Experimental method for characterizing relaxation characteristics of bolted joint structure

A connection structure and experimental method technology, applied in the testing of machine/structural components, testing of mechanical components, special data processing applications, etc., can solve the problem of bolt connection structure relaxation, complex manufacturing process, and non-universal applicability of relaxation characteristic curves and other problems to achieve the effect of solving hidden safety hazards and solving the high cost of materials in the equipment manufacturing industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

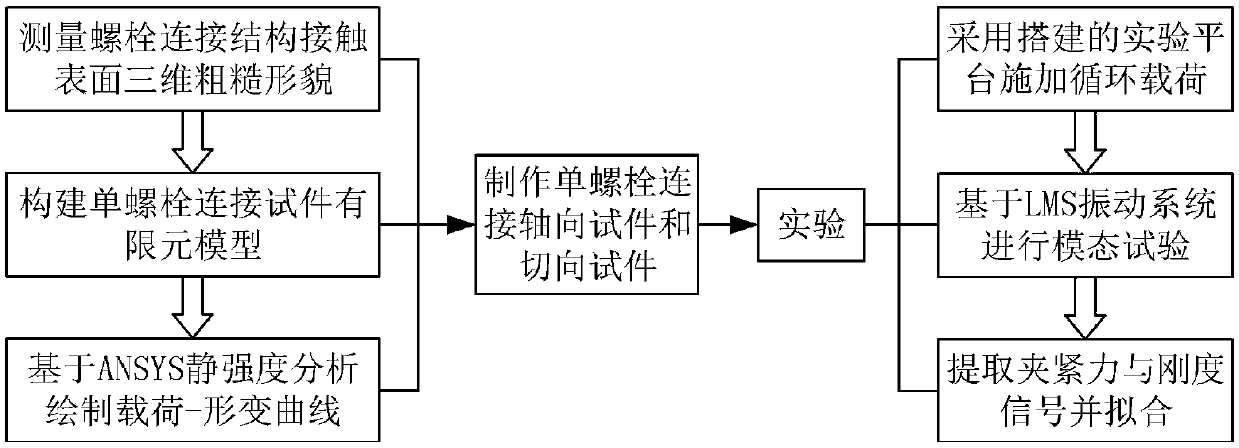

[0023] In order to make designers and maintenance personnel in engineering fields such as machinery / civil engineering more aware of the experimental method proposed by the present invention and its advantages, the present invention will be further described in conjunction with the accompanying drawings in specific embodiments. figure 1 Shown is the overall experimental scheme of the present invention, and the specific implementation steps are described as follows.

[0024] Step 1: Construction of the finite element model of the single-bolt connection specimen;

[0025] A three-dimensional surface topography instrument is used to measure the contact surface in the bolted connection structure to obtain the three-dimensional rough surface topography. figure 2 On the basis of the shown finite element contact model considering the real rough surface topography, the finite element models of the single bolt connection axial specimen and tangential specimen are constructed.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com