Electric arc additive manufacturing method and device with electromagnetic field and forced processing being combined for assisting

A technology of additive manufacturing and electromagnetic field, which is applied in the field of additive manufacturing, can solve the problems of easy deformation of formed parts, coarse structure, difficulty in suppressing metallurgical defects, etc., and achieve the effect of suppressing pores and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

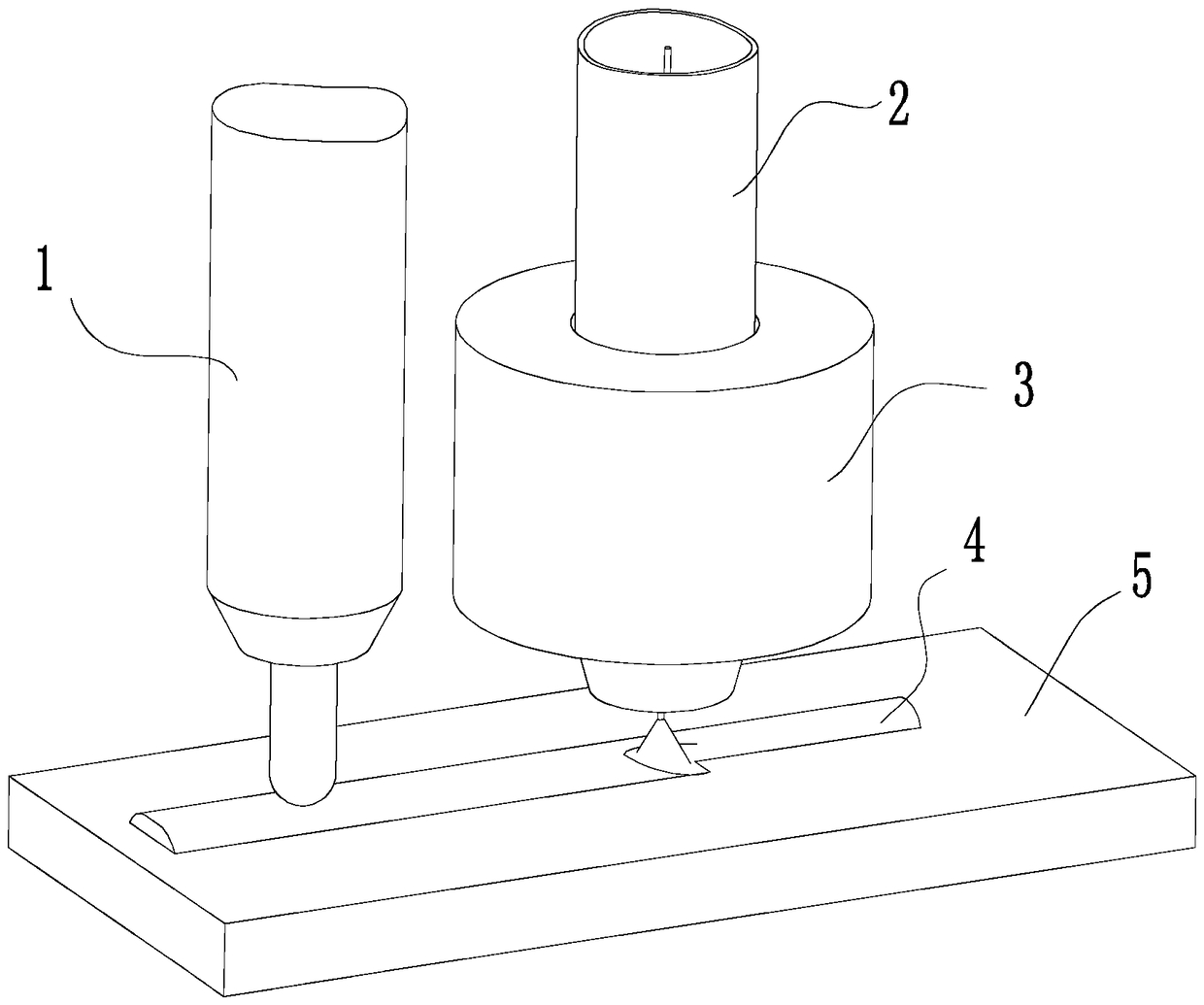

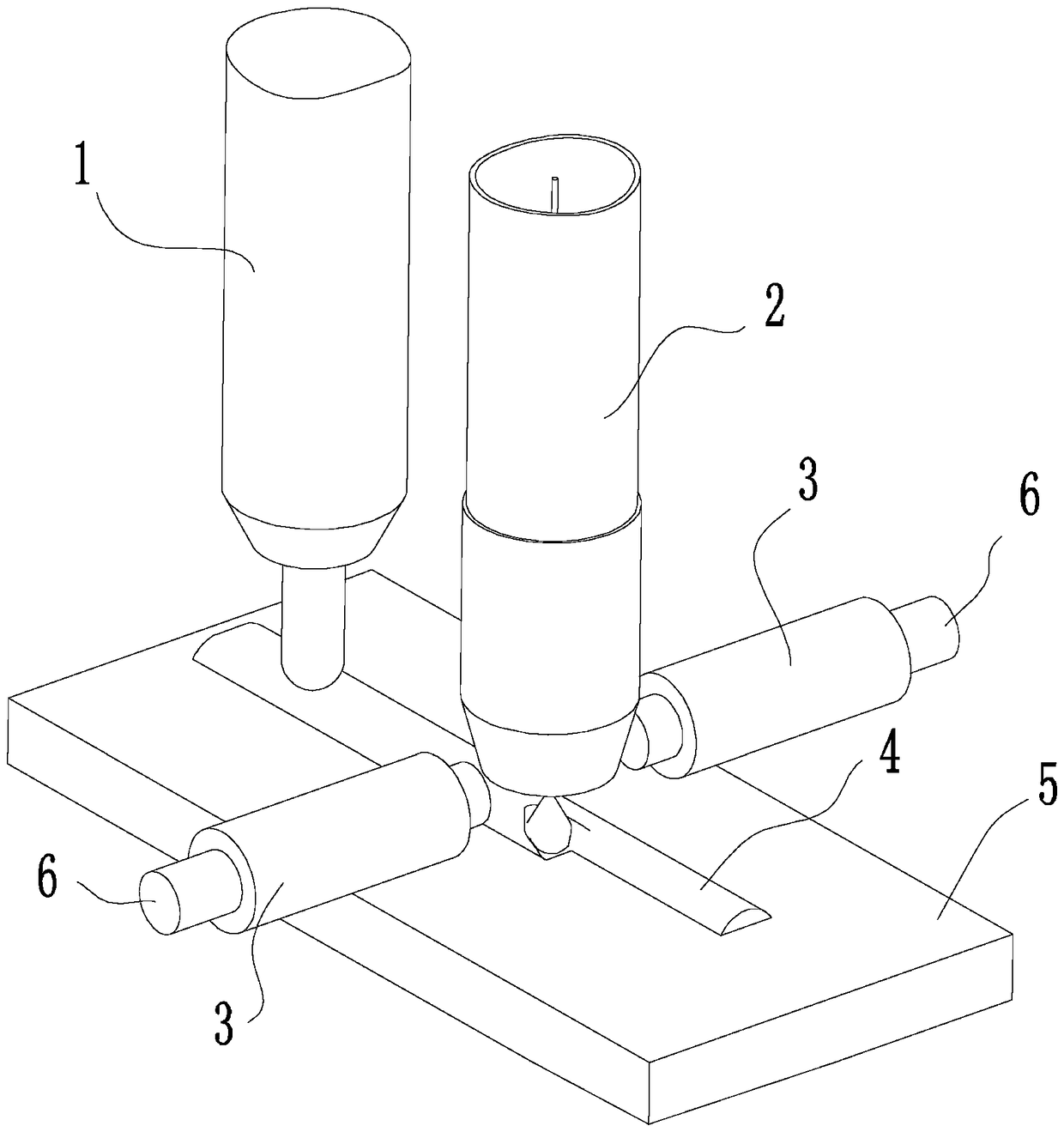

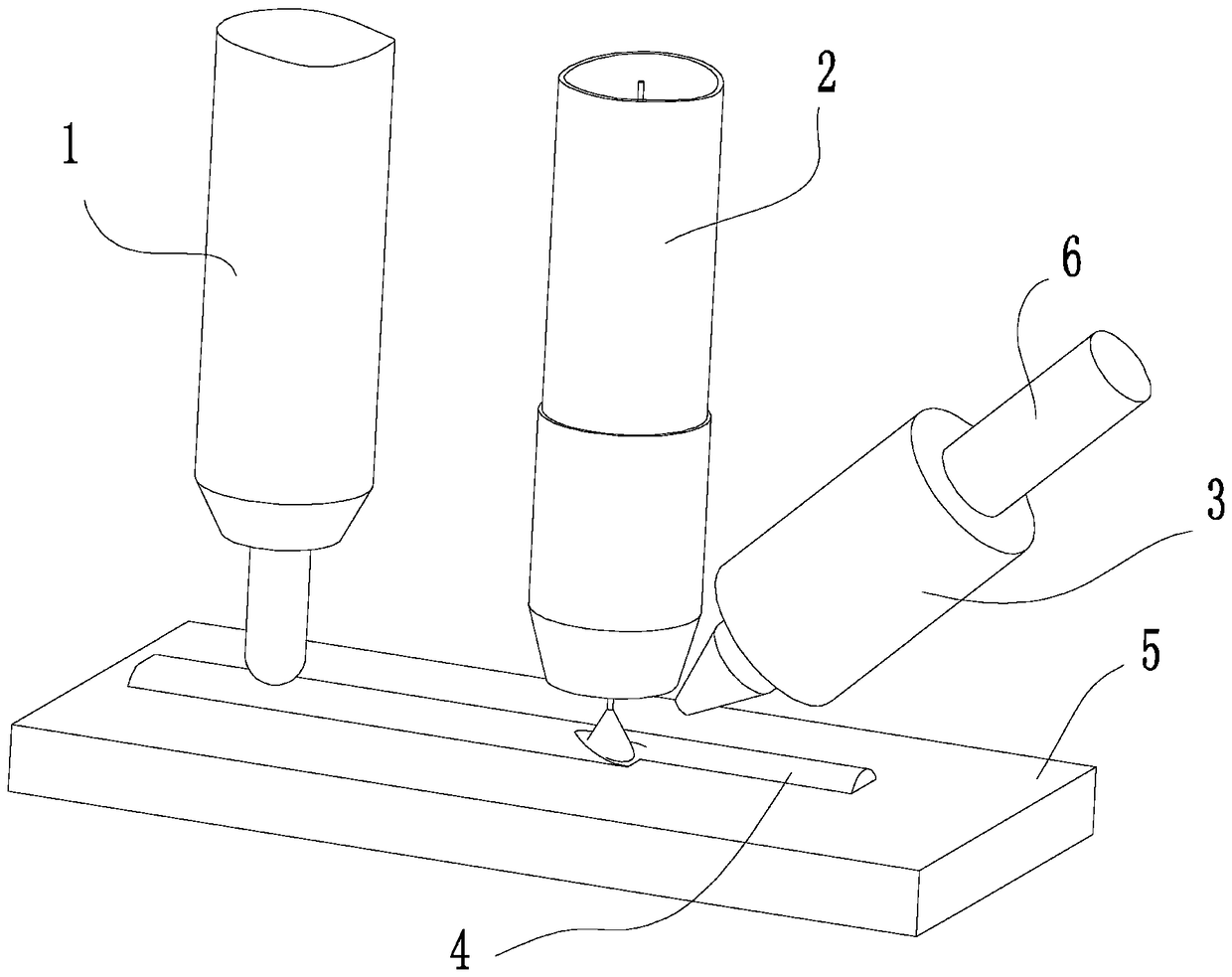

[0036] Such as Figure 1-6 As shown, the arc additive manufacturing method assisted by the combination of electromagnetic field and forced processing changes the heat and mass transfer of the molten pool through an external magnetic field, and changes the stress distribution state of the formed workpiece through plastic forced processing, thereby changing the deposition process, including: The entire forming process from molten pool solidification and crystallization, solid phase transition to recrystallization, and plastic deformation; the forming process of the workpiece is affected by various physical fields such as electromagnetic, heat, and force, and the metallurgy, microstructure, and stress-strain distribution of the formed parts are controlled to improve Formed part properties. By using the above-mentioned additive manufacturing method, in the manufacturing process, the electromagnetic field and forced processing are combined to assist on the weld bead, and the extern...

Embodiment 2

[0038] Add an electromagnetic field generating device 3 around the welding torch 2, and change the magnetic field size of the electromagnetic field generating device in the molten pool area by changing the excitation current of the electromagnetic field generating device 3 or the relative position and inclination angle of the electromagnetic field generating device 3 relative to the welding torch 2 And the distribution of the magnetic field, and then change the size and direction of the external magnetic field of the molten pool, so as to control the convection and heat and mass transfer of the molten pool through the external magnetic field. A forced processing device 1 is added behind the welding torch 2 , and the forced processing device 1 is connected to the traveling mechanism of the welding torch to implement plastic forced processing on the deposited weld bead 4 on the substrate 5 .

Embodiment 3

[0040] The equipment for realizing the arc additive manufacturing method assisted by the combination of electromagnetic field and forced processing, which includes a welding torch 2, the axis of the welding torch 2 is perpendicular to the substrate 5, the welding torch 2 is installed on the welding torch traveling mechanism, and the welding torch traveling mechanism A forced processing device 1 is installed, and the forced processing device 1 is located directly above the deposited and formed weld bead 4; an electromagnetic generating device 3 that moves with the welding torch 2 is installed on the welding torch 2 or the welding torch traveling mechanism. By using the above-mentioned additive manufacturing equipment, the combined auxiliary effect of electromagnetic field and forced processing can be realized, thereby achieving the best manufacturing effect.

[0041] Further, the welding process parameters of the welding torch 2, the excitation parameters of the electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com