Photovoltaic assembly hot spot temperature calculating method

A photovoltaic module, hot spot temperature technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as battery microcracks, hot spot temperature rise research has not been carried out systematically, local high temperature of photovoltaic modules, etc., to achieve reliable results, Reduces the risk of hot spots and saves time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0034] The invention provides a method for calculating the hot spot temperature of a photovoltaic module, comprising the following steps:

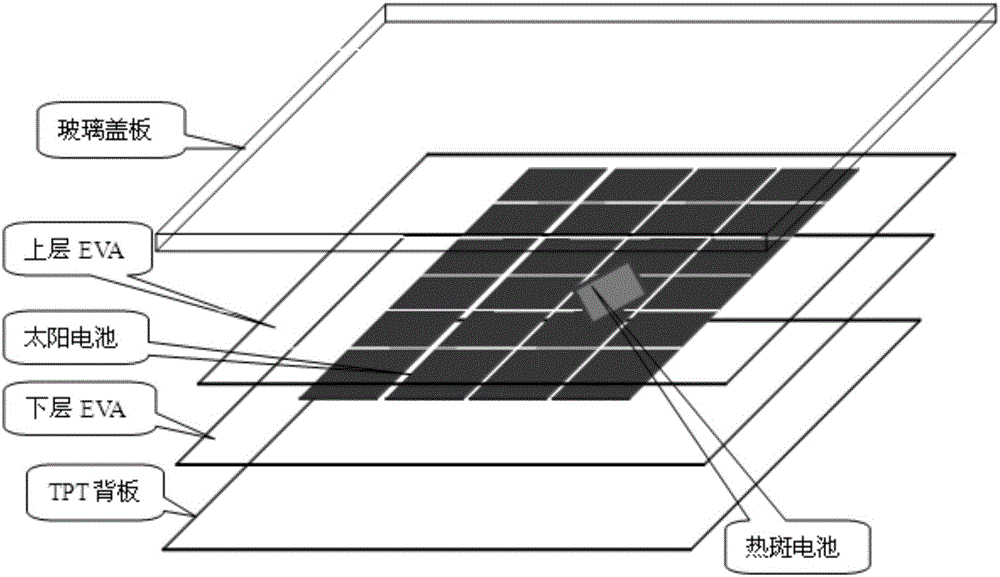

[0035] 1) Use ANSYS software to simulate photovoltaic modules, such as figure 1 As shown, the photovoltaic module includes a glass cover plate distributed from top to bottom, an upper layer of EVA, a solar cell, a lower layer of EVA and a TPT back sheet, and the solar cell is composed of S cells.

[0036] 2) Input the thermal conductivity of the materials of each part of the solar cell photovoltaic module, among which, the thermal conductivity of the main materials of the solar cell module used in the simulation by ANSYS software is shown in Table 1 below.

[0037]

[0038] Table 1

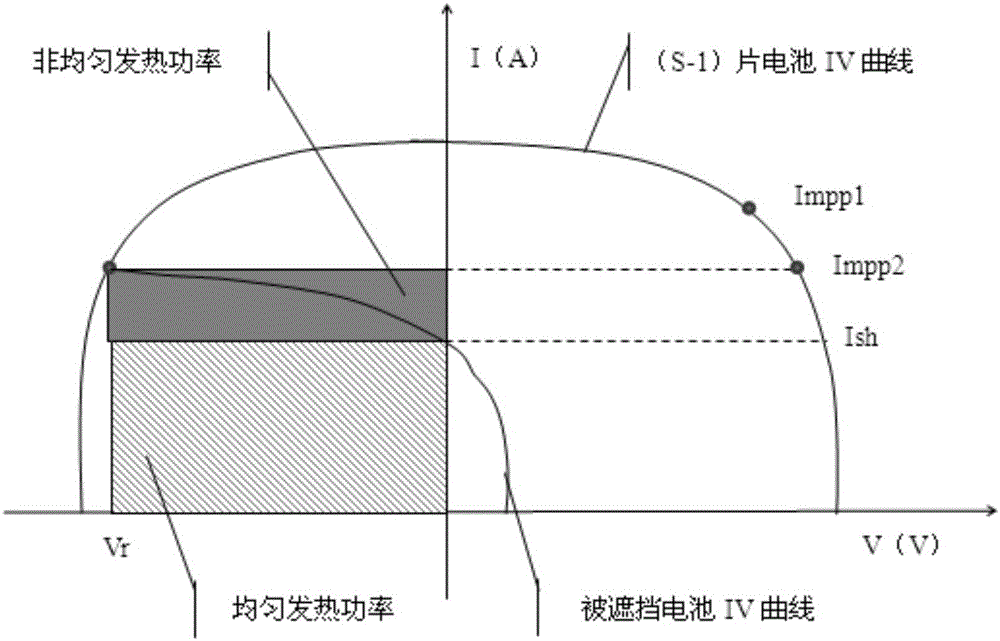

[0039] 3) Any one cell in the simulated solar cell is blocked, and the blocked cell shows uniform heat generation and becomes the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com