Waterproof rain cloth and preparation method thereof

A technology of waterproof rain cloth and waterproof layer, which is applied in chemical instruments and methods, epoxy resin glue, adhesive types, etc. , to avoid the breeding of bacteria and bad smell, to avoid the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

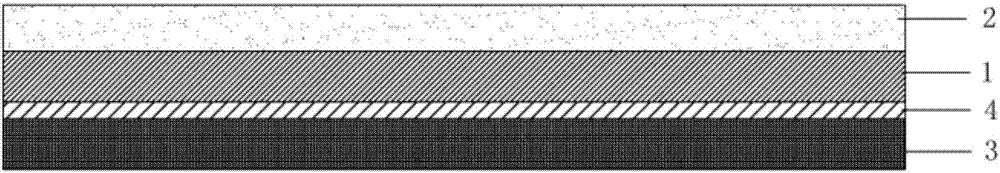

[0028] Such as figure 1 Shown, a kind of waterproof rain cloth and preparation method of the preferred embodiment of the present invention;

[0029] The waterproof rain cloth includes a base layer 1, the base layer 1 is a non-woven fabric layer, and also includes a waterproof coating 2 arranged on the upper surface of the base layer 1, and an elastic waterproof layer 3 arranged on the lower surface of the base layer 1, The elastic waterproof layer 3 is connected to the base layer 1 through an adhesive layer 4 . Wherein, the waterproof coating 2 is a graphene-modified polyurethane coating, the elastic waterproof layer 3 is a titanium dioxide / natural rubber nanocomposite material layer, and the bonding layer 4 is a graphene-modified epoxy resin binder layer.

[0030] The preparation method of waterproof rain cloth of the present invention comprises the steps:

[0031] (1) Preparation of graphene-modified polyurethane coating: disperse graphene oxide in the water phase, and th...

Embodiment 2

[0040] A kind of waterproof rain cloth and preparation method of the preferred embodiment of the present invention;

[0041] The waterproof rain cloth includes a base layer, which is a non-woven fabric layer, and also includes a waterproof coating arranged on the upper surface of the base layer, and an elastic waterproof layer arranged on the lower surface of the base layer, and the elastic waterproof layer and The base layers are connected by a bonding layer. Wherein, the waterproof coating is a graphene-modified polyurethane coating, the elastic waterproof layer is a titanium dioxide / natural rubber nanocomposite material layer, and the adhesive layer is a graphene-modified epoxy resin adhesive layer.

[0042] The preparation method of waterproof rain cloth of the present invention comprises the steps:

[0043](1) Preparation of graphene-modified polyurethane coating: disperse graphene oxide in the water phase, and then carry out emulsification reaction with polyurethane pre...

Embodiment 3

[0052] A kind of waterproof rain cloth and preparation method of the preferred embodiment of the present invention;

[0053] The waterproof rain cloth includes a base layer, which is a non-woven fabric layer, and also includes a waterproof coating arranged on the upper surface of the base layer, and an elastic waterproof layer arranged on the lower surface of the base layer, and the elastic waterproof layer and The base layers are connected by a bonding layer. Wherein, the waterproof coating is a graphene-modified polyurethane coating, the elastic waterproof layer is a titanium dioxide / natural rubber nanocomposite material layer, and the adhesive layer is a graphene-modified epoxy resin adhesive layer.

[0054] The preparation method of waterproof rain cloth of the present invention comprises the steps:

[0055] (1) Preparation of graphene-modified polyurethane coating: disperse graphene oxide in the water phase, and then carry out emulsification reaction with polyurethane pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com