Hoist hydraulic control system and crane

A hydraulic control system and oil pressure control technology, which is applied in the hoist hydraulic control system and crane field, can solve problems such as insufficient construction, hydraulic shock, and endangering hoisting safety, so as to improve stability, prevent hydraulic shock, and improve the use of hoisting The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

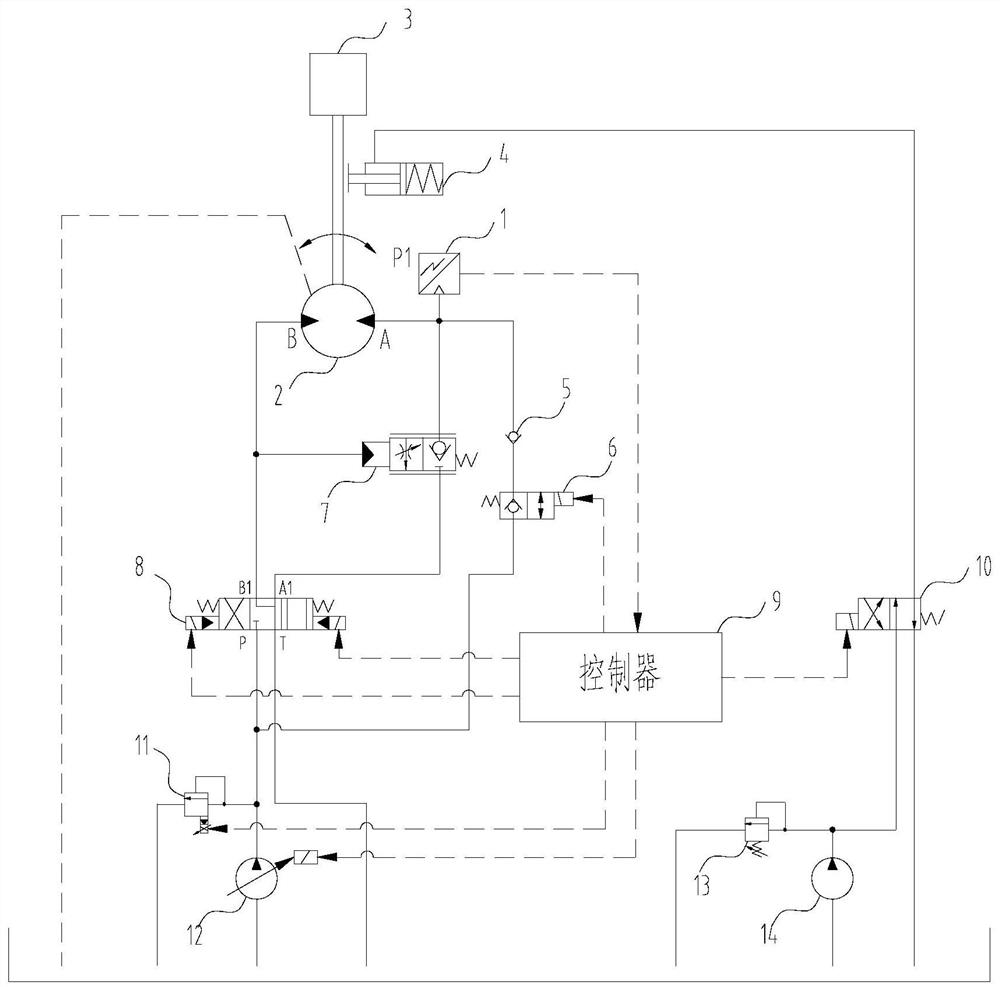

[0047] This embodiment provides a winch hydraulic control system, please refer to figure 1 , this winch hydraulic control system includes:

[0048] The winch hydraulic motor 2 is provided with a first oil port for controlling lifting and a second oil port for controlling lowering;

[0049] The brake 4, the brake 4 can selectively abut against the output shaft of the winch hydraulic motor 2, so as to control the brake of the winch hydraulic motor 2;

[0050] The main oil pump 12, the main oil pump 12 is connected with the hoist hydraulic motor 2, so as to supply oil to the hoist hydraulic motor 2;

[0051] The first reversing valve 8, the first reversing valve 8 is arranged between the hoist hydraulic motor 2 and the main oil pump 12, the first reversing valve 8 is used to control the communication between the main oil pump 12 and the first oil port or the second oil port ;

[0052] A balance valve 7, the balance valve 7 is arranged between the first oil port and the second ...

Embodiment 2

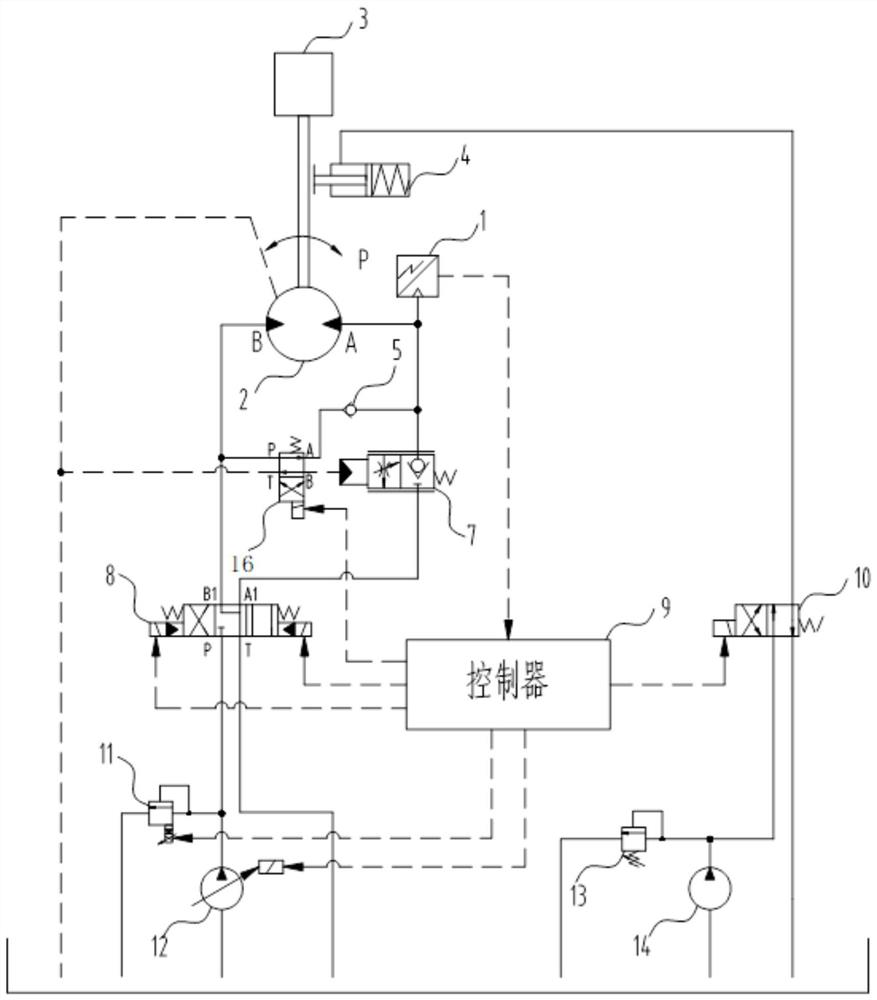

[0075] This embodiment provides a winch hydraulic control system, please refer to figure 2 , this winch hydraulic control system includes:

[0076] The winch hydraulic motor 2 is provided with a first oil port for controlling lifting and a second oil port for controlling lowering;

[0077] The brake 4, the brake 4 can selectively abut against the output shaft of the winch hydraulic motor 2, so as to control the brake of the winch hydraulic motor 2;

[0078] The main oil pump 12, the main oil pump 12 is connected with the hoist hydraulic motor 2, so as to supply oil to the hoist hydraulic motor 2;

[0079] The first reversing valve 8, the first reversing valve 8 is arranged between the hoist hydraulic motor 2 and the main oil pump 12, the first reversing valve 8 is used to control the communication between the main oil pump 12 and the first oil port or the second oil port ;

[0080] A balance valve 7, the balance valve 7 is arranged between the first oil port and the second...

Embodiment 3

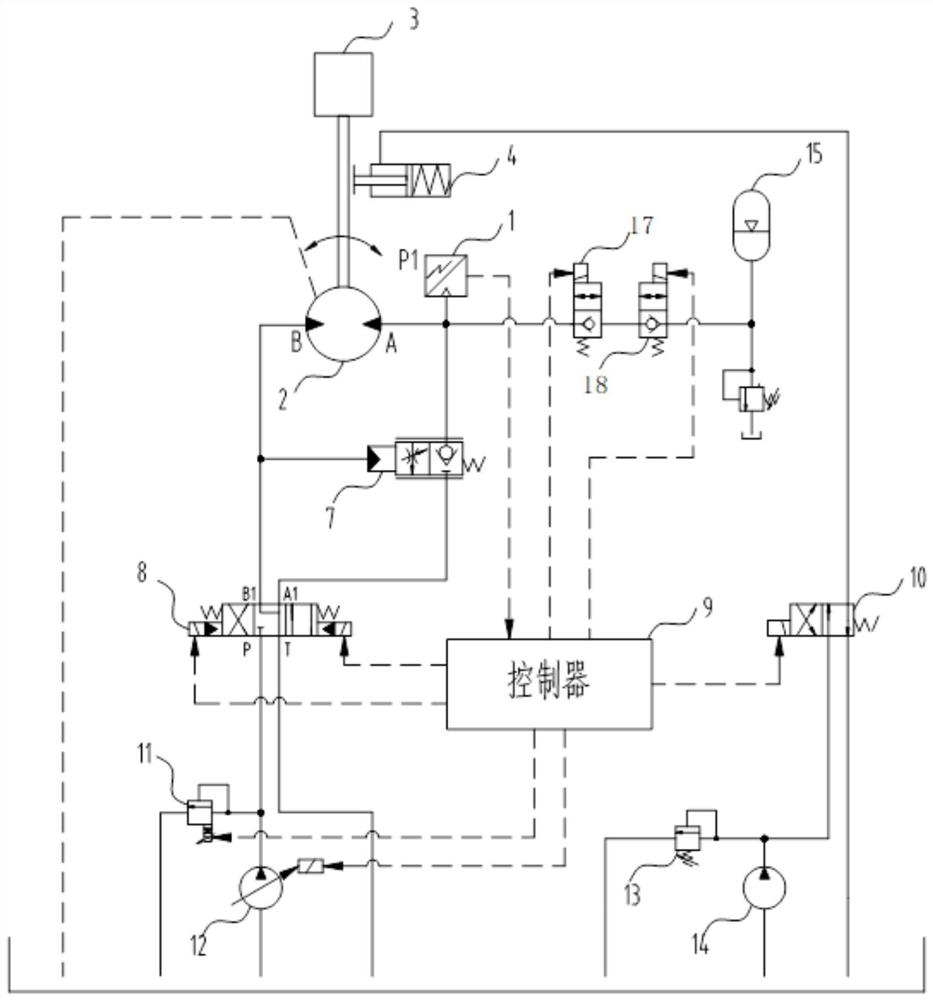

[0105] This embodiment provides a winch hydraulic control system, please refer to image 3 , this winch hydraulic control system includes:

[0106] The winch hydraulic motor 2 is provided with a first oil port for controlling lifting and a second oil port for controlling lowering;

[0107] The brake 4, the brake 4 can selectively abut against the output shaft of the winch hydraulic motor 2, so as to control the brake of the winch hydraulic motor 2;

[0108] The main oil pump 12, the main oil pump 12 is connected with the hoist hydraulic motor 2, so as to supply oil to the hoist hydraulic motor 2;

[0109] The first reversing valve 8, the first reversing valve 8 is arranged between the hoist hydraulic motor 2 and the main oil pump 12, the first reversing valve 8 is used to control the communication between the main oil pump 12 and the first oil port or the second oil port ;

[0110] A balance valve 7, the balance valve 7 is arranged between the first oil port and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com