Method for vibrating power-generation analysis finite element by different shapes of cantilever beam piezoelectric vibrators

A technology of piezoelectric vibrator and vibration power generation, applied in piezoelectric/electrostrictive/magnetostrictive devices, electrical components, chemical instruments and methods, etc., can solve the problems of lack of simulation analysis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

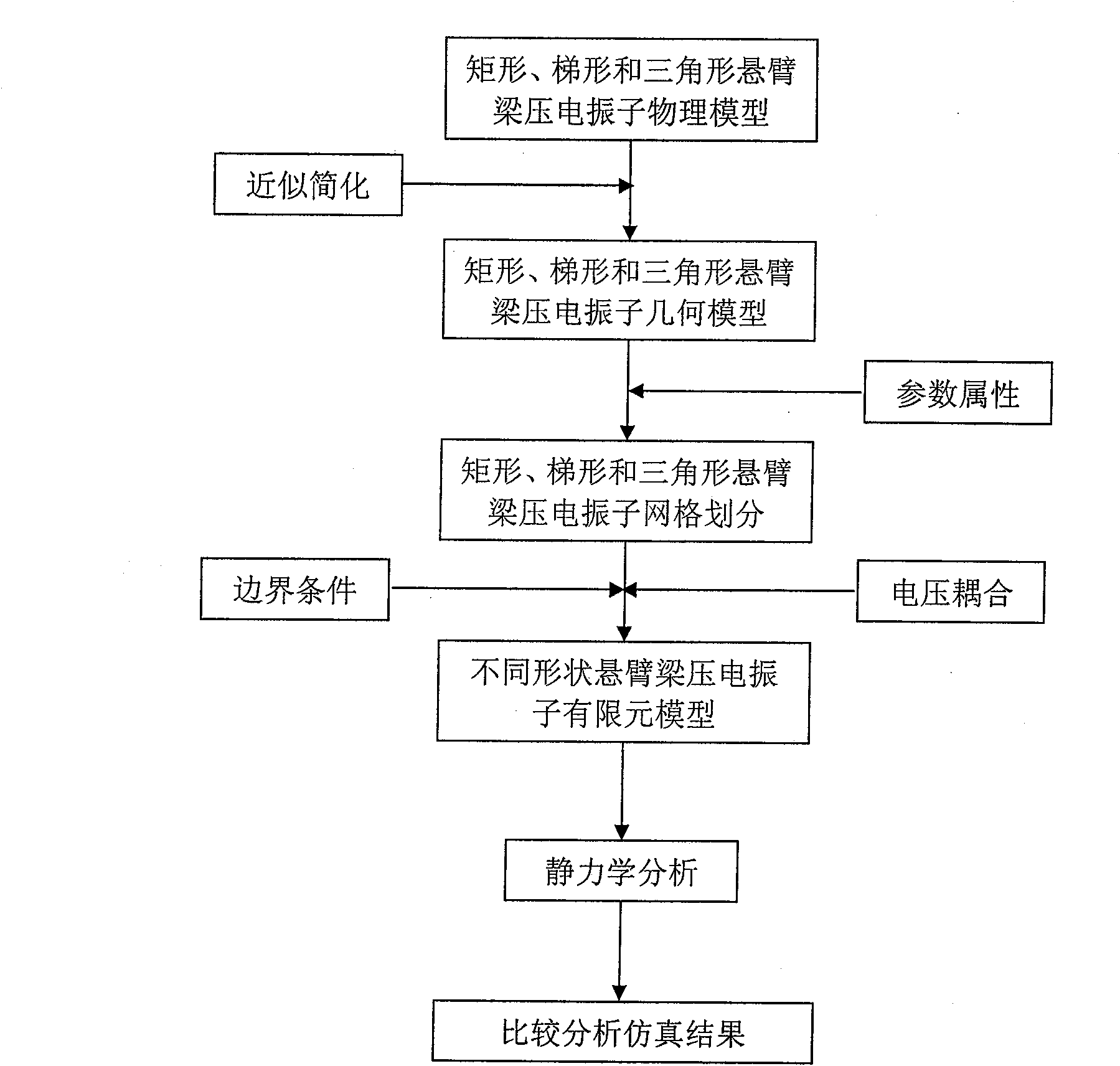

[0021] The flow process of the inventive method sees figure 1 , the cantilever piezoelectric vibrator used for vibration power generation is composed of two piezoelectric ceramic sheets, a metal substrate and electrodes. The piezoelectric ceramic sheet is made of PZT-5H, and the metal substrate material is nickel alloy. Since the piezoelectric ceramic sheet is hard and brittle, it is pasted on the metal substrate. In order to generate more electricity, two piezoelectric ceramic sheets are connected in parallel according to the same polarization direction.

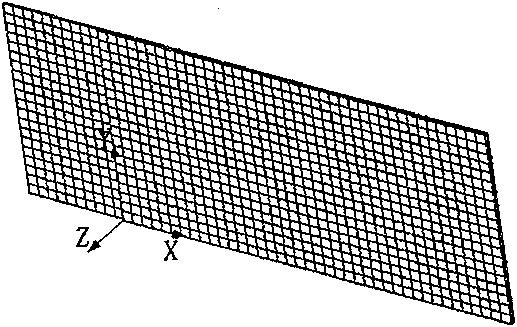

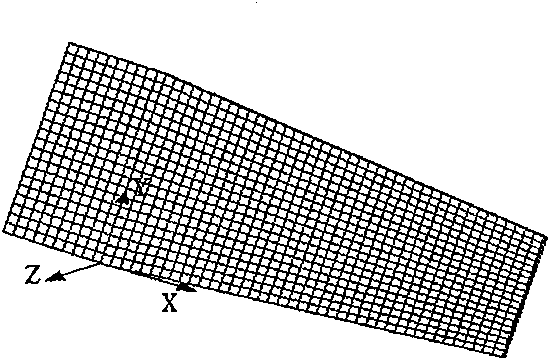

[0022] The present invention will be described step by step in detail for rectangular, trapezoidal and triangular cantilever beam piezoelectric vibrators below with reference to the accompanying drawings.

[0023] Step 1: Approximate simplification, using Soliworks software to establish geometric models of rectangular, trapezoidal and triangular cantilever beam piezoelectric vibrators with the same length, thickness and ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com