Direct current brushless motor provided with brake and used for clutch

A brushless DC and clutch technology, applied in the field of electric motors, can solve the problems of inability to lock the mechanism, rebound, affecting the positioning accuracy of the controller, etc., and achieve the effects of improving production efficiency, improving waterproof, and ensuring the applicable environment and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

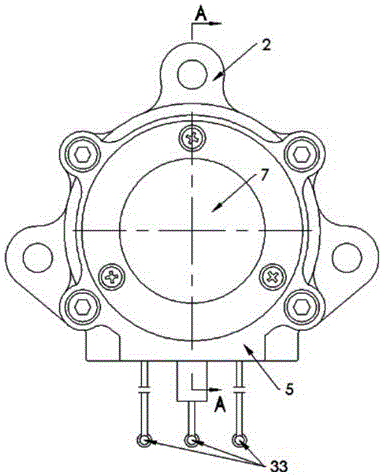

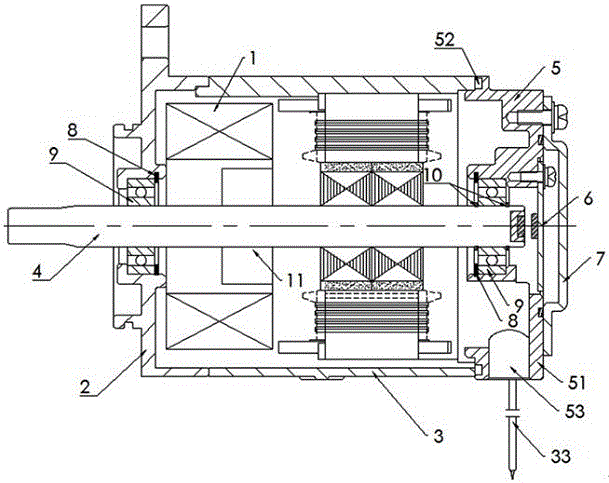

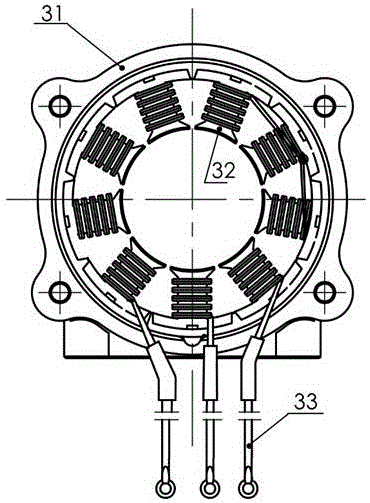

[0018] Depend on figure 1 , figure 2 It is known that a DC brushless motor for a clutch with a brake is composed of an electromagnetic brake 1, a front end cover assembly 2, a stator assembly 3, a rotor assembly 4, an end cover assembly 5, a sensor assembly 6 and a sensor protection cover 7 Composition; the left end of the stator assembly 3 is fixed with a front end cover assembly 2, the right end of the stator assembly 3 is fixed with an end cover assembly 5, the sensor assembly 6 is installed on the end cover assembly 5, and the sensor protection cover 7 is fixed on the end cover assembly 5 to cover the sensor assembly 6; the front end cover assembly 2 and the end cover assembly 5 are respectively fixed with a bearing 9 through a snap spring 8; the left end of the rotor assembly 4 It is connected with the bearing 9 on the front end cover assembly 2, and its right end is connected with the bearing 9 on the end cover assembly 5, and is limited by the circlip II10 provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com