A press liquid filling device with self-adaptive multi-stage pressure relief control

A liquid filling device and self-adaptive technology, which is applied in the direction of fluid pressure actuators, mechanical equipment, servo motor components, etc., can solve problems such as increased liquid filling speed, unbalanced pressure distribution, and limited liquid flow rate, etc., to achieve unloading process Stable and fast, uniform pressure distribution in the flow channel, avoiding the effects of movement and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Best practice:

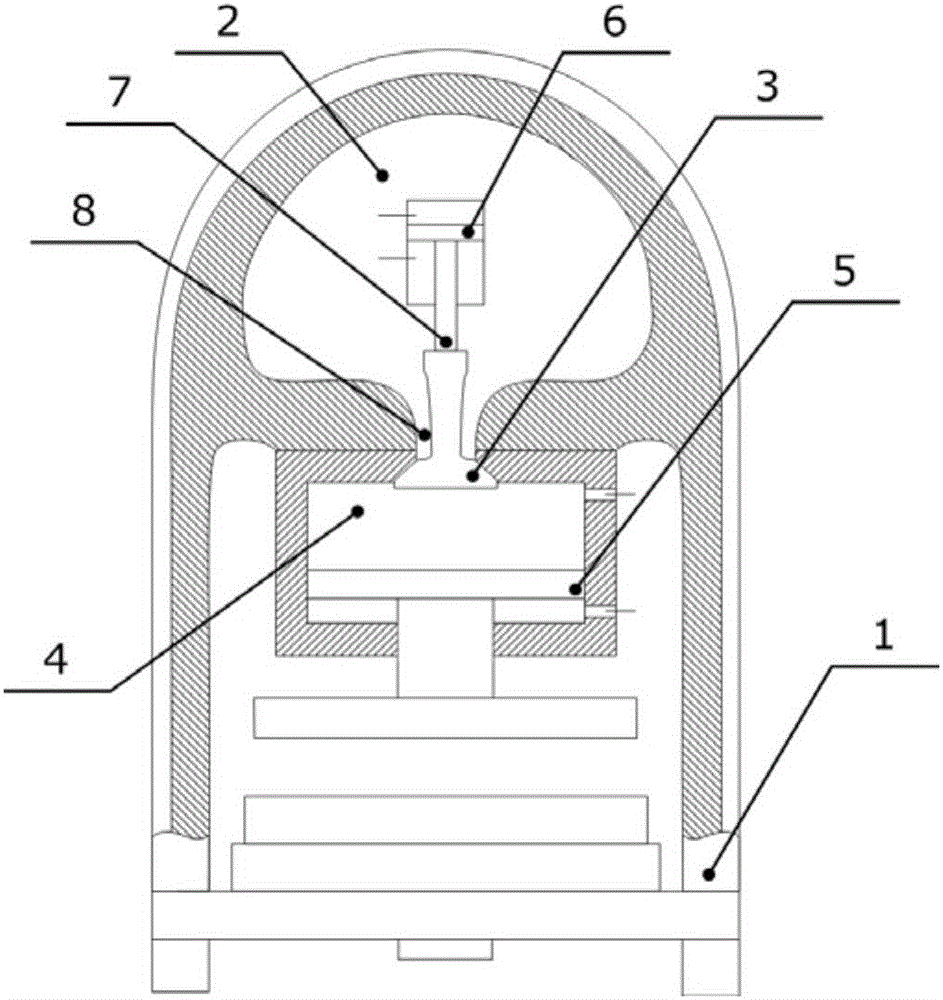

[0040] refer to figure 1 , schematically represents the assembly of an adaptive multi-stage pressure relief control press liquid filling device in a hydraulic press according to the present invention. The liquid filling device 3 arranged between the liquid filling tank 2 and the main cylinder 4 can be used in equipment such as the hydraulic machine 1, and plays an important role in the two main working conditions of the main cylinder 4 filling and returning. During the liquid filling process, by controlling the upper end of the oil cylinder 6 to enter the oil, as the main oil cylinder 4 falls, the liquid in the liquid filling tank 2 quickly enters the main oil cylinder 4 through the opened liquid supply device 3, and pushes the main cylinder piston 5 downward. After the pressing process is completed, the main oil cylinder 4 needs to be returned. In this process, the high pressure in the main oil cylinder 4 needs to be removed first, and then the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com