Finite element parametric modeling method of power transmission steel pipe pole

A technology of parametric modeling and power transmission steel, applied in the direction of electric digital data processing, special data processing applications, instruments, etc., can solve the problems of low precision, poor accuracy, rough modeling of power transmission steel pipe rods, etc., and achieve high model accuracy, The effect of improving efficiency and quality, improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0032] Example: Finite element parametric modeling and mechanical calculation of 110GJ17-24 steel pipe rod for power transmission

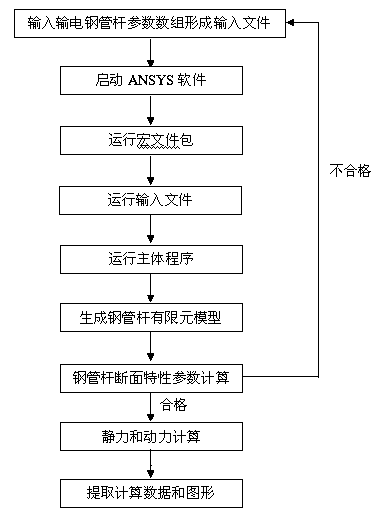

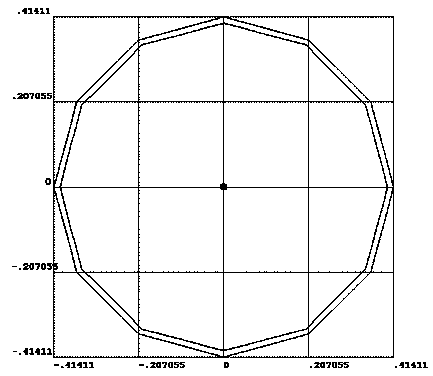

[0033] 1. Parameter identification and extraction of transmission steel pipe poles. Open the self-edited APDL command flow parameter input file, and input the steel pipe pole and cross-arm parameter array: the number of barrel sections and cross-arm, the number of polygonal sides, length, and polygon unit number of the section; input the geometric parameter array of the barrel section: height, wall thickness , the inner distance of the upper end, and the inner distance of the lower end; input the geometric parameter array of the cross arm: length, wall thickness, side length of the small head, and side length of the large head; input the array of flange parameters: inner diameter, outer diameter, plate thickness , bolt hole diameter, bolt quantity; input ground wire parameter array: diameter, unit weight, split number, tension coefficient; input l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com