Converter controlled power generator

An inverter-controlled technology, applied in the field of inverter-controlled generators, can solve problems such as difficulty in obtaining output power and reduced operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

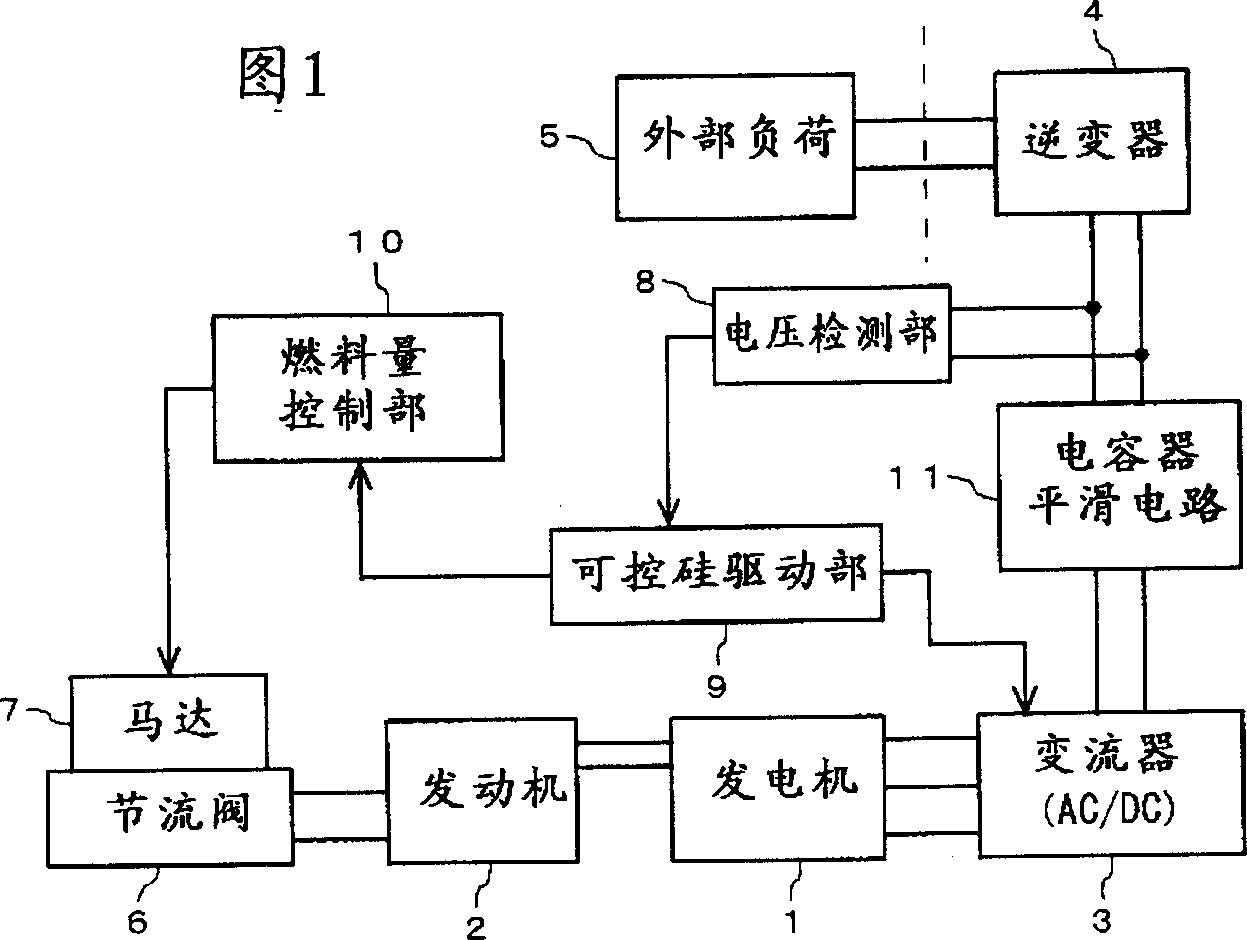

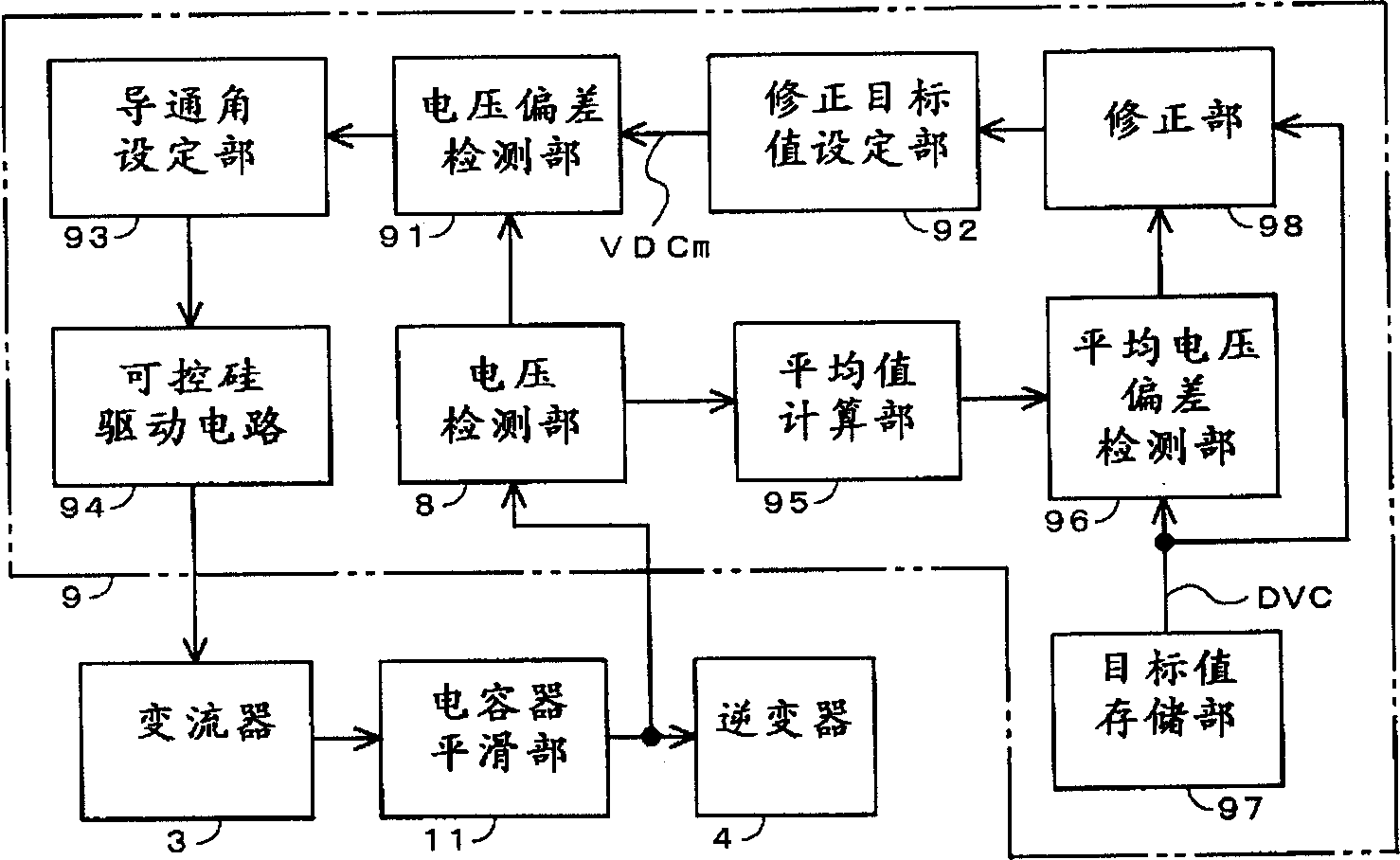

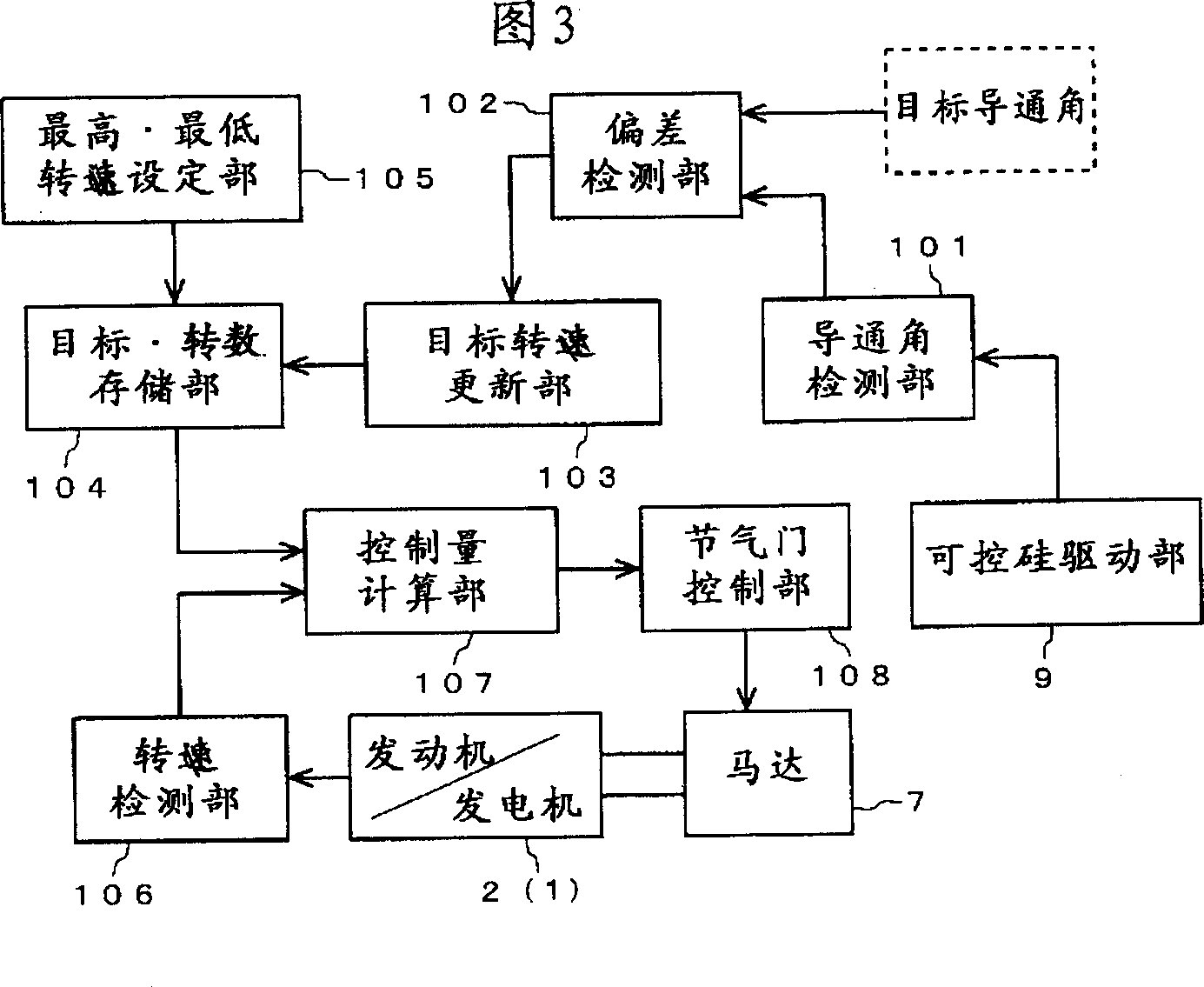

[0021] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. FIG. 1 is a functional block diagram showing an inverter-controlled engine. A permanent magnet multi-pole generator (hereinafter simply referred to as "generator") 1 is driven by an (internal combustion) engine 2 and generates multi-phase (typically 3-phase) alternating current. The generated alternating current is converted into direct current after full-wave rectification by the converter 3. The converter 3 is a rectification circuit formed by combining thyristors (generally semiconductor rectifying elements) as semiconductor rectifying elements into a bridge. constitute. The DC power is smoothed by the capacitor smoothing circuit 11 and input to the inverter 4, and the inverter 4 supplies single-phase AC power of a commercial frequency (for example, 50 Hz) to the external load 5 connected to the output side. In order to adjust the opening degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com