Fine mask screening process analysis method

A fine mask and process analysis technology, applied in the field of fine mask stretching process analysis, can solve the problem of high test cost and achieve the effect of saving test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

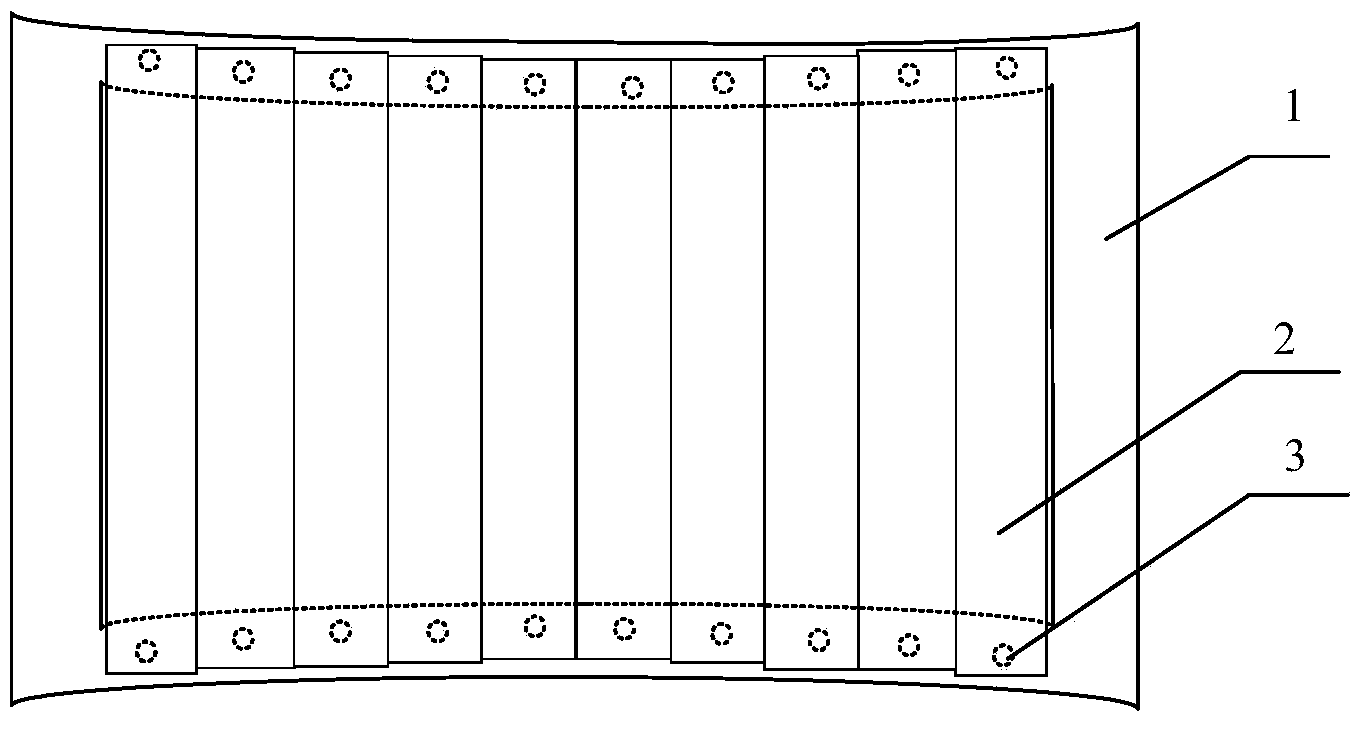

[0042] In order to enable those skilled in the art to better understand the technical solution of the present invention, a method for analyzing the fine mask sheet stretching process provided by the present invention will be described in detail below with reference to the accompanying drawings.

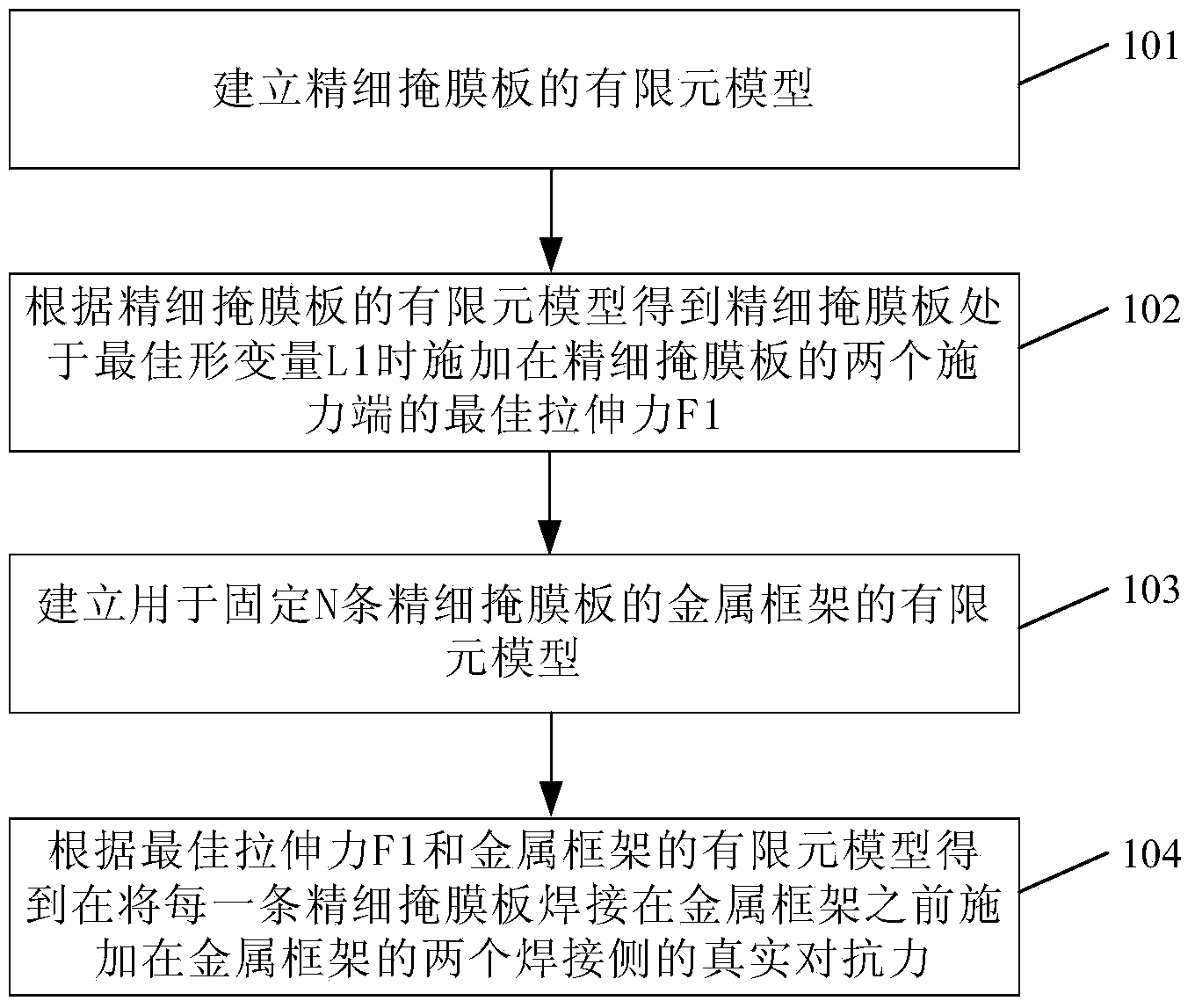

[0043] figure 2 The flow chart of the analysis method for the fine mask stretching process provided by the embodiment of the present invention, such as figure 2 As shown, the analysis method includes:

[0044] Step 101: Establish a finite element model of the fine mask.

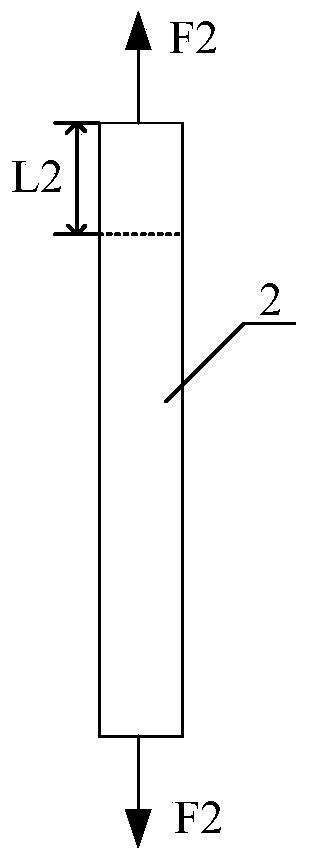

[0045]In step 101, a corresponding APDL command stream is written according to the specification and size of the fine mask plate, and the APDL command stream is run in ANSYS software to establish a finite element model of the fine mask plate. Specifically, based on the symmetry of the fine mask plate and the calculation speed of the ANSYS system, the quarter model of the fine mask plate can be established through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com