High-radiation film type metal compound material and manufacturing method thereof

A technology of metal composite materials and manufacturing methods, applied in the direction of metal layered products, chemical instruments and methods, heat exchange equipment, etc., can solve the problems of low hardness and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments with reference to the accompanying drawings.

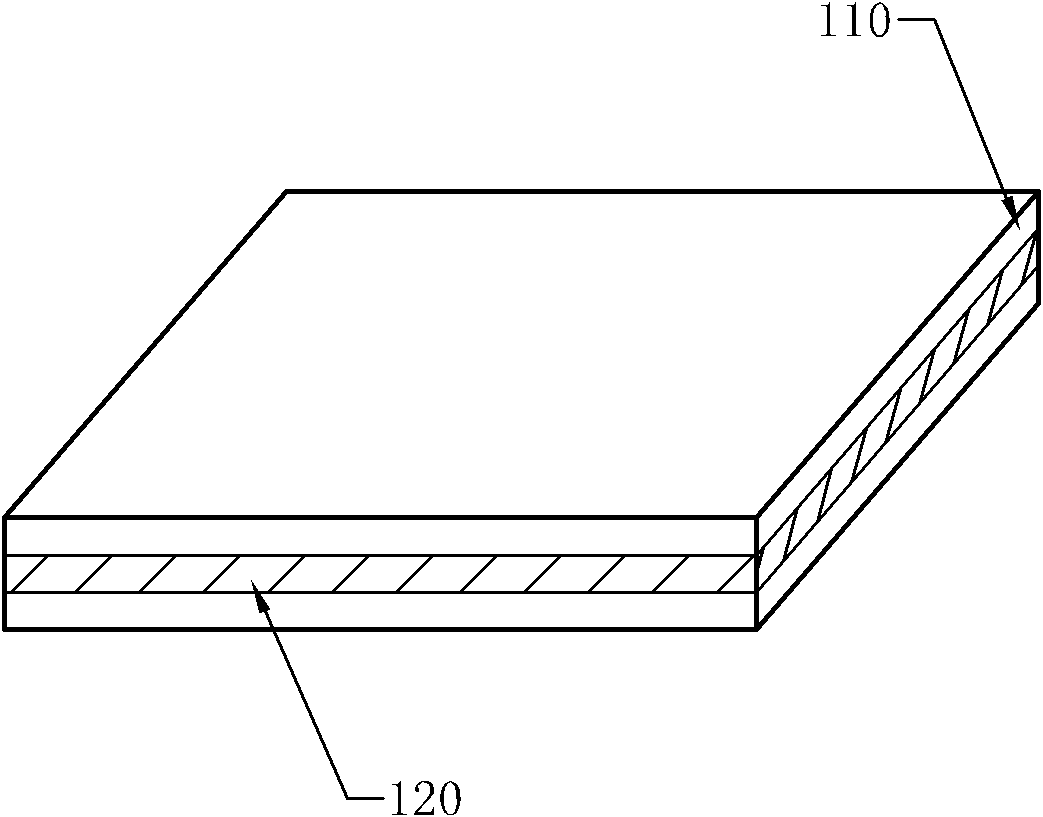

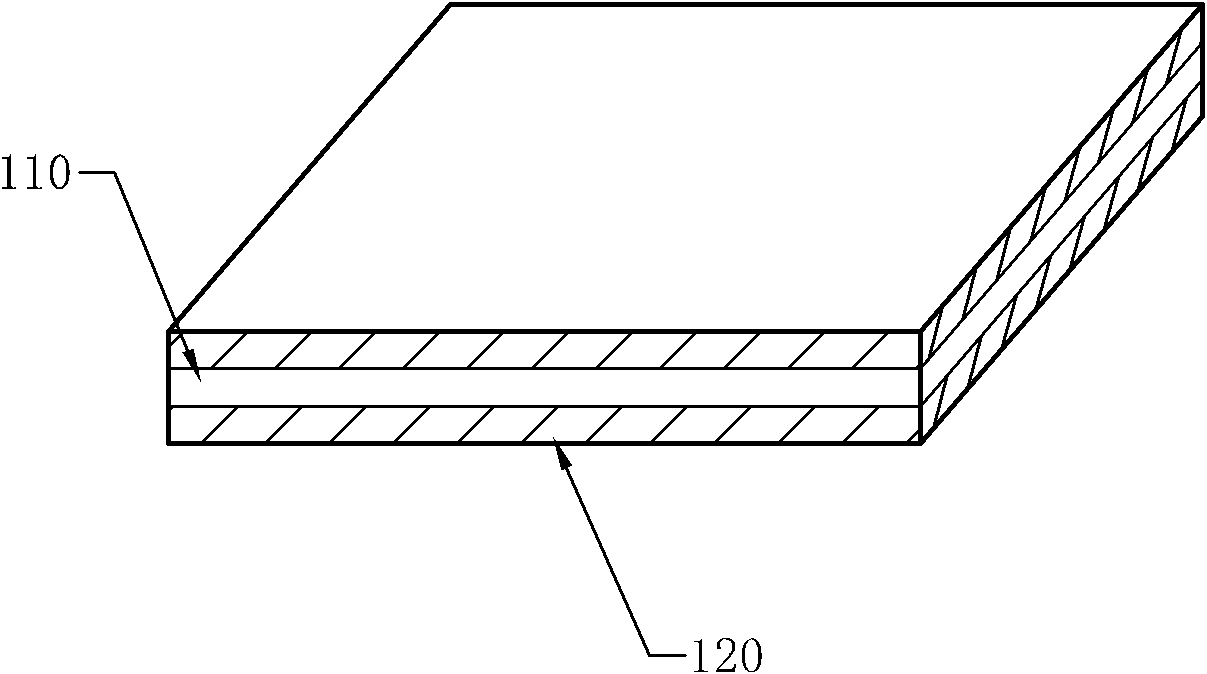

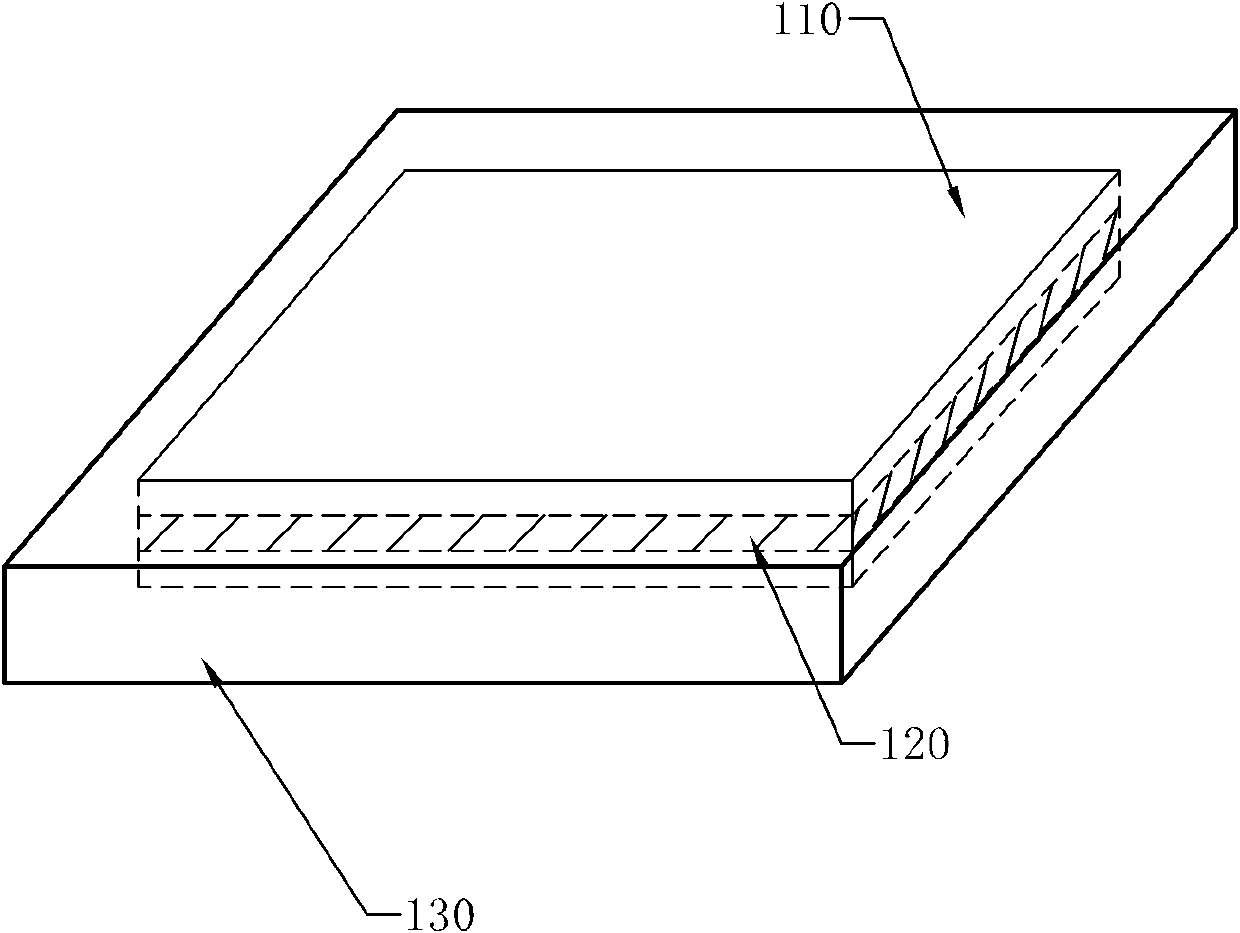

[0033] Picture 1-1 and Figure 1-2 They are structural schematic diagrams of two different lamination forms of the high heat dissipation film-type metal composite lamination structure. A high heat dissipation film metal composite material according to the present invention includes a metal body layer and a high heat dissipation film layer overlapping with it, wherein the metal body layer and the high heat dissipation film layer comprise at least three layers.

[0034] like Picture 1-1 As shown, the laminated structure metal body layer and the high heat dissipation film layer include three layers in total. And with the metal body layer 110 as the base, the high heat dissipation film layer 120 is located between the two metal body layers 100 .

[0035] Correspondingly, in practical applications, the metal body layer 110 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com