Carburizing cylindrical gear parameterized simulation and analysis method and CAE system

A parametric simulation, cylindrical gear technology, applied in design optimization/simulation, geometric CAD, electrical digital data processing, etc., can solve the lack of carburized gear modeling and analysis technology research, can not carburized gear design calculation and structural optimization , Unable to carburize gear strength calculation and performance analysis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

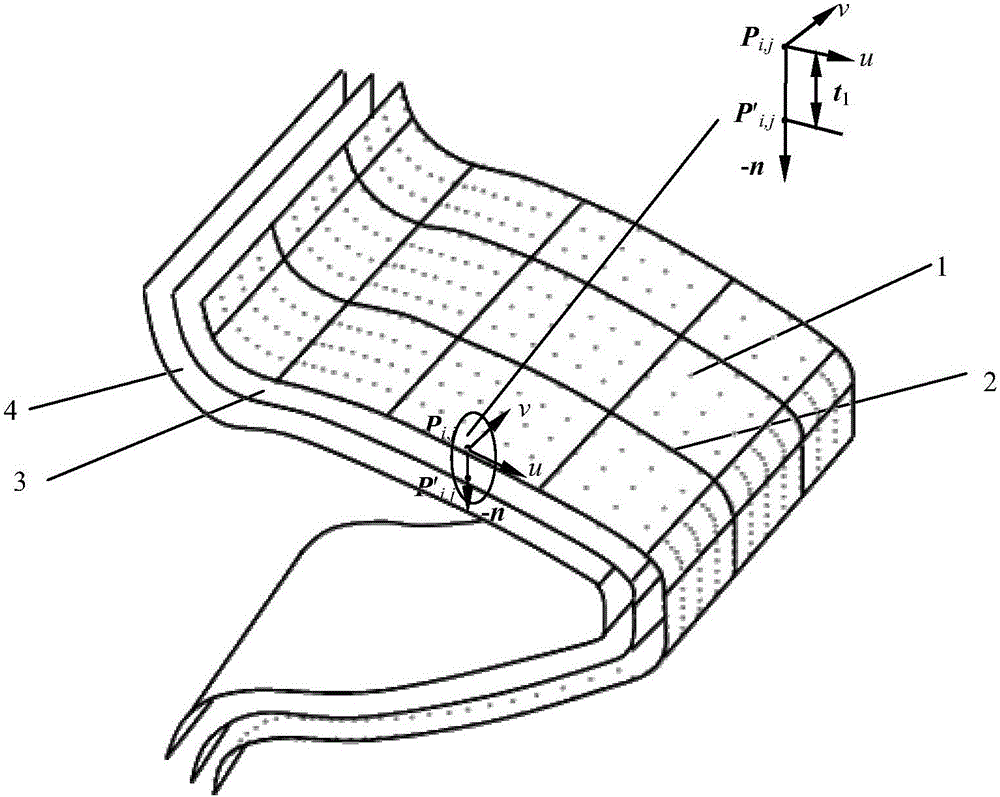

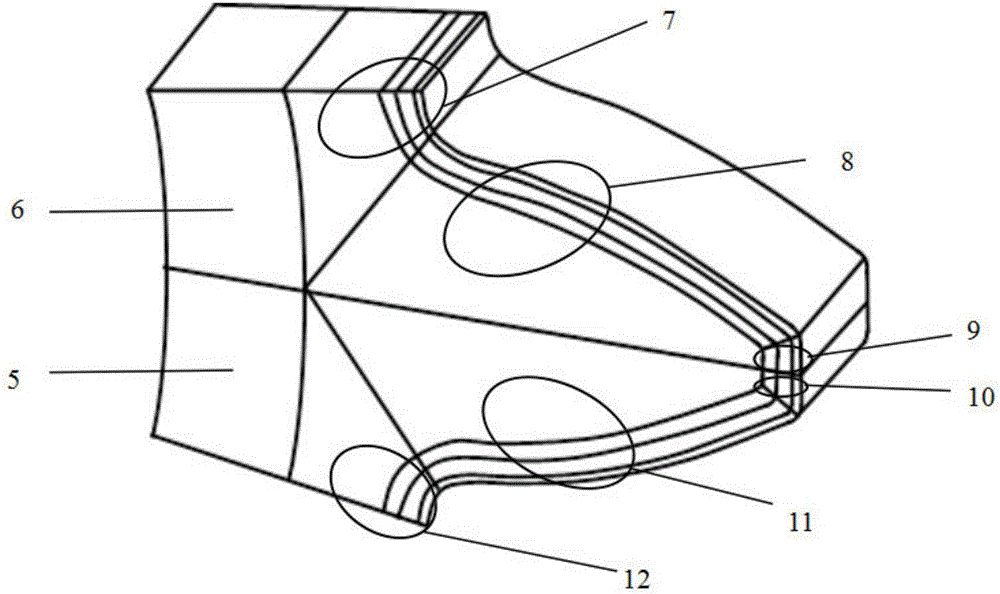

[0034] A method for parametric simulation analysis of carburized cylindrical gears, comprising the following steps,

[0035] (1) Acquisition of original parameters: According to the requirements of actual working conditions, the original parameters of carburized cylindrical gears are obtained. The original parameters include tooth profile parameters, material parameters and working condition parameters; the tooth profile parameters include the number of teeth, modulus, and Helix angle, pressure angle, tooth width, displacement coefficient, addendum height coefficient, head clearance coefficient and carburizing depth, material parameters include driving and driven gear body material characteristic parameters and carburized layer surface material characteristic parameters, gear body material The characteristic parameters include elastic modulus, Poisson's ratio, density, contact fatigue limit and bending fatigue limit. The characteristic parameters of the surface material of the ...

Embodiment 2

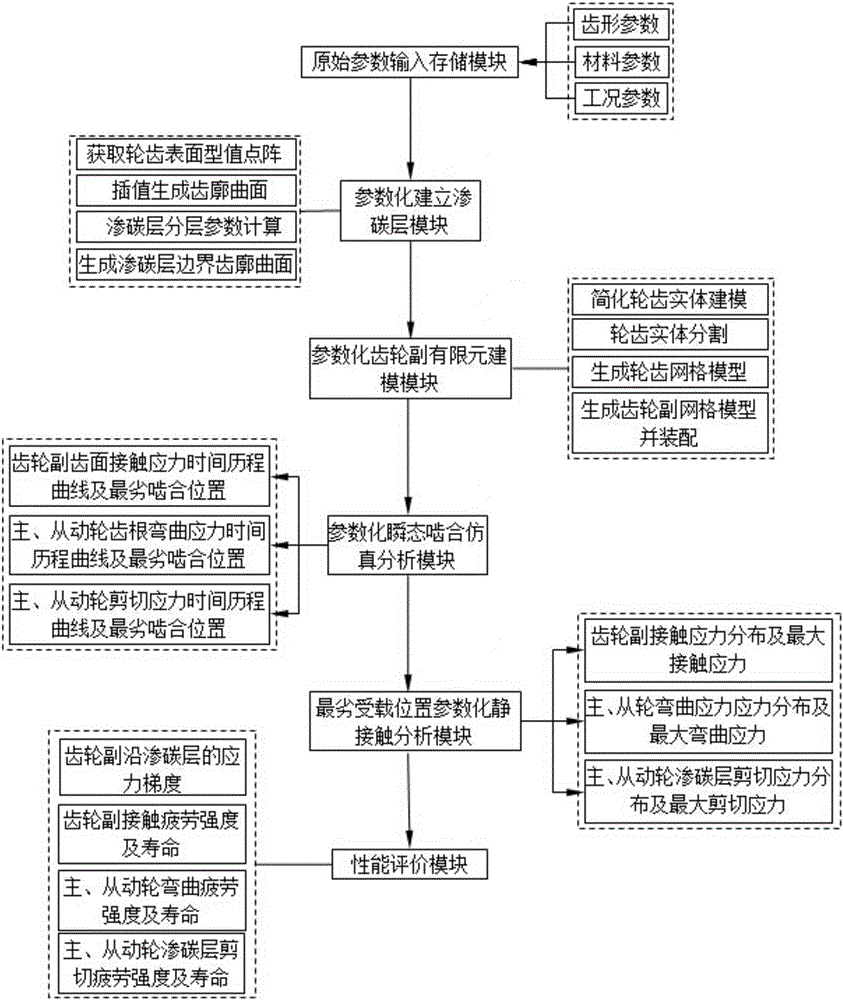

[0050] Such as image 3 As shown, a CAE system based on the parametric simulation analysis method of carburized cylindrical gears, based on Visual C++2012 to carry out secondary development of ANSYS14.5, to realize parametric finite element modeling and parametric instantaneous The whole simulation process of dynamic meshing simulation analysis, parameterized static contact analysis of the worst loaded position and performance evaluation, the system is built on the platform of Visual C++2012, written using Microsoft MFC combined with ANSYS parametric design language APDL command, the system The structure is designed based on dialog boxes.

[0051] The CAE system includes the following modules:

[0052] Original parameter input storage module 1: This module is used to input the original parameters of the carburized cylindrical gear according to the actual working conditions, including gear tooth profile parameters, material parameters and working condition parameters. Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com