Method for predicting residual life of storage tank

A storage tank and life-span technology, applied in instruments, calculations, electrical digital data processing, etc., can solve the problems of reducing the effective strength of storage tanks, corrosion defects, and scrapping storage tanks, and achieve reliable technical support and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

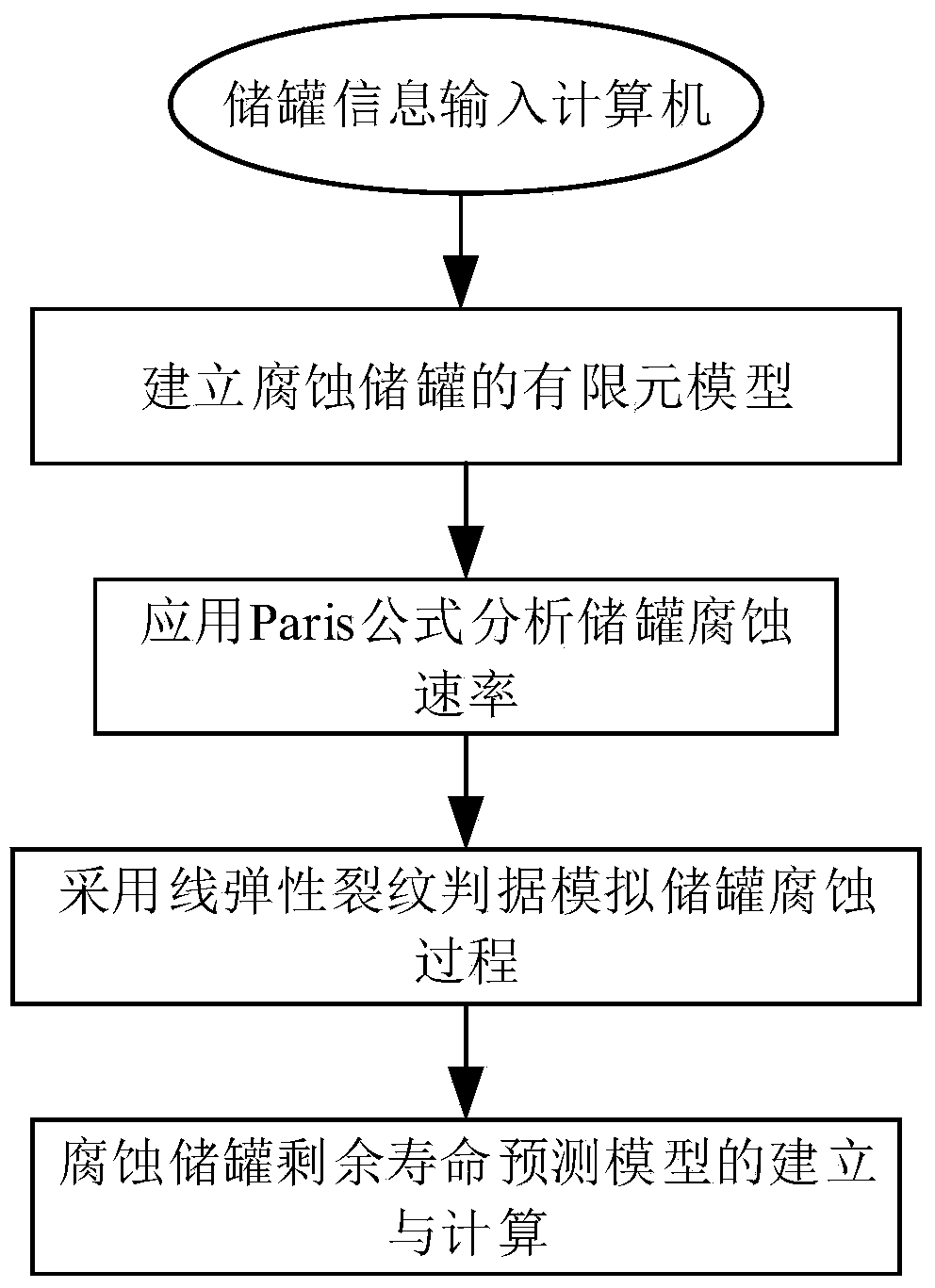

[0017] The present invention will be further described and elaborated below in conjunction with the accompanying drawings.

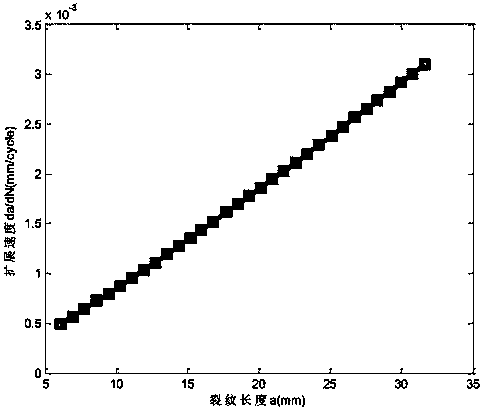

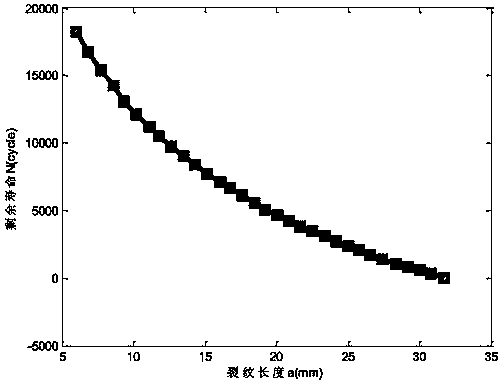

[0018] In the process of predicting the remaining life of a corroded storage tank, a finite element model of the corroded storage tank structure is established, which can truly simulate the stress of the storage tank, and the Paris formula is used to predict the corrosion rate of the storage tank under the action of multiple factors, taking into account the remaining wall thickness Effects of failure on storage tanks, using the linear elastic crack criterion, to obtain critical failure wall thickness to predict remaining life of corroded storage tanks. The application of the invention can provide reliable technical support for oil field field and theoretical research, thereby making due contributions to prolonging the service life of storage tanks.

[0019] The specific steps of the establishment of the prediction model for the remaining life of the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com