Method of predicting residual life of gearbox by utilizing modified gray model

A grey model, life prediction technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve problems such as inability to adapt, difficult to overcome interference factors, affecting the normal operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

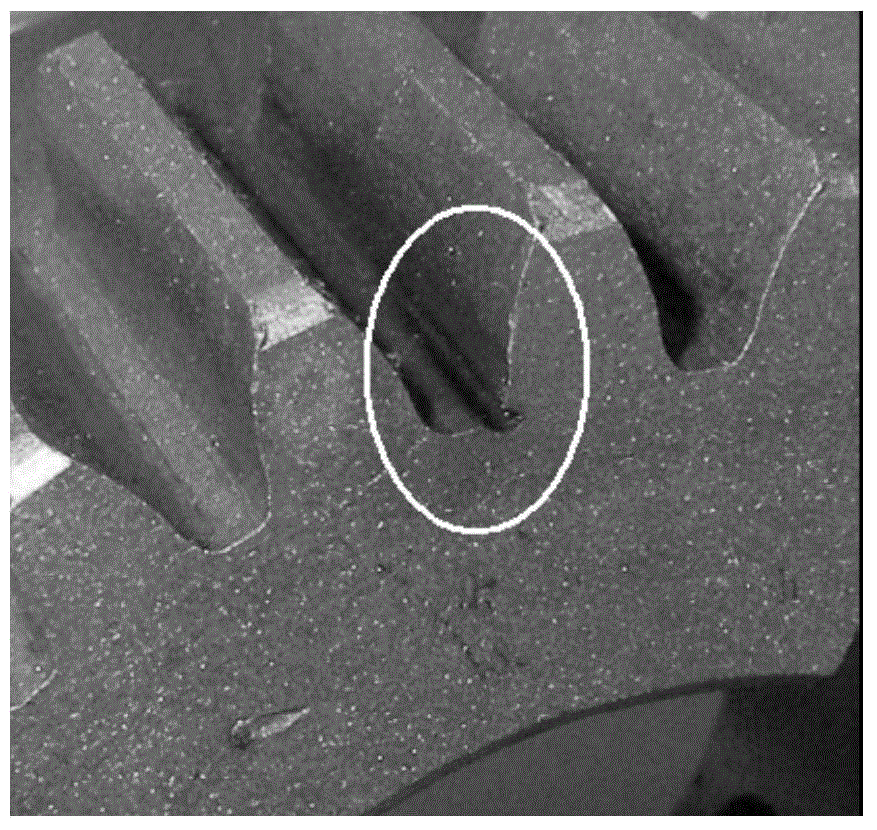

[0046] The method of the invention is suitable for predicting the remaining life of a gearbox. Among them, fatigue crack failure is a common and unpredictable failure mode in gearboxes, which mainly occurs at the tooth root inside the gearbox. If left unchecked, it can lead to serious failure of the gears, which in turn leads to failure of the entire system, resulting in significant economic losses. Therefore, trying to predict the remaining life of the gearbox in the early stage of failure has practical significance for avoiding the secondary failure of the gearbox and ensuring its healthy operation.

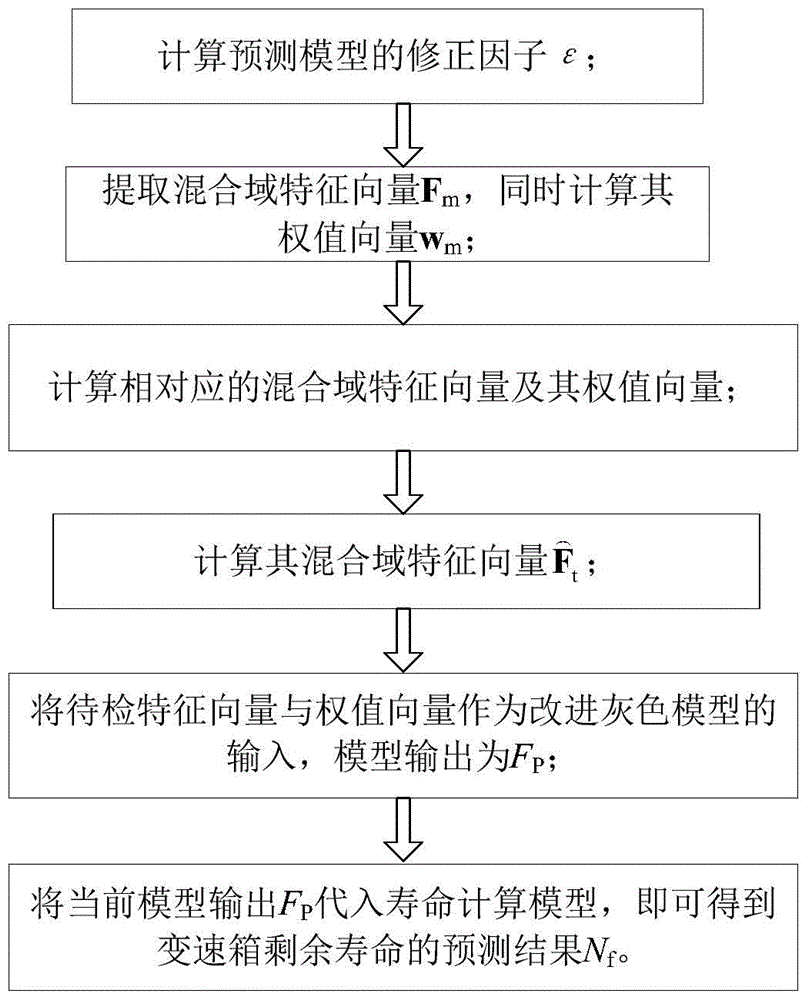

[0047] As shown in Figure 1, the method for utilizing the improved gray model of the present invention to carry out the remaining life prediction of gearbox, its steps are:

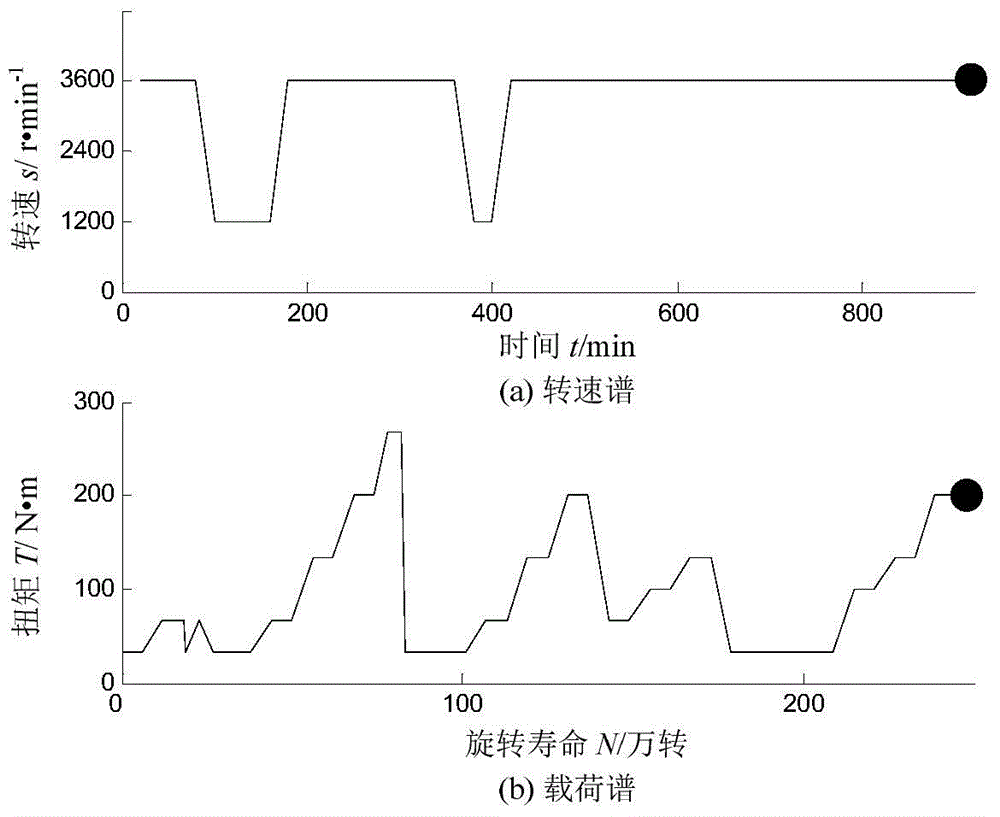

[0048](1) Based on the dynamic information of the damage e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com