Ply optimization design method of vehicle anti-collision beams

An optimized design, anti-collision beam technology, applied in the field of layup angle optimization design of carbon fiber composite anti-collision beam, can solve the problems of social loss, death and injury, vehicle insecurity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

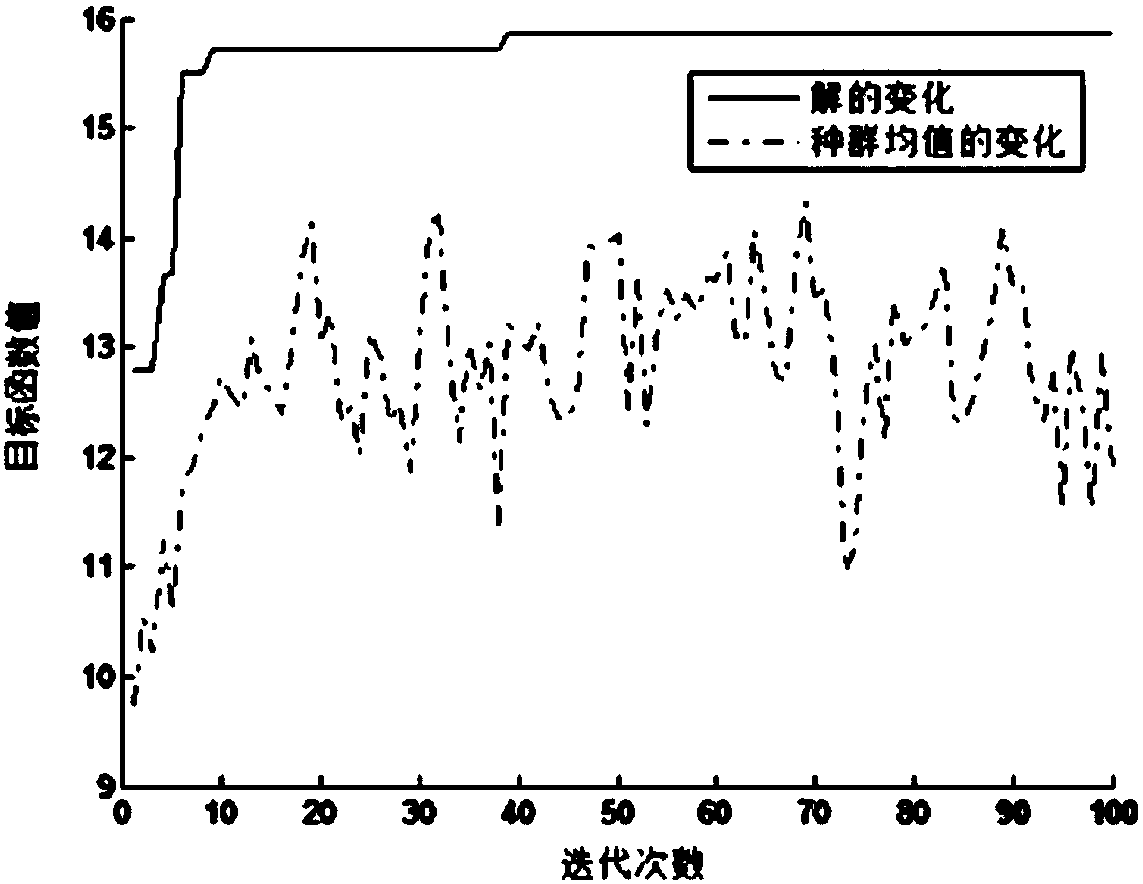

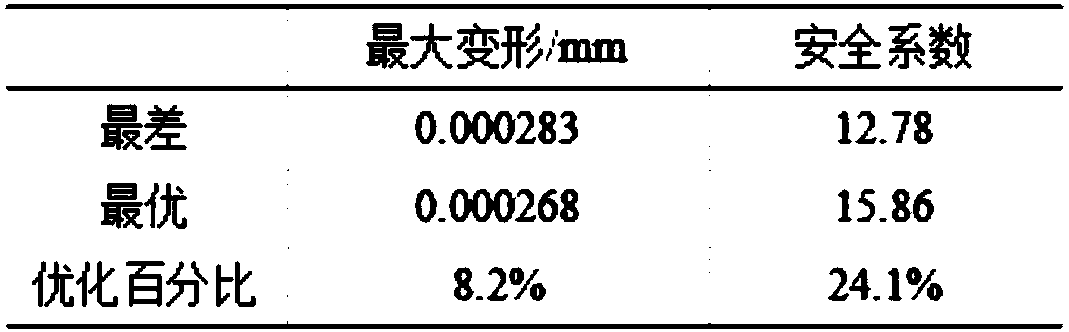

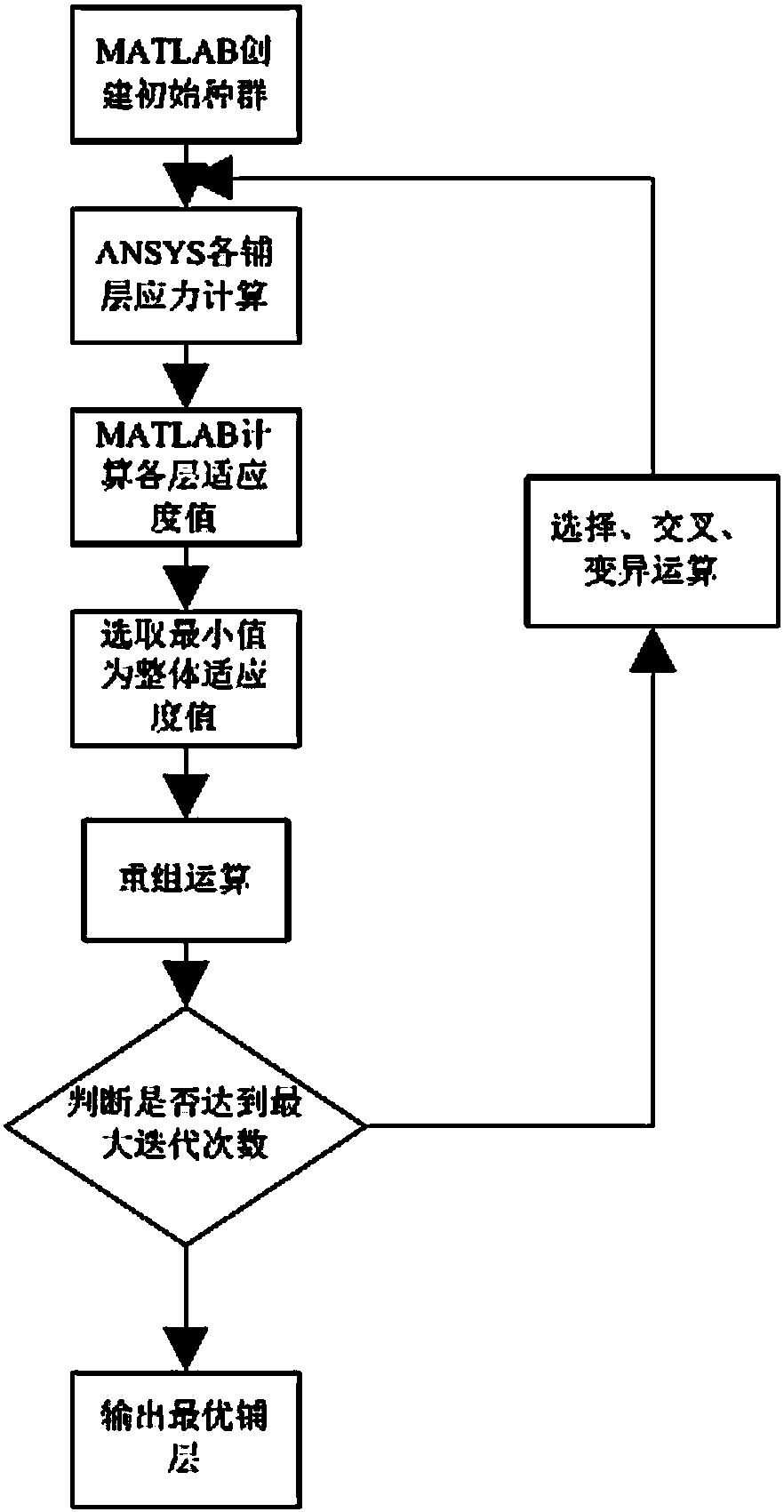

[0035] Such as Figure 1 to Figure 3 As shown, an optimization design method for automobile anti-collision beam pavement, the optimization elements are:

[0036] 1. Design variable: In the optimization process of the laminate, the variable is the ply angle of each layer of the laminate. By changing the value of the ply angle of each layer, the overall structural performance of the laminate is changed;

[0037] 2. Constraints: In the process of chromosome coding, the plies used are standard ply angles of 0°, ±45°, and 90°. In MATLAB coding, an integer code is used to represent the ply angle, respectively using [0 / 1 / 2 / 3] indicates the ply angle [-45° / 0° / 45° / 90°];

[0038] 3. Fitness function: According to the Cai-Wu tensor theory strength ratio equation:

[0039] (F xx σ 2 x+ 2F xy σ x σ y +F yy σ 2 y +F ss τ 2 xy )R 2 +(F x σ x +F y σ y )R-1=0 (1)

[0040] The single layer with a smaller strength ratio is the first to fail, that is, the first failure layer;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com