Distributed fiber sensing method and device for simultaneously measuring temperature and strain

A distributed optical fiber, temperature measurement technology, applied in the direction of measuring devices, optical devices, thermometers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

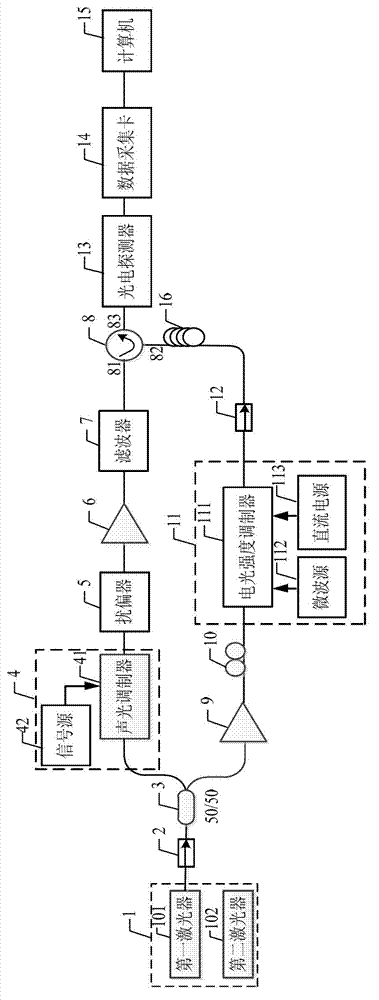

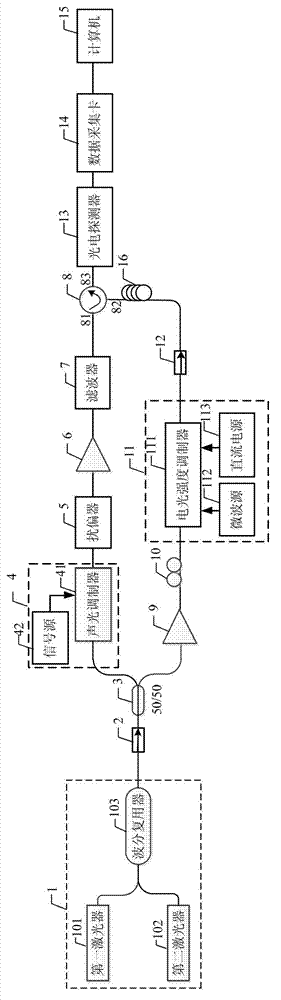

[0037] A distributed optical fiber sensing technology that realizes simultaneous measurement of temperature and strain described in the present invention is based on Brillouin Optical Time Domain Analysis Technology (BOTDA) as an example, injecting pulses at both ends of a common single-mode optical fiber used for sensing The pump light is injected into the other end of the continuous probe light after frequency shifting by the electro-optical intensity modulator. It can be BOTDA technology based on gain (the frequency of the pump light is higher than that of the probe light) or loss (the frequency of the probe light is higher than that of the pump light).

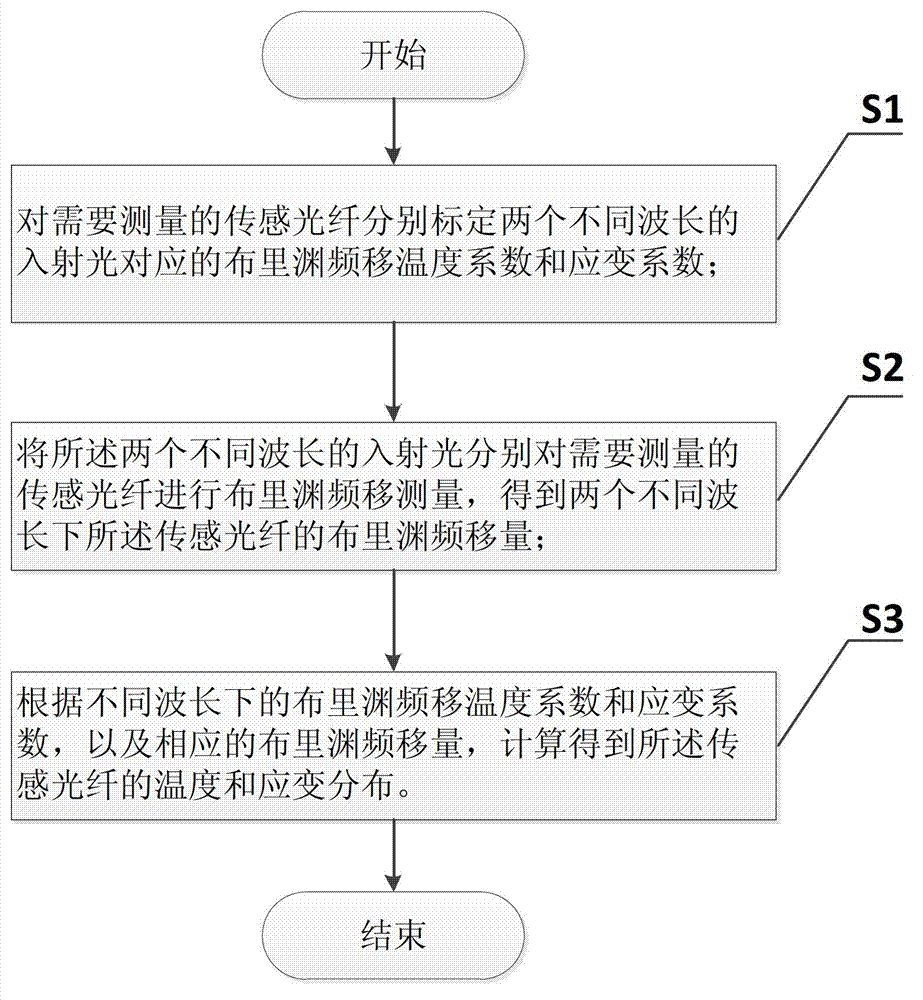

[0038] Such as figure 1 Shown is a flow chart of the method of the present invention. Specifically include:

[0039] S1. Calibrate the Brillouin frequency shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com