Lifting control system of loader moving arm and method

A technology of control system and motorized arm, applied in the direction of earth mover/shovel, construction, etc., can solve problems such as nodding impact, and achieve the effect of avoiding hydraulic impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation will be described below in conjunction with the accompanying drawings.

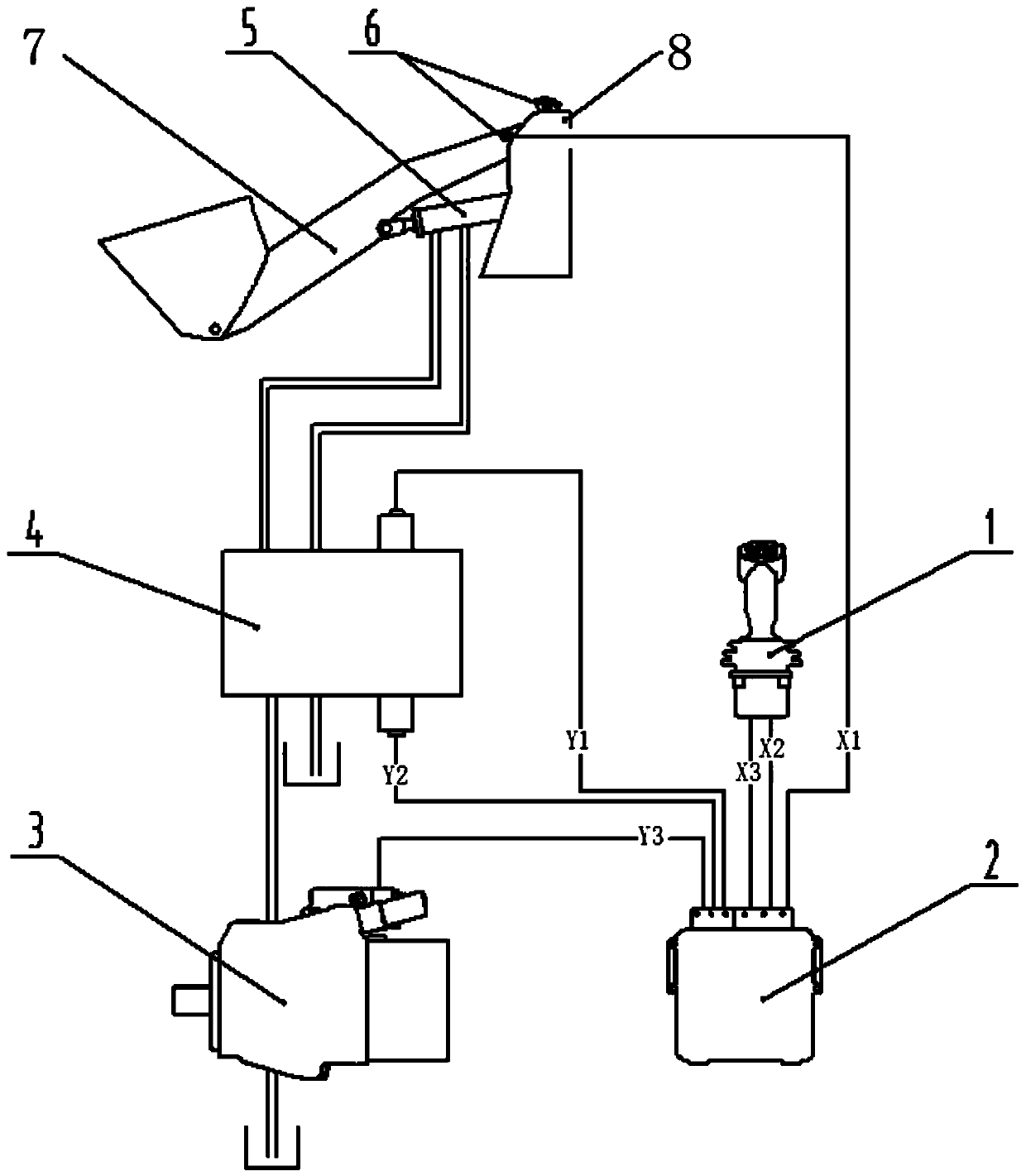

[0022] Such as figure 1 As shown, the arm lifting control system of the loader includes an electromagnetic reversing valve 4 , a boom cylinder 5 , a hydraulic pump 3 , an electric control handle 1 , a controller 2 , and a limit sensing device 6 .

[0023] The limit sensing device 6 is composed of an inductive proximity switch installed on the front frame 8 and an induction target metal fixed on the boom 7 (the induction target metal can also be a certain position on the boom). The inductive proximity switch is connected to the controller 2 through the boom position signal line X1. When the sensing target metal enters the sensing range of the inductive proximity switch, the inductive proximity switch is closed and turned on, and the controller detects that the inductive proximity switch is closed. The position signal associated with on is a limit signal, otherwise it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com