Method for producing rare-earth magnet

A manufacturing method and rare earth technology, which are applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of inability to obtain rare earth magnets, and achieve the effect of improving coercivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] 1. Fabrication of quenching zone

[0079] With the atomic number ratio of Nd, Fe, Co, B, and Ga at the ratio of 14:76:4:5.5:0.5, weigh the specified amount of Nd, Fe, Co, B, and Ga, and use an arc melting furnace to make an alloy cast piece. Next, the alloy ingot was melted at high frequency in a single-roll furnace, and the copper roll was sprayed under the following single-roll furnace operating conditions to form a quenched strip.

[0080] Conditions of use of single roller furnace

[0081] Injection pressure 0.4kg / cm 3

[0082] Roll speed 2000rpm~3000rpm

[0083] Melting temperature 1450℃

[0084] Based on magnetic separation, Nd containing amorphous 14 Fe 76 co 4 B 5.5 Ga 0.5 Composed of quenching zone.

[0085] The obtained nanoparticle structure band was partially sampled, and the magnetic properties were measured by VSM, and it was confirmed that it was hard magnetic. In addition, the crystal particle diameter of the nano particle organization band i...

Embodiment 2

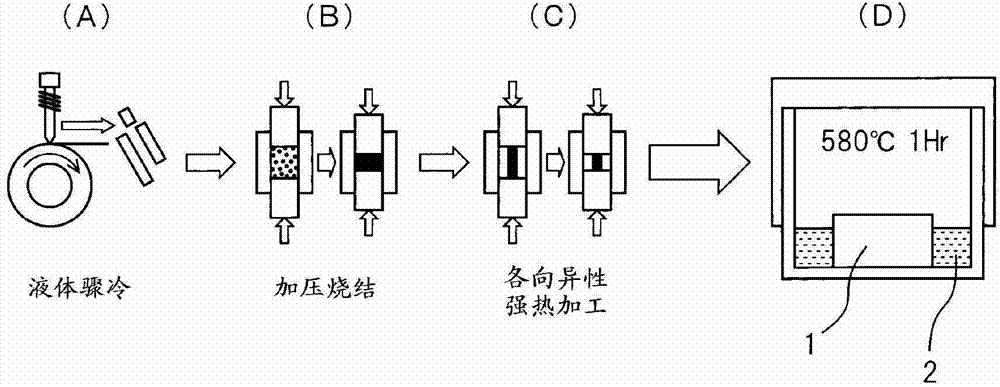

[0096] In addition to using sintered bodies, and using figure 2 The pressing device shown in (C) was subjected to intense heat processing under the following conditions, and anisotropy was performed in the same manner as in Example 1 to obtain a molded body, and the same as in Example 1 was performed except for using this molded body The contact treatment was performed for 1 hour in a NdCu liquid phase at 580°C.

[0097] Strong heat processing conditions

[0098] 20% compression processing at a deformation rate of 1.0 / s at 650-750°C (plastic processing rate: 20%)

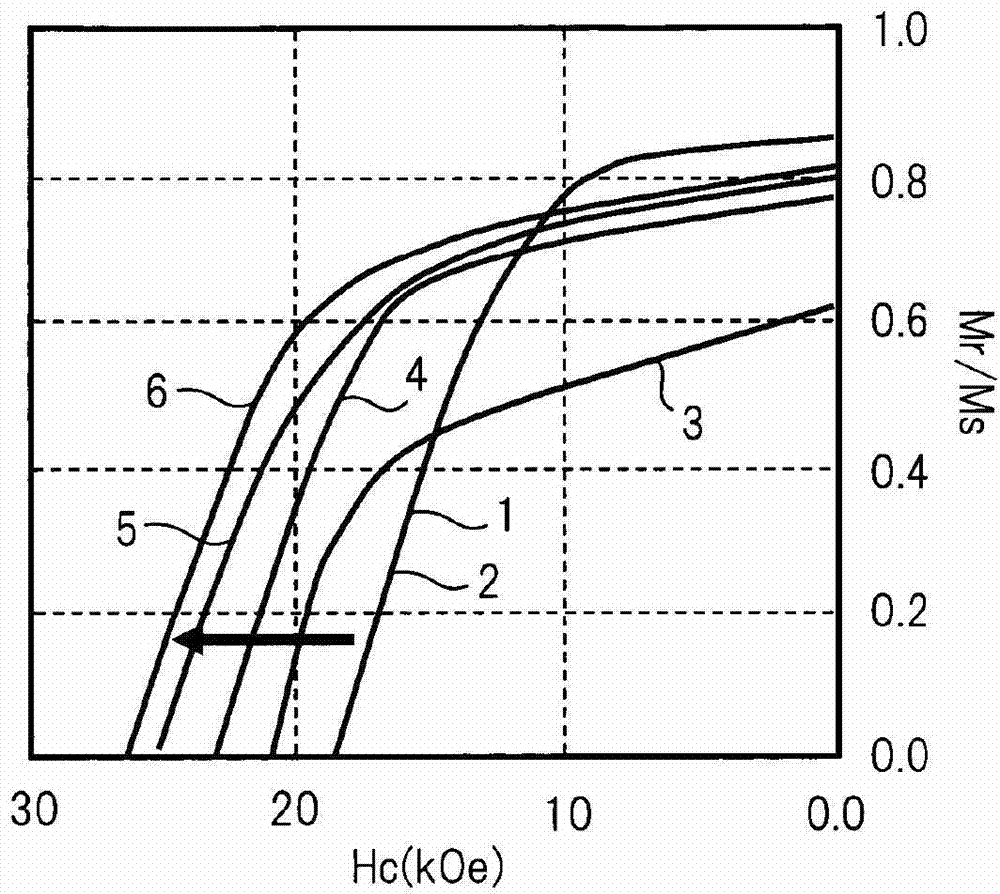

[0099] The results of the demagnetization curves measured for the obtained rare earth magnets are shown together with other results in figure 1 middle.

Embodiment 3

[0101] Except for using a sintered body and performing intense heat processing under the following conditions, anisotropy was performed in the same manner as in Example 1 to obtain a molded body. The contact treatment was performed for 1 hour in the NdCu liquid phase.

[0102] Strong heat processing conditions

[0103] 40% compression processing at a deformation rate of 1.0 / s at 650-750°C (plastic processing rate: 40%)

[0104] The results of the demagnetization curves measured for the obtained rare earth magnets are shown together with other results in figure 1 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com