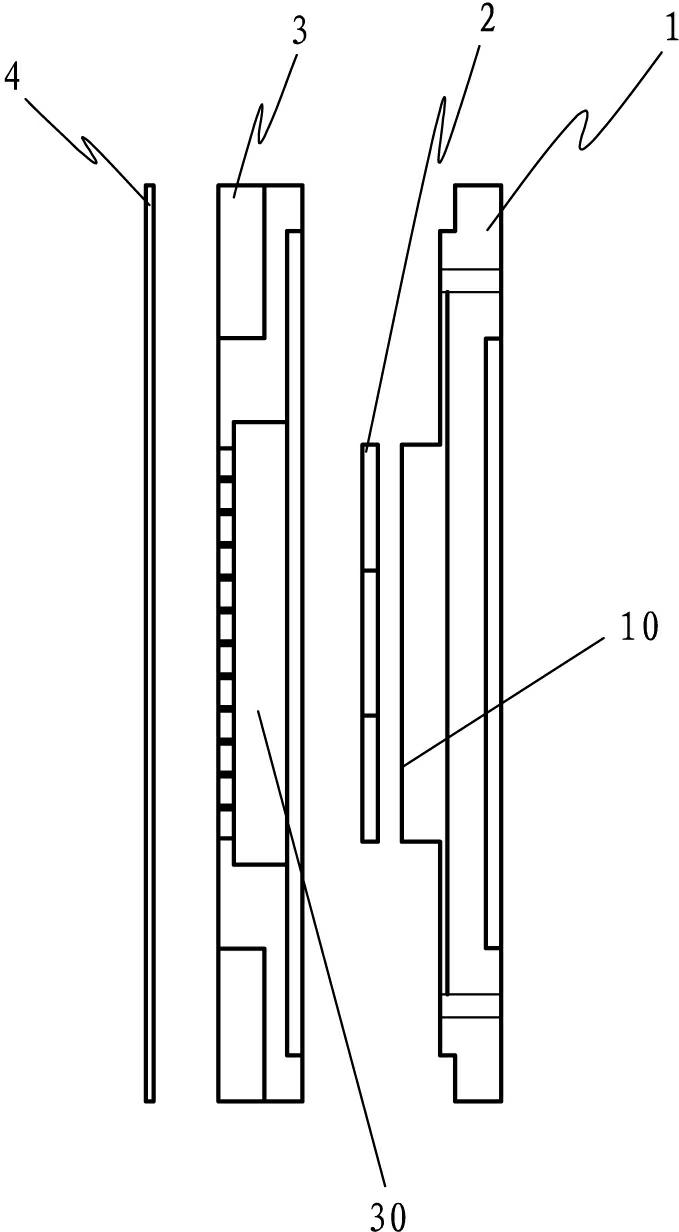

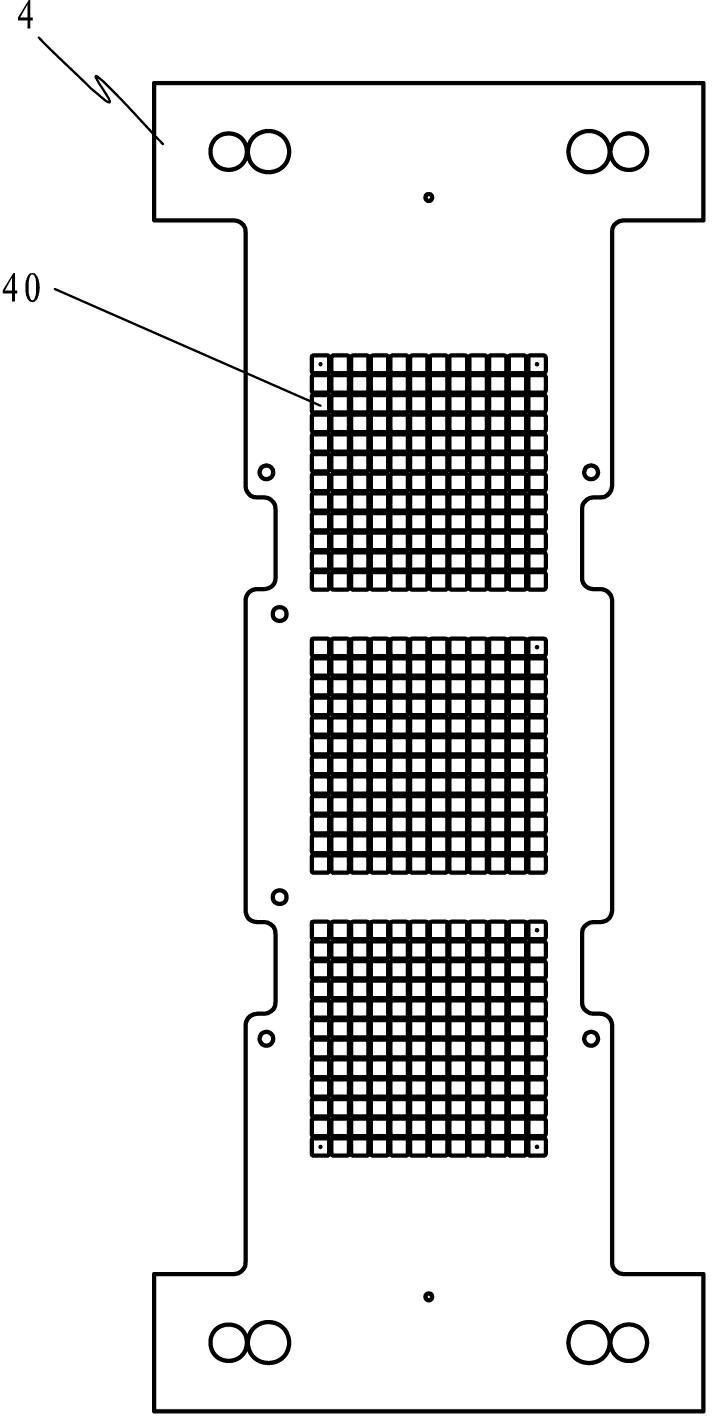

[0036] Example: see Figure 1 to Figure 16 , an electroplating device for a lead frame, comprising a spray plate 1, an anode plate 2, a substrate 3, and a mask base plate 4 from bottom to top, and a plurality of electroplating through holes 40 are arranged in an array on the mask base plate, such as image 3 As shown, the above-mentioned through holes respectively correspond to the electroplating unit area (lead frame pad) on the lead frame, and the electroplating device completes the electroplating operation of the lead frame at one time through the electroplating solution injection circuit on the injection plate 1 and the anode plate 2 .

[0037] see Figure 4 to Figure 7 Groove 30 is arranged on the substrate 3, and the bottom surface of the groove is provided with some through holes 301 superimposed with the plated through hole 40 of the mask base plate 4. The through holes on the two plates are square holes. Groove 30 cooperates to form the support frame of electroplatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com