Inner surface stress and temperature monitoring method of internal combustion engine main bearing based on fiber bragg grating

A fiber grating and main bearing technology, which is applied in the direction of physical/chemical change thermometers, thermometers, measuring devices, etc., can solve the problems of structural space limitation, lack of main bearing surface temperature and strain distribution, and achieve accurate structural optimization design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

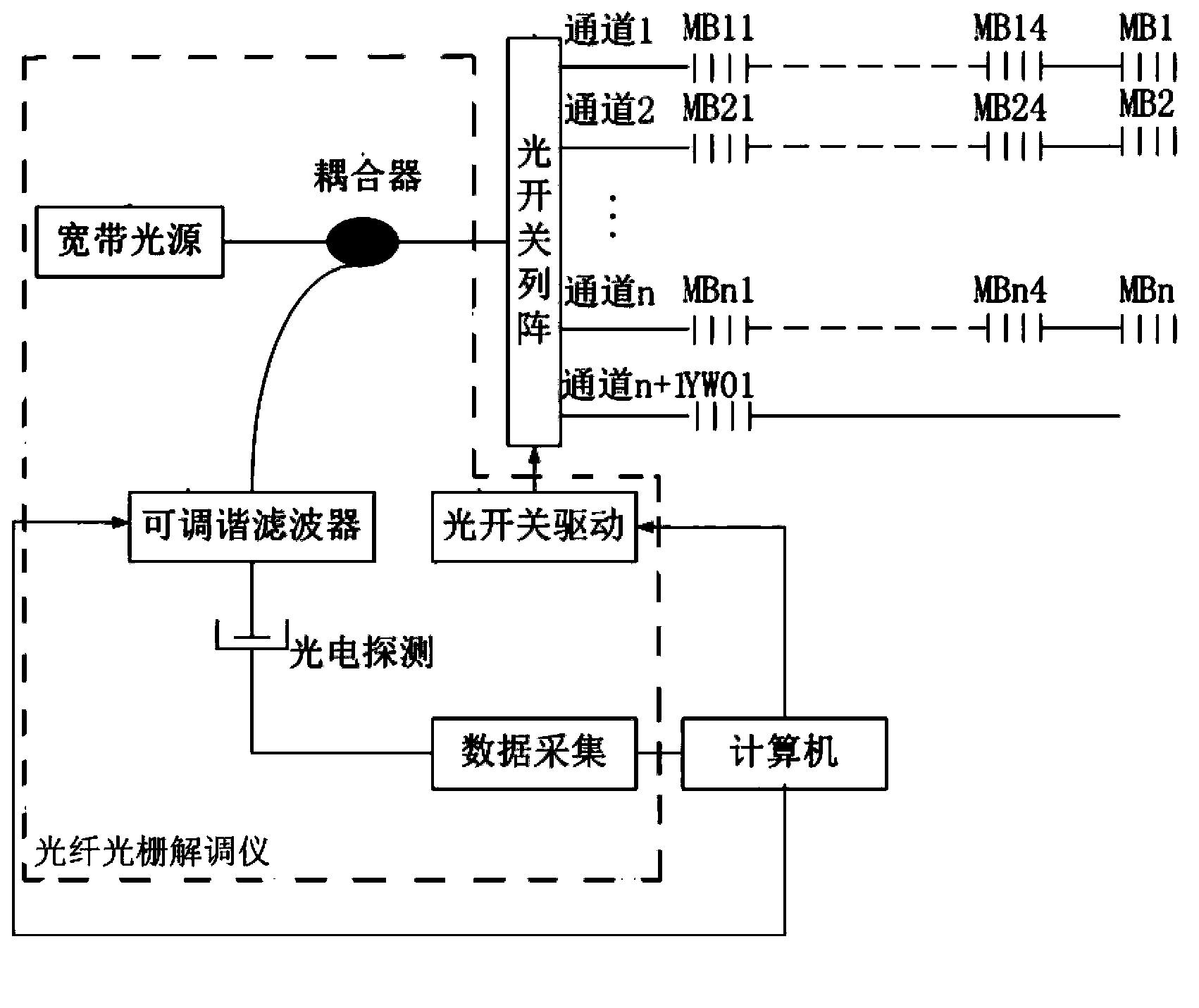

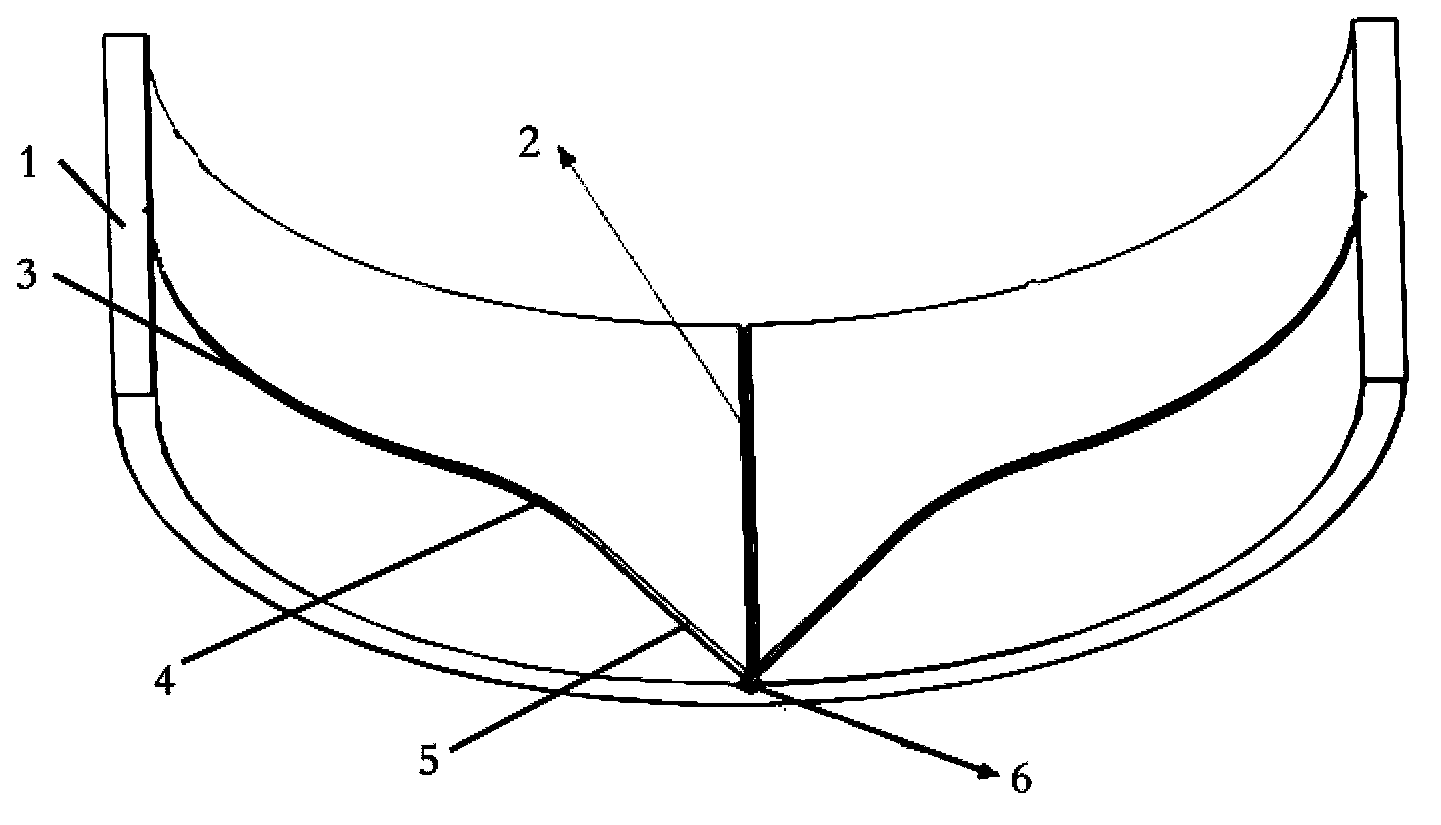

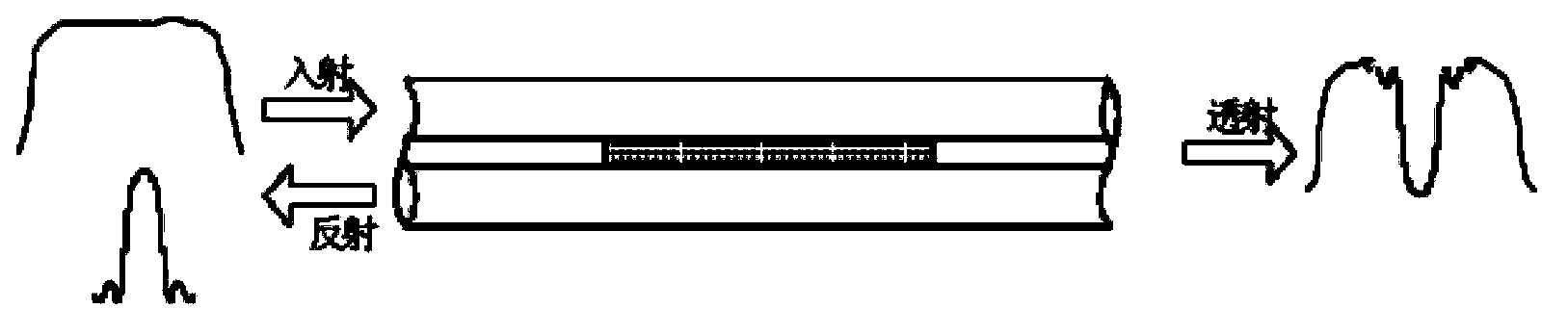

[0034] figure 1 It is a structural schematic diagram of an embodiment of the present invention, which includes a sequentially connected fiber grating sensing device, a fiber grating demodulator and a controller (using a computer in this embodiment); wherein the fiber grating sensing device includes at least one group of main Bearing sensor group (n group in this embodiment) and engine oil temperature sensor; Fiber Bragg grating demodulator includes broadband light source, coupler, optical switch array, tunable filter, photodetector and data acquisition module, wherein broadband light source passes through The coupler is connected to the optical switch array, the optical switch array is connected to the fiber grating sensing device, the tunable filter is connected to the coupler to sample the optical signal, and the photodetector is connected to the tunable filter to convert the sampled optical signal to For electrical signals, the data acquisition module is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com