Method for quickly designing mechanical products based on virtual instruments and reverse engineering

A virtual instrument and reverse engineering technology, applied in the direction of instruments, computing, special data processing applications, etc., can solve the problems of scattered functions, large investment costs, lack of management systems, etc., to achieve the effect of simple and convenient operation and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

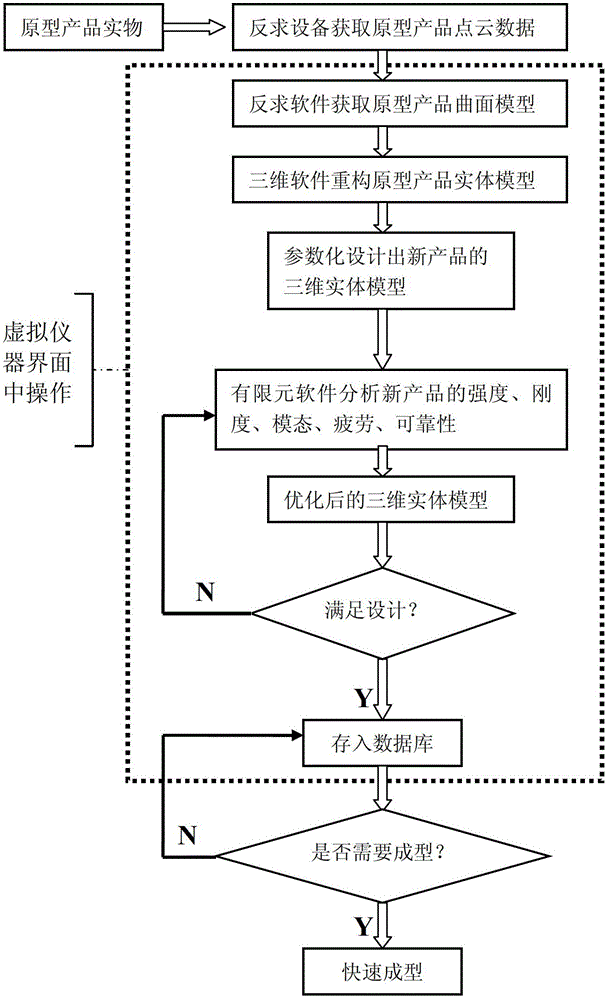

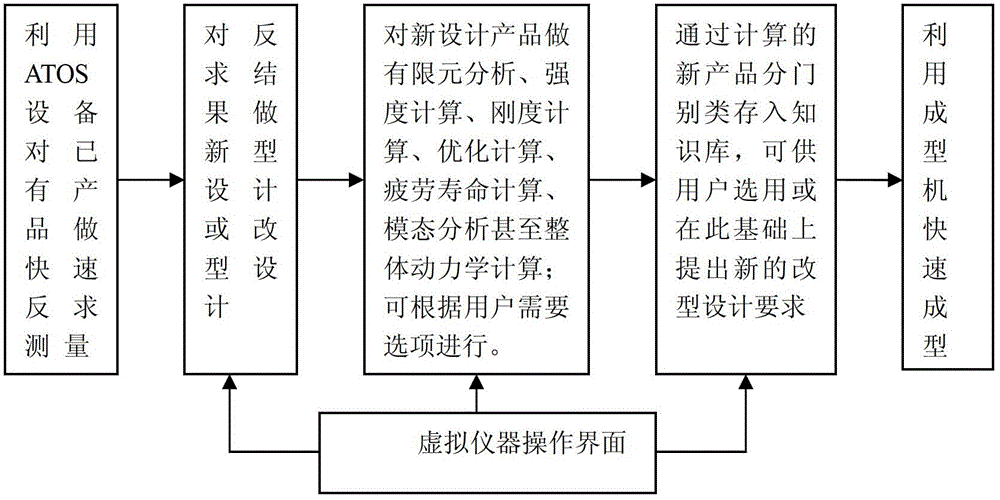

[0028] The present invention will be further described below in conjunction with accompanying drawing.

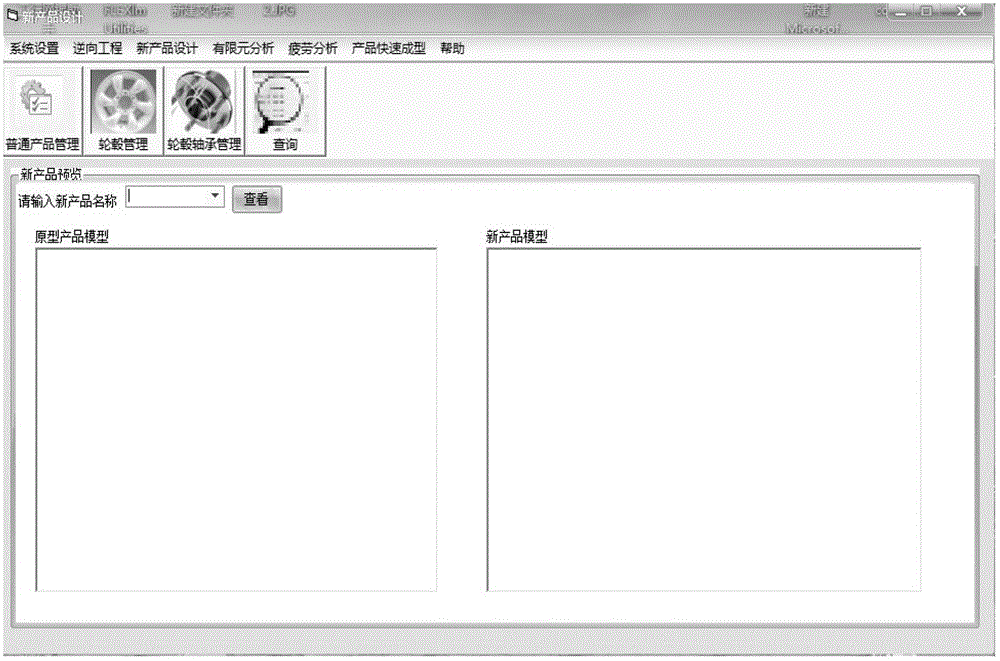

[0029] Such as figure 1 with figure 2 As shown, the present invention has done a lot of follow-up secondary development research work on the basis of reverse engineering (reverse design), applies virtual instruments to the design process, improves flexibility, and is mainly aimed at mechanical products and parts Products, developed a set of rapid research and development system that integrates reverse measurement of mechanical products, innovative design based on prototypes, multi-functional calculation analysis and molding. The virtual instrument can integrate all the software with calculation functions together, through the programming of the computer, it can realize the call of various calculation software, and can display the calculation results, and finally can realize the integrated reverse measurement, three-dimensional modeling, modification design, It is a rapid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com