Ultrasonic non-destructive abrasion-resistant coating thickness and elastic modulus measuring method

A wear-resistant coating, elastic modulus technology, used in measuring devices, using ultrasonic/sonic/infrasonic waves, using sonic/ultrasonic/infrasonic waves to analyze solids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

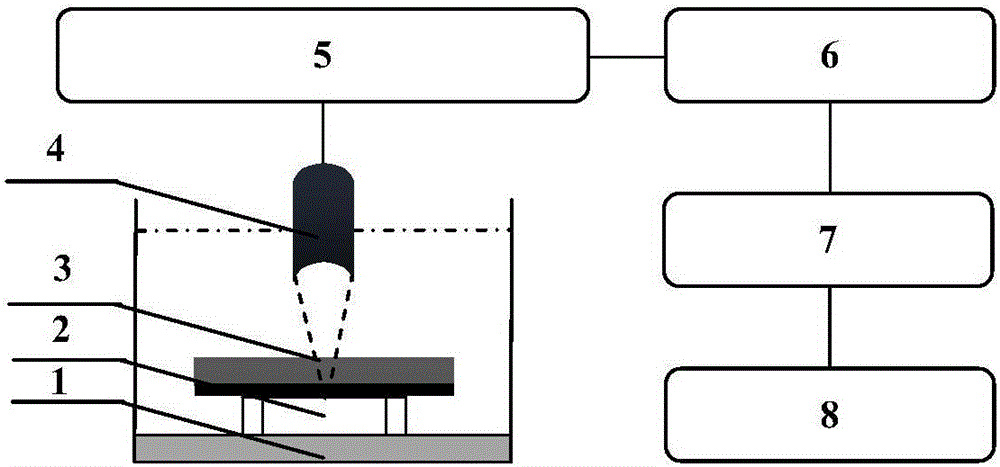

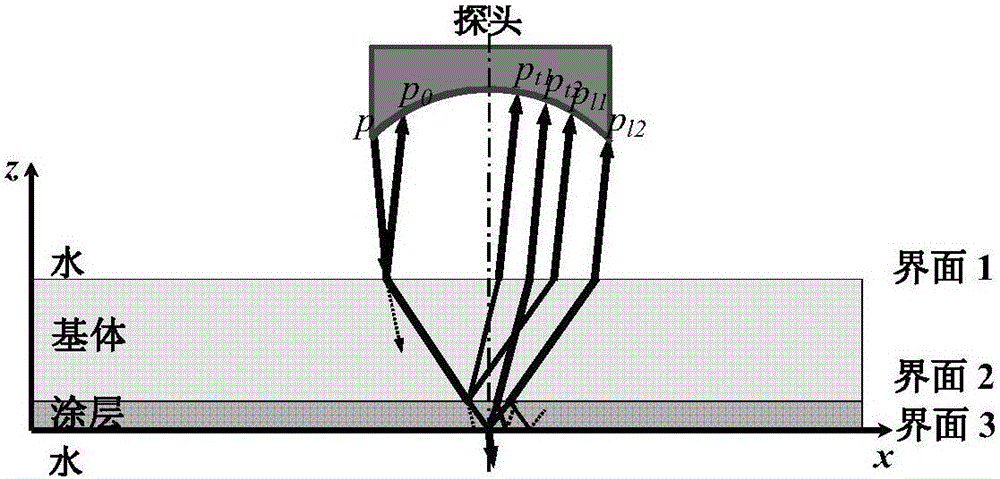

[0037] This ultrasonic non-destructive measurement method of wear-resistant coating thickness and elastic modulus adopts such as figure 1 The one shown includes the sink 1, the sample stage 2, the wear-resistant coating sample 3, the water immersion focusing probe 4, the XYZ three-dimensional stepping control device 5, the ultrasonic flaw detector 6, the digital oscilloscope 7 and the ultrasonic pulse echo of the computer 8. Method for measuring the thickness and elastic modulus of wear-resistant coatings. The specific implementation steps are as follows:

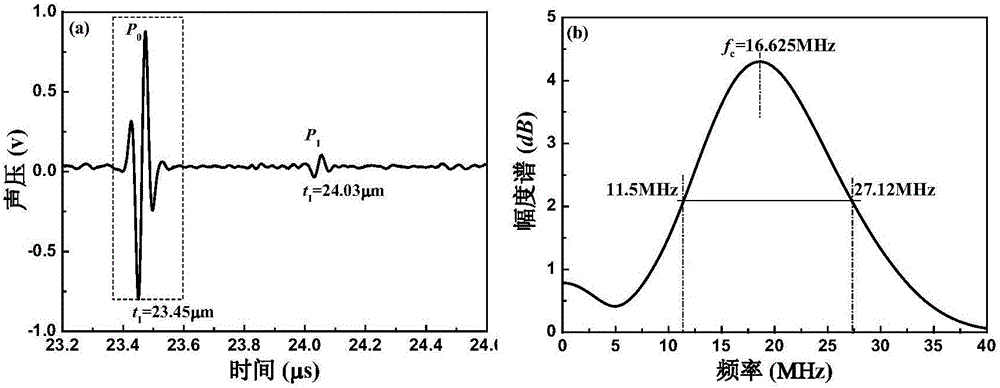

[0038] Step a. Determine the angle of incidence α: Put a stainless steel sample with a thickness of h = 1.62 mm on the sample table 2 in the sink 1, and use the XYZ three-dimensional stepping control device 5 to adjust the distance between the immersion focus probe 4 and the sample. Relative position, the focus of the water immersion focusing probe is vertically focused on the surface of the stainless steel sample. The USIP4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com