Fatigue life prediction method for high-modulus asphalt mixture pavement

A technology of fatigue life prediction and asphalt mixture, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not considering the influence and difference of fatigue life, and achieve a wide range of applications and reliable calculation results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

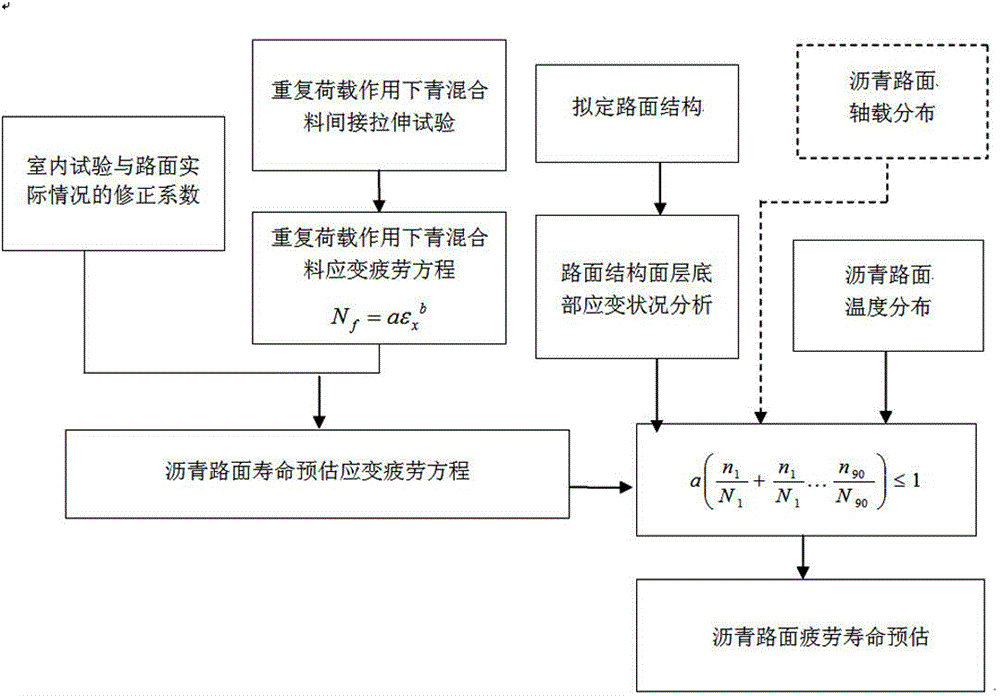

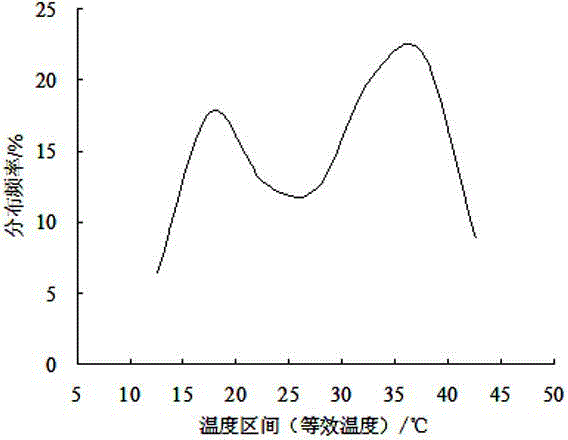

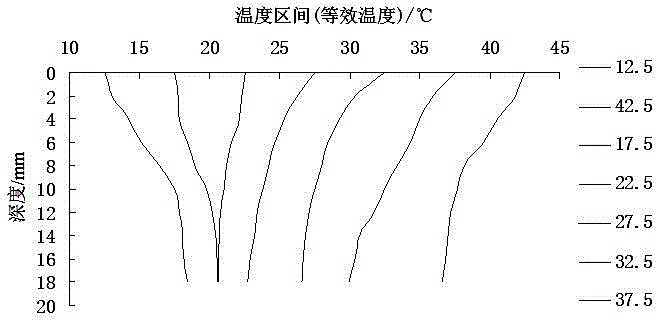

[0036] attached figure 1 It is a schematic diagram of the process of the high modulus asphalt mixture pavement fatigue life prediction method of the present invention, as can be seen from the figure, the high modulus asphalt mixture pavement fatigue life prediction method of the present invention is based on the structural temperature distribution of the high modulus asphalt mixture pavement, the pavement material The dynamic modulus and temperature axial load distribution are the basic parameters; the fatigue strain equation is fitted with the results of the indirect tensile fatigue test In the formula, N f is the number of load actions during fatigue failure, a is a parameter, ε x is the horizontal strain, and b is the parameter; use ANSYS software to construct the finite element model of the pavement structure, and calculate the maximum tensile strain at the bottom of the layer in different axle load levels and different temperature zones; according to Miner’s fatigue cum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com