High-heat-conductivity anisotropic polymer-based composite material and preparation method thereof

A composite material and anisotropic technology, applied in the field of thermally conductive composite material preparation, can solve the problems of high thermal resistance between fillers, low efficiency in increasing thermal conductivity, etc., and achieve the effects of simple preparation process, economical cost, and broad thermal conductivity application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

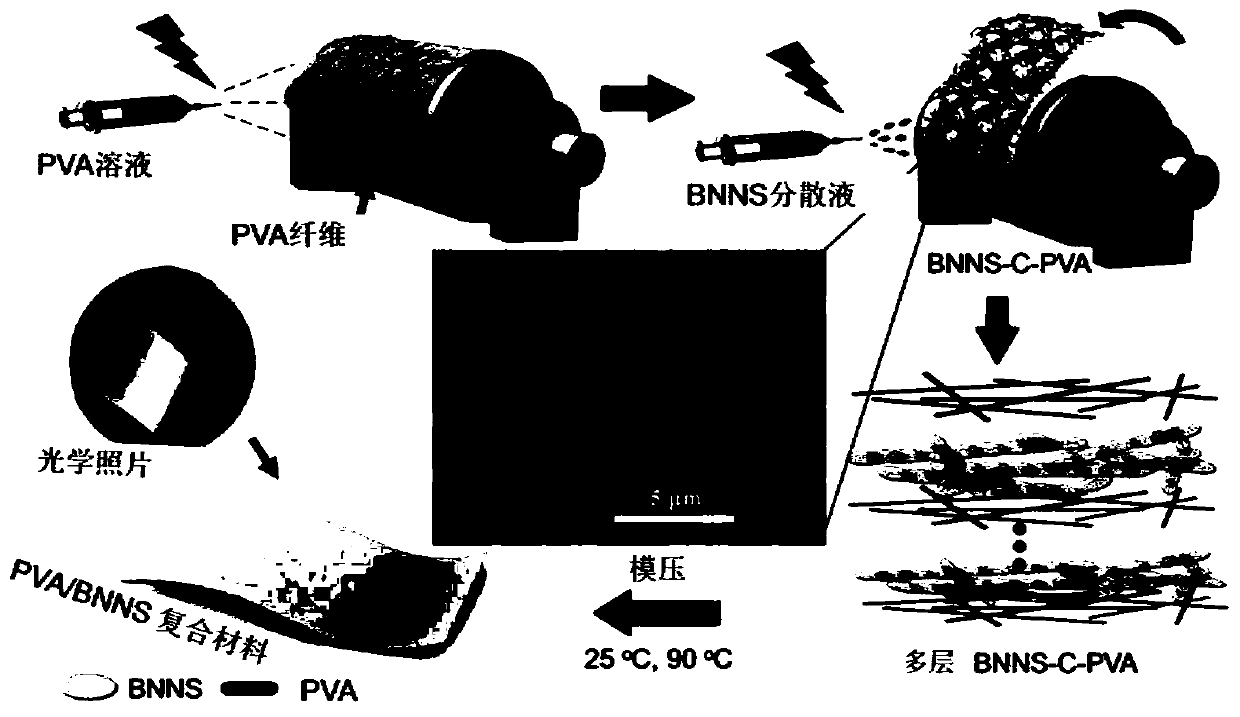

[0038] This embodiment relates to a composite fiber and a method for preparing a composite material. The composite fiber is composed of boron nitride nanosheets covered with PVA nanofibers. The composite material is made by laminating composite fibers and hot pressing. The preparation process of composite materials such as figure 1 shown, prepared by the following steps:

[0039]A. Liquid phase exfoliation of hexagonal boron nitride (h-BN): According to the method of liquid phase ultrasonic exfoliation and centrifugal classification reported in the literature (Chen, et al., Adv. Funct. Mater. 2017, 27, 1604754.) Preparation of boron nitride nanosheets (BNNS);

[0040] B. Electrospinning of PVA: A certain amount of PVA white particle powder was dissolved in deionized water at a concentration of 18 wt%, and stirred in a beaker for 1 hour at ambient temperature. Then the stirred solution was left to stand for 0.5 h, and then transferred to a vacuum oven at room temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com