Intelligent escalator energy saving device

A technology for escalators and energy-saving devices, which is applied in escalators, transportation and packaging, sustainable construction, etc., can solve the problems of increased equipment volume, large energy consumption of escalators, and large mechanical wear and tear, and achieves low maintenance costs and maintenance difficulties. Small, number-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

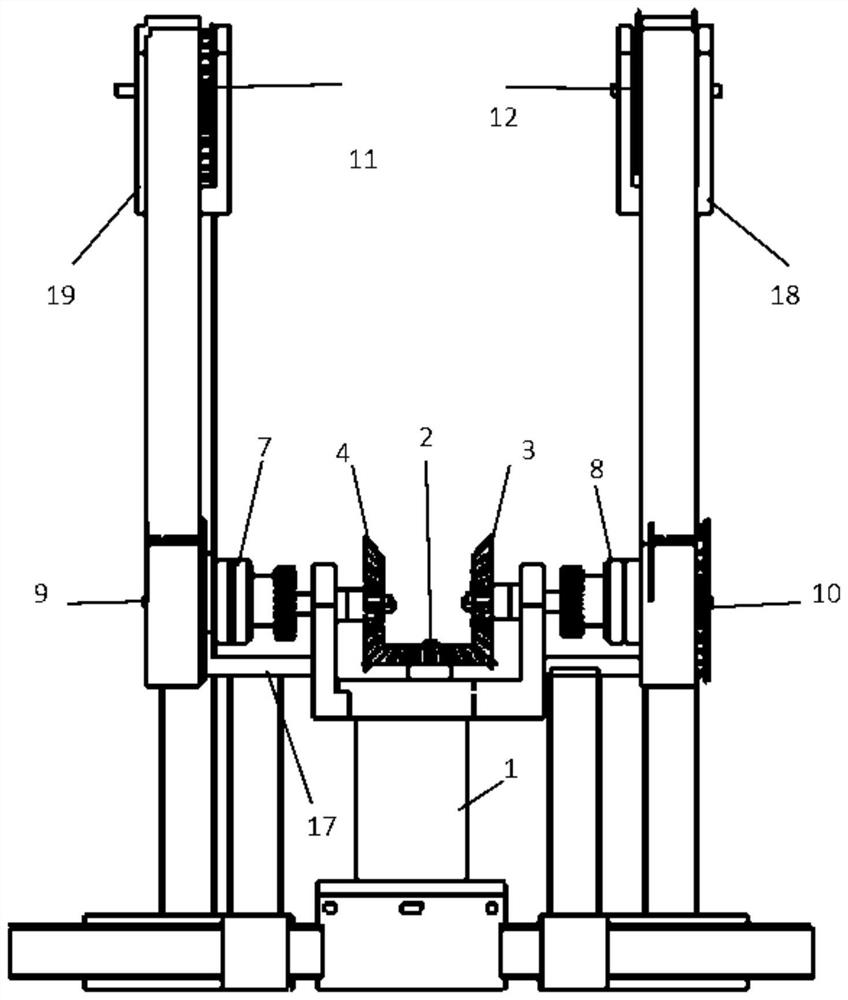

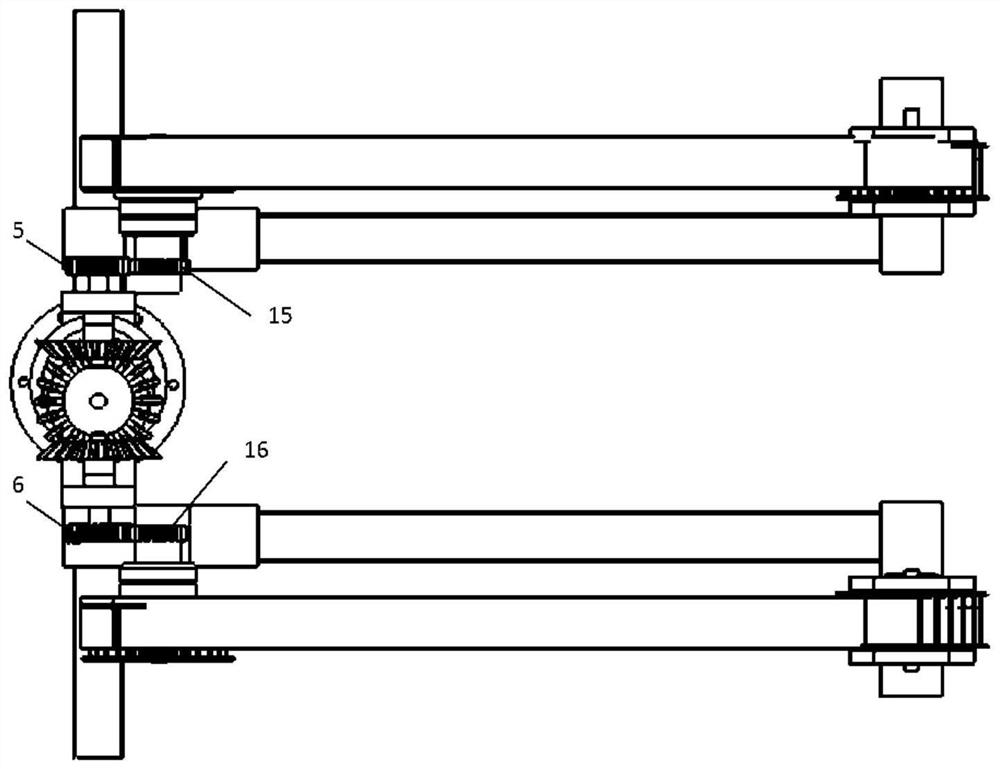

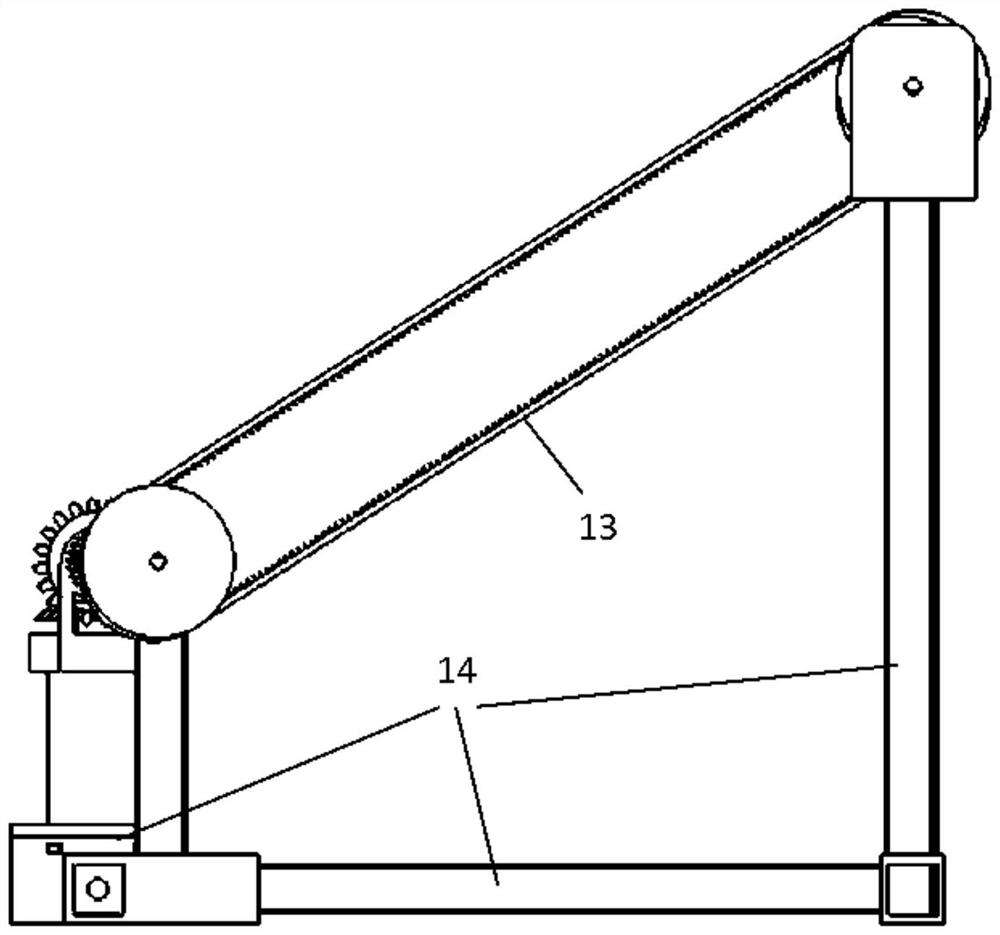

[0036] The intelligent escalator energy-saving device is composed of a bracket system, a connection system, and a transmission system. The transmission system is composed of two symmetrical parts. The connection system connects the two parts of the transmission system. The bracket system supports the connection system and the transmission system;

[0037] The support system includes motor sleeve 1, support 1 14, support 2 17, special structure 1 18 and special structure 2 19;

[0038] The connection system includes bevel gear one 2, bevel gear two 3, bevel gear three 4 and the shell;

[0039] The transmission system includes spur gear 1 5, spur gear 2 6, electromagnetic clutch 1 7, electromagnetic clutch 2 8, timing pulley 1 9, timing pulley 2 10, timing pulley 3 11, timing pulley 4 12, and timing belt 13 , the supporting spur gear one 15 of electromagnetic clutch, the supporting spur gear two 16 of electromagnetic clutch.

[0040] In the support system, the motor sleeve 1 is...

Embodiment 2

[0062] combine figure 1 , figure 2 , image 3 , figure 1 It is the hardware structure diagram of the intelligent escalator energy-saving device, figure 2 It is the top view of the intelligent escalator energy-saving device, image 3 It is a side view of an intelligent escalator energy-saving device. We can see that the composition of the present invention includes: a motor sleeve 1, a bevel gear 2, a bevel gear 2 3, a bevel gear 3 4, a spur gear 5, a spur gear 2 6, an electromagnetic Clutch one 7, electromagnetic clutch two 8, synchronous pulley one 9, synchronous pulley two 10, synchronous pulley three 11, synchronous pulley four 12, synchronous belt 13, support one 14, the spur gear one 15 that electromagnetic clutch is matched, The supporting spur gear two 16 of electromagnetic clutch, support two 17, special structure one 18, special structure two 19 are formed. The motor sleeve 1 is nested in the bracket, and the bevel gear 1 is connected with the DC motor, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com