Manufacturing method and manufacturing device for coil component

A coil component and manufacturing device technology, applied in coil manufacturing, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problems of roller core terminal adhesion, resin overflow, sealing, etc., to achieve Effect of reducing characteristic variation and improving characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

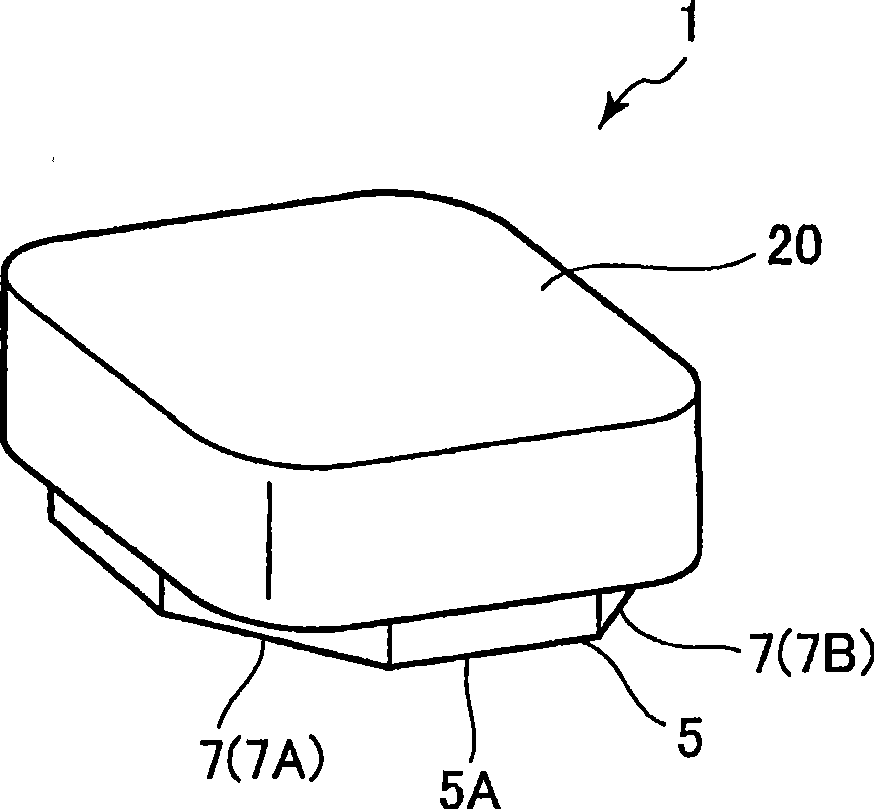

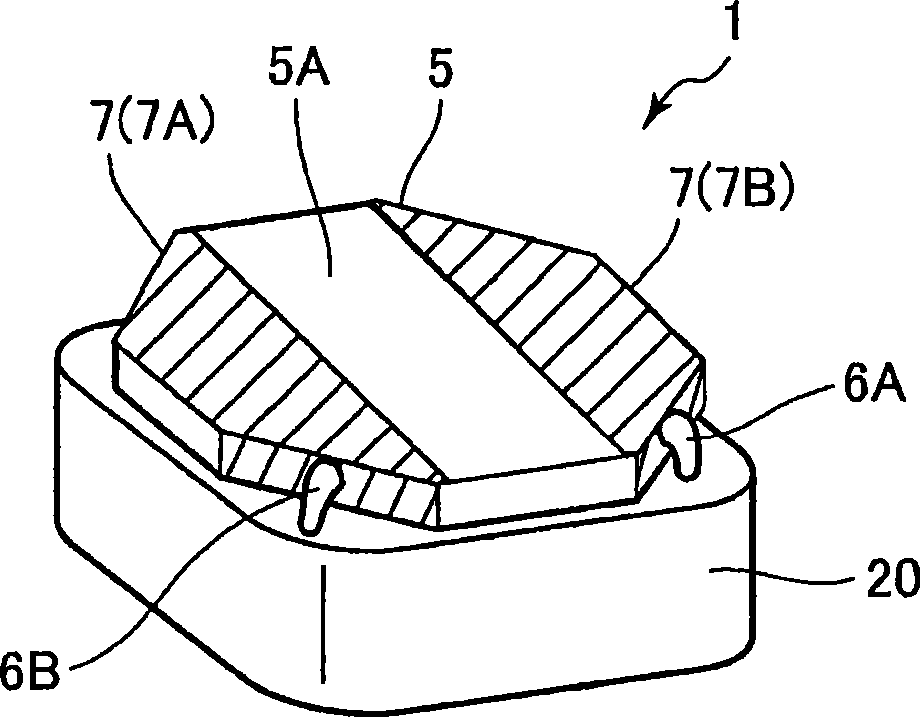

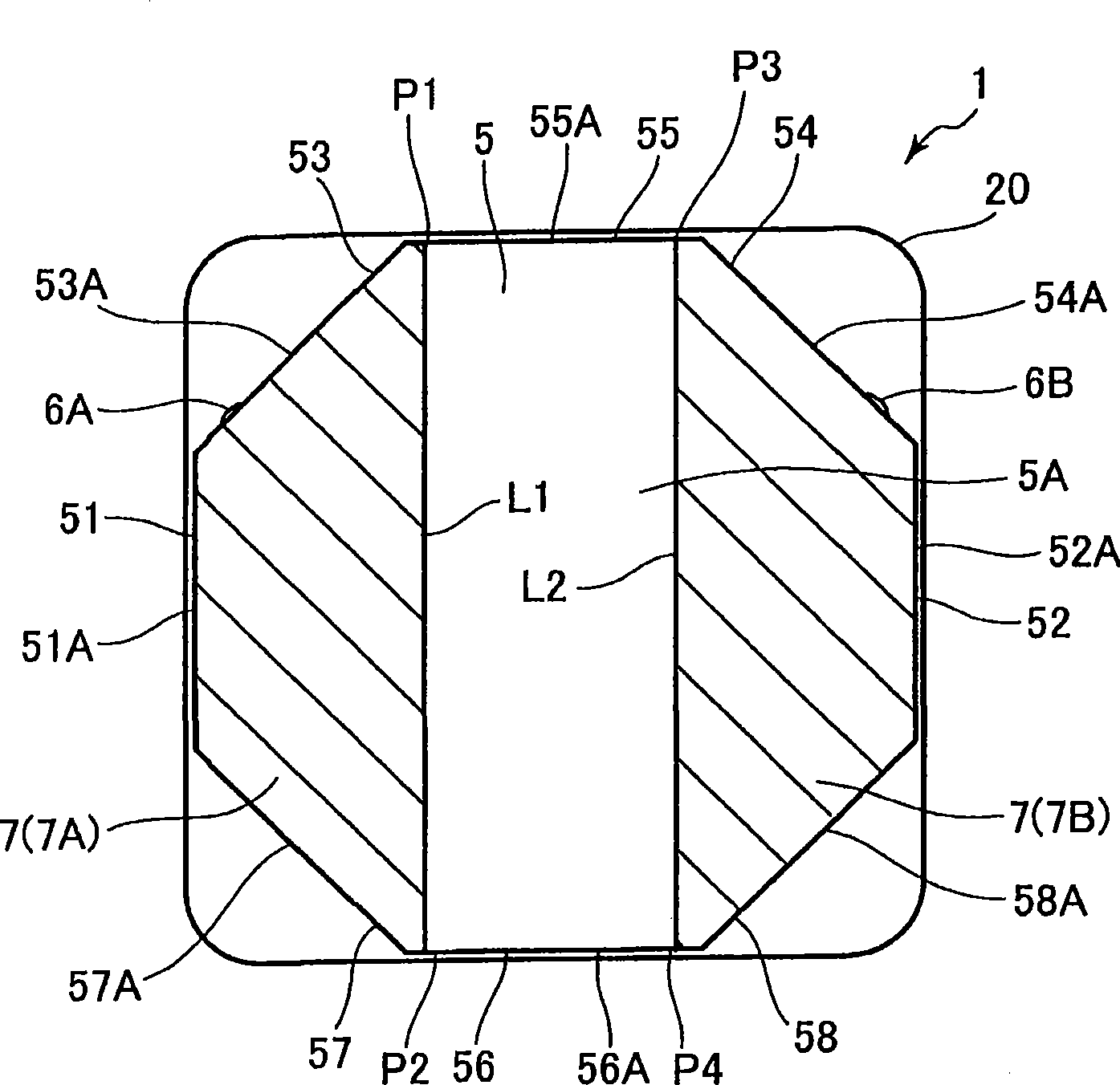

[0060] Refer below figure 1 — Figure 8 A coil component according to an embodiment of the present invention, its manufacturing method, and its manufacturing apparatus will be described. First, the coil component will be described. Coil part 1, specifically, is a kind of power system coil part, such as Figure 4 As shown, it is mainly composed of a core 2 , a winding 6 , a terminal electrode portion 7 and a resin portion 20 . The portion of the coil component 1 other than the resin portion 20 corresponds to a coil portion.

[0061] The core 2 is composed of a substantially cylindrical winding core portion 3 ( Figure 7 etc.) and a pair of first flange portion 5 and second flange portion 4 provided on both ends of the winding core portion 3. Since the first flange portion 5 and the second flange portion 4 are symmetrical in shape, unless otherwise mentioned, only the first flange portion 5 will be described, and the description of the second flange portion 4 will be omitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com