Hydraulic system of construction machine

A hydraulic system and construction machinery technology, applied in the field of hydraulic systems, can solve problems such as the decrease in engine speed, achieve the effects of preventing hydraulic shock, improving fuel efficiency, and preventing a sharp drop in engine speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Advantages and features of the present invention and methods for achieving them will be clarified with reference to the accompanying drawings and the following embodiments described in detail.

[0071] Throughout the specification, the same reference numerals refer to the same constituent elements, and the same constituent elements as those in the prior art are given the same numerals and repeated explanation thereof will be omitted.

[0072] On the other hand, the following terms are set in consideration of the functions in the present invention, and may vary depending on the manufacturer's intention or customary practice. Therefore, these terms should be defined based on the entire contents of this specification. definition.

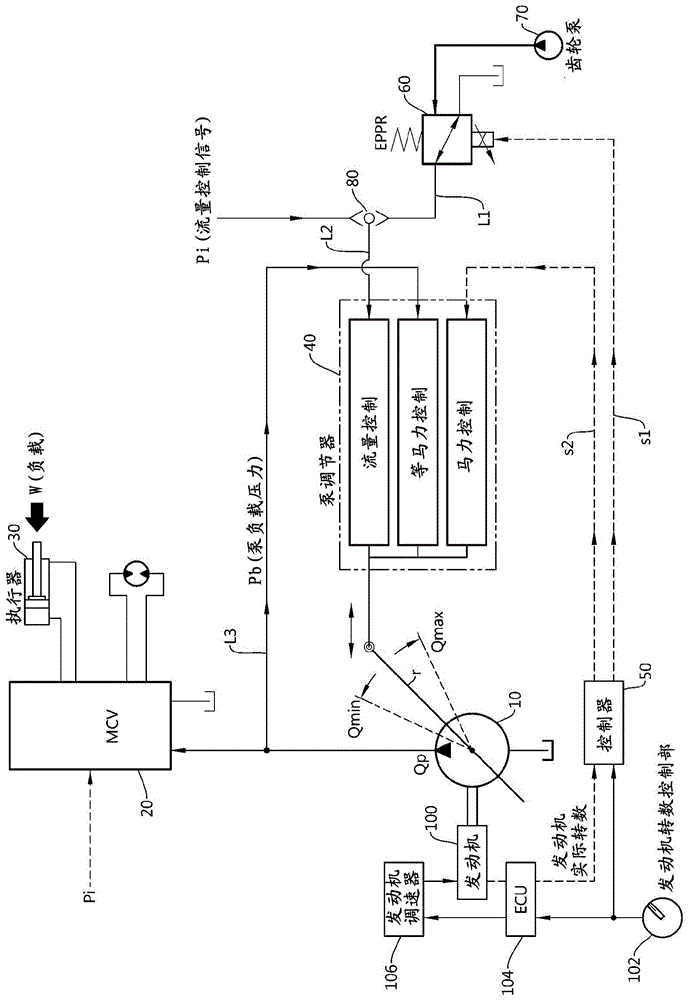

[0073] Refer below Figure 5 , the hydraulic system of the construction machine according to one embodiment of the present invention will be described.

[0074] Attached picture Figure 5 It is a figure for explaining the hydraulic system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com