Method used for realizing blade fatigue crack detection through static blade displacement detection

A fatigue crack and static displacement technology, applied in the field of blade fatigue crack detection, can solve problems such as the inability to detect the health status of rotor blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

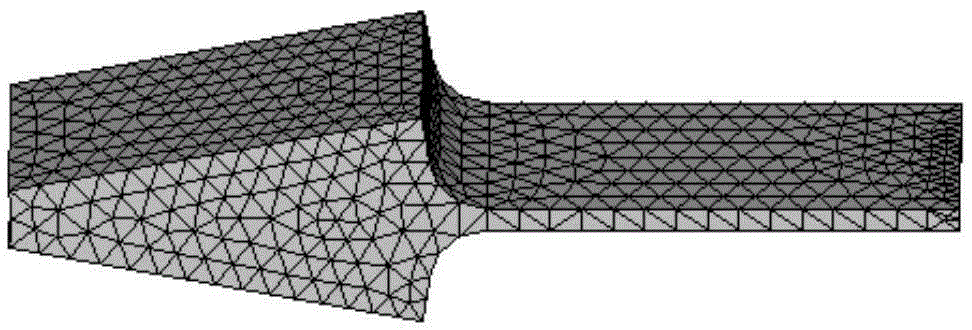

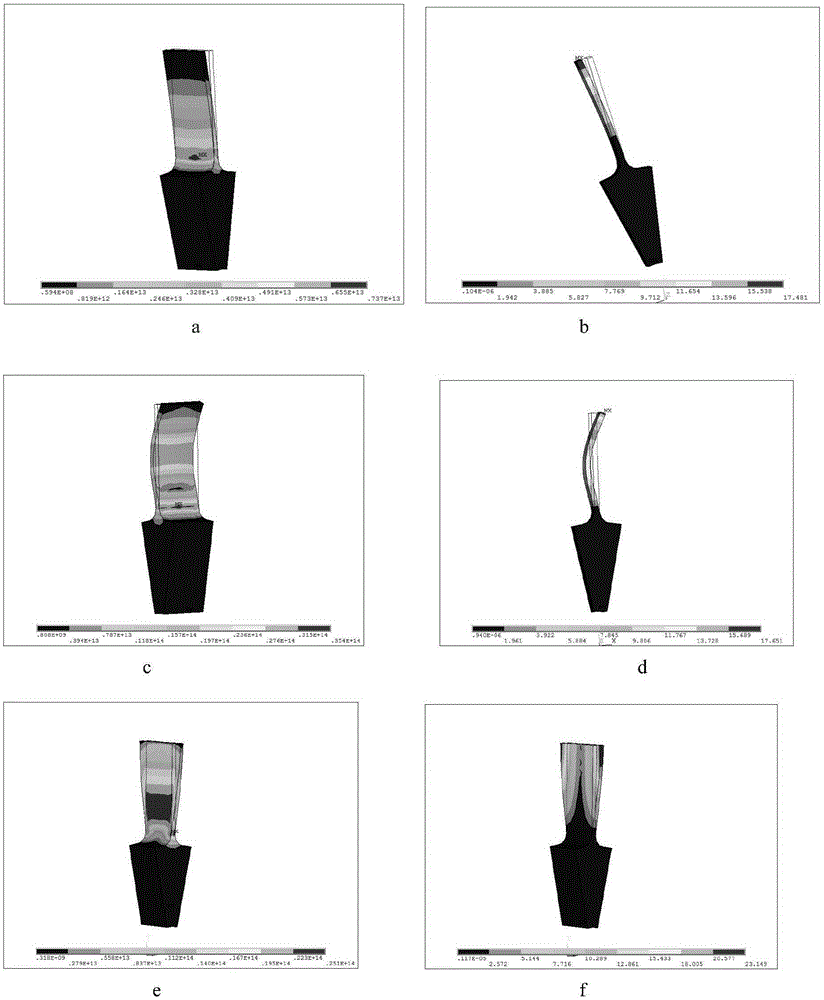

[0033] In terms of on-line detection of blade cracks, there is no mature technology at present, and it is also a current research hotspot. The blade is equivalent to a cantilever beam. When there is a crack, the vibration mode curve will be discontinuous at the crack. If the blade mode curve can be measured, the accurate identification of the blade crack parameters can be realized.

[0034] The invention is a method for detecting fatigue cracked blades by measuring, analyzing and comparing the vibration parameters of rotating blades. Specifically, the online detection of blade fatigue cracks is realized by measuring the blade static displacement of the fatigue cracked blades and comparing the parameters of normal blades.

[0035] The invention aims to find a method to realize the identification of fatigue cracked blades in the early stage of blade cracks, and minimize the impact of blade cracks on the safe operation of rotating machinery.

[0036] The inquiry method that the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com