Patents

Literature

36results about How to "Ensuring sufficient uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

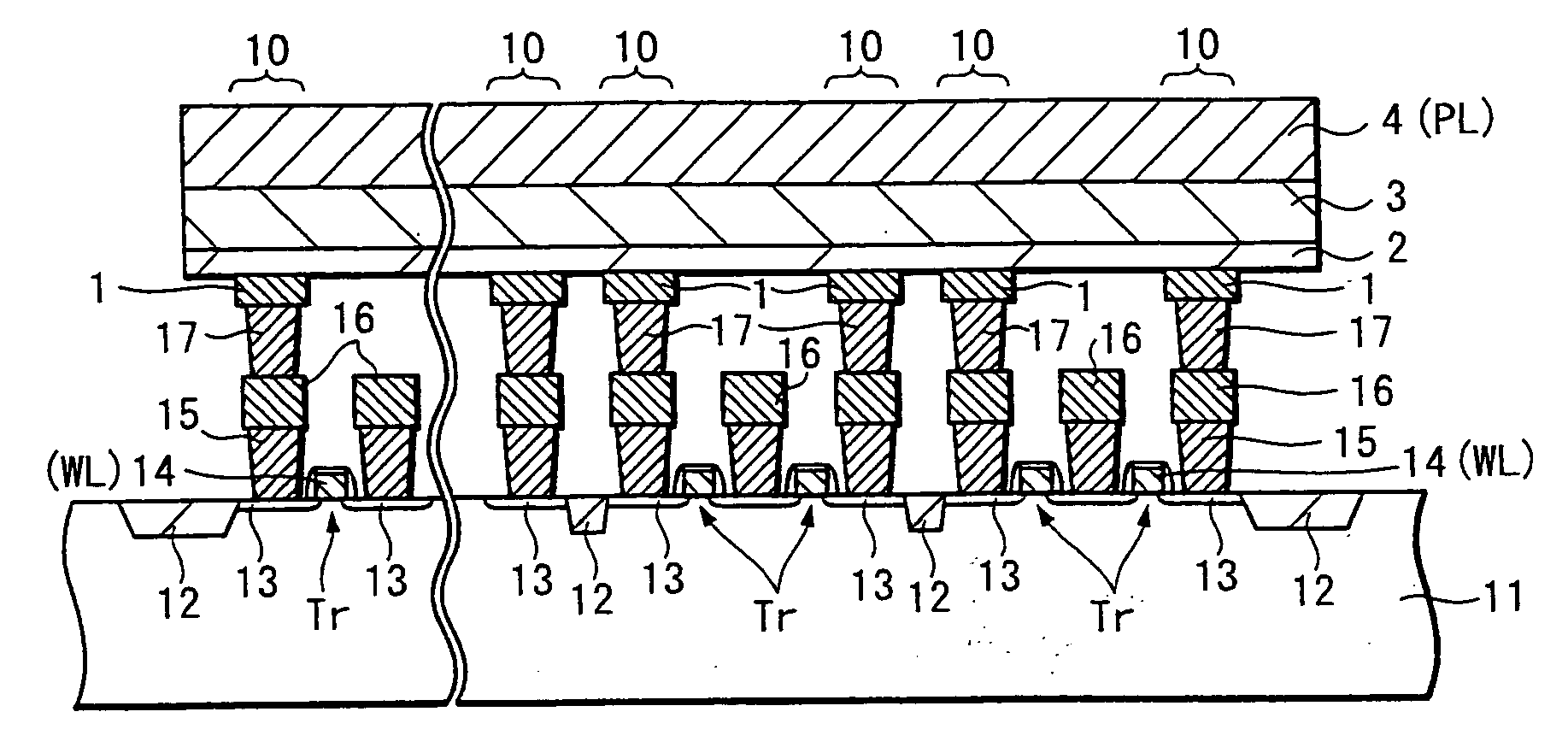

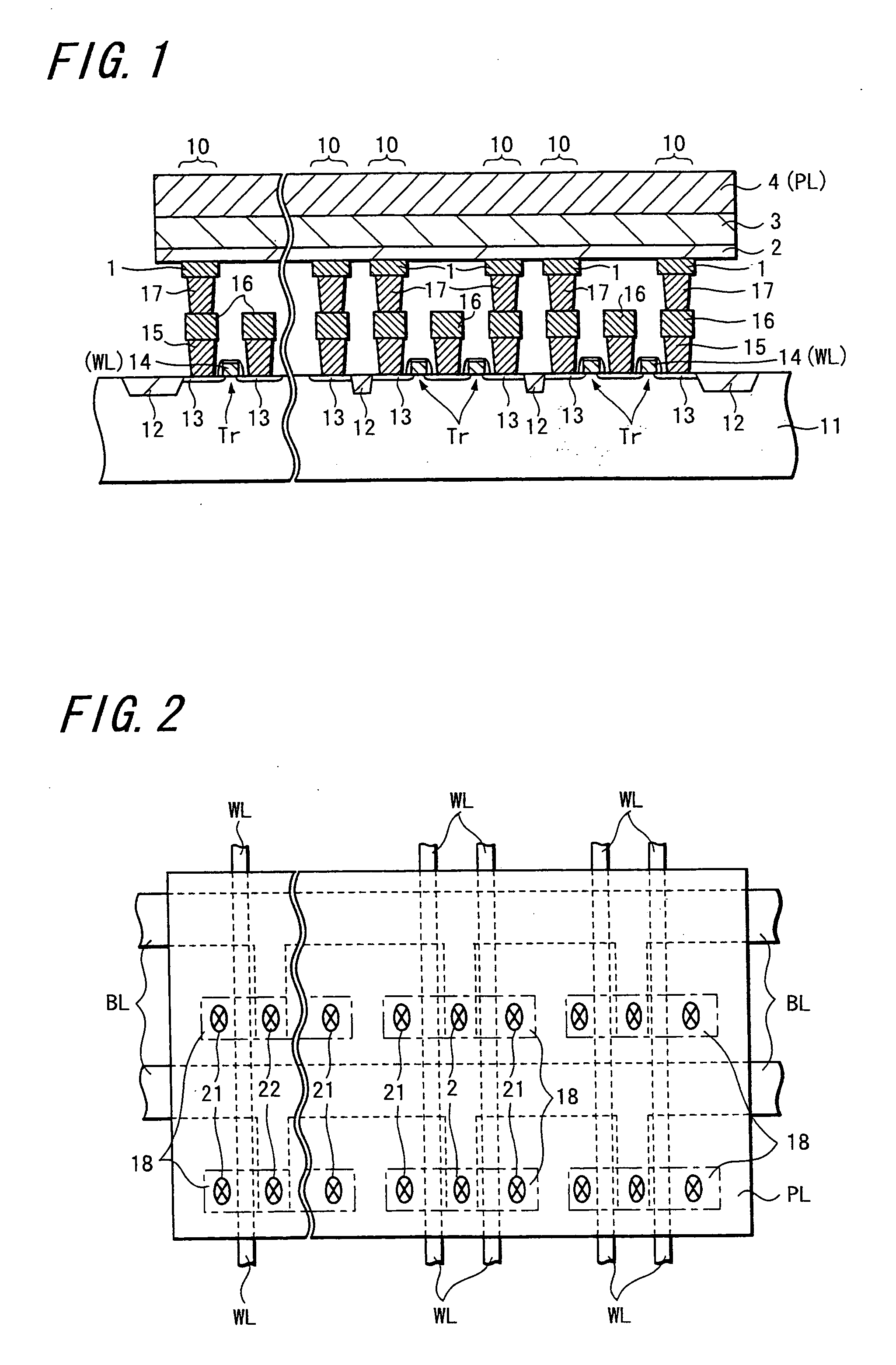

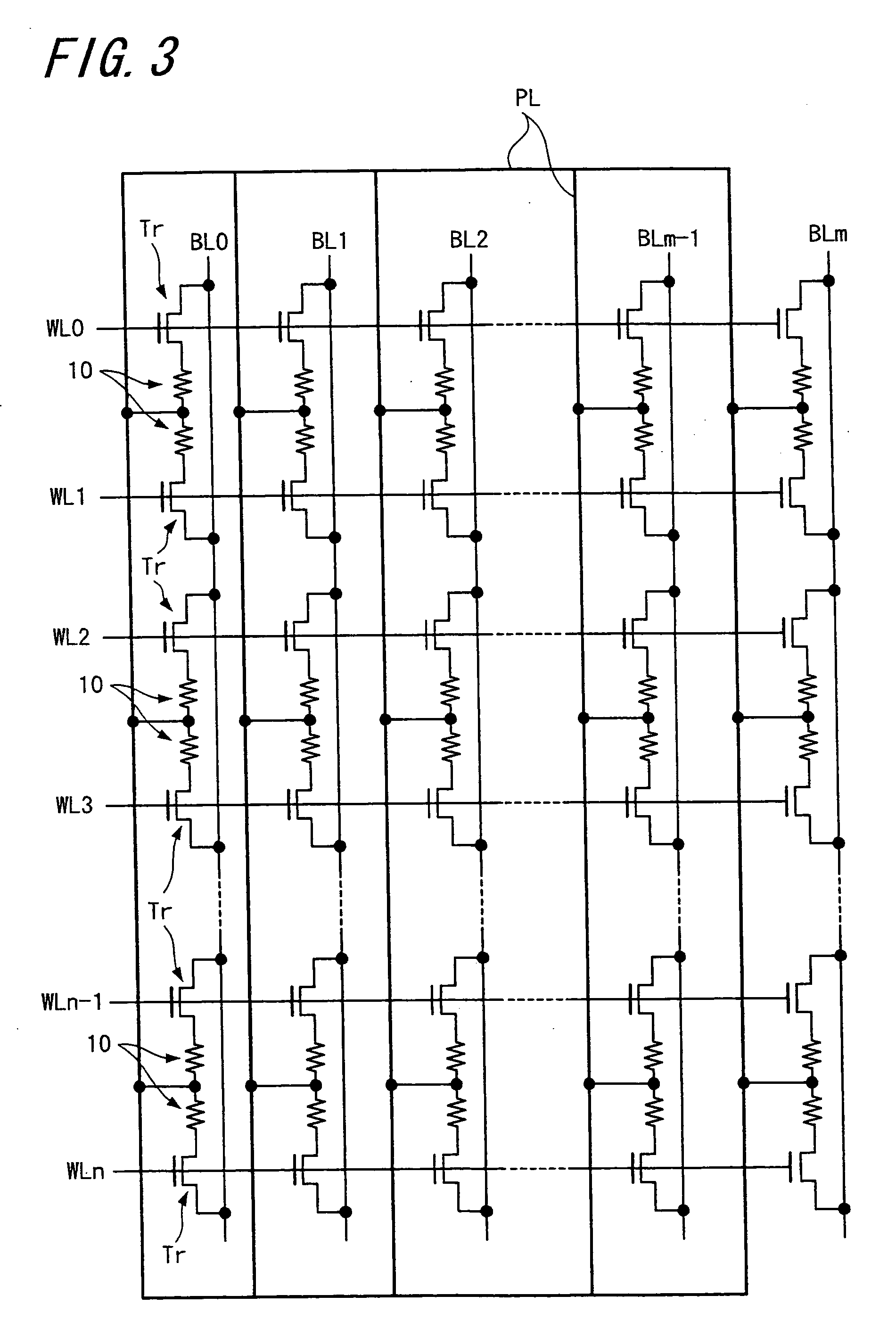

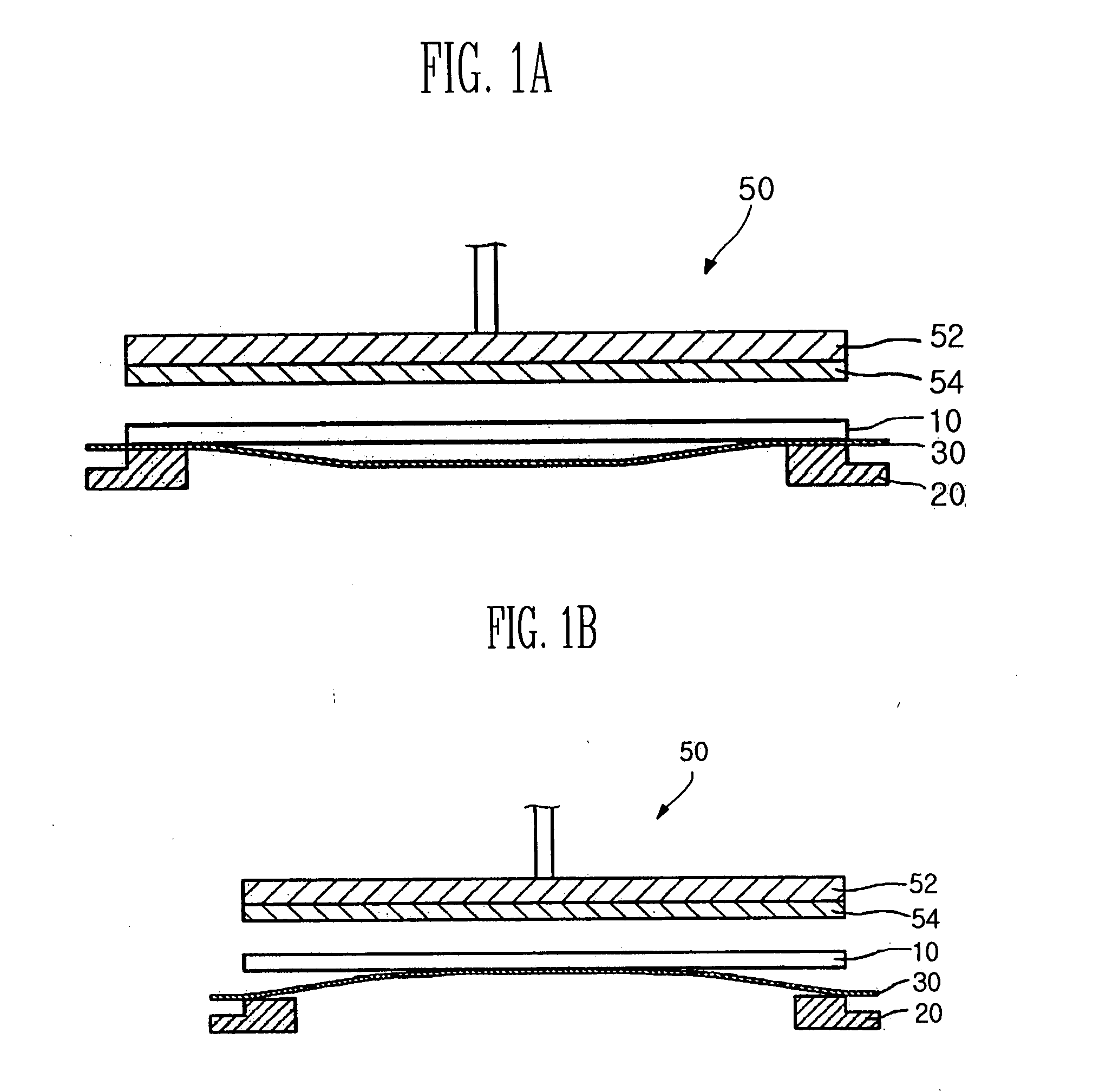

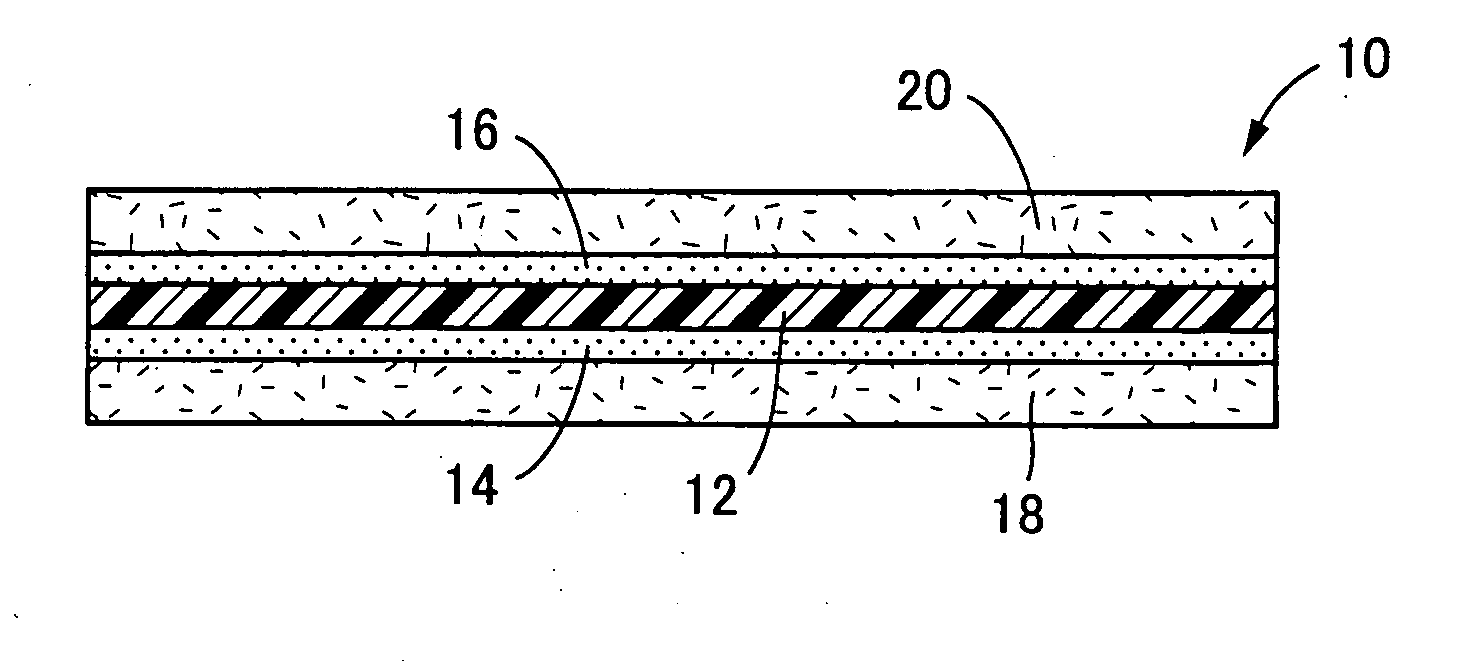

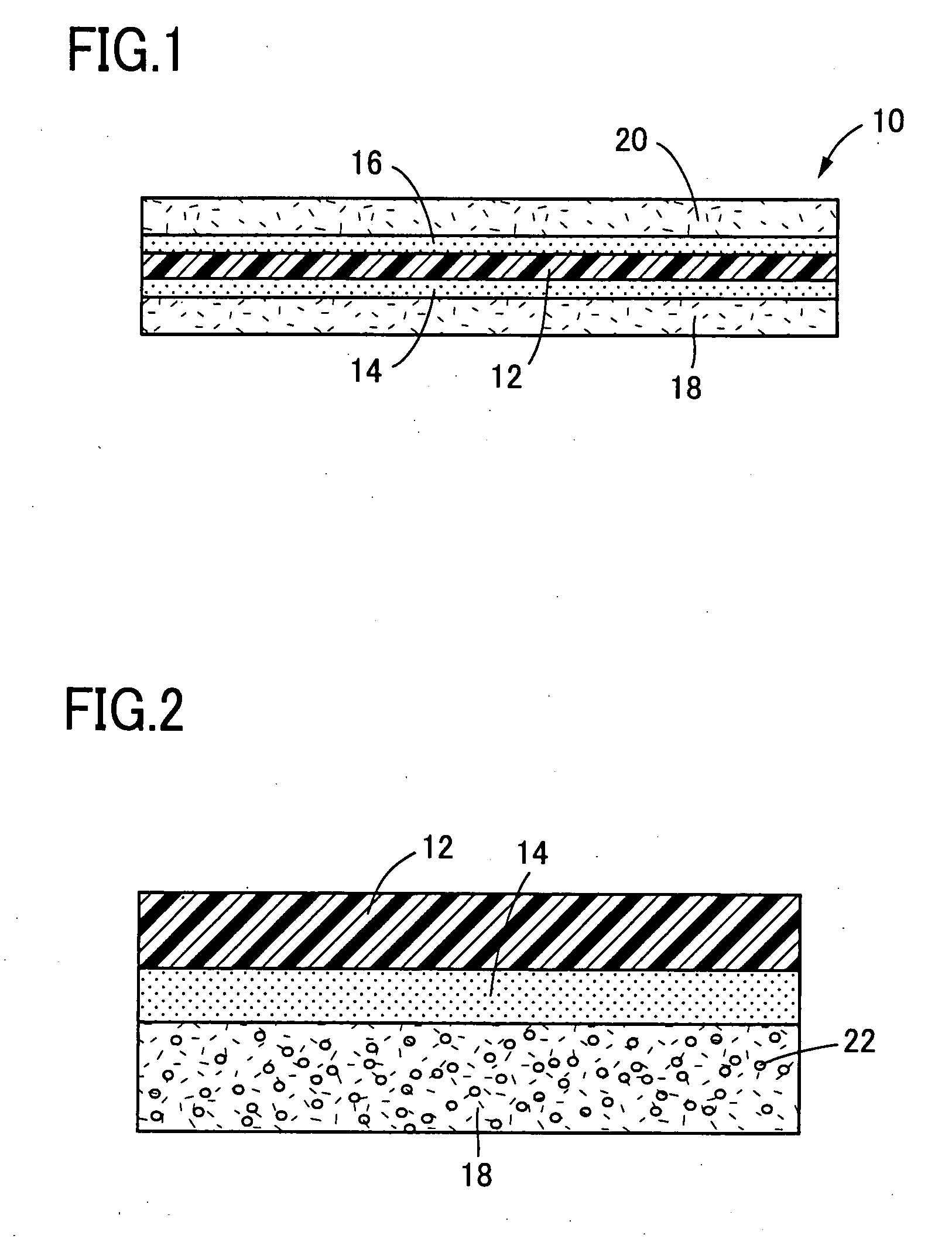

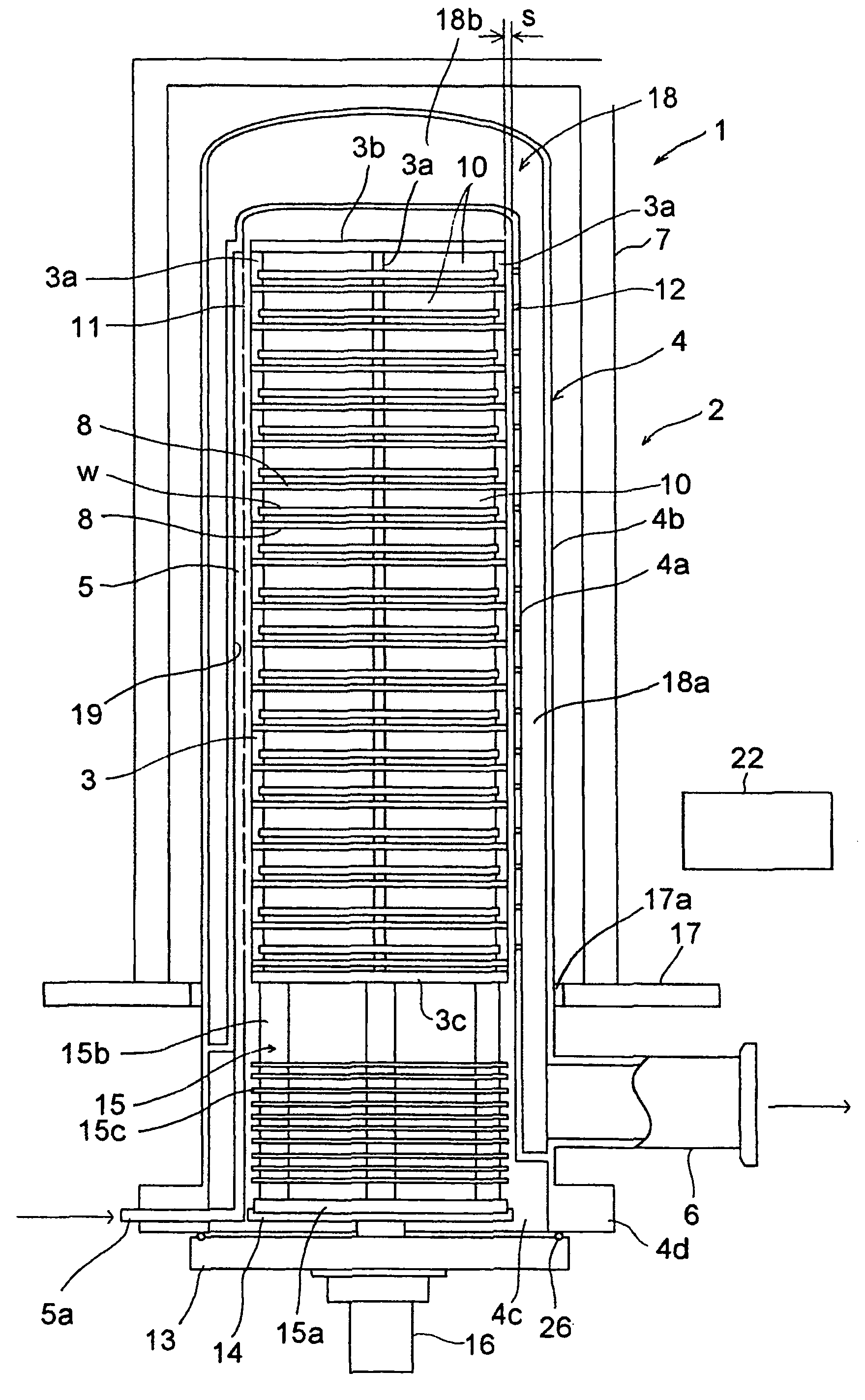

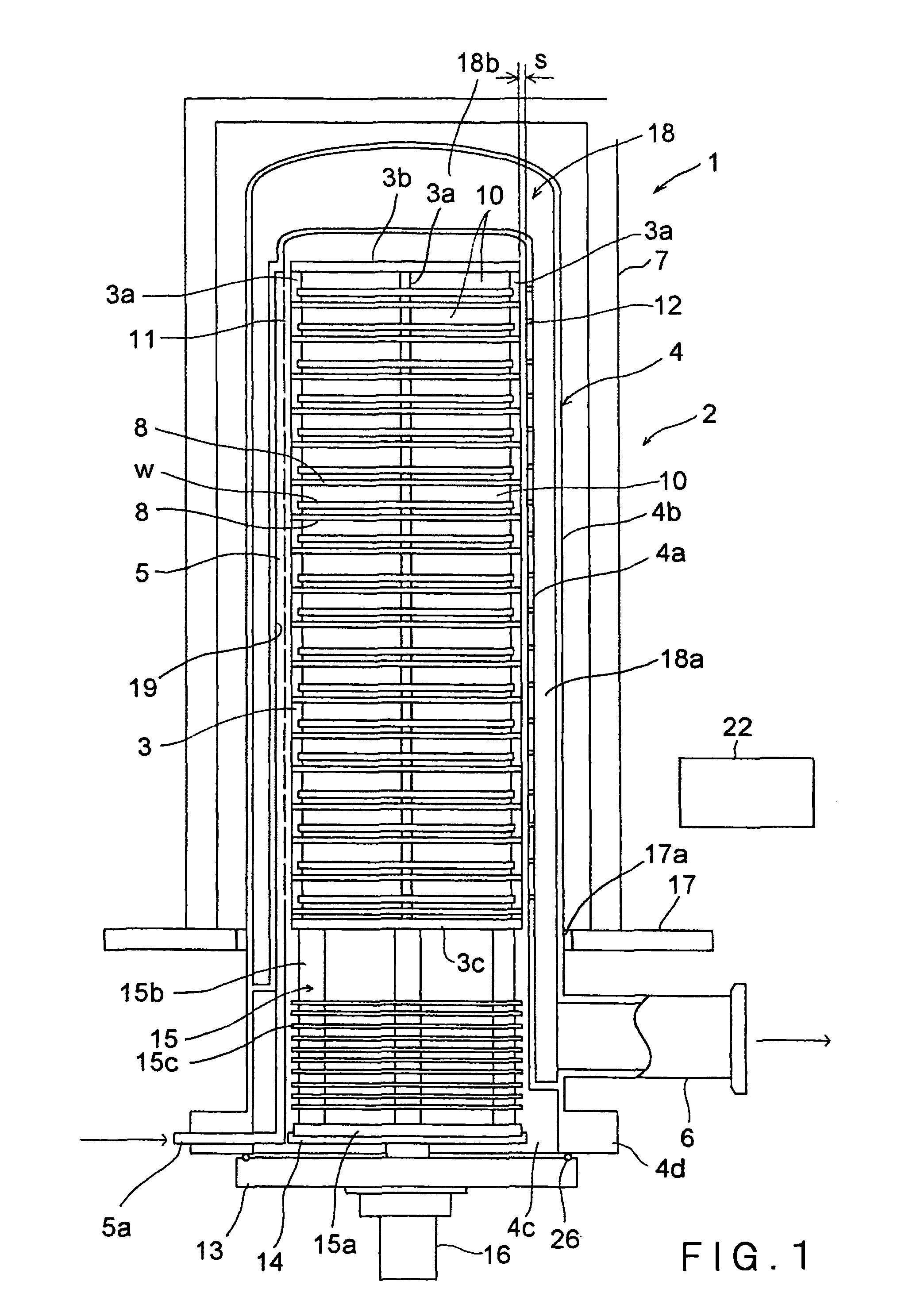

Storage Element

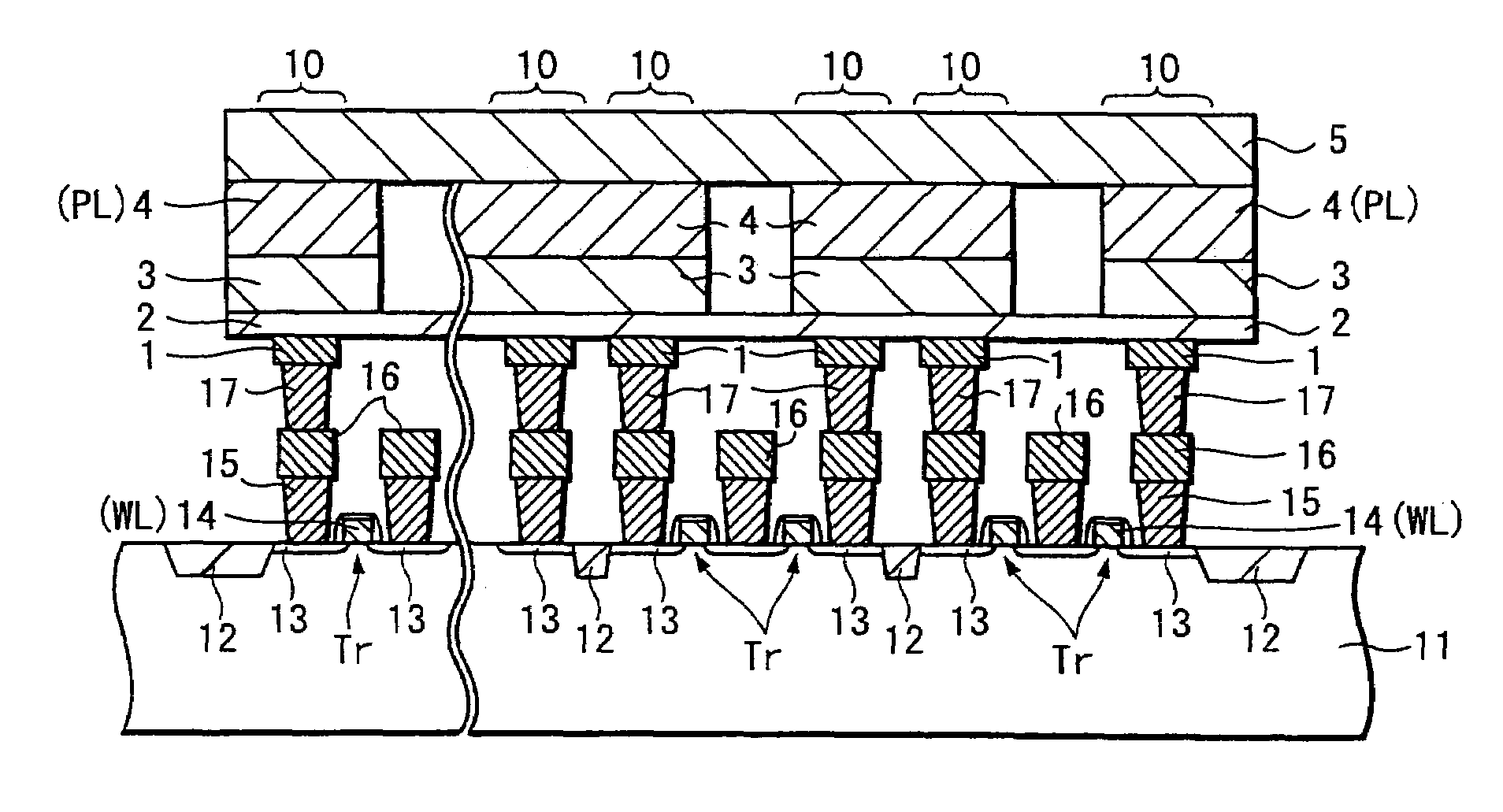

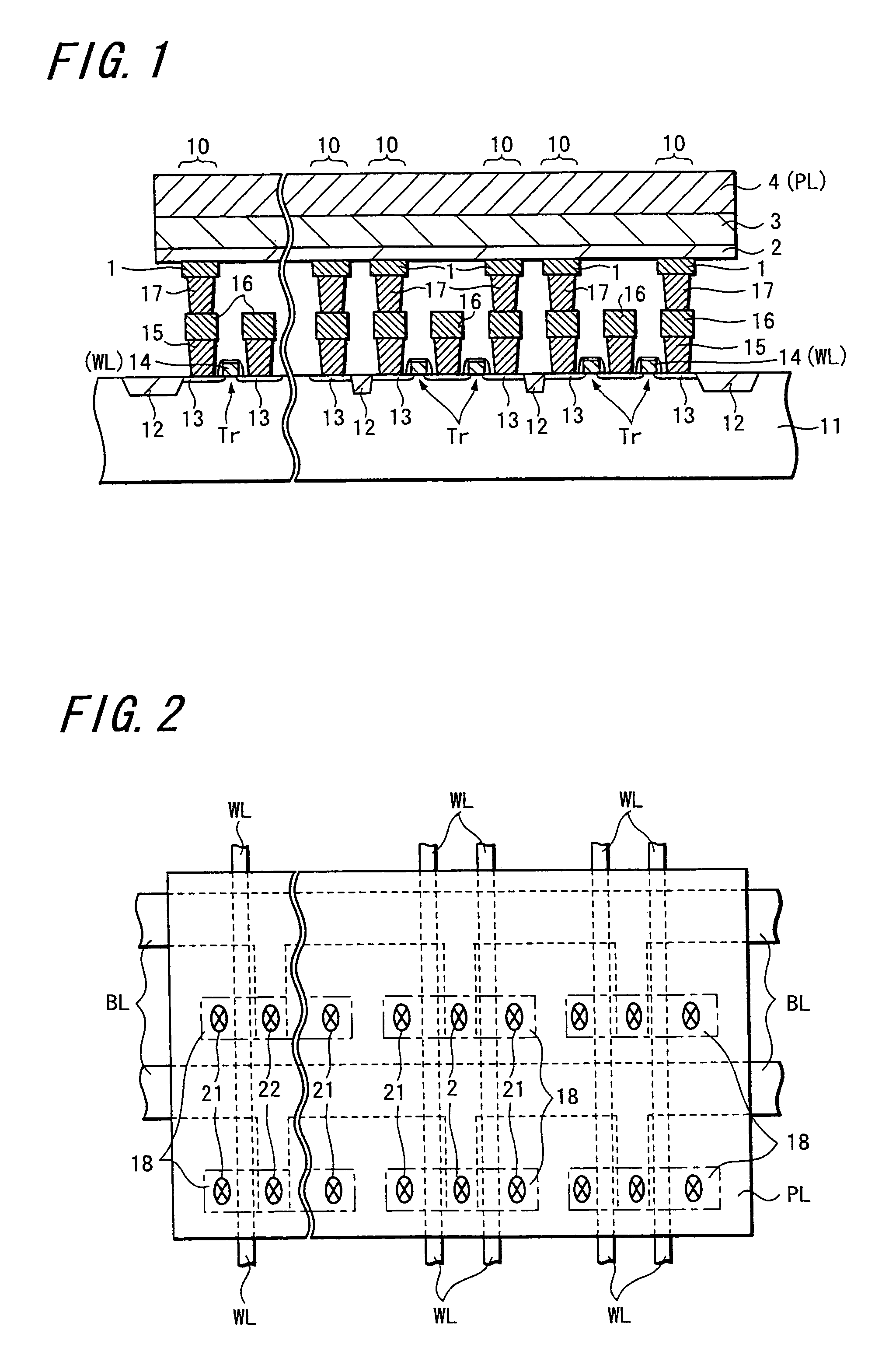

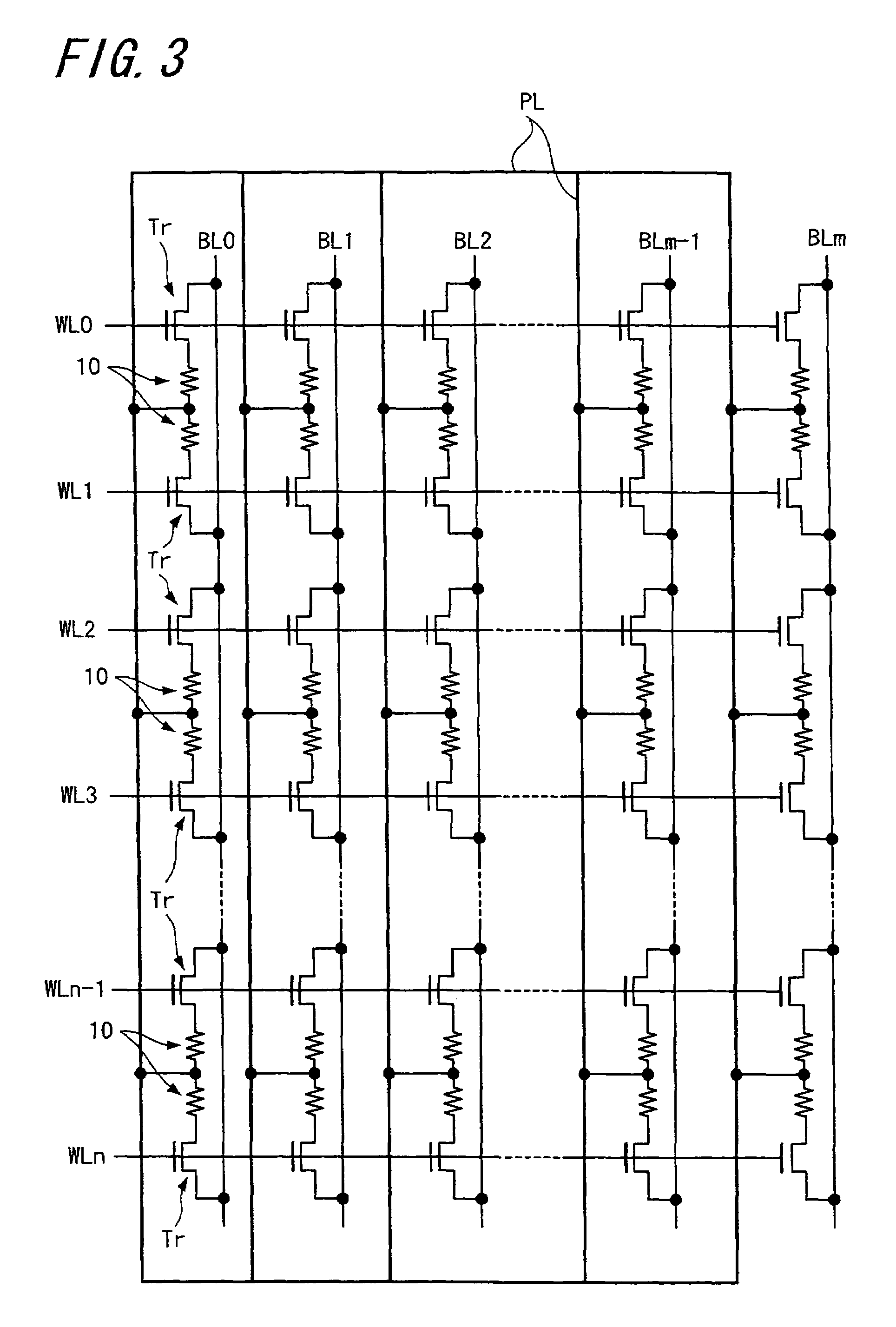

InactiveUS20080083918A1Improve accuracyEnsuring sufficient uniformitySolid-state devicesDigital storageHigh densityEngineering

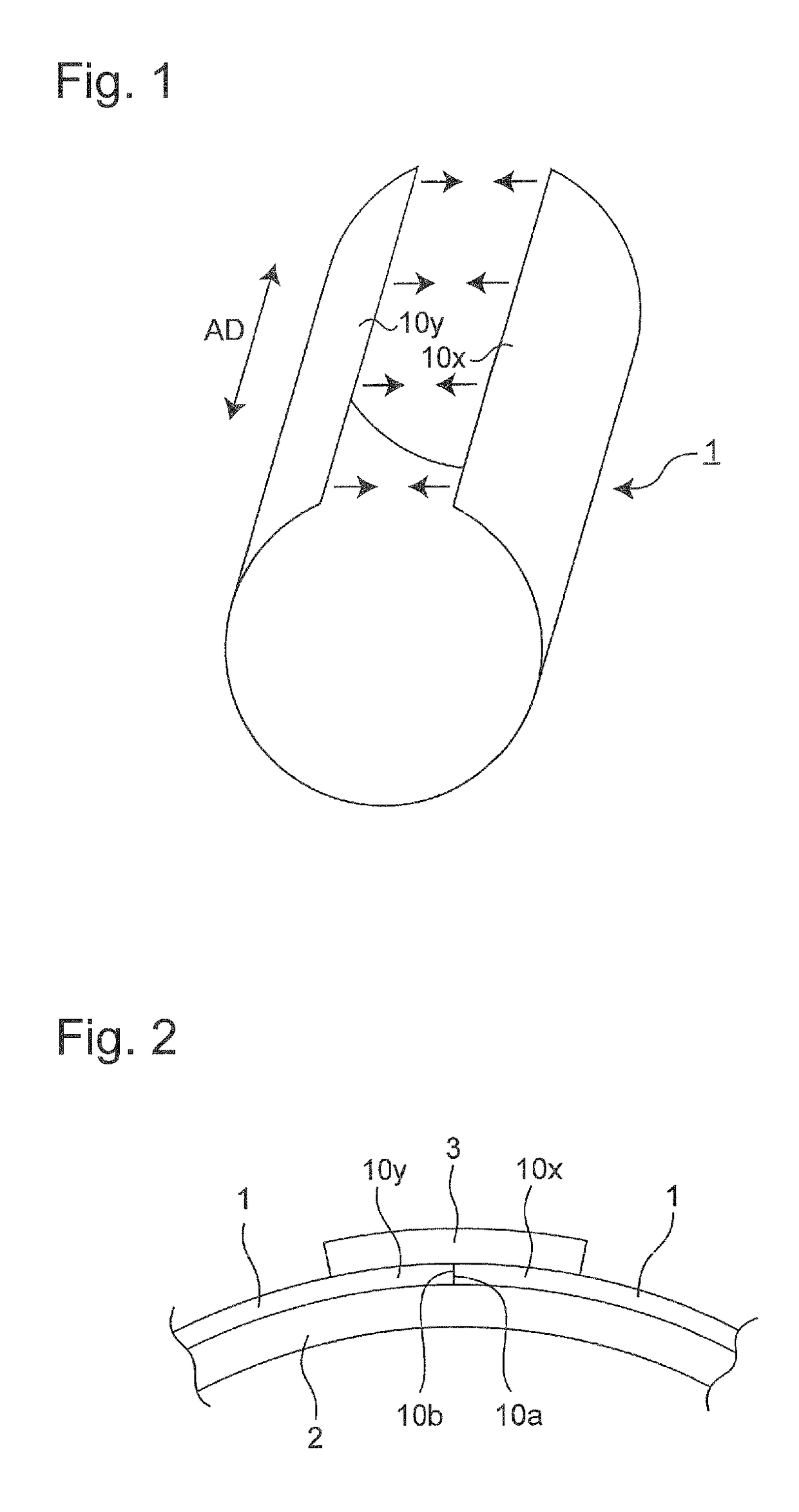

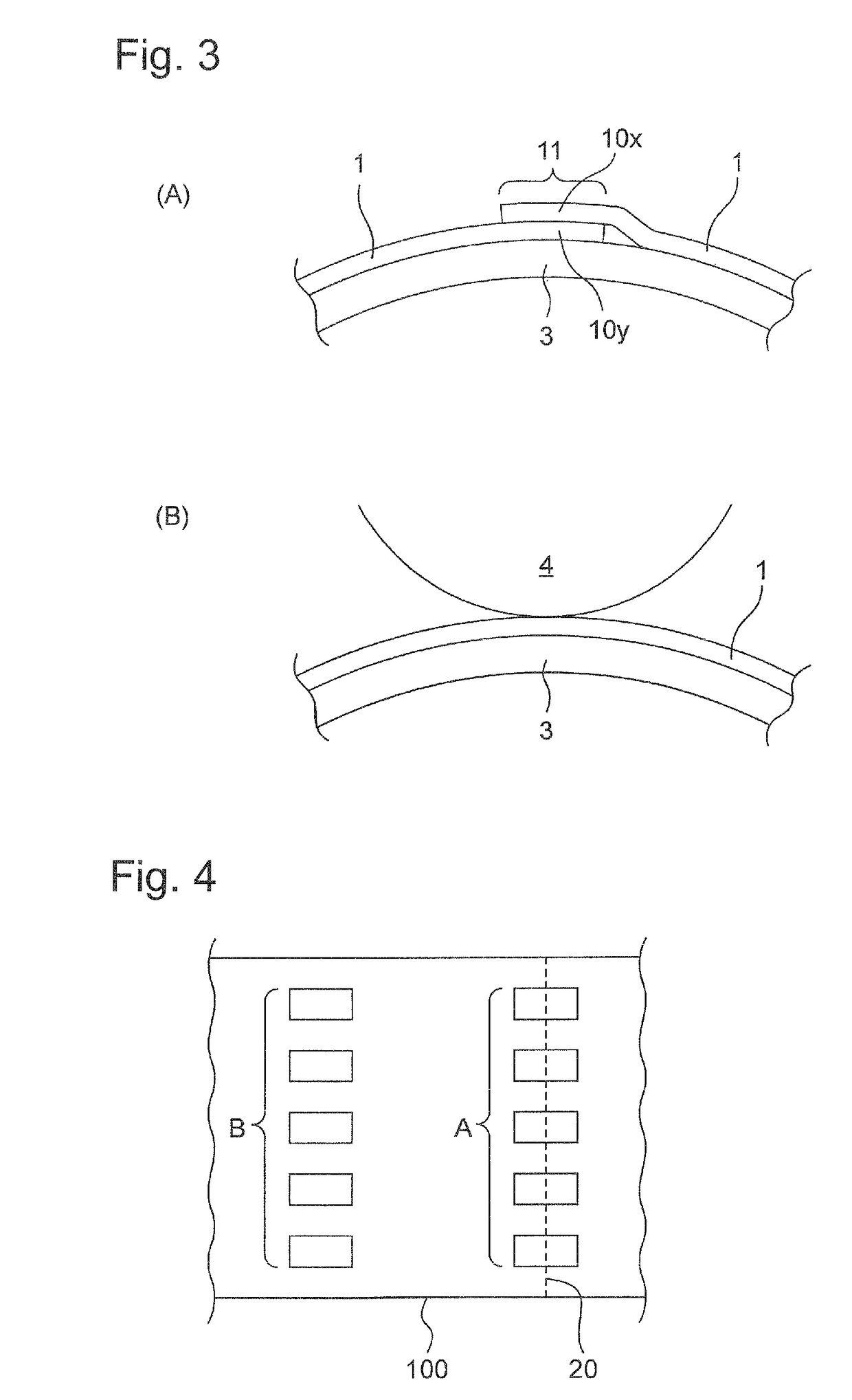

It is intended to provide a storage element having an arrangement which becomes able to be manufactured easily with high density.A storage element includes resistance changing elements 10 having recording layers 2, 3 provided between two electrodes 1, 4 and in which resistance values of the recording layers 2, 3 are reversibly changed with application of electric potential with different polarities to these two electrodes 1, 4, at least part of the layers 2, 3 constructing the recording layers of the resistance changing elements 10 being formed commonly by the same layer in a plurality of adjacent memory cells.

Owner:SONY CORP

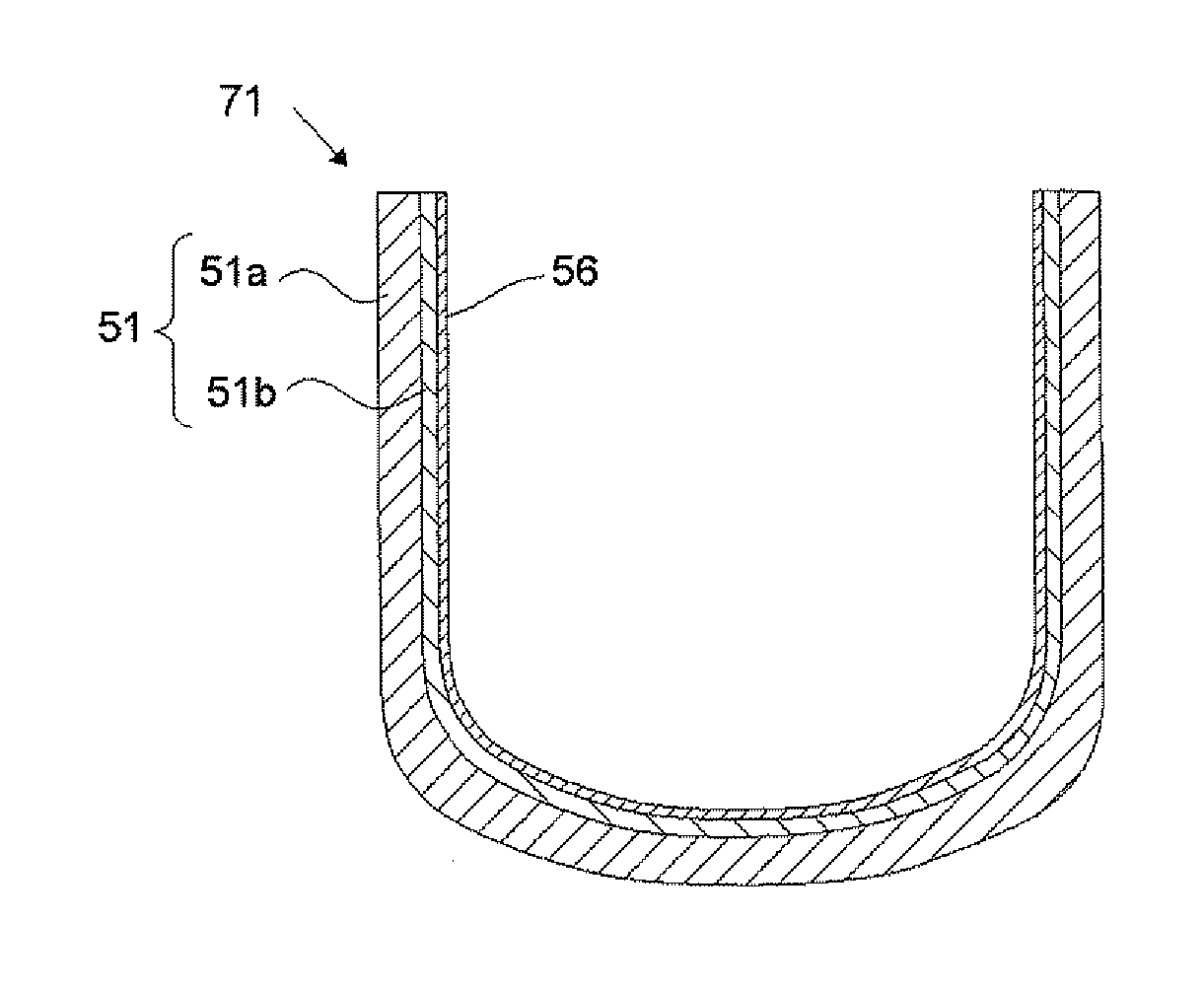

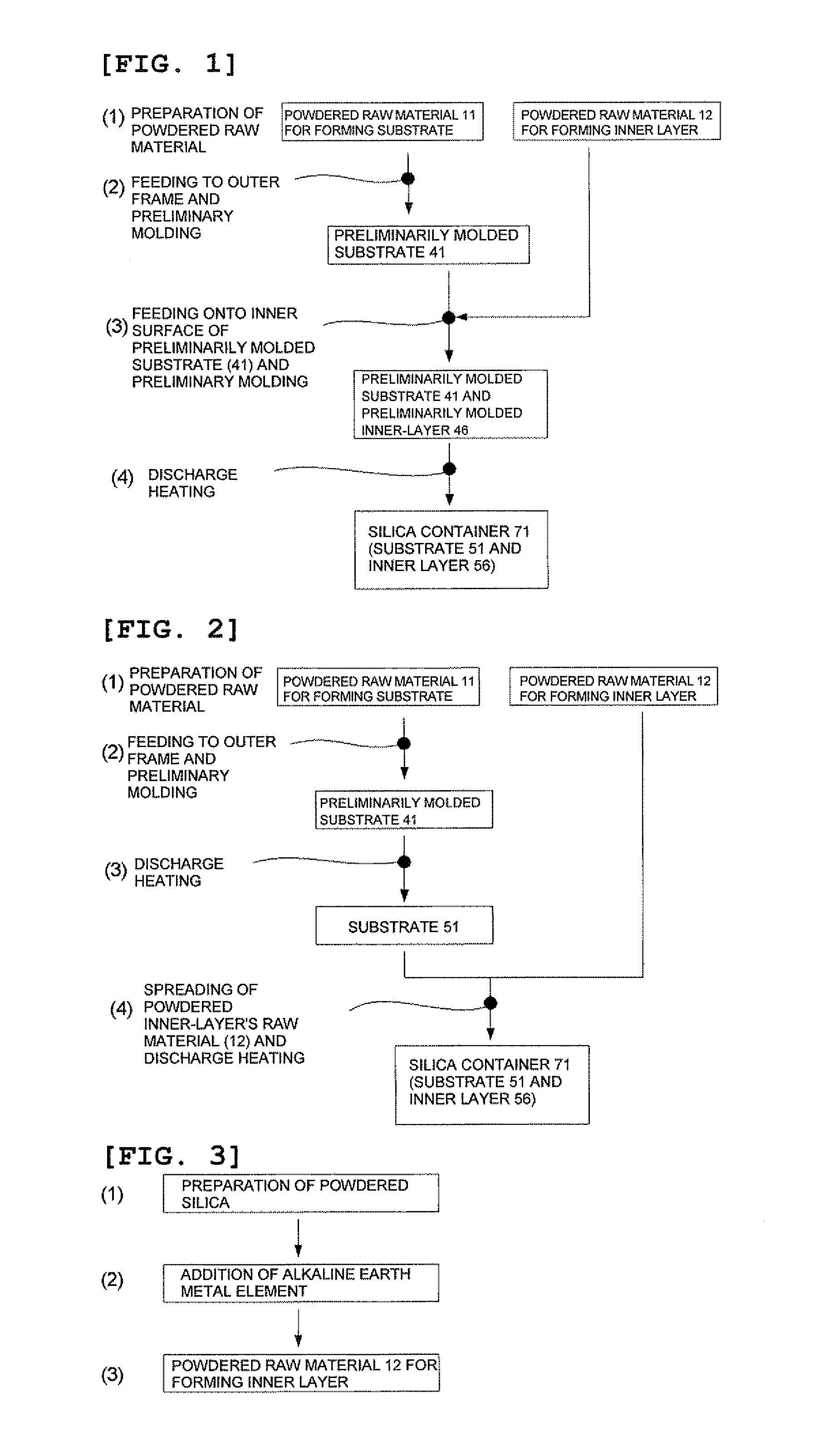

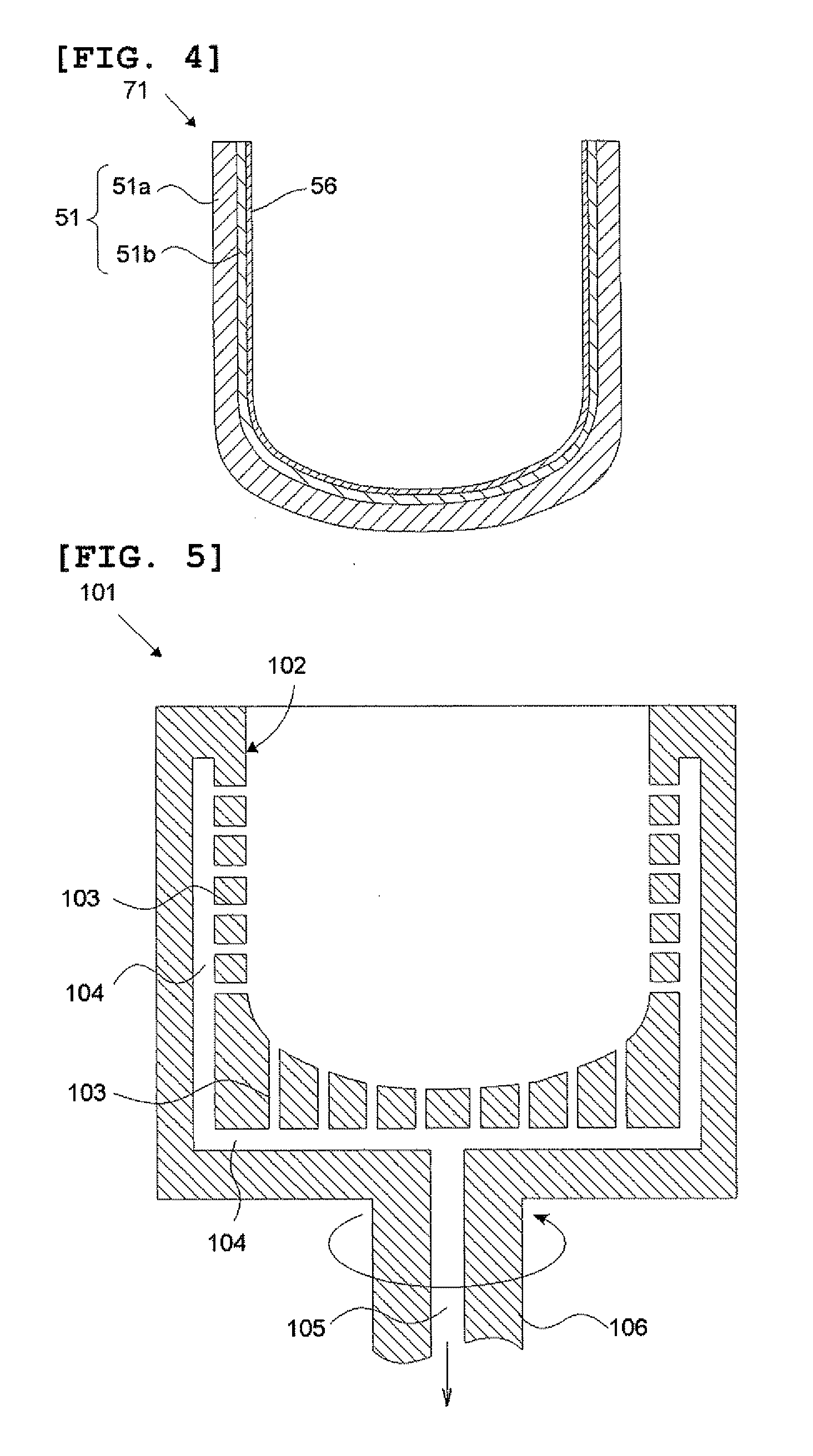

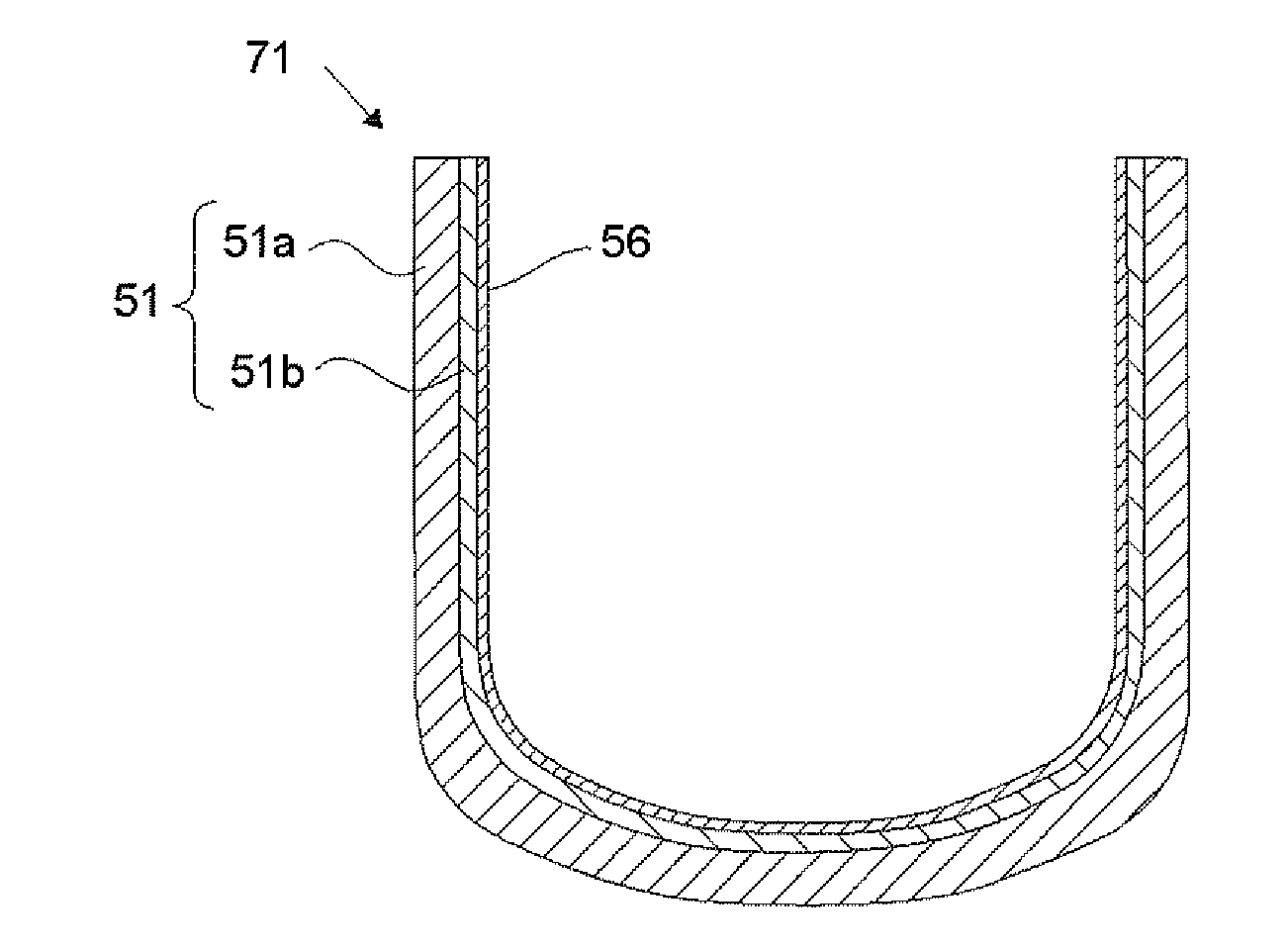

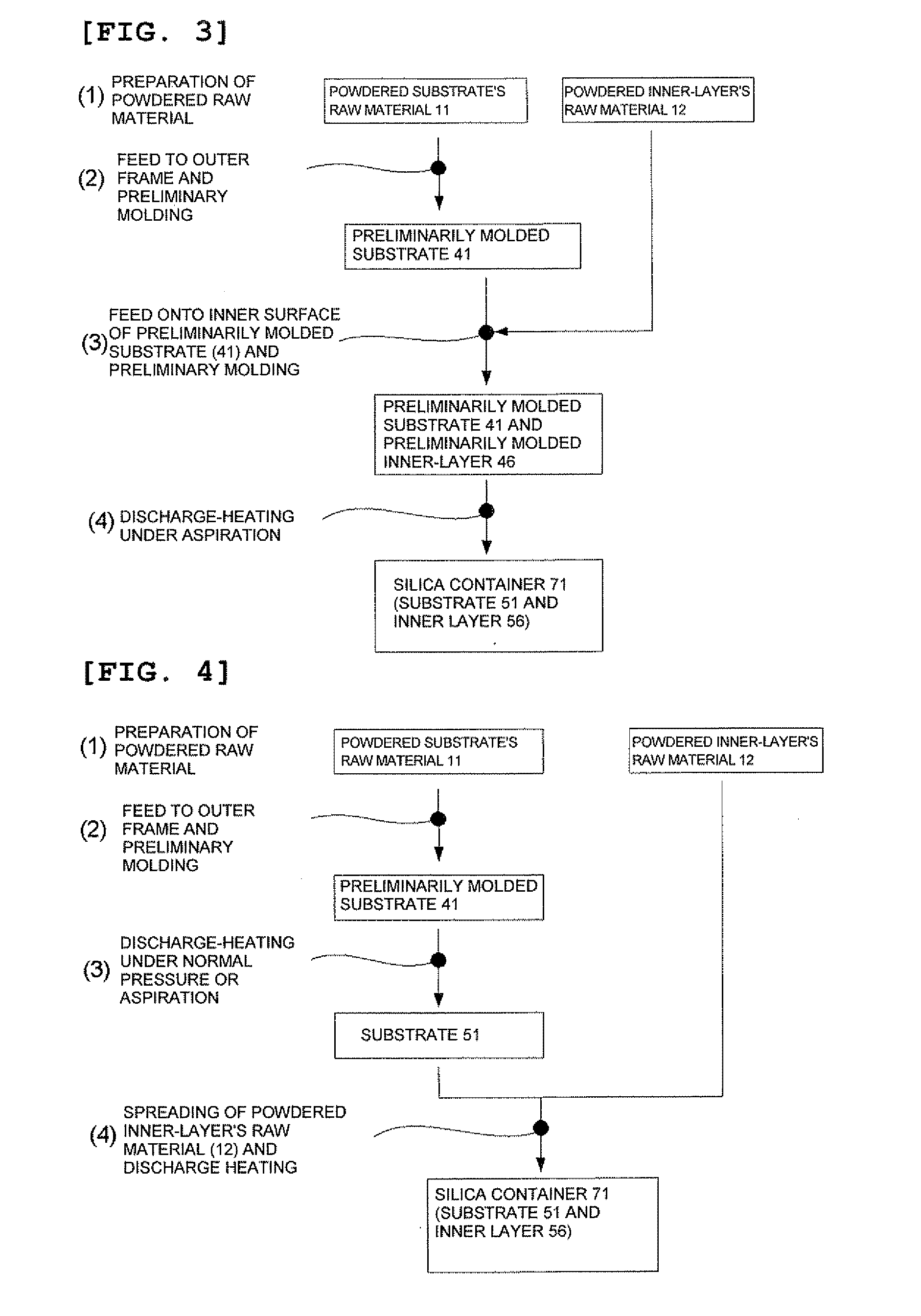

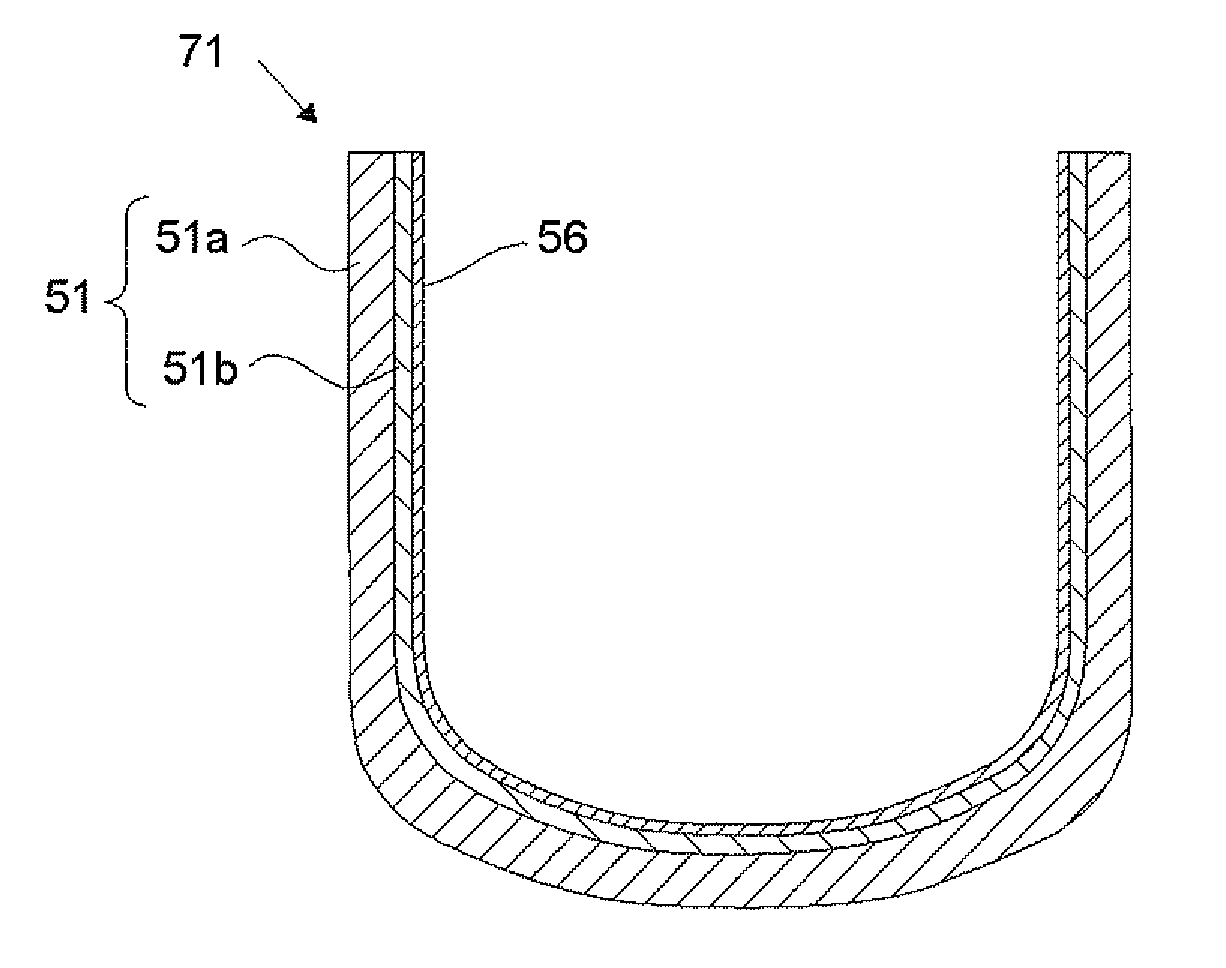

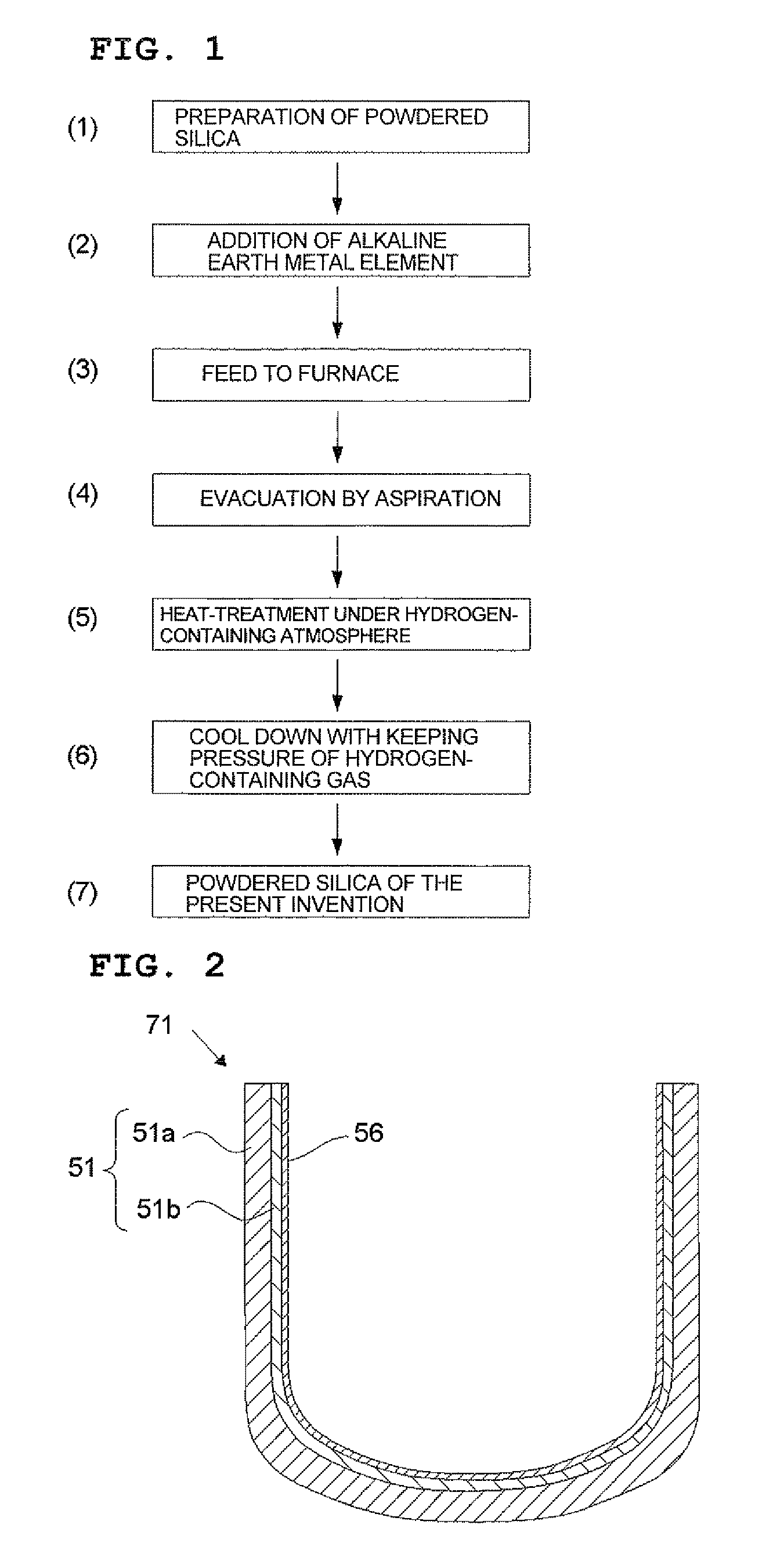

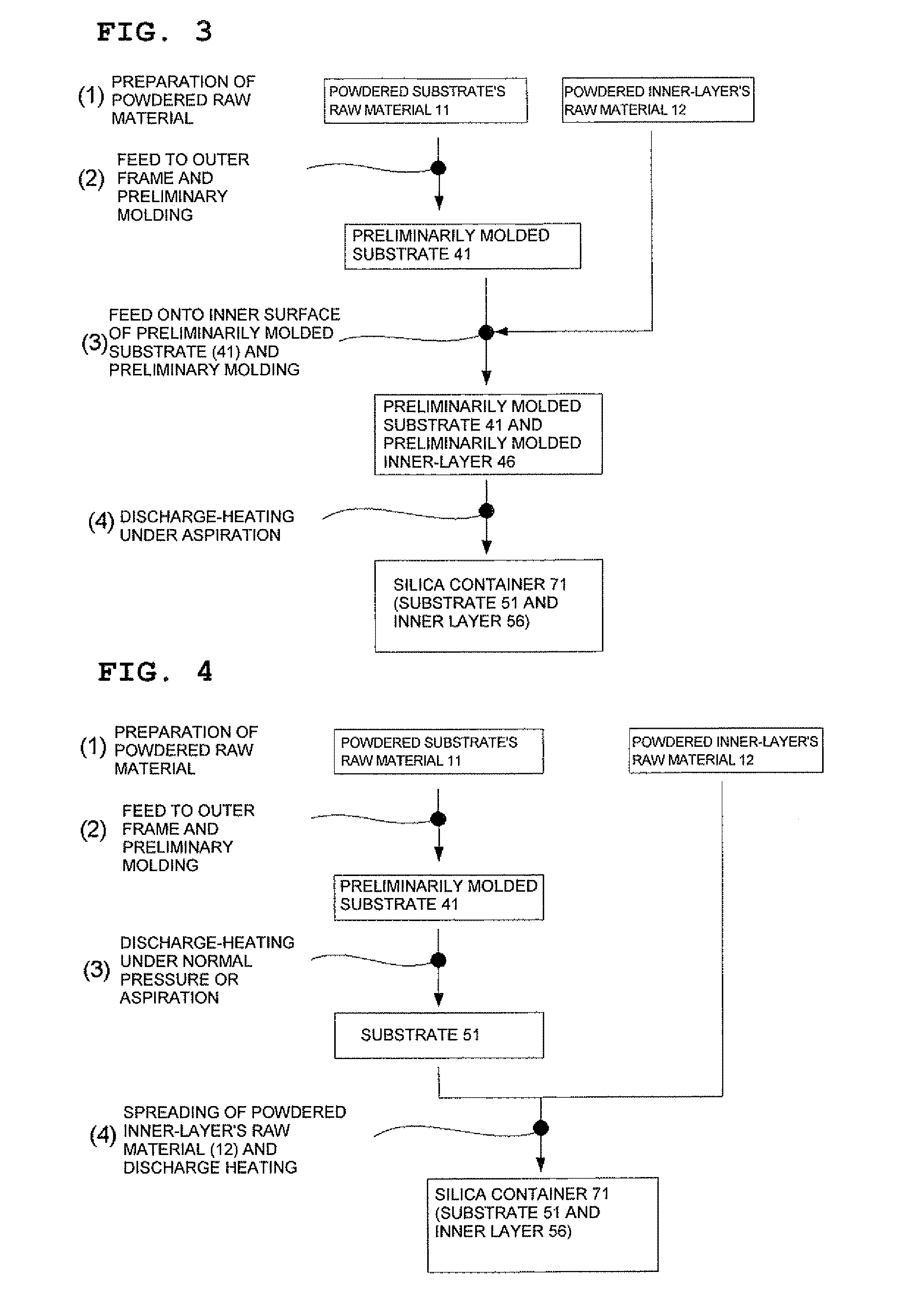

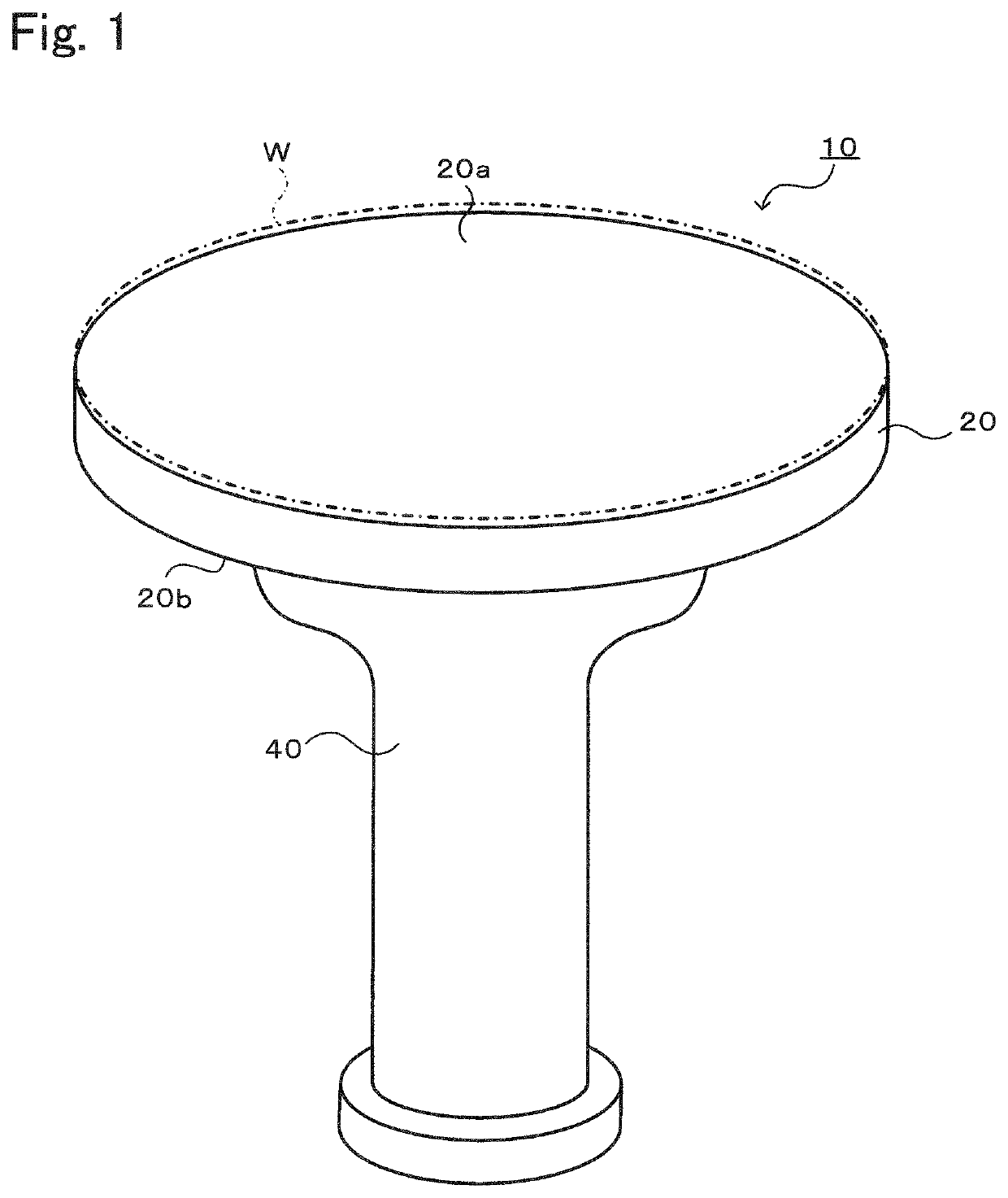

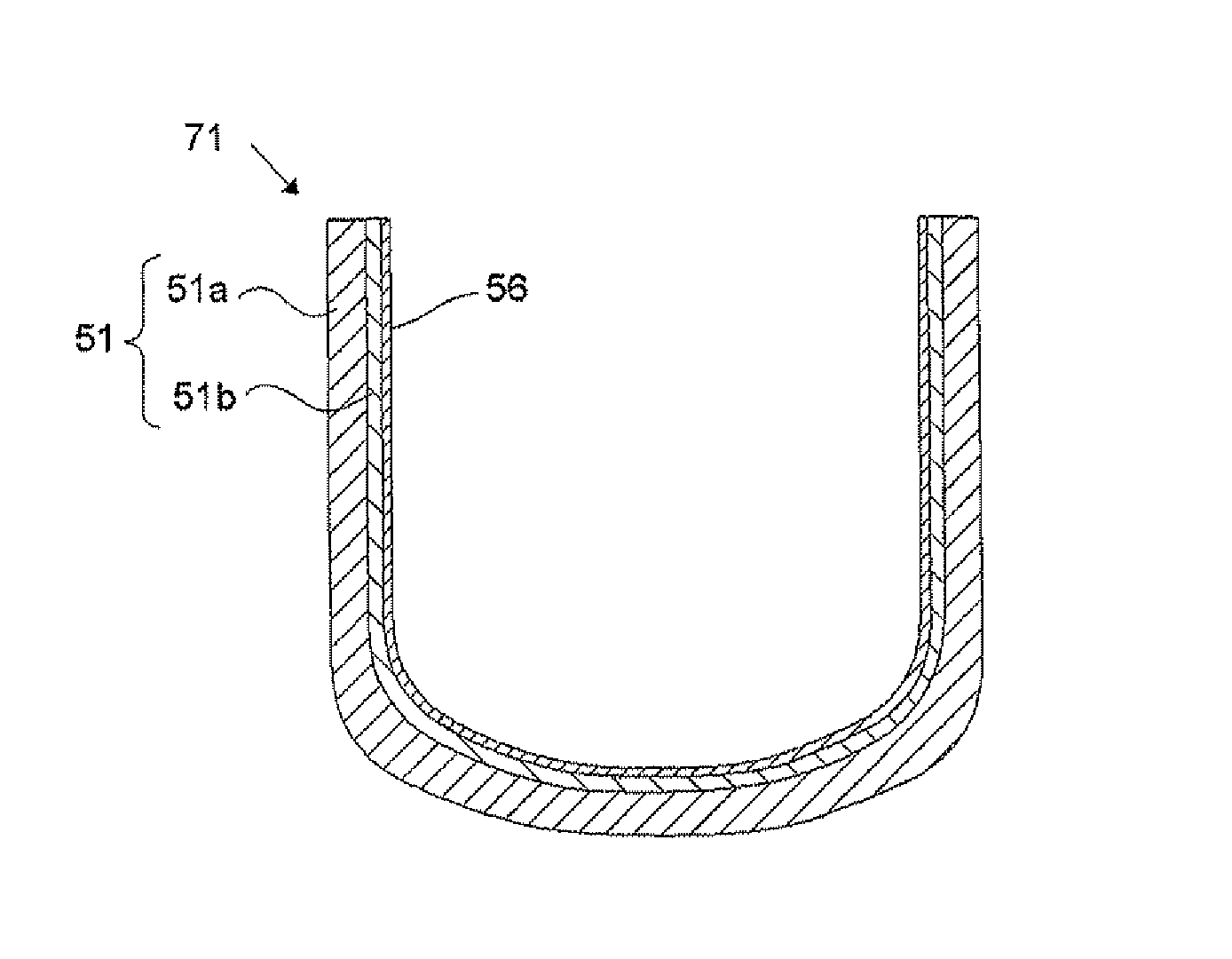

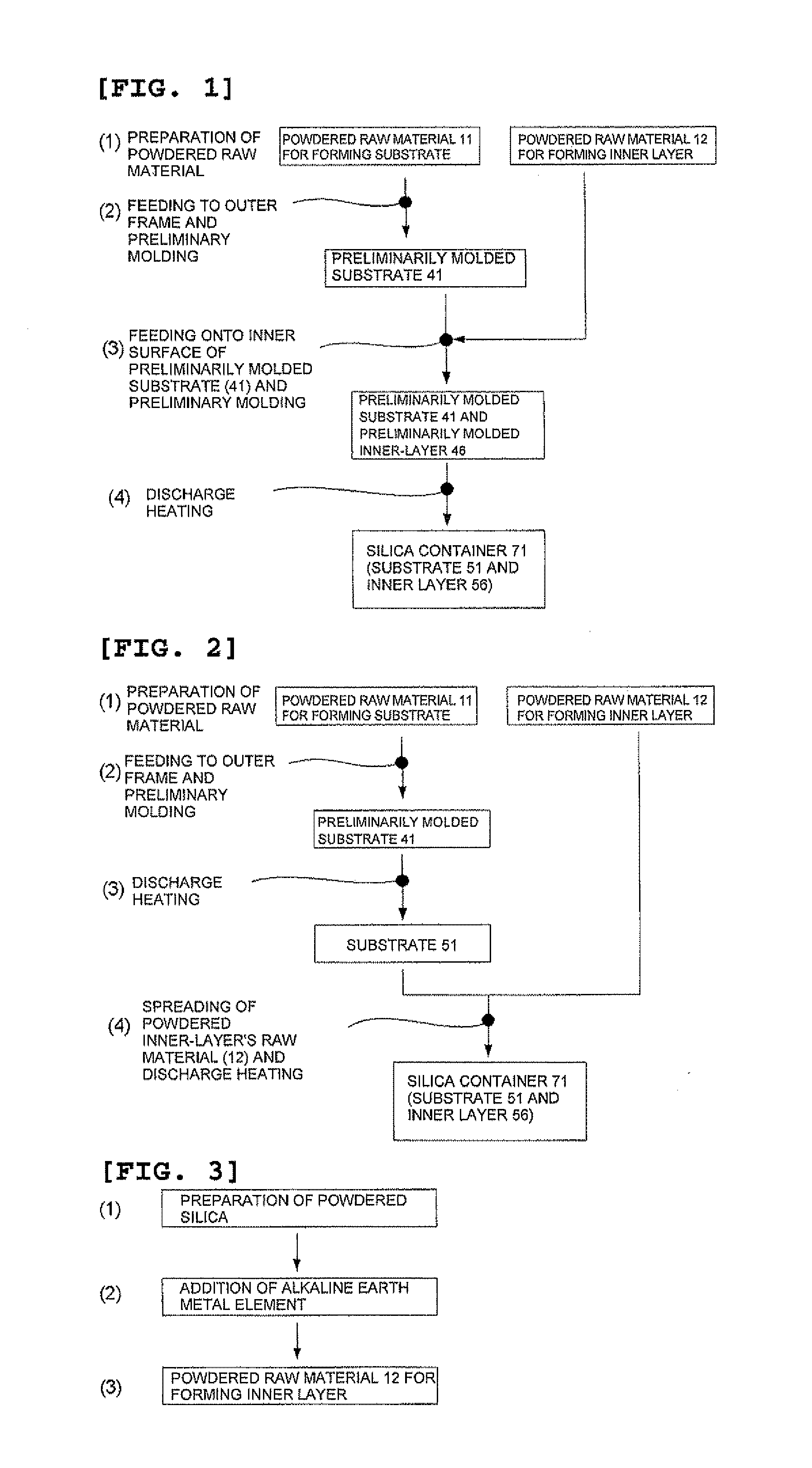

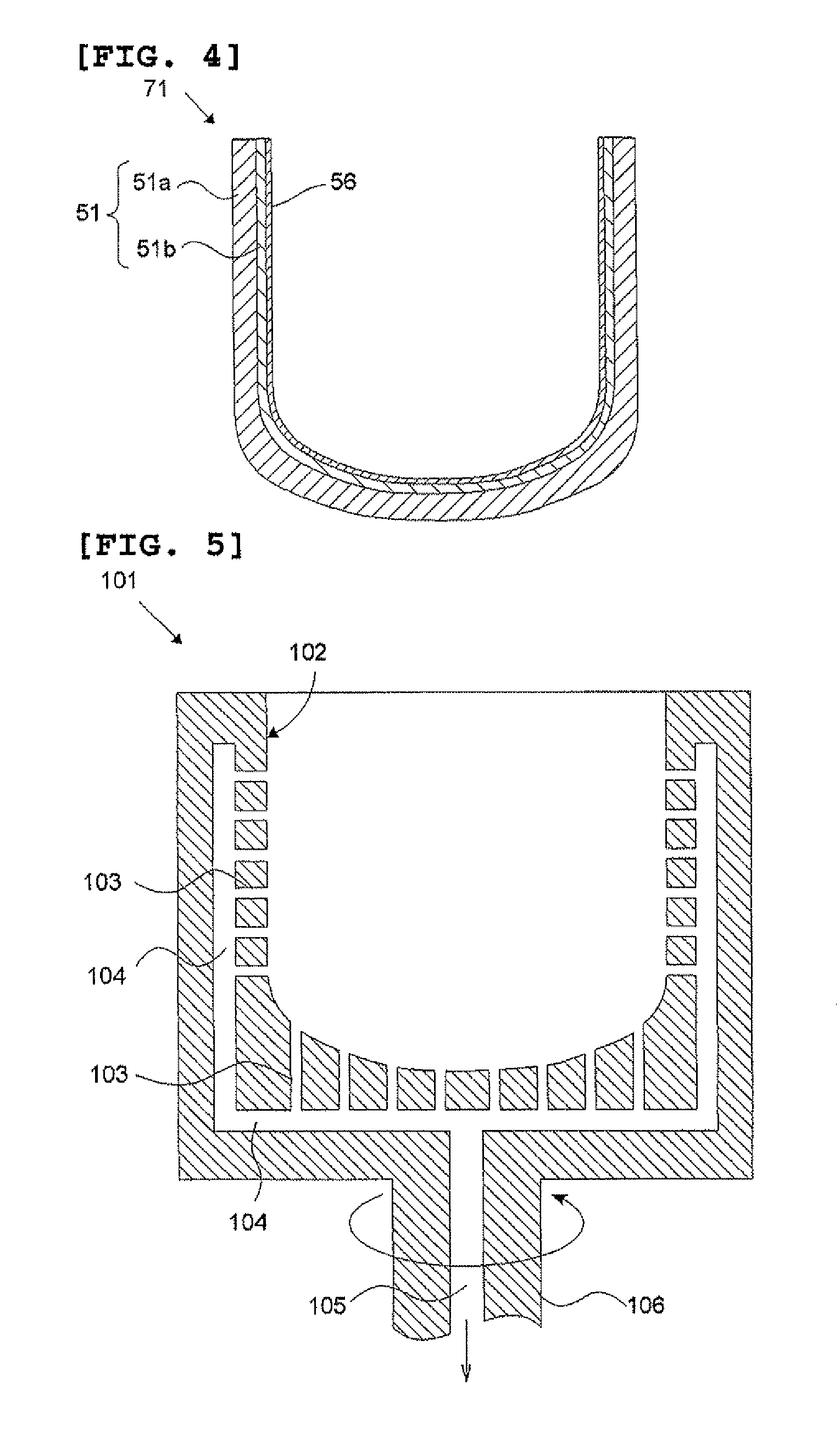

Silica container and method for producing the same

InactiveUS20110272322A1Increased durabilitySuppress generationAfter-treatment apparatusPolycrystalline material growthHydrogenFused glass

The present invention is a method for producing a silica container having a substrate containing gaseous bubbles in its outer peripheral part and an inner layer comprised of a transparent silica glass formed on an inner surface of the substrate, wherein a powdered raw material for forming a substrate containing Li, Na, and K with the total concentration of 50 or less ppm by weight and a powdered raw material for forming an inner layer containing Ca, Sr, and Ba with the total concentration of 50 to 2000 ppm by weight are prepared; a preliminarily molded substrate is formed in a frame; a preliminarily molded inner layer is formed on an inner surface of the preliminarily molded substrate; and the preliminarily molded substrate and molded inner layer are heated from inside thereof by a discharge-heat melting method under a gas atmosphere containing a hydrogen gas or a helium gas or a gas mixture thereof with the ratio of more than 10% by volume thereby making an outer peripheral part of the preliminarily molded substrate to a sintered body and an inner peripheral part of the preliminarily molded substrate and the preliminarily molded inner layer to a fused glass body. With this, a method for producing a silica container, producible with a low cost and having a high durability and dimensional precision, and a container of this sort can be provided.

Owner:SHIN ETABU QUARTZ PRODS

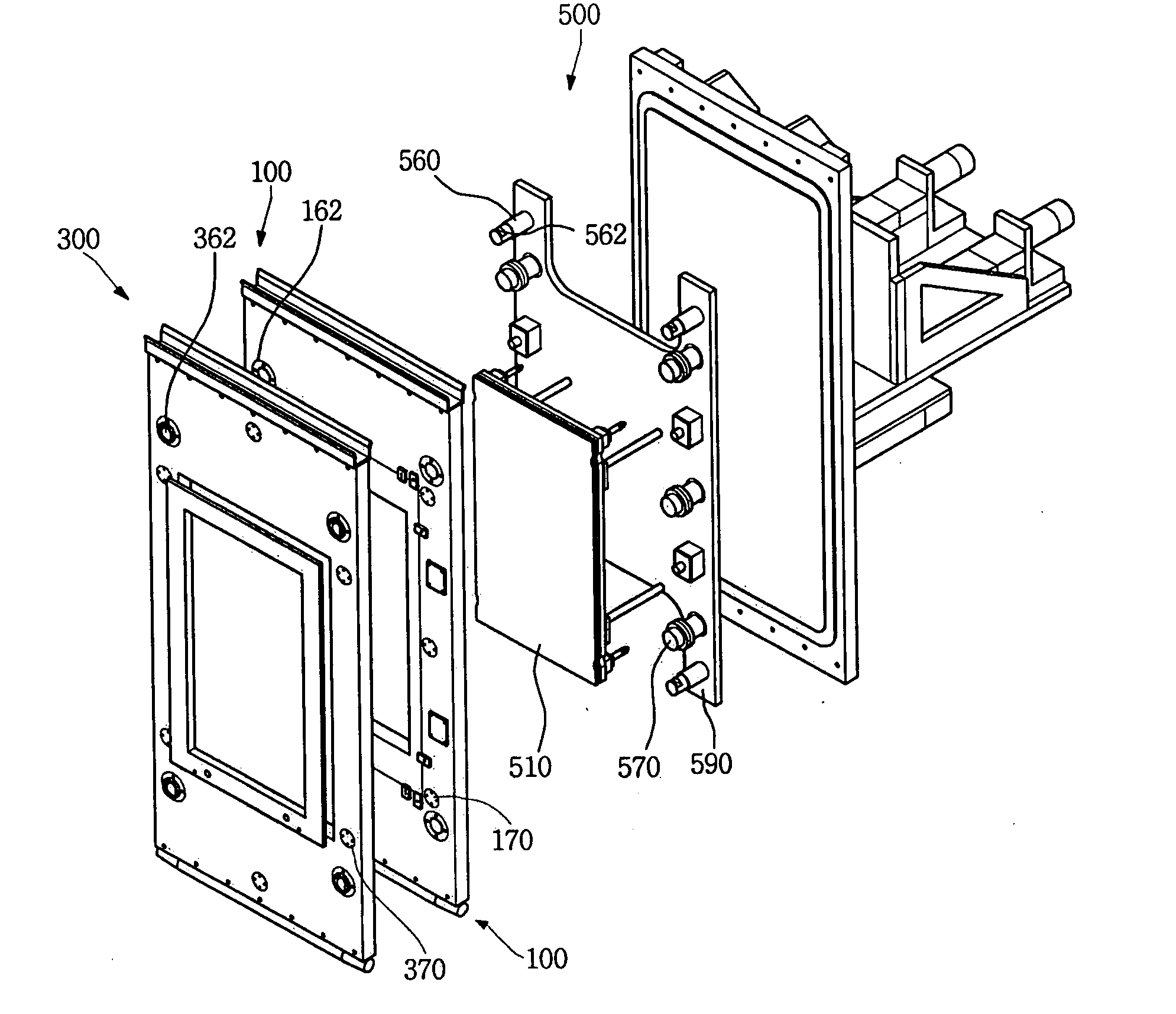

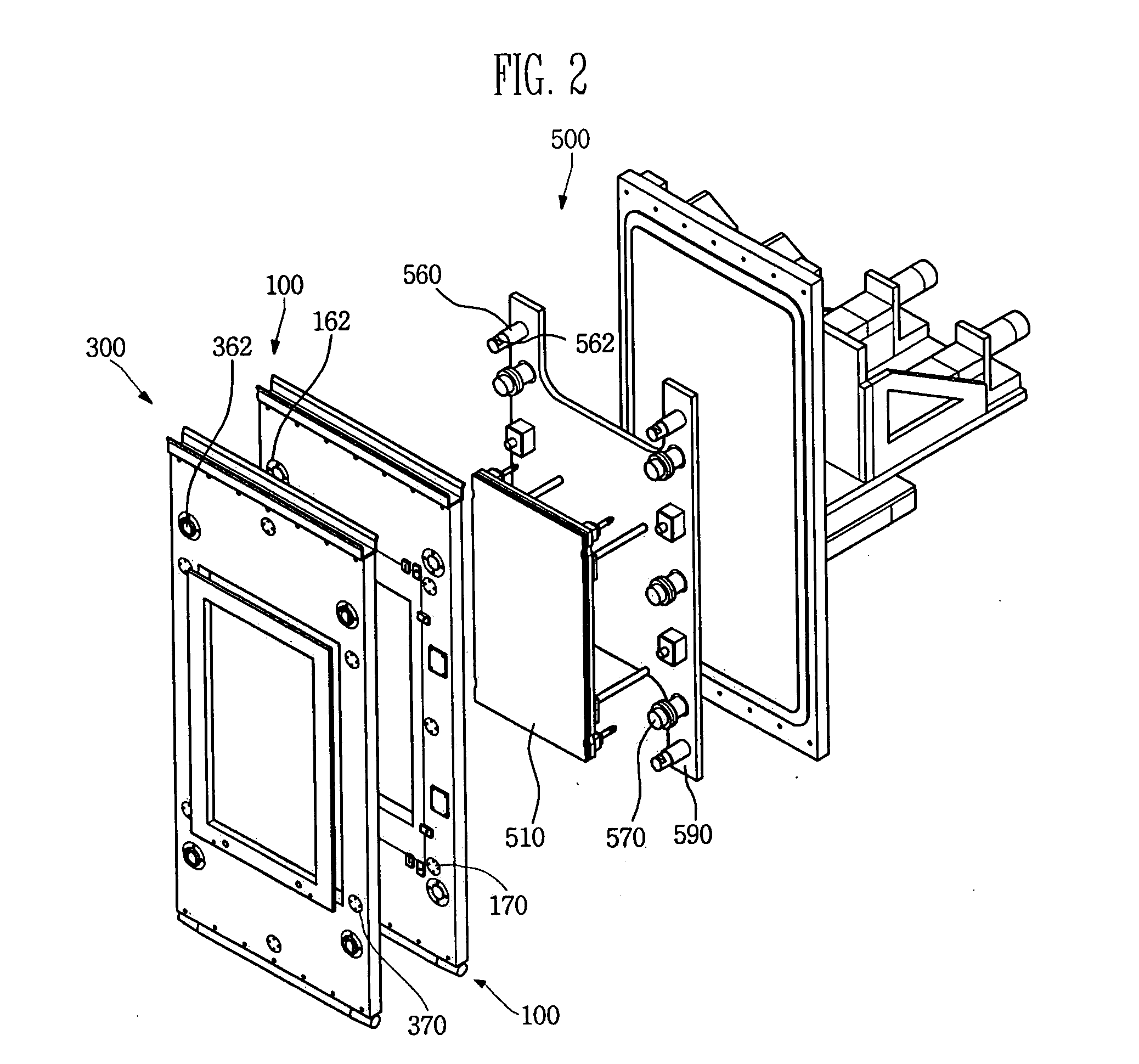

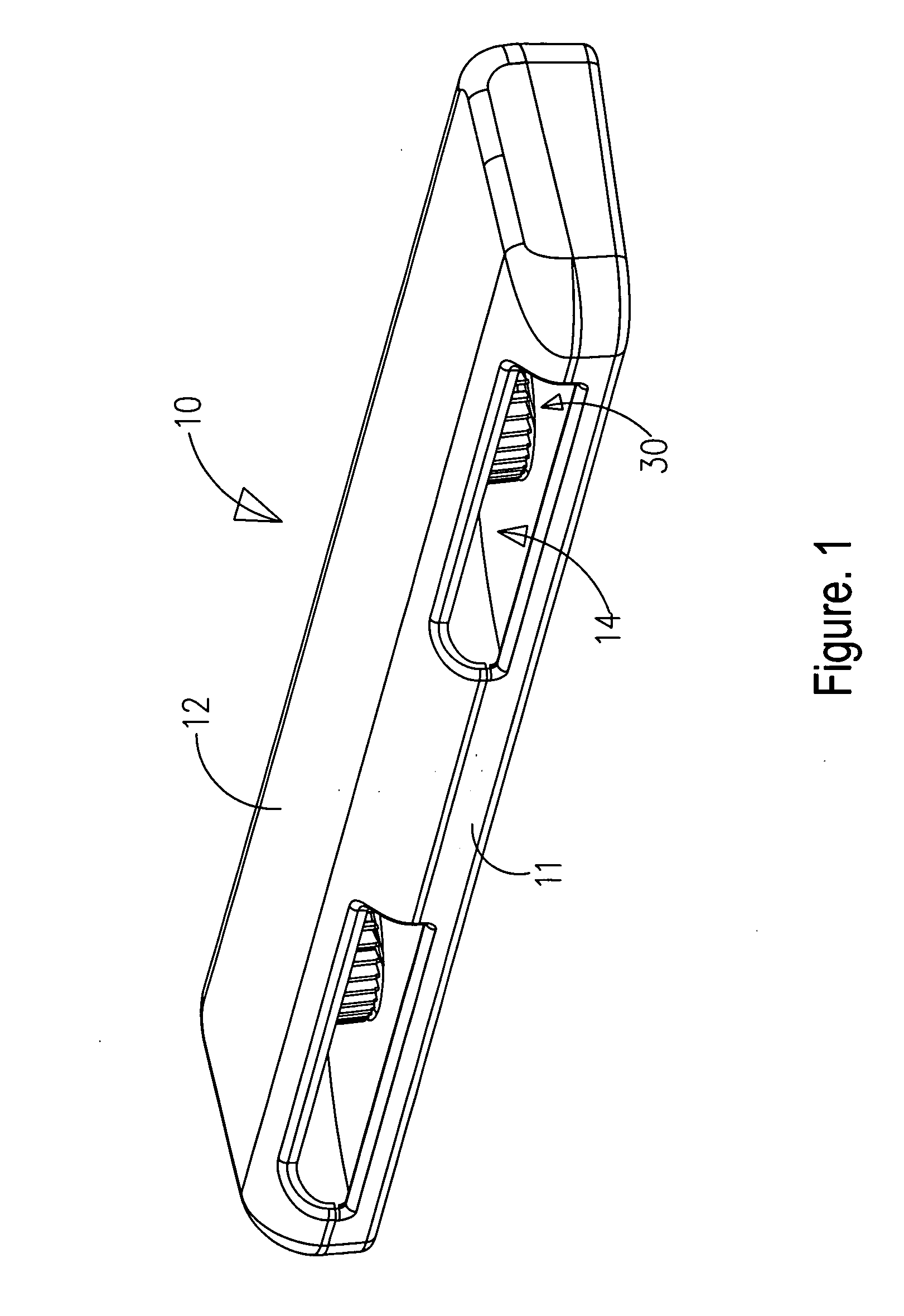

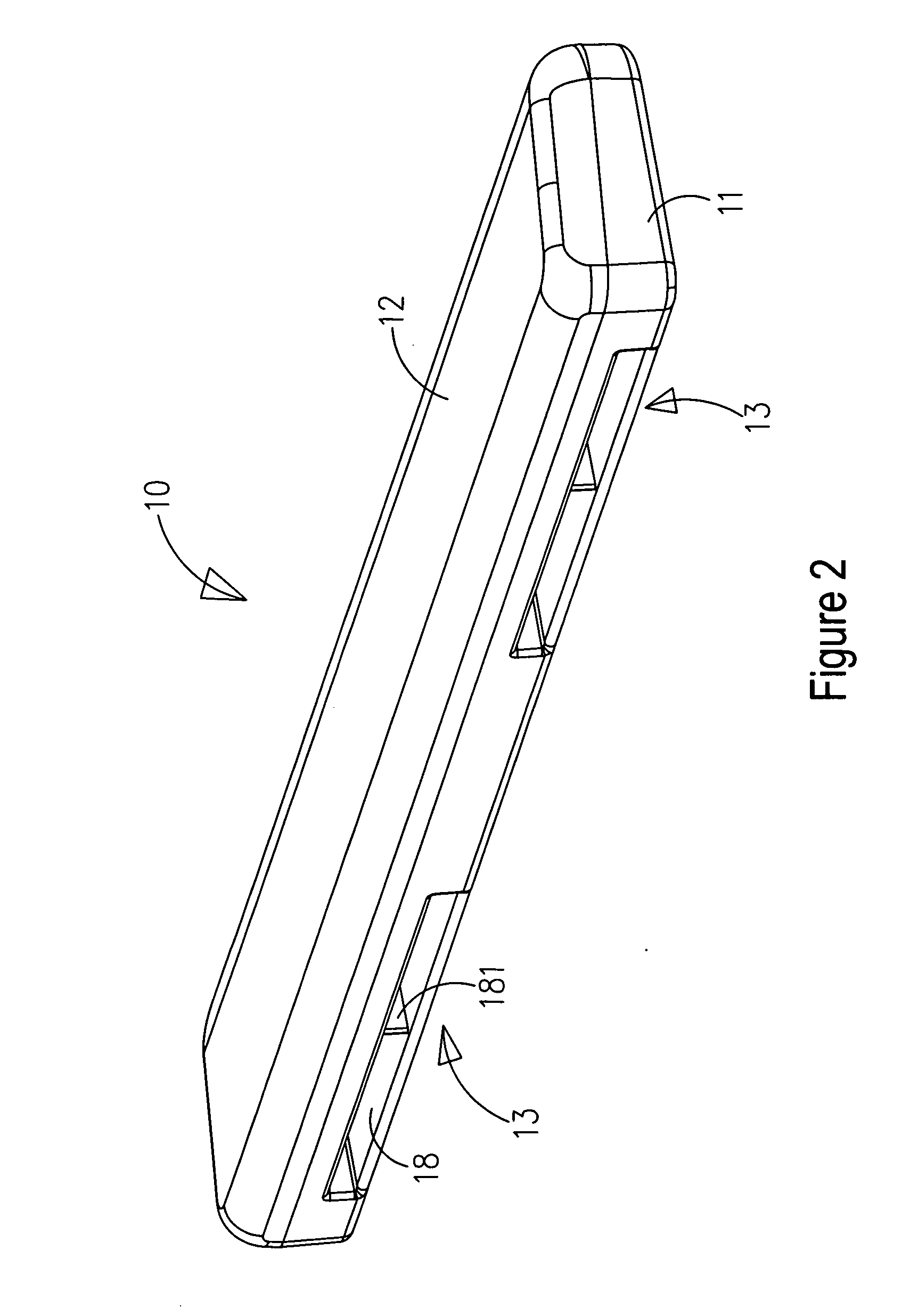

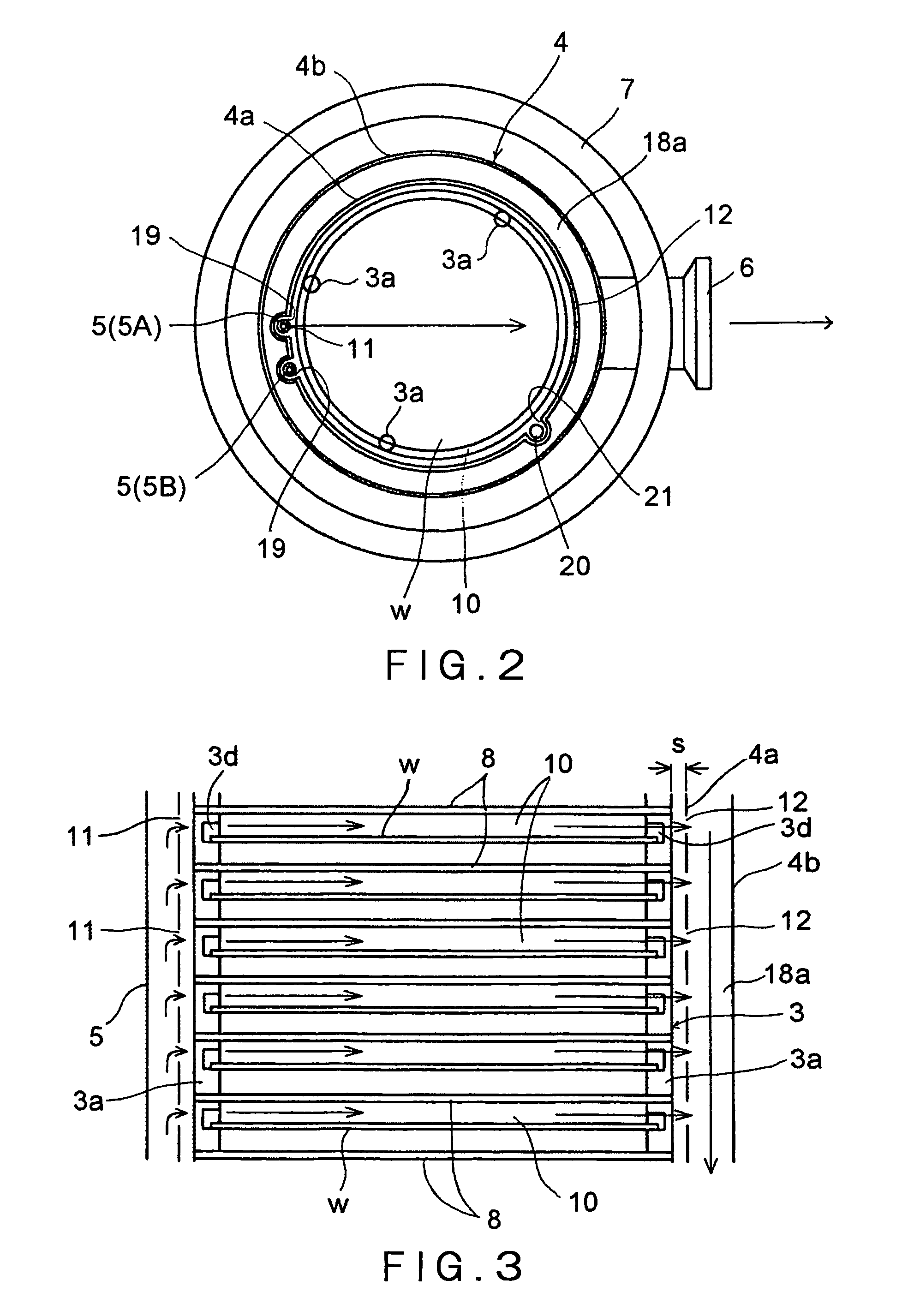

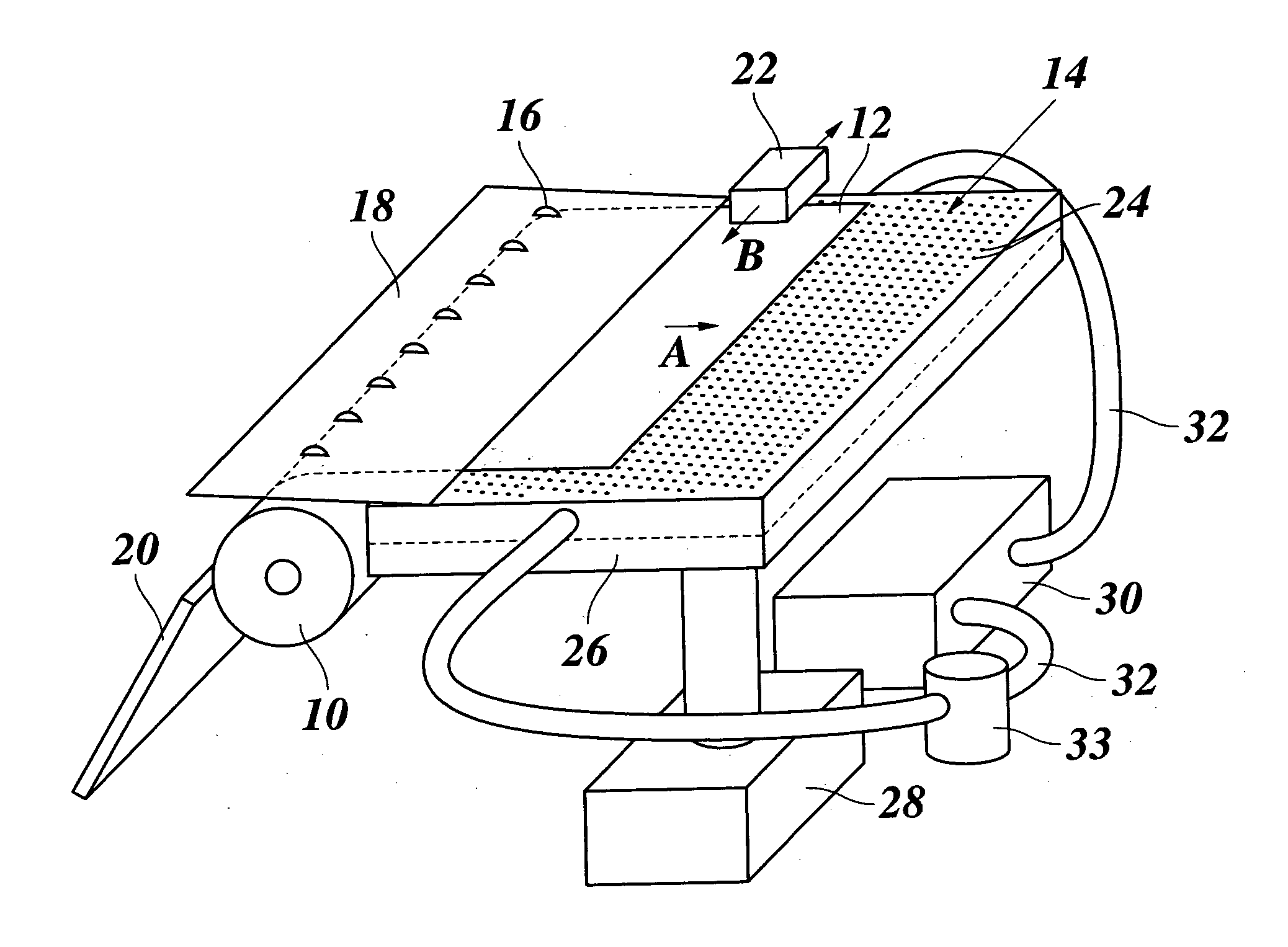

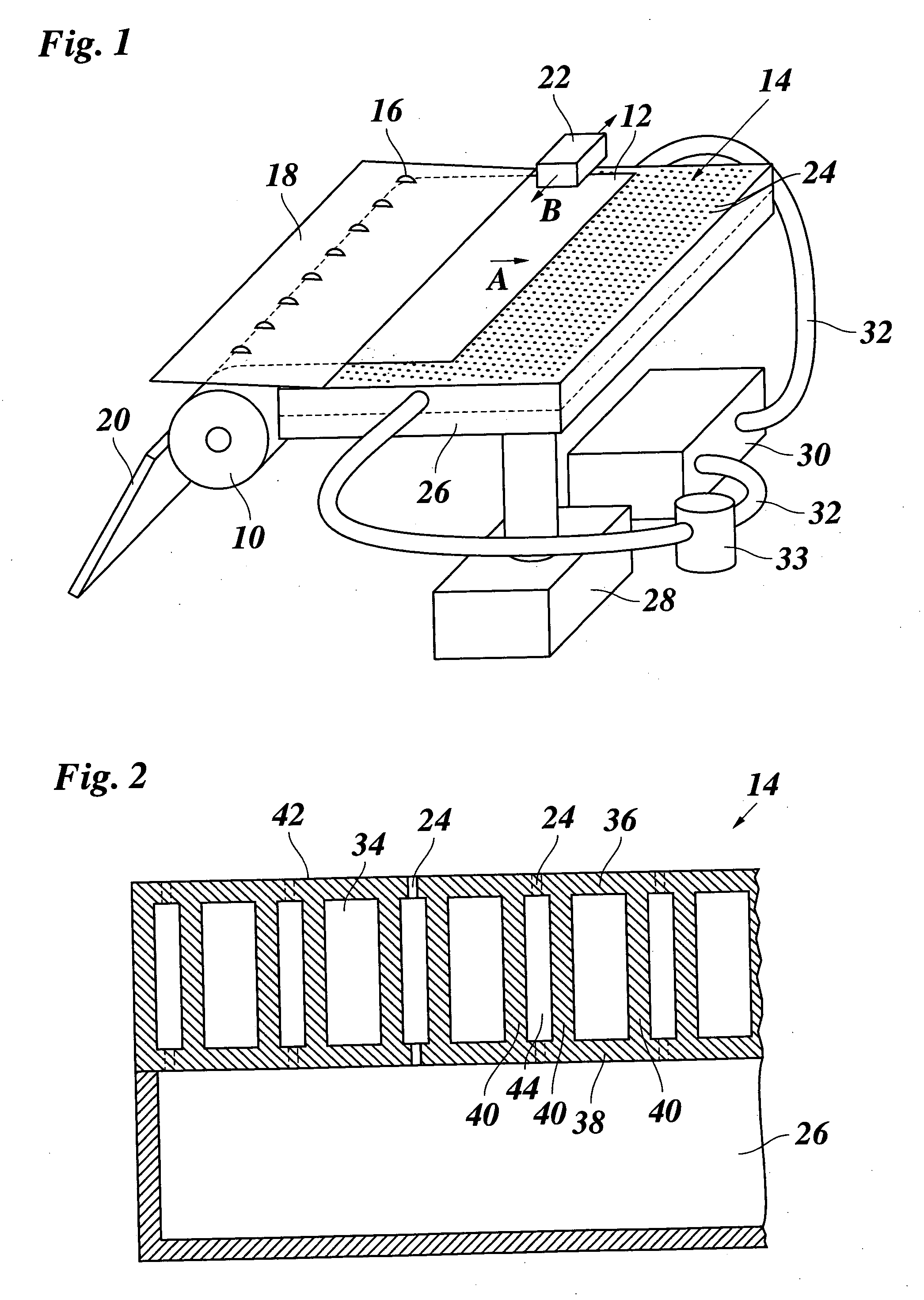

Alignment system, vertical tray transporting assembly, and deposition apparatus with the same

InactiveUS20060150910A1Minimize impactEnsuring sufficient uniformityVacuum evaporation coatingSputtering coatingEngineeringDeposition process

An alignment system, a vertical tray transporting assembly and a deposition apparatus having the same allow alignment of high precision, and perform a stable deposition process in a short period of time, minimize the effect of fine particles during transportation, and secure a sufficient uniformity of a mask by fixing and supporting a vertically disposed substrate using a fixing holder member and an auxiliary attaching member in a tray of a vertical in-line deposition alignment system.

Owner:SAMSUNG DISPLAY CO LTD

Electrode for electrochemical capacitor

InactiveUS7508650B1Avoid insufficient thicknessEnsuring sufficient uniformityHybrid capacitor electrodesElectrolytic capacitorsPorous carbonConductive polymer

An electrode for an electrochemical capacitor which comprises a porous carbon substrate having thereon at least a first or innermost layer comprising a first inherently conductive polymer and a second or outermost layer comprising a second inherently conductive polymer. This abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:MORE ENERGY

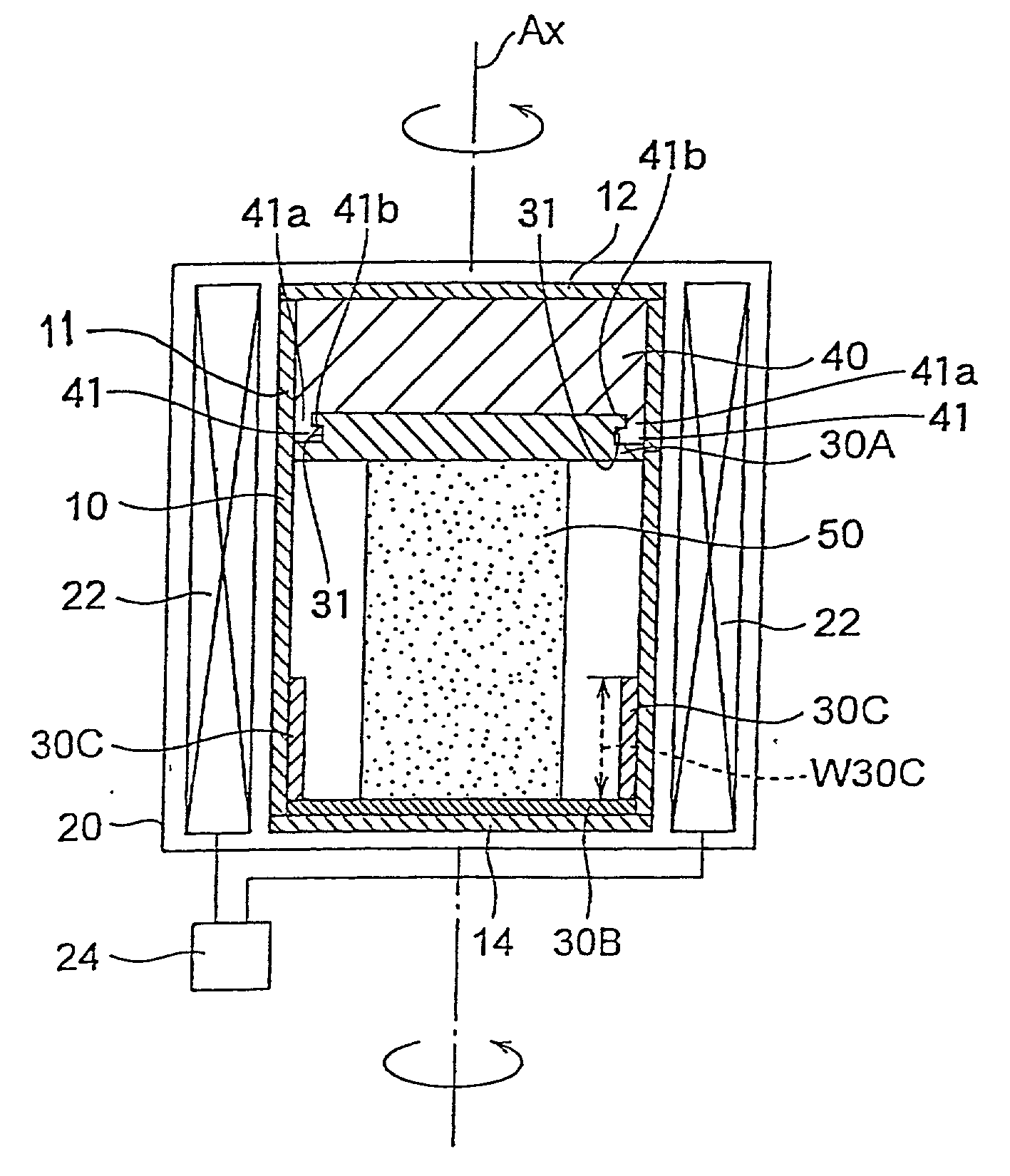

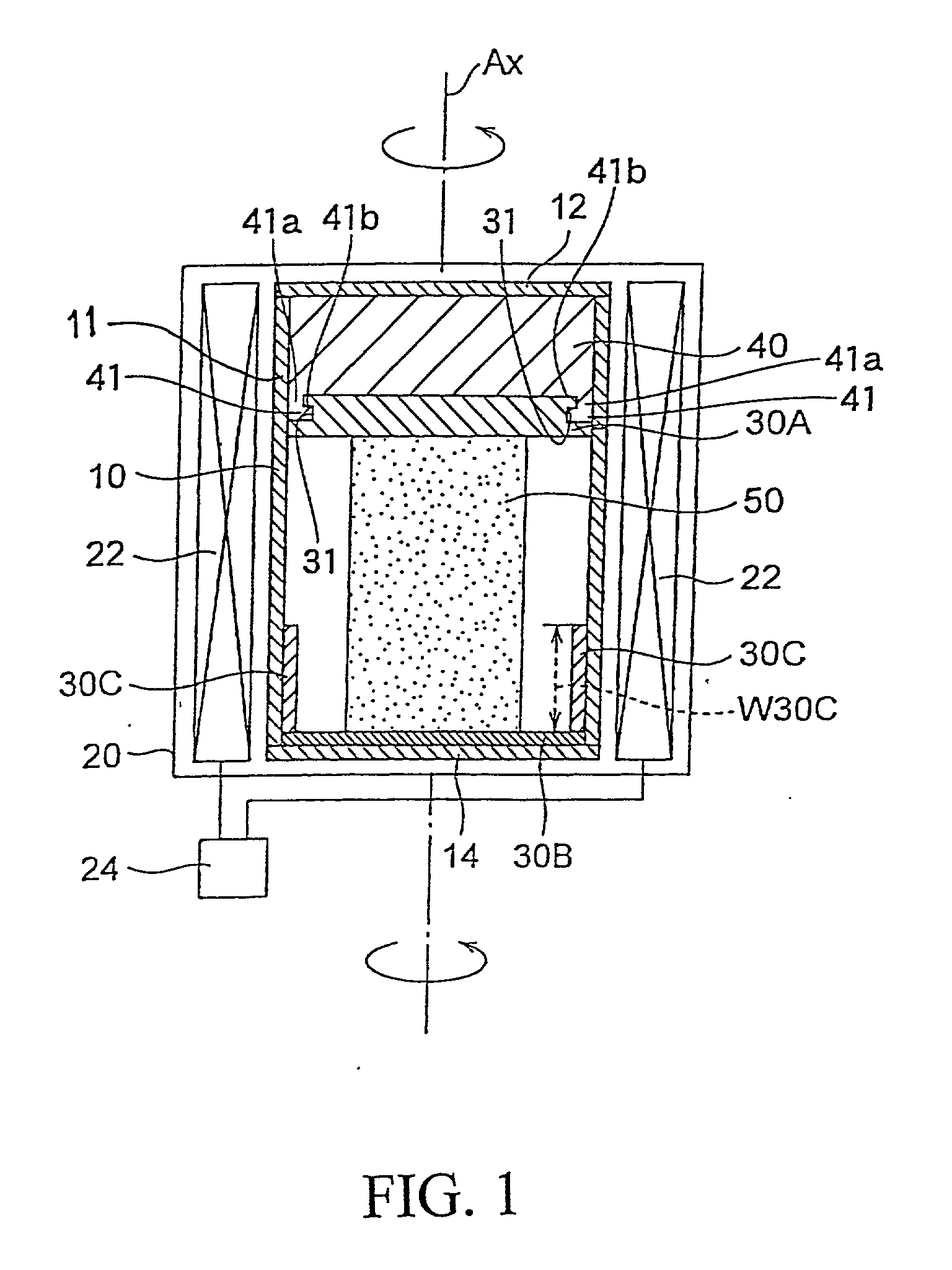

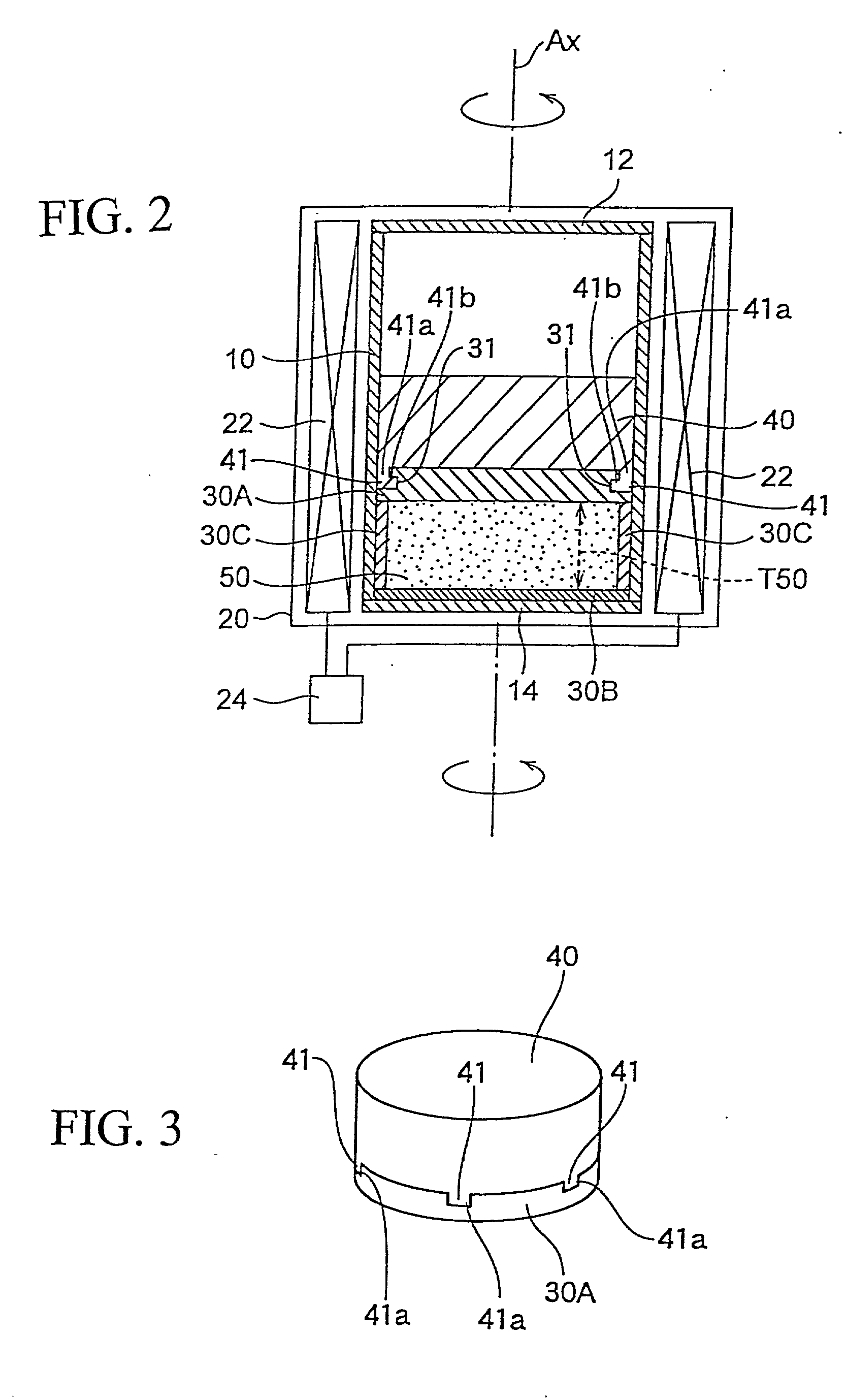

Synthetic silica glass molding method, synthetic silica glass molding apparatus, and synthetic silica glass

InactiveUS20020050152A1Ensuring sufficient uniformitySuppress crystallizationGlass pressing apparatusGlass reforming apparatusShell moldingSilicon dioxide

A method is provided for molding a synthetic silica glass member. The method includes accommodating a synthetic silica glass bulk inside a molding vessel; interposing an elastic member having a ventilating property between a pressing member and the synthetic silica glass bulk; providing a fastener for fastening at least peripheral edge portions of the elastic member to the pressing member; and pressing the synthetic silica glass bulk against the molding vessel by the pressing member in a high-temperature condition to mold the synthetic silica glass bulk into a synthetic silica glass member having a shape conforming to a shape of the space defined by the pressing member and the molding vessel, the synthetic silica glass bulk being pressed in such a manner that the pressing member and the elastic member tightly fasten to each other through the fastener.

Owner:NIKON CORP

Storage device with reversible resistance change elements

InactiveUS7560724B2Improve accuracyEnsuring sufficient uniformitySolid-state devicesDigital storageHigh densityElectrical polarity

Owner:SONY CORP

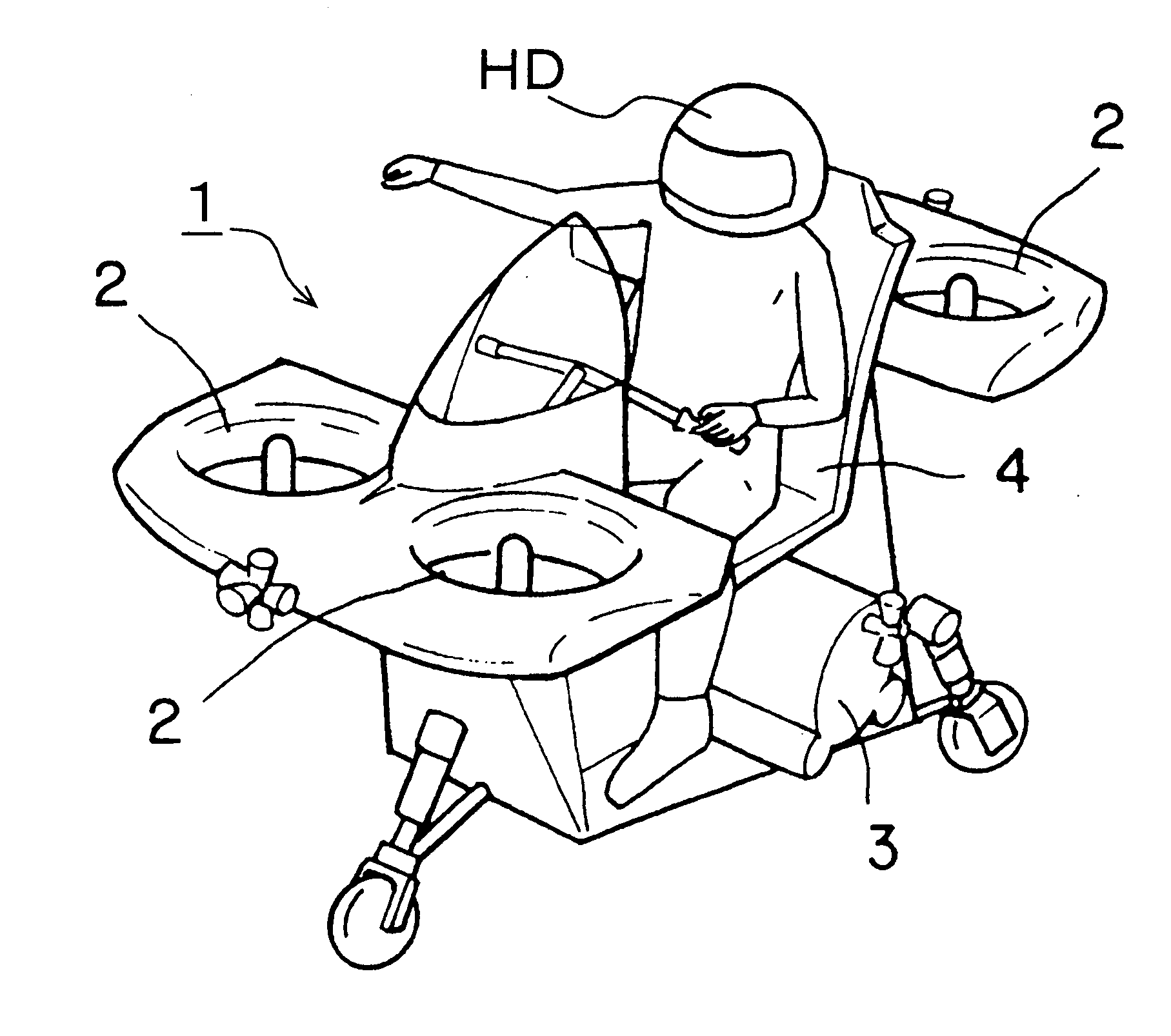

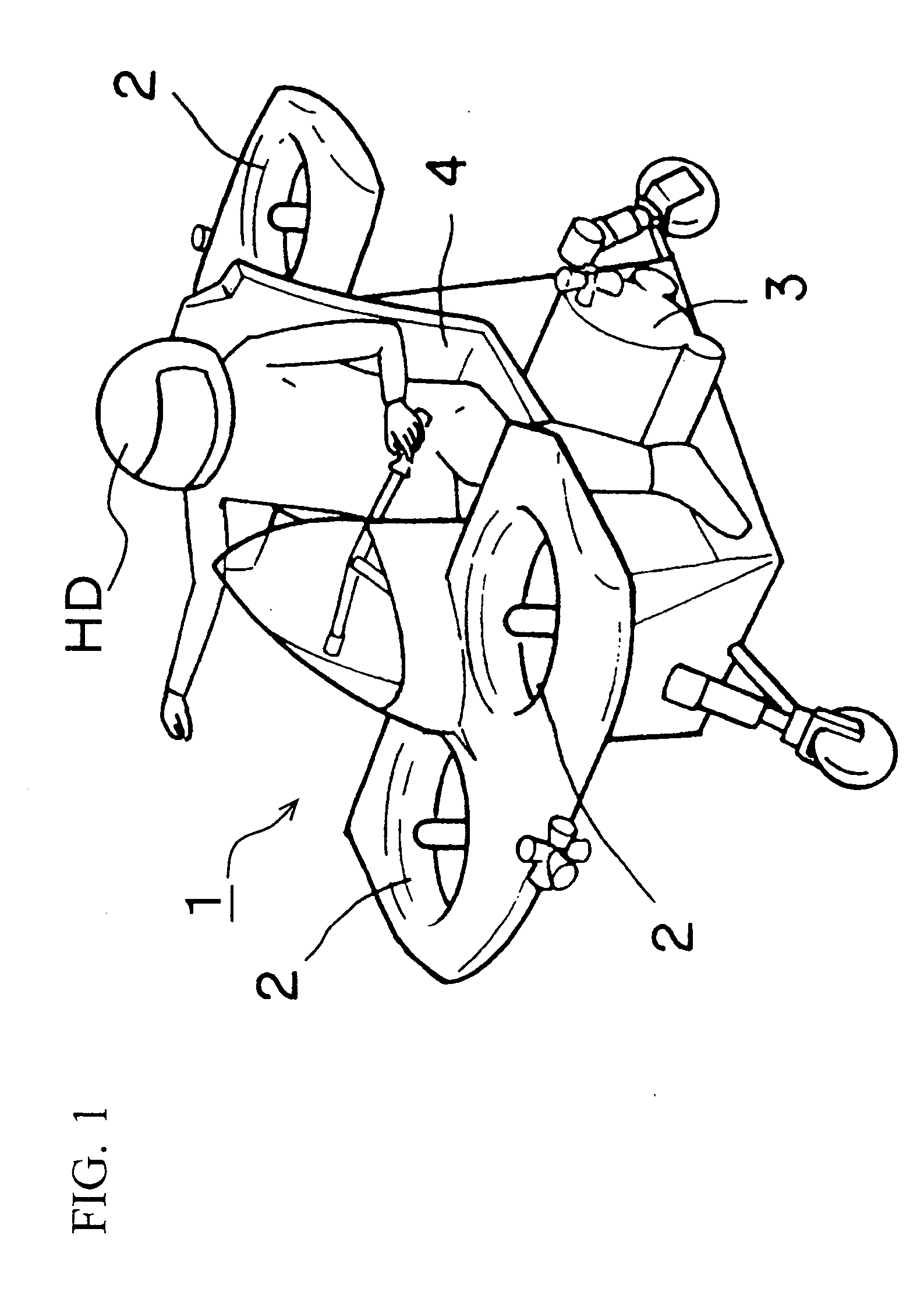

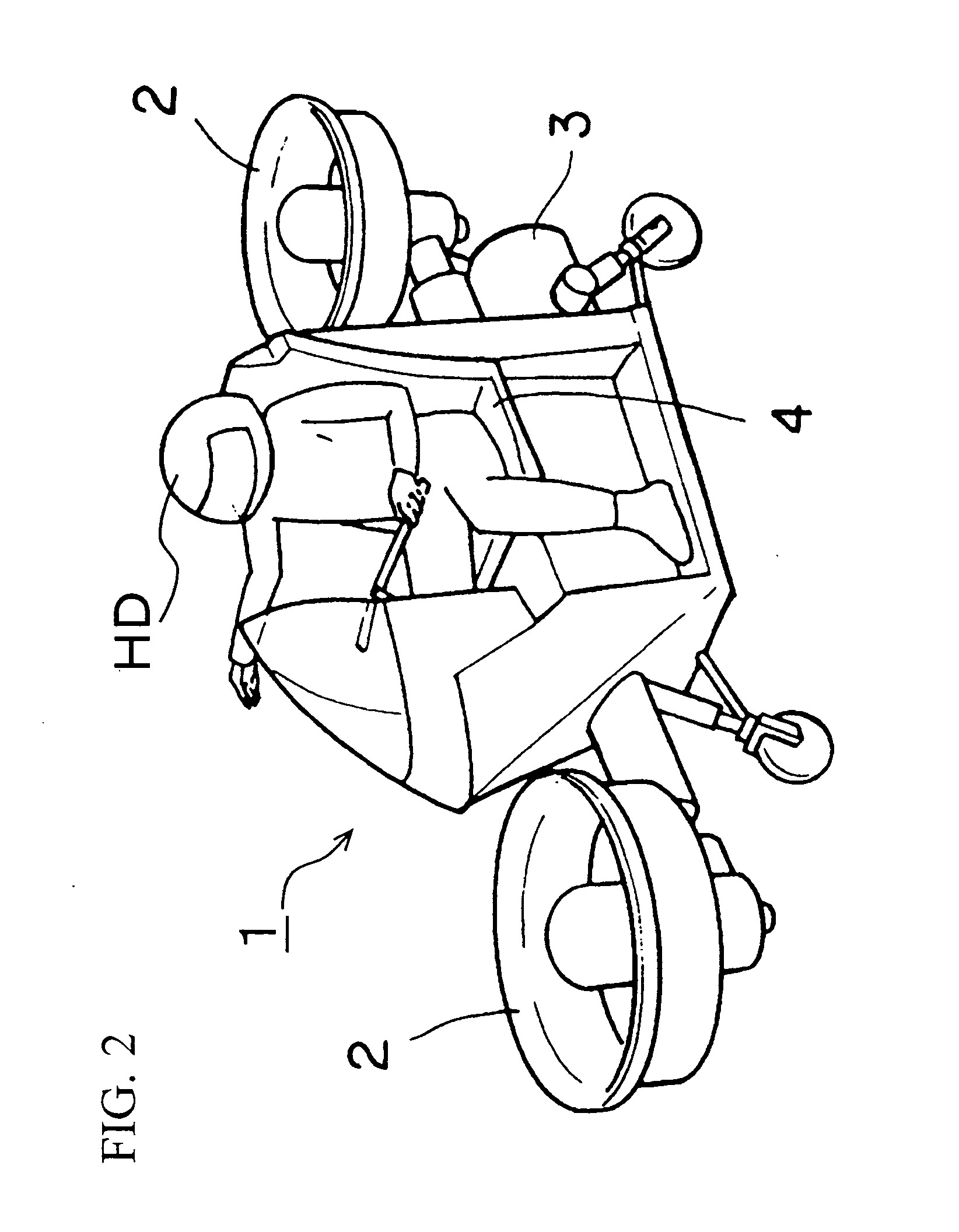

Vertical take-off and landing aircraft

InactiveUS20070290097A1Improve responsivenessGuaranteed smooth progressAircraft navigation controlVertical landing/take-off aircraftsFlight vehicleTurbine

An object of the invention is to prevent non-uniformity in the temperature distribution from occurring in a tip turbine fan in a vertical take-off and landing aircraft that uses the tip turbine fan as a source of thrust. In a vertical take-off and landing aircraft provided with a tip turbine fan in which a fan is rotated by blowing, in an annular turbine chamber provided around a rotation shaft of the fan at the center, compressed gas to a tip turbine attached to the fan to enable vertical take-off and landing, three or more compressed gas intake ports for supplying compressed gas to said turbine chamber are provided at regular intervals along the circumference of the turbine chamber.

Owner:TOYOTA JIDOSHA KK

Laminated layer fuel cell and method for manufacturing the same

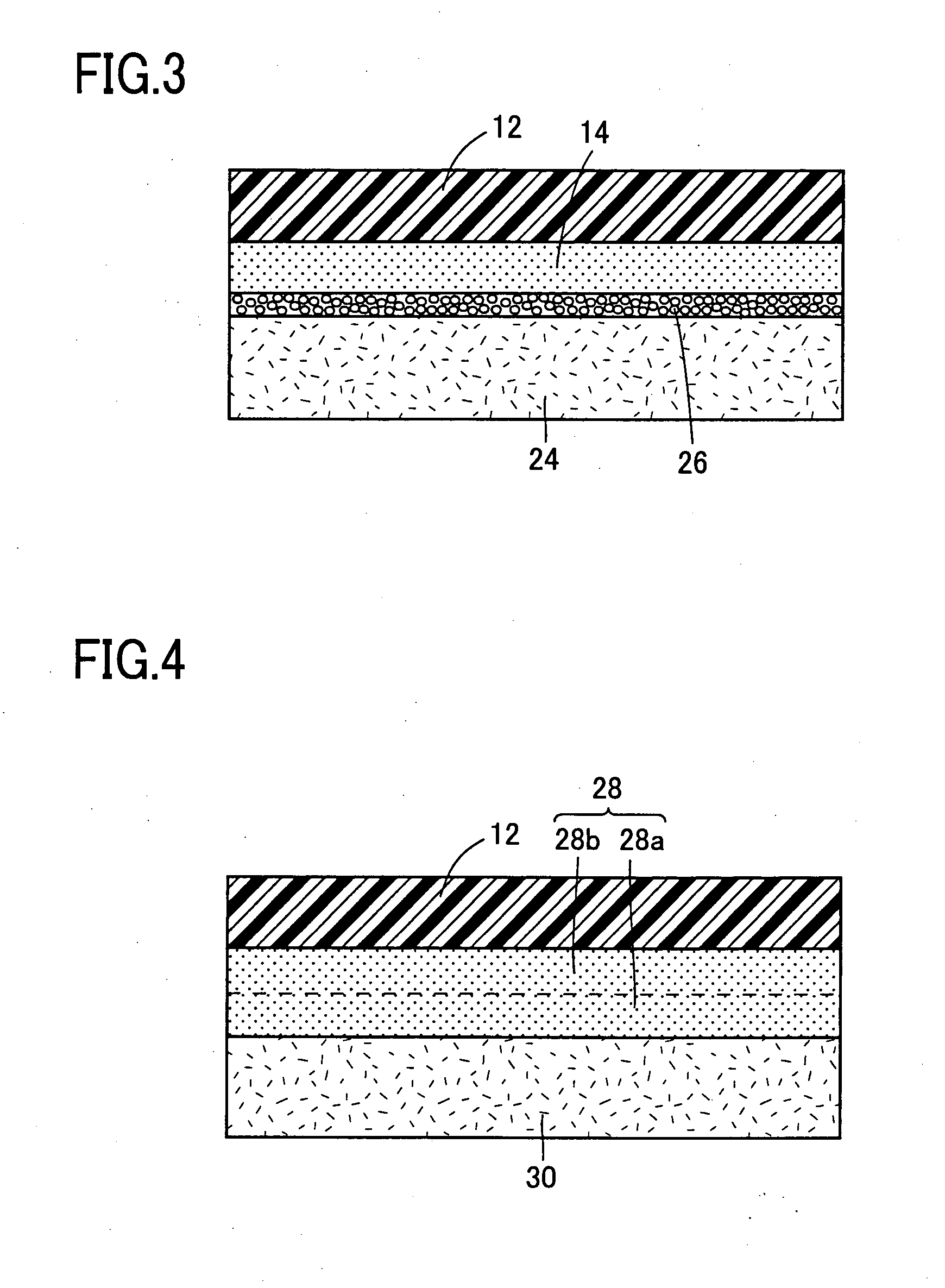

InactiveUS20080138683A1Increase productionLower performance requirementsFinal product manufactureCell electrodesPolymer electrolytesComposite electrode

A laminated layer fuel cell includes a solid polymer electrolyte layer, a pair of catalyst layers, and a pair of gaseous diffusion electrode layers, one of the pair of catalyst layers and one of the pair of gaseous diffusion electrode layers being formed on one side of the solid polymer electrolyte layer, and the other of the pair of catalyst layers and the other of the pair of gaseous diffusion electrode layers being formed on the other side of the solid polymer electrolyte layer, wherein the one of the pair of catalyst layers and the one of the pair of the gaseous diffusion electrode layers constitute a composite electrode layer, and the composite electrode layer has an amount in a range of 10000 to 12000 ml·mm / cm2 / min of air flow permeation in the thickness direction in a dried state.

Owner:NORITAKE CO LTD

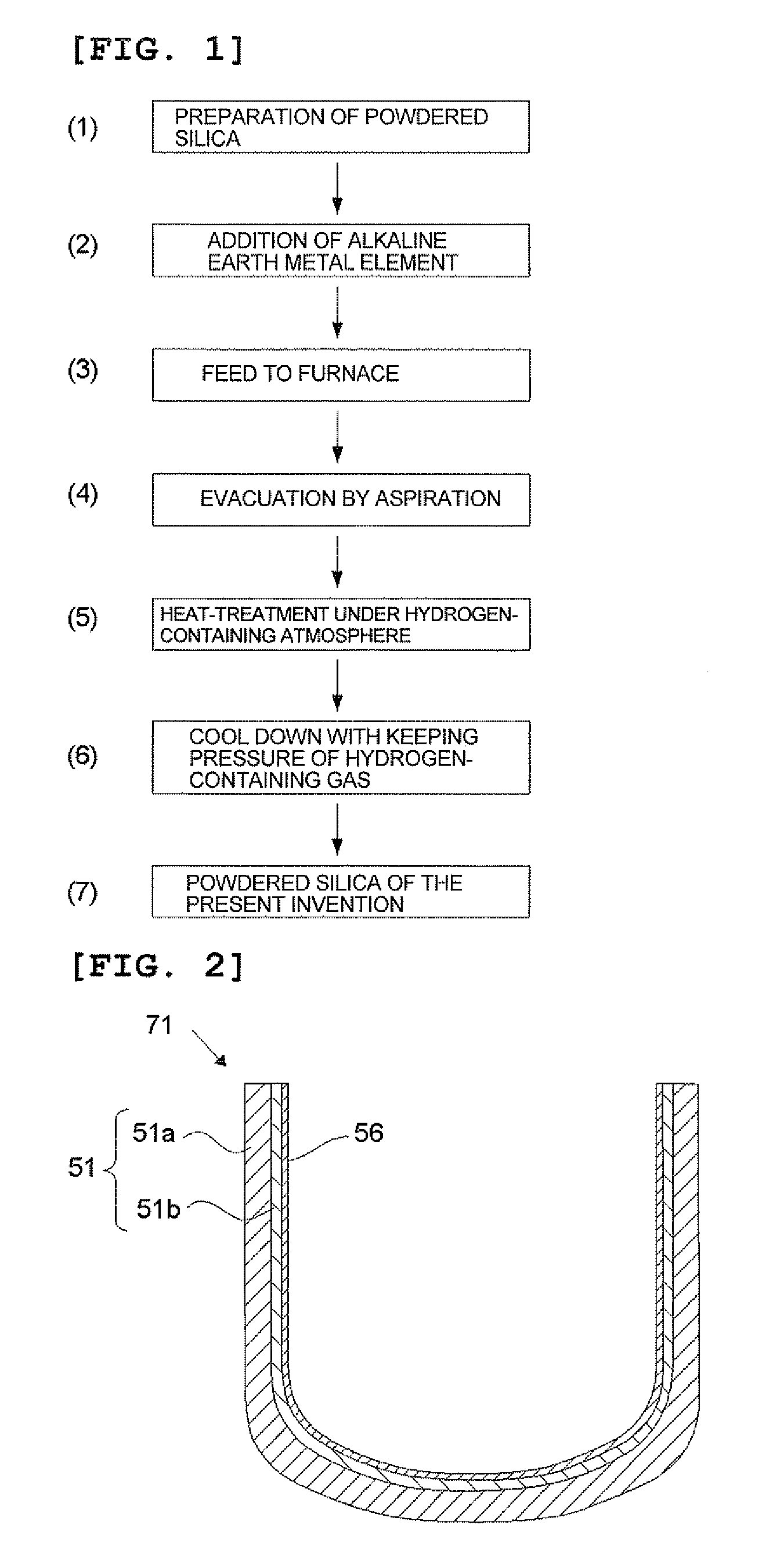

Powdered silica, silica container, and method for producing them

InactiveUS20110256330A1Increased durabilitySuppress generationSilicaBy pulling from meltHydrogen moleculeSilicon dioxide

A method is provided for producing a silica container arranged with a substrate, having a rotational symmetry, comprised of mainly a silica, and containing gaseous bubbles at least in its peripheral part, and an inner layer, formed on an inner surface of the substrate and comprised of a transparent silica glass; wherein a powdered silica, having particle diameter of 10 to 1000 μm, containing Ca, Sr, and Ba with the total concentration of 50 to 5000 ppm by weight, and releasing hydrogen molecules with the amount of 3×1016 to 3×1019 molecules / g upon heating at 1000° C. under vacuum, is prepared at least as a powdered raw material for forming the inner layer, and then the inner layer is formed from the powdered silica as the powdered raw material for forming the inner layer.

Owner:SHIN ETABU QUARTZ PRODS

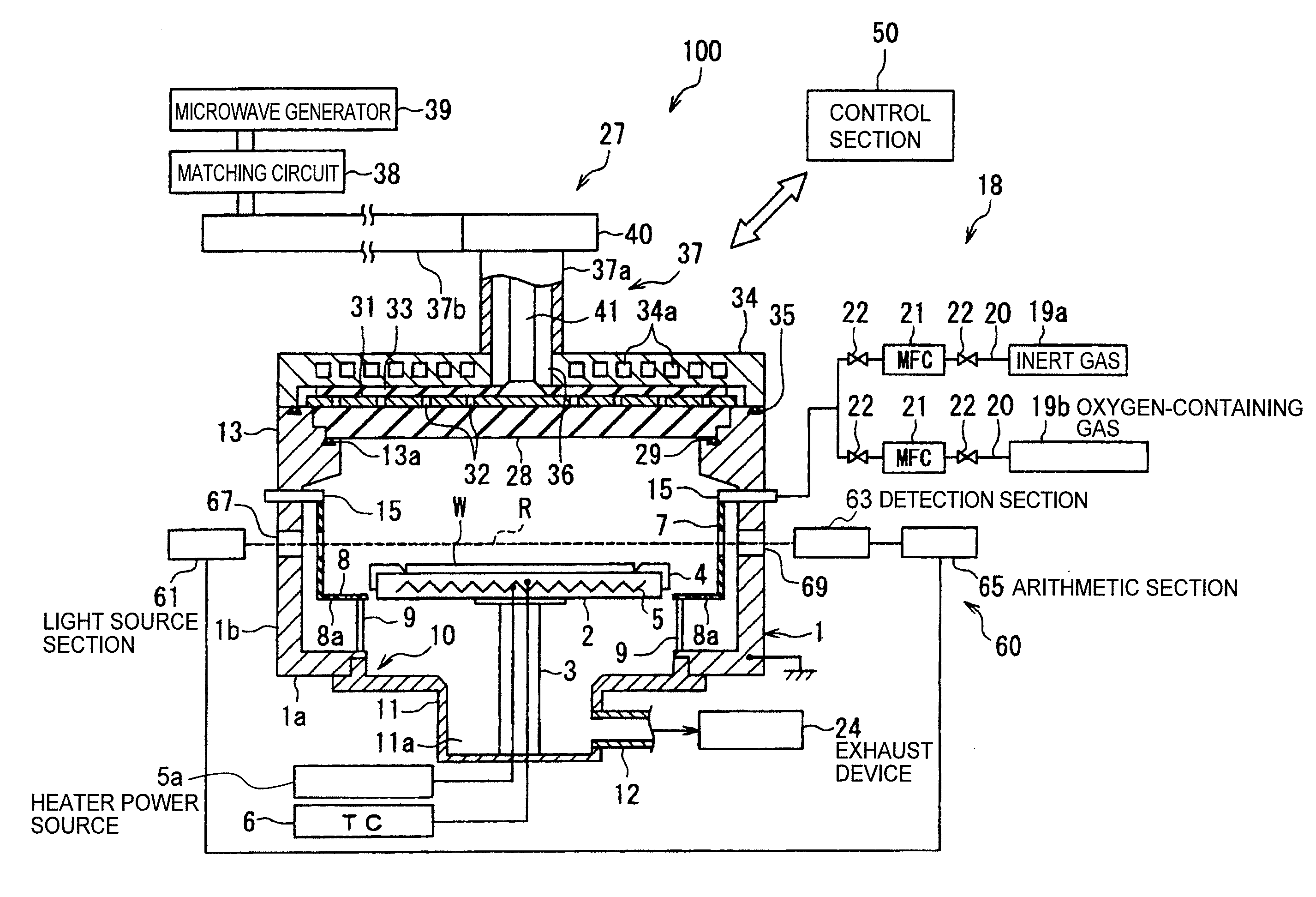

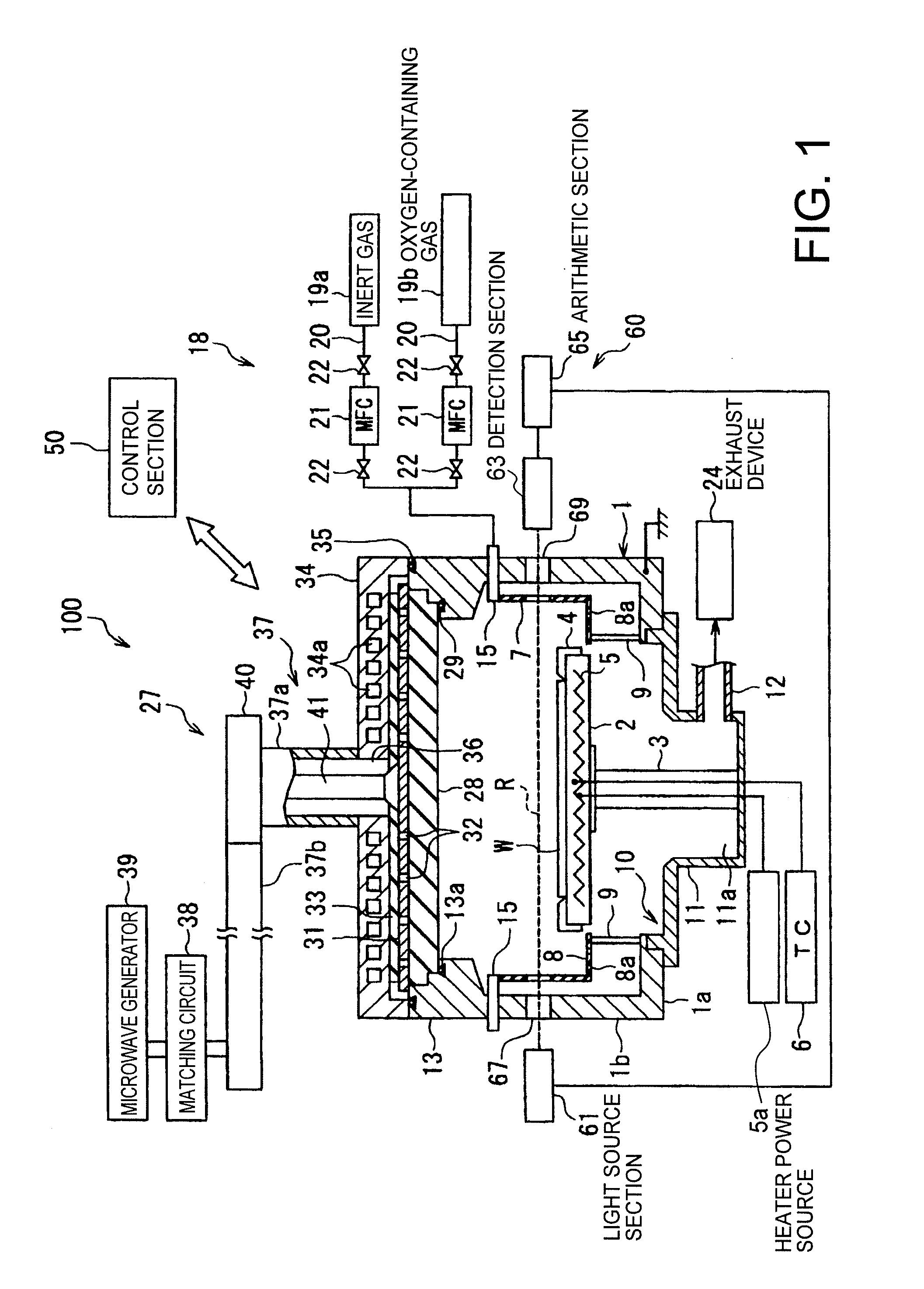

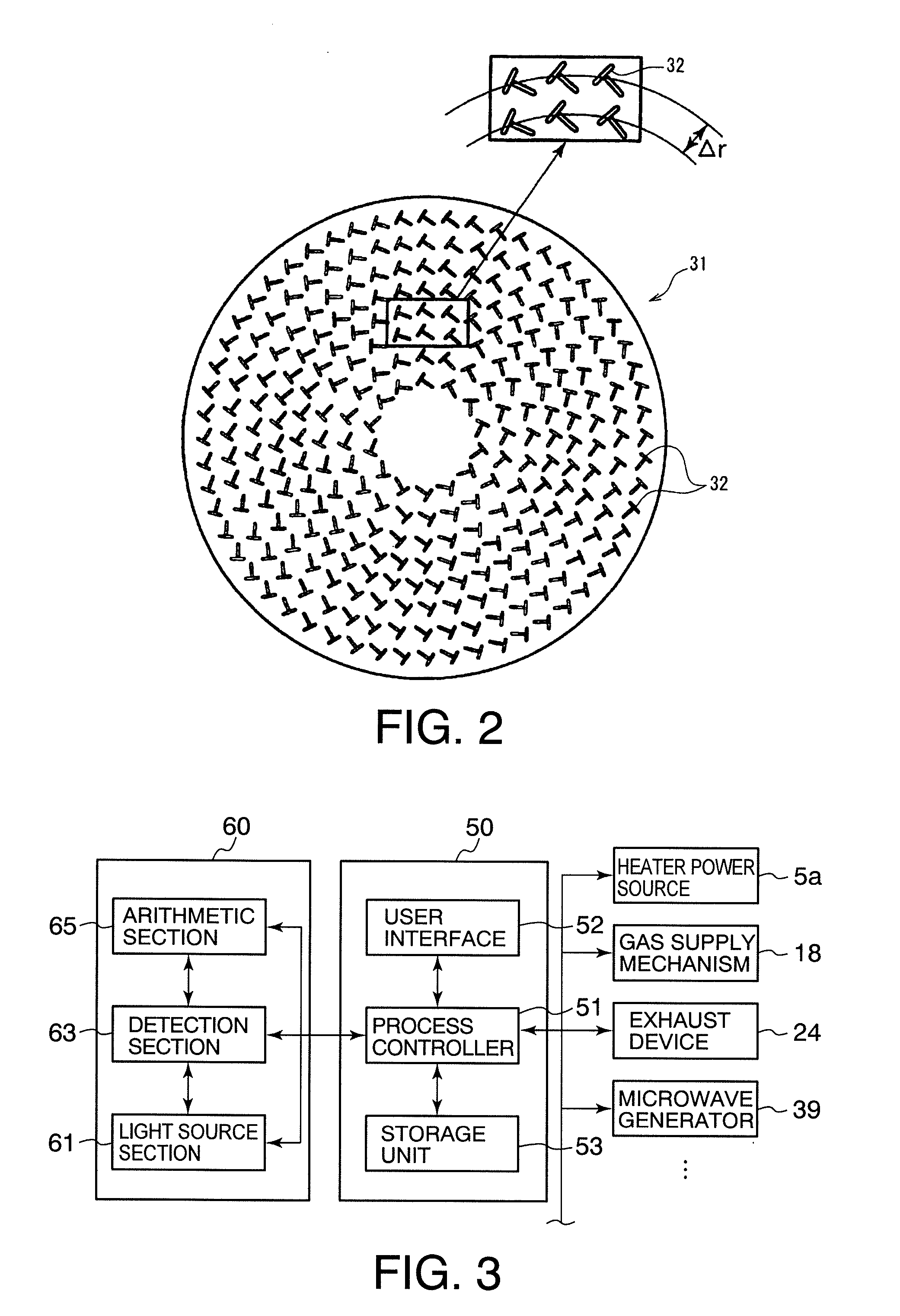

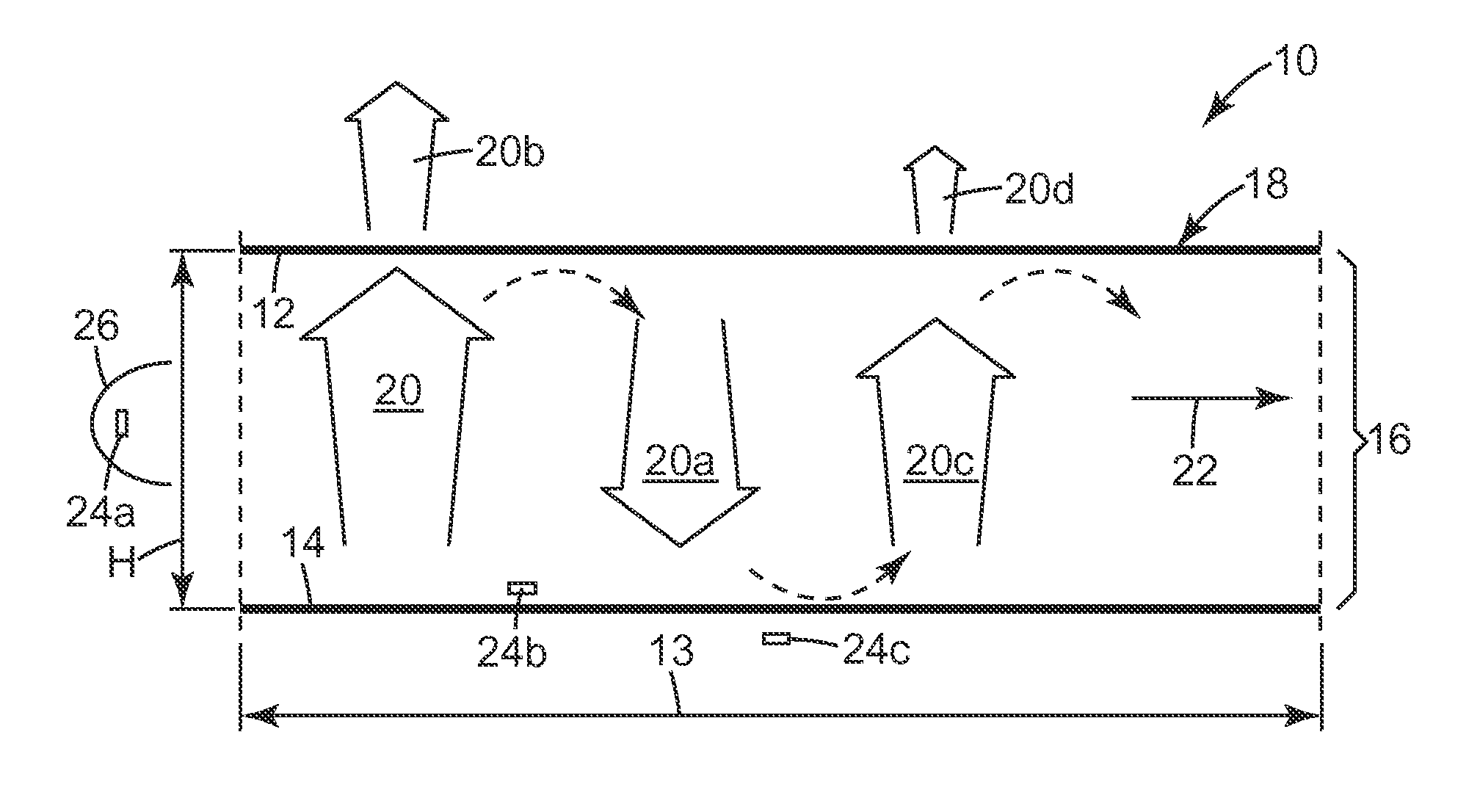

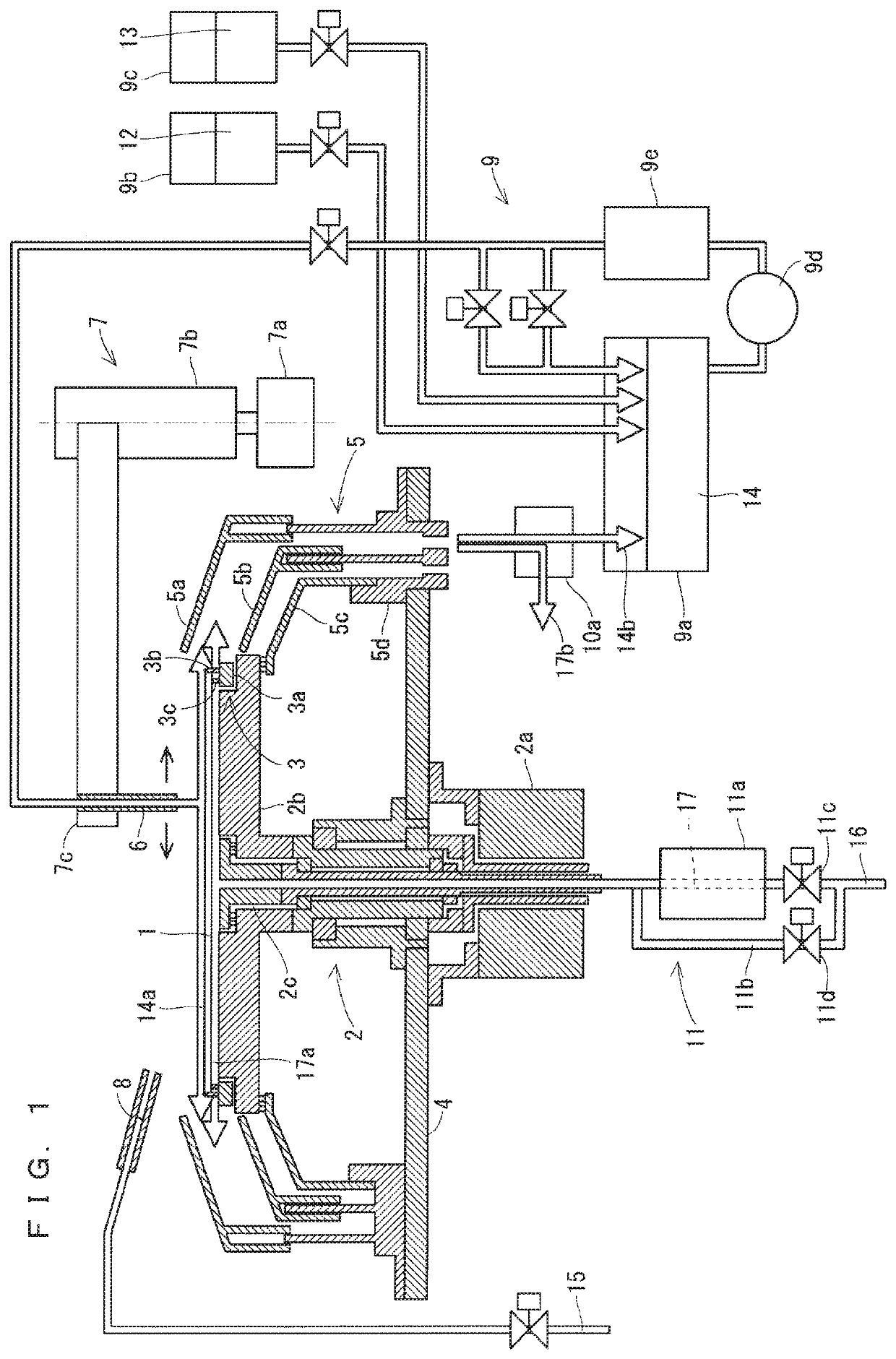

Plasma processing apparatus, plasma processing method and end point detection method

InactiveUS20110174776A1Improve accuracyHigh-precision detectionLiquid surface applicatorsElectric discharge tubesMonochromatorLaser light

A plasma processing apparatus (100) includes: a plasma generation means for generating a plasma in a processing chamber (1); a measurement section (60) for measuring an integrated value of the particle number of an active species contained in the plasma and moving toward a processing object (wafer W); and a control section (50) for controlling the apparatus in such a manner as to terminate plasma processing when the measured integrated value has reached a set value. The measurement section (60) measures the particle number of the active species by emitting a predetermined laser light from a light source section (61) toward the plasma, and receiving the laser light in a detection section (63) provided with a VUV monochromator.

Owner:TOKYO ELECTRON LTD

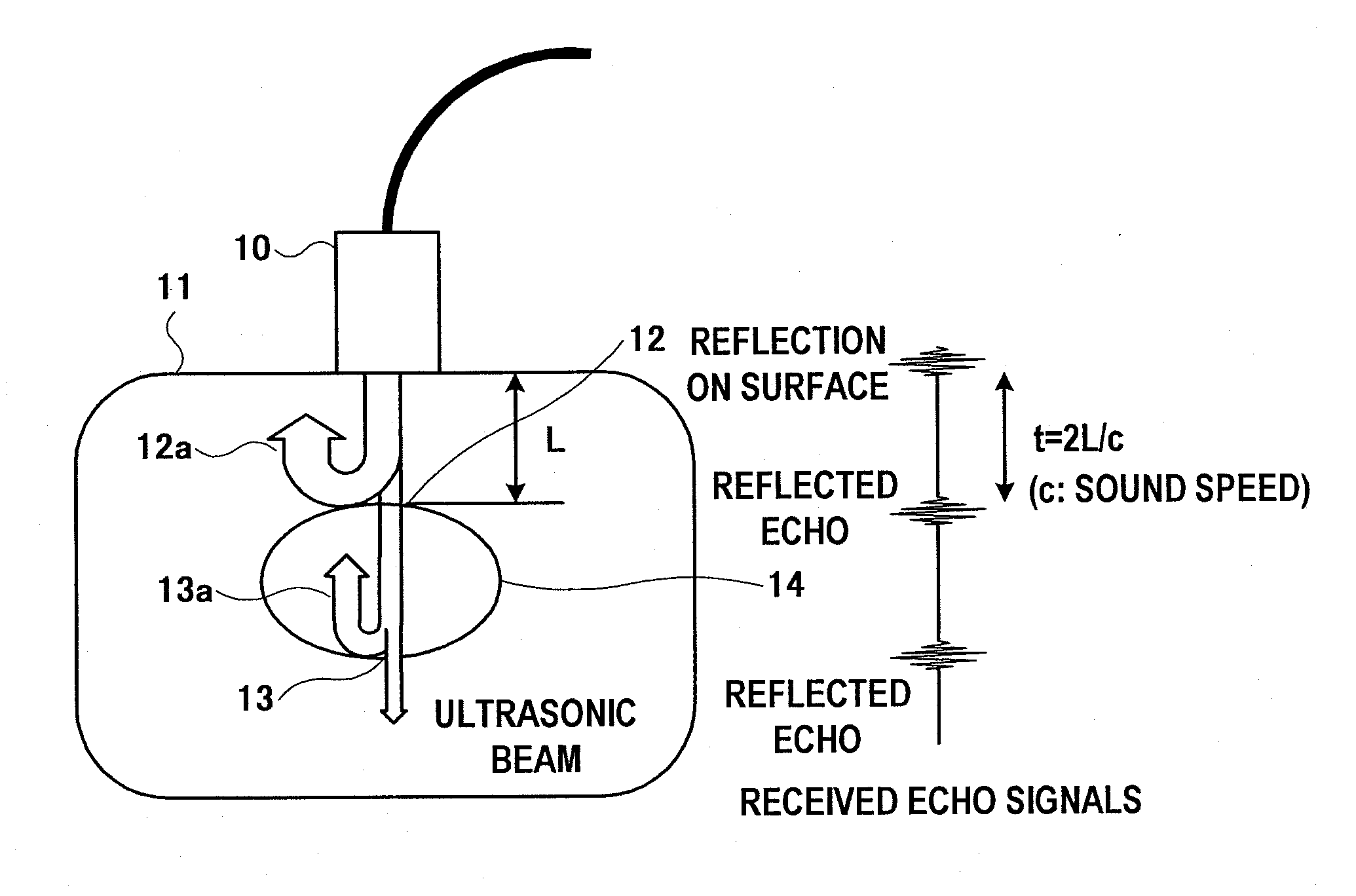

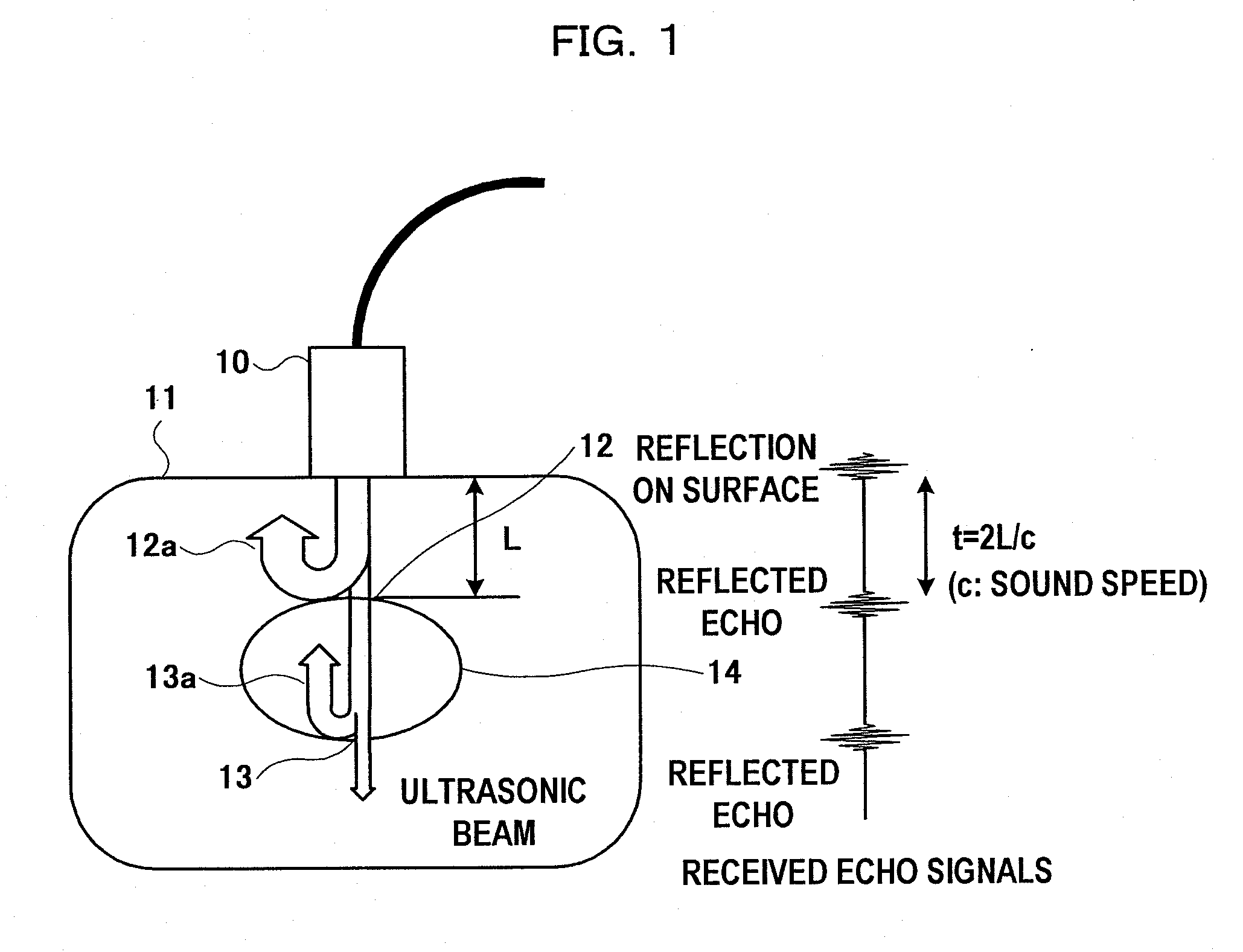

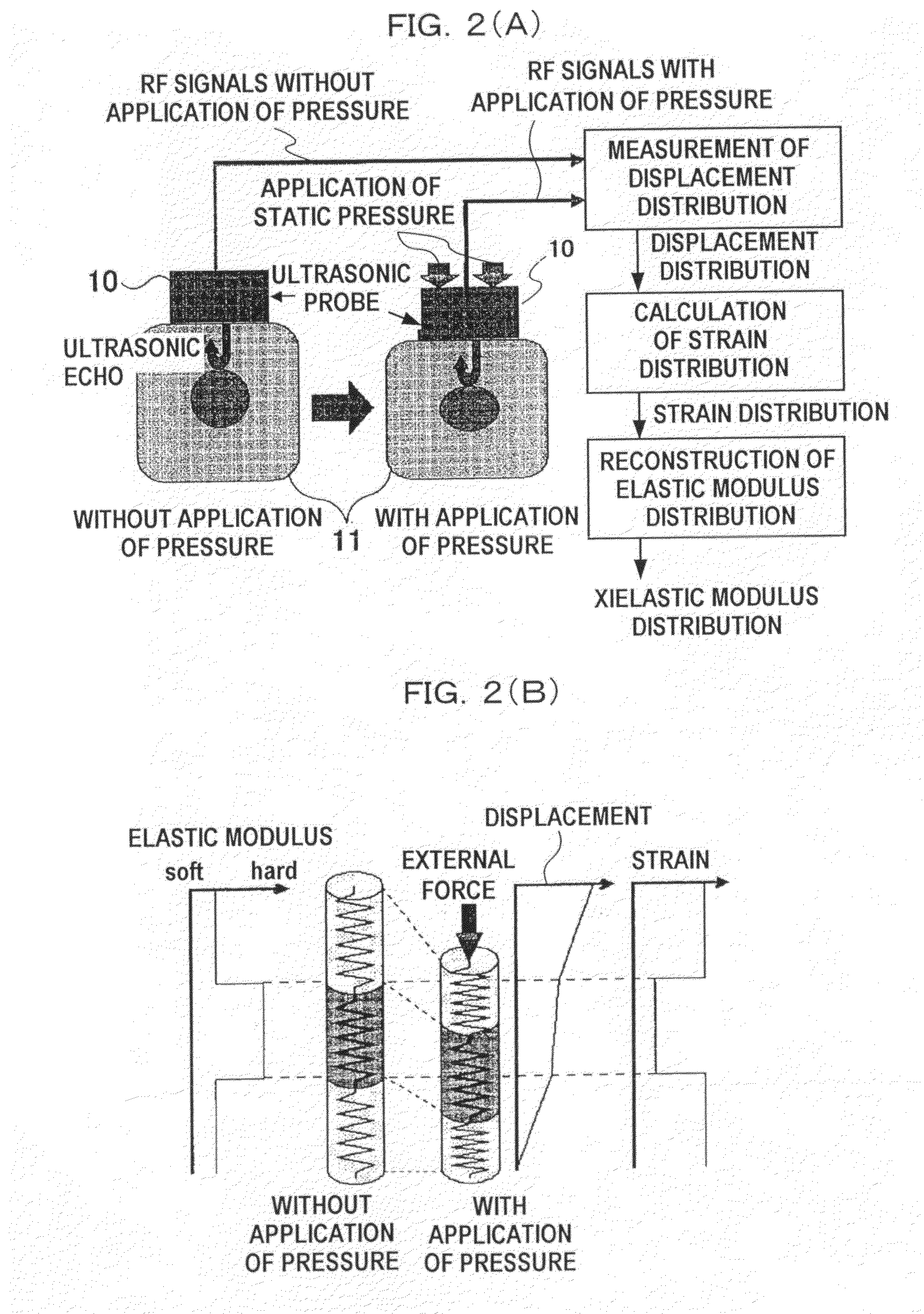

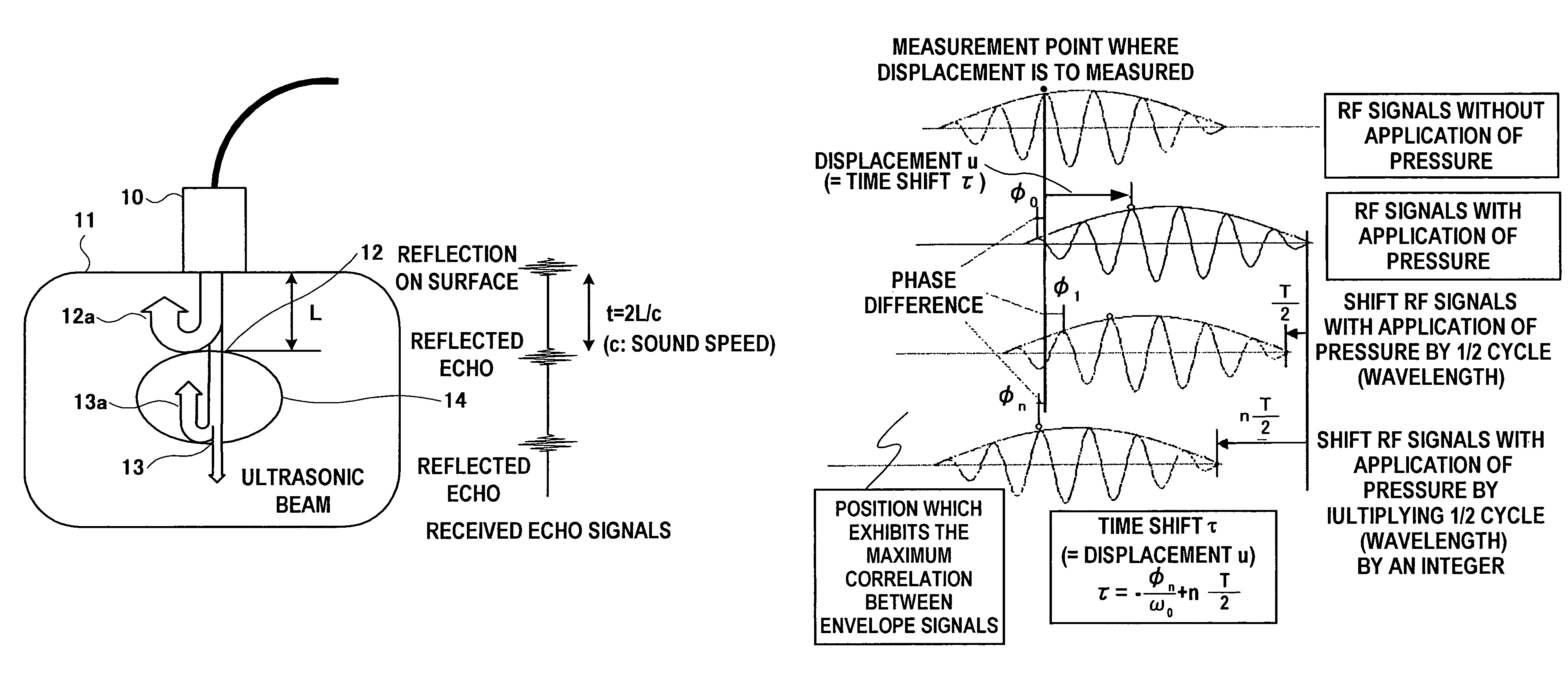

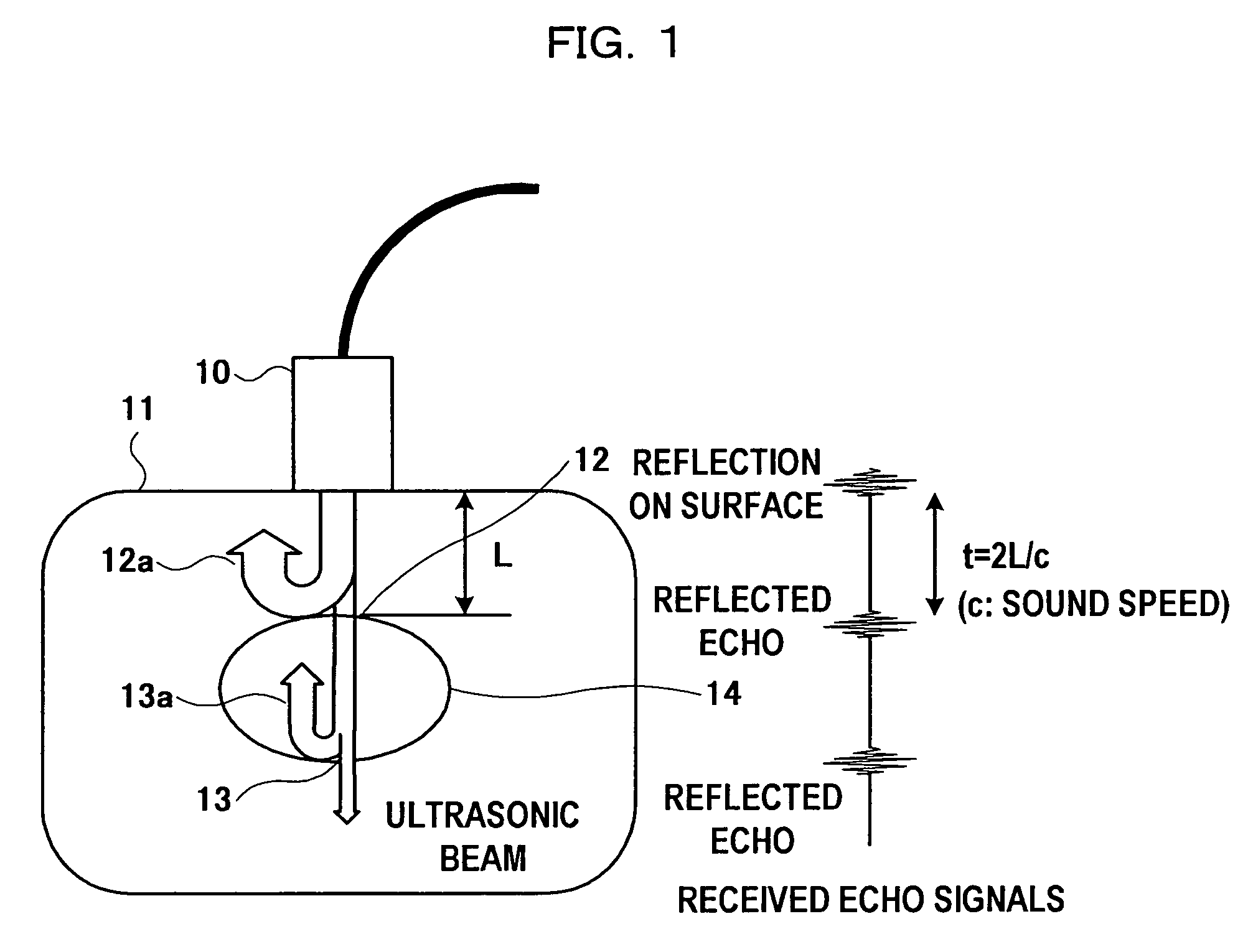

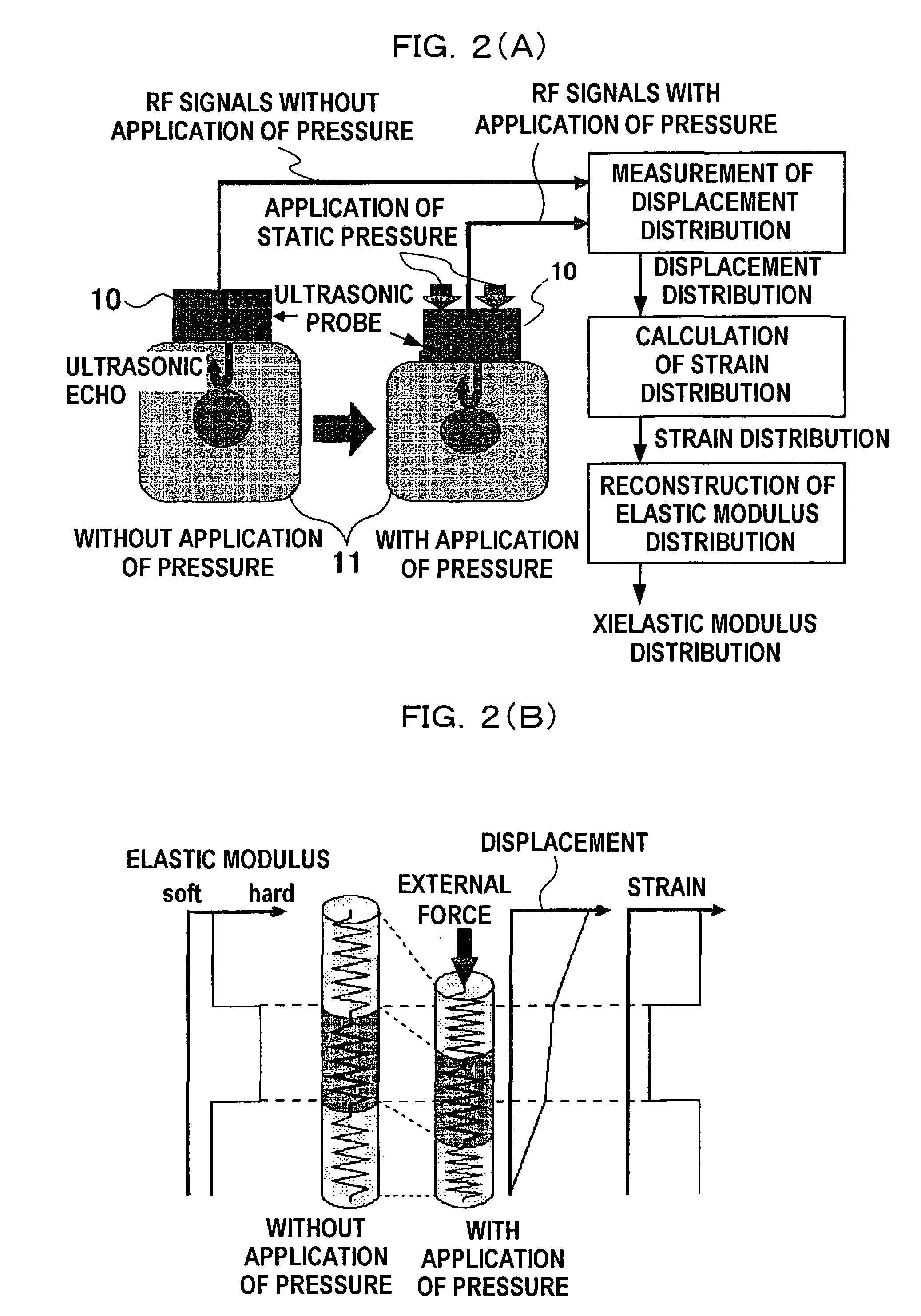

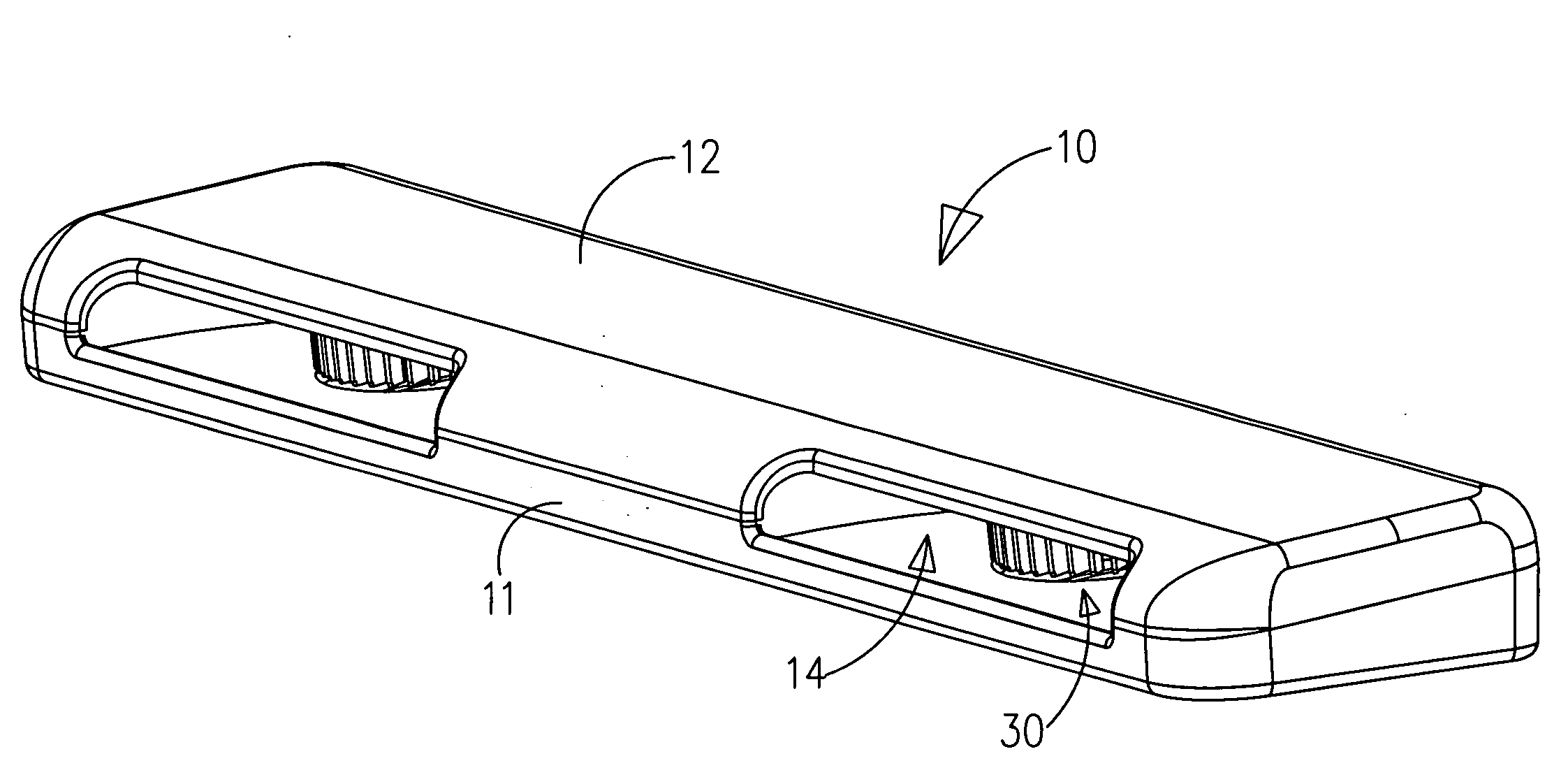

Ultrasonic diagnosis system and distortion distribution display method

ActiveUS20110125019A1Solve the real problemReduce computing timeOrgan movement/changes detectionDiagnostic recording/measuringCorrelation coefficientSonification

An ultrasonic diagnosis system and strain distribution display method utilizing an ultrasonic probe for performing transmission / reception of ultrasonic signals to / from a subject, a storage arrangement for storing the properties of signals detected with the ultrasonic probe, a correlation computer for calculating a correlation coefficient between the properties with and without pressure applied to the subject, and a phase difference between the received signals with and without application of pressure, based upon the properties stored in the storage arrangement with and without pressure applied to the subject, a computer for calculating a displacement of each measurement point, and a strain distribution of tissue of the subject due to application of pressure, based upon the correlation coefficient and phase difference calculated by the correlation computer, and a display for displaying the strain distribution.

Owner:FUJIFILM HEALTHCARE CORP

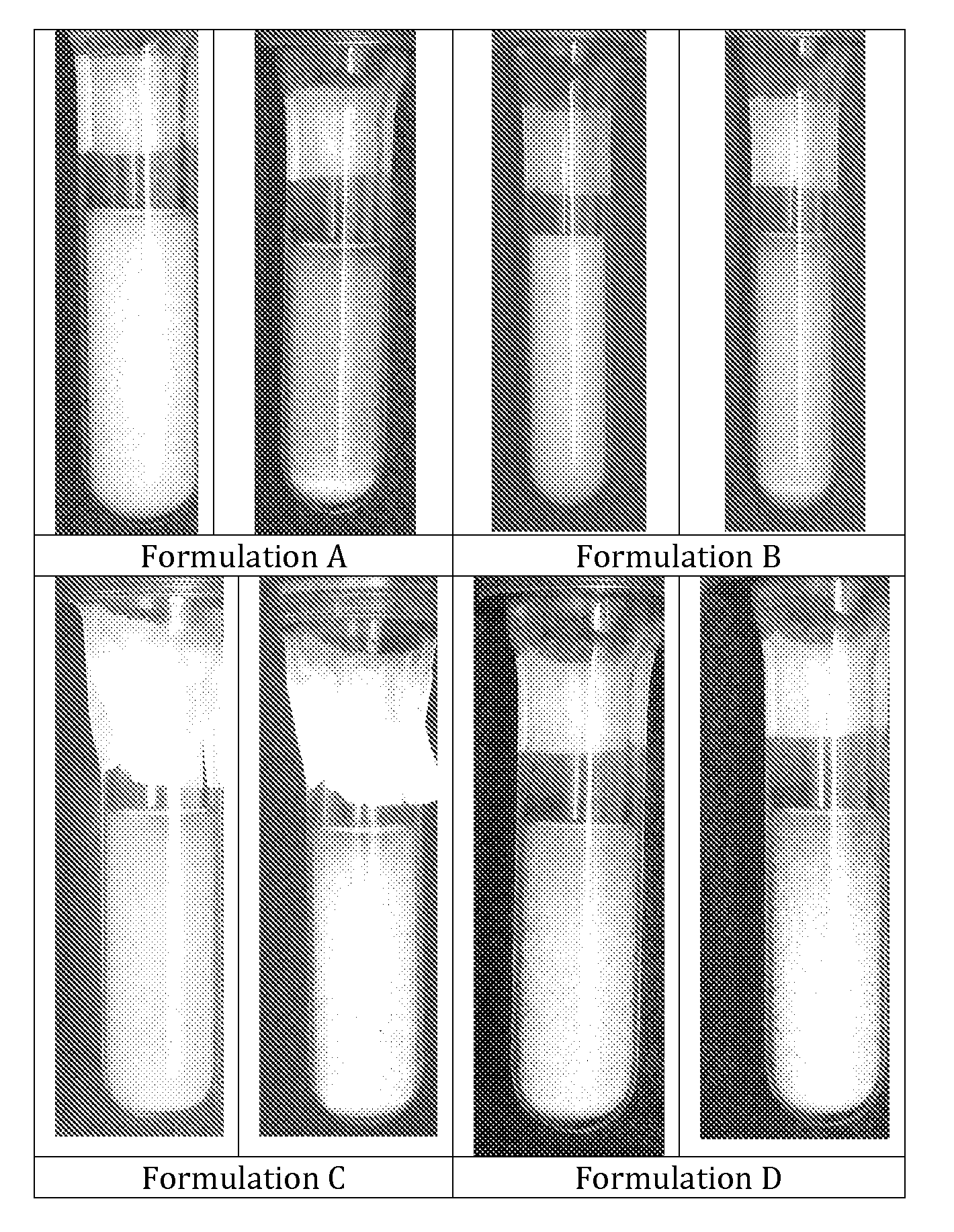

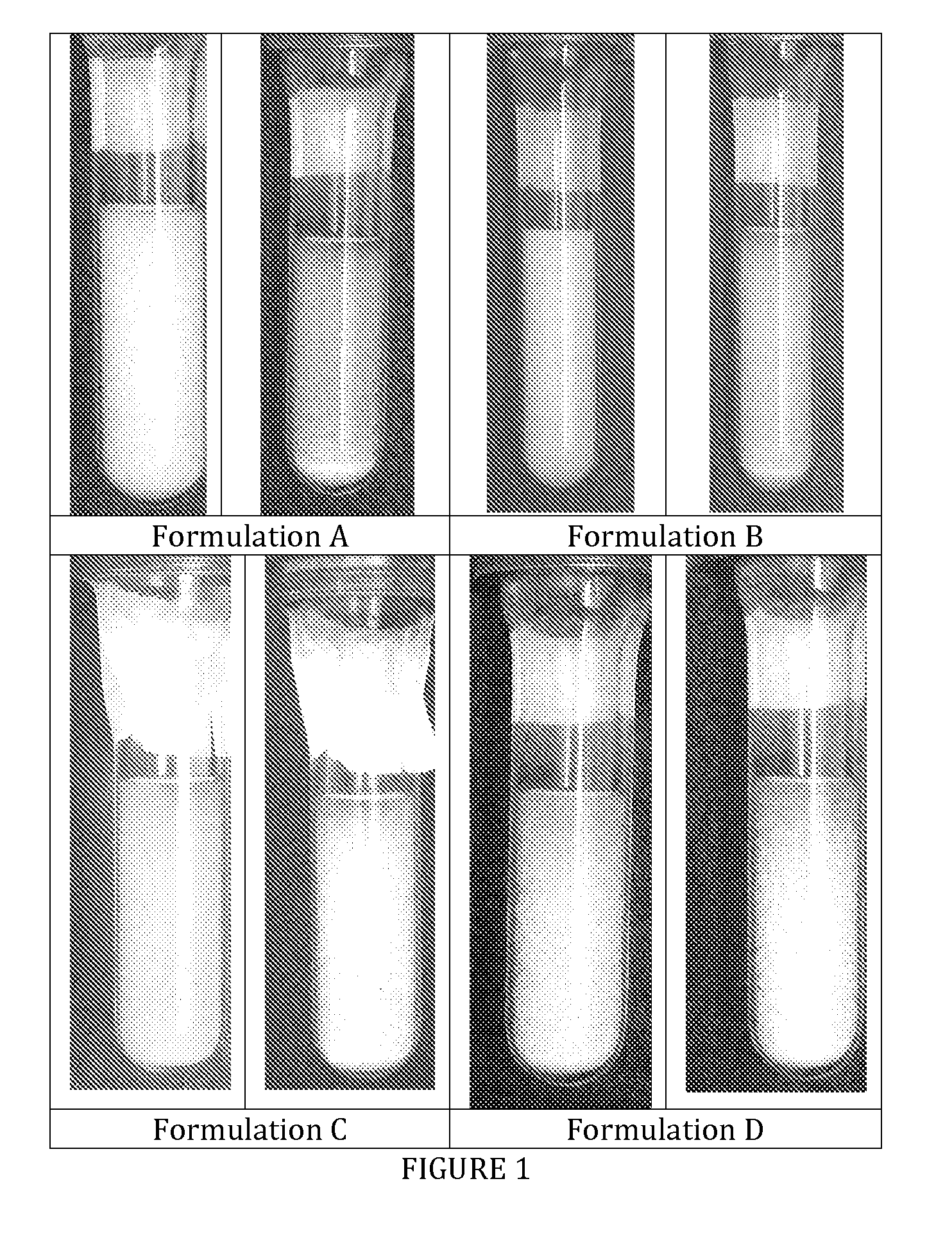

Non-ozone depleting medicinal formulations with low greenhouse effect

InactiveUS20120207685A1Satisfactory uniformity of doseStable suspension formulationsDispersion deliveryAntipyreticMedicineAtmospheric ozone

Pharmaceutical pressurized metered dose inhalers are disclosed having a composition free of CFCs and totally or partially free of HFAs, thus allowing the manufacture of medicinal aerosols without damaging the atmospheric ozone layer and with low or negligible greenhouse effect.

Owner:LAB PABLO CASSARA

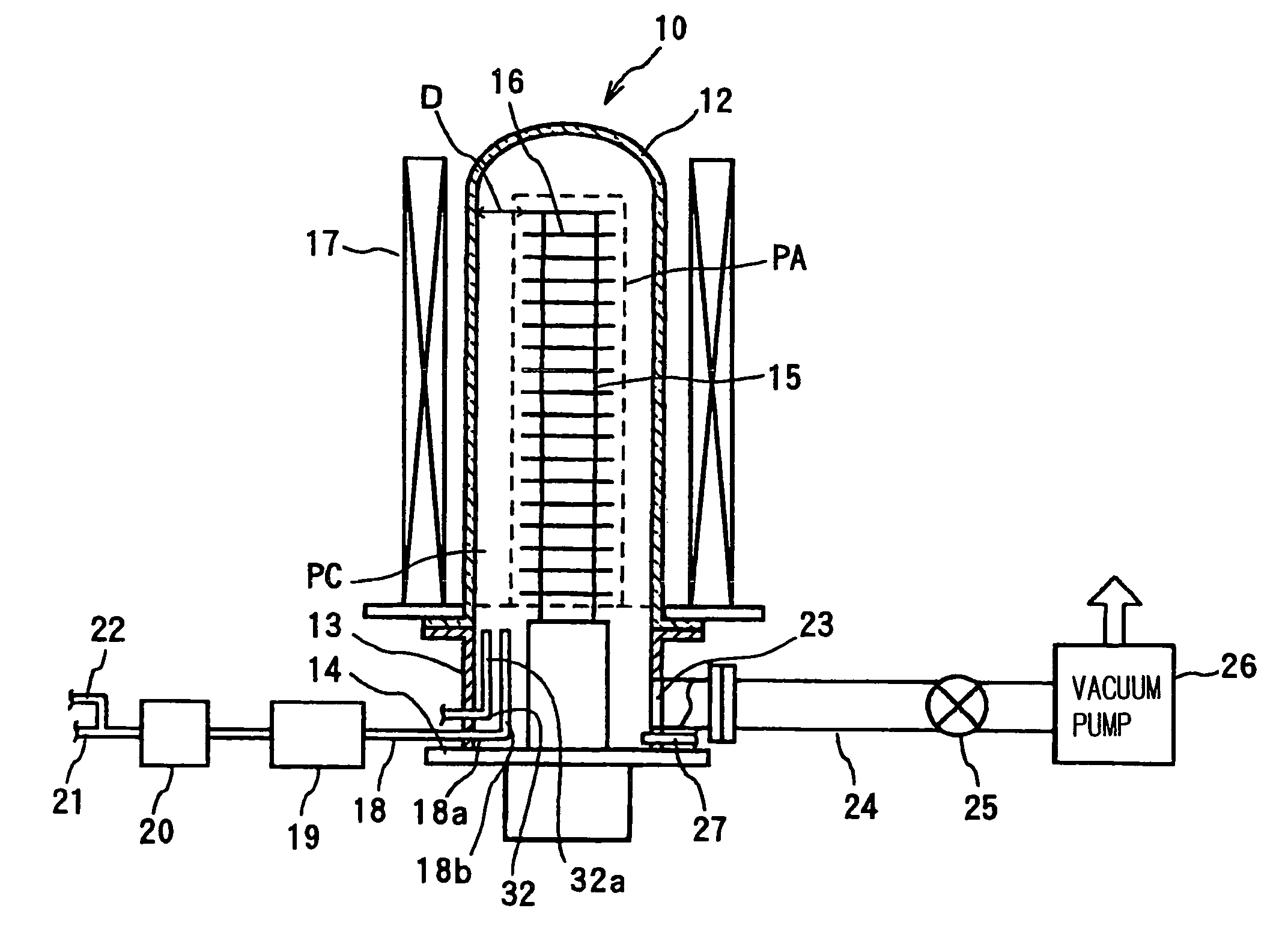

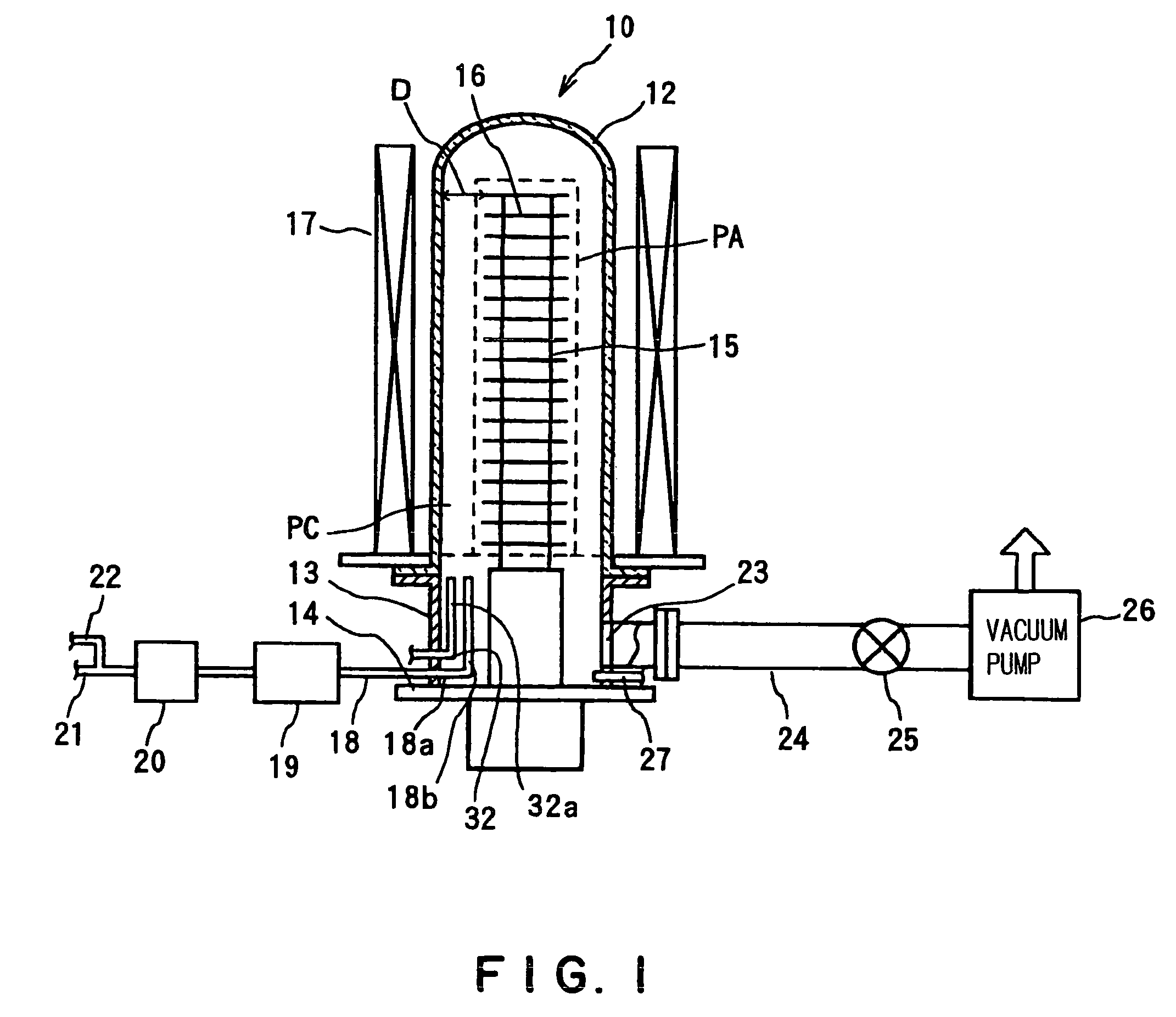

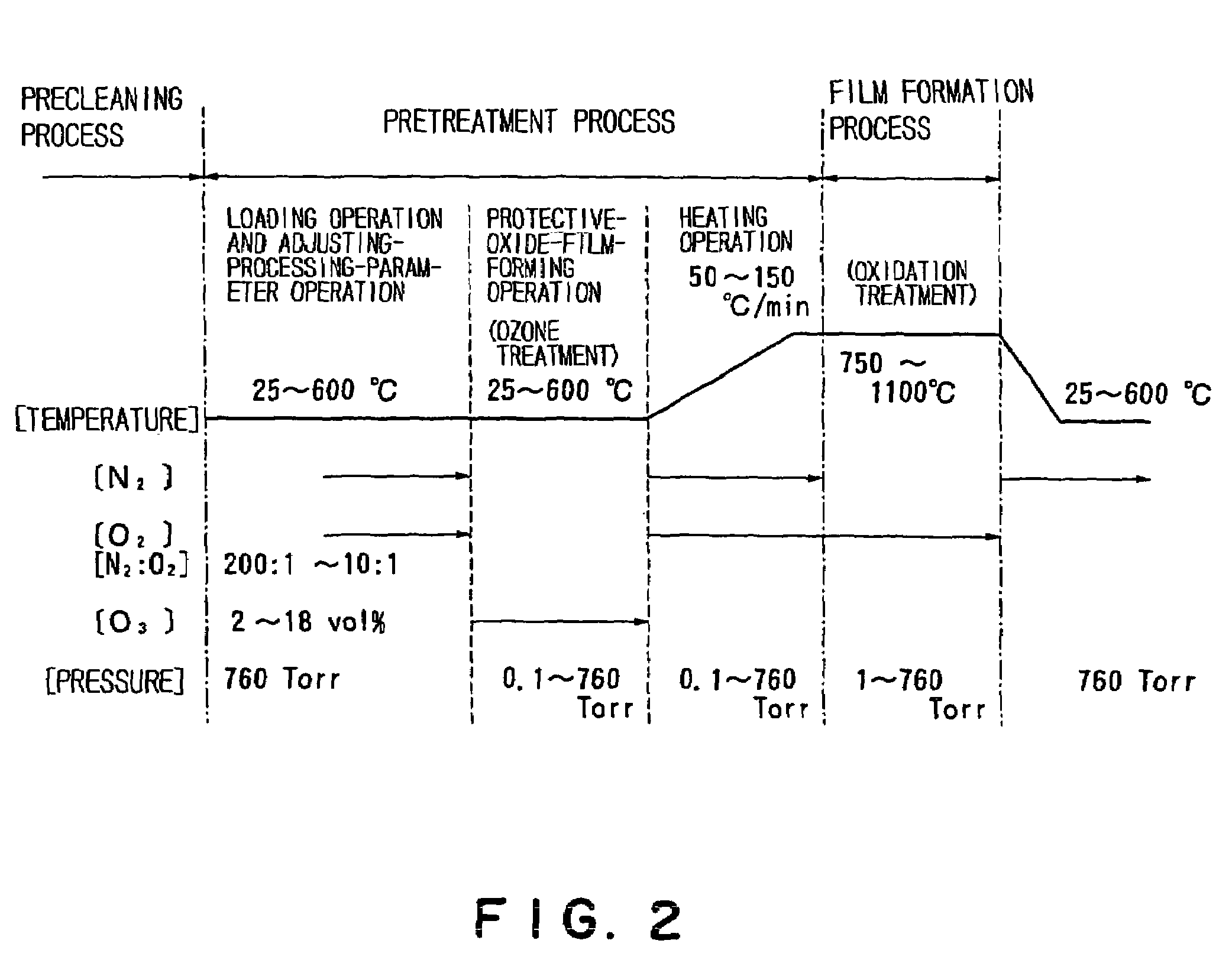

Oxide film forming method

InactiveUS7064084B2Improve featuresSolution to short lifeSemiconductor/solid-state device manufacturingSemiconductor devicesPre treatmentOxidative treatment

To provide a method for the formation of oxide films to form with advantage a high-quality oxide film having excellent uniformity in film thickness and film quality over the entire wafer. The method for the formation of oxide films comprises: the pretreatment process of forming a protective oxide film on the surface of a wafer positioned in a reaction vessel by performing oxidation treatment with radical oxidative species or an atmosphere containing radical oxidative species under depressurized conditions; and the oxide-film-formation process of forming an oxide film on the wafer by performing oxidation treatment at a predetermined temperature under depressurized conditions. The oxide-film-formation process is preferably performed following the pretreatment process in a continuous manner in the reaction vessel in which the pretreatment process is performed. The pretreatment process is preferably performed at a temperature lower than the temperature for the oxide-film-formation process and also preferably performed under depressurized conditions, the level of the depressurization being higher than the level for the oxide-film-formation process. A high-quality gate-insulating film for a transistor chip can be formed according to this method for the formation of oxide films.

Owner:TOKYO ELECTRON LTD

Ultrasonic diagnosis system and strain distribution display method

ActiveUS8041415B2Solve the real problemReduce computing timeOrgan movement/changes detectionCatheterCorrelation coefficientSonification

An ultrasonic diagnosis system and strain distribution display method utilizing an ultrasonic probe for performing transmission / reception of ultrasonic signals to / from a subject, a storage arrangement for storing the properties of signals detected with the ultrasonic probe, a correlation computer for calculating a correlation coefficient between the properties with and without pressure applied to the subject, and a phase difference between the received signals with and without application of pressure, based upon the properties stored in the storage arrangement with and without pressure applied to the subject, a computer for calculating a displacement of each measurement point, and a strain distribution of tissue of the subject due to application of pressure, based upon the correlation coefficient and phase difference calculated by the correlation computer, and a display for displaying the strain distribution.

Owner:SHIINA TSUYOSHI +1

Heat dissipation device for portable computer

InactiveUS20090080150A1Improve cooling effectRapidity in air-blowingDigital data processing detailsCooling/ventilation/heating modificationsNoise generationEngineering

This invention relates to a heat dissipation device for portable computer. The heat dissipation device comprises: a housing including at least one fan casing and at least one duct, said fan casing having an air suction opening which communicates with said duct, at least one air outlet communicating with said fan casing being provided at the front end of said housing, at least one air inlet communicating with said fan casing being provided at the rear end of said housing; and at least one side-blow fan provided within the fan casing, the air suction face of the side-blow fan being opposite to the air suction opening, the air introducing from the air inlet into the duct passes being sucked by the side-blow fan into the fan casing after passing through the air suction opening and blowing out through the air outlet. In this manner, excellent heat dissipation effect collocating with the use of a portable computer can be obtained. In addition, noise generation is effectively prevented. Therefore, the effectiveness in practical application and the product quality can be further enhanced positively.

Owner:CHANG CHE HUA +2

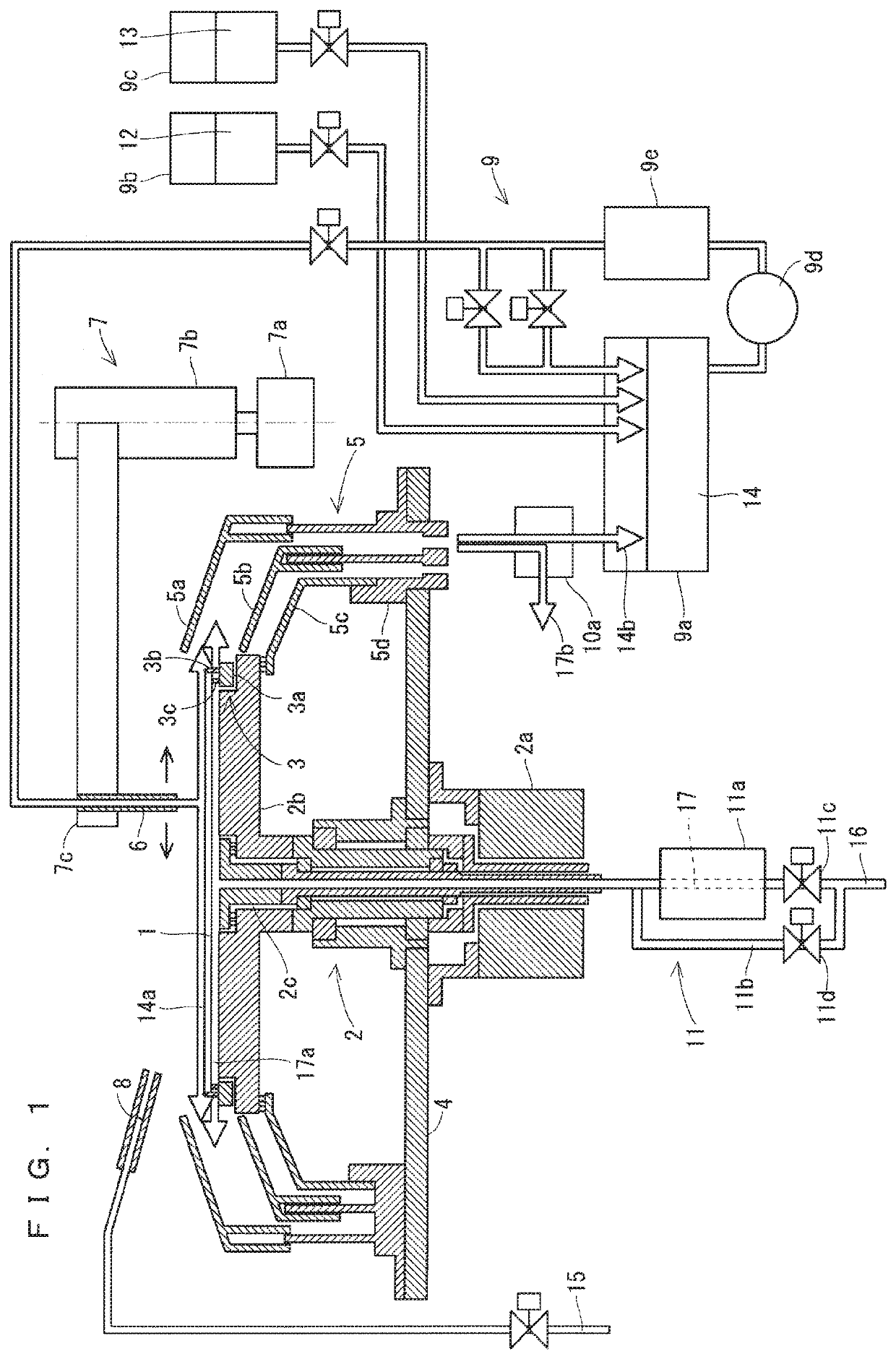

Substrate processing apparatus and substrate processing method

ActiveUS7807587B2Efficient removalEnsuring sufficient uniformityLiquid surface applicatorsSemiconductor/solid-state device manufacturingVacuum pressureProcess engineering

Owner:TOKYO ELECTRON LTD

Powdered silica, silica container, and method for producing them

InactiveUS8460769B2High inhibiting effect of impurity diffusionIncreased durabilitySilicaBy pulling from meltHydrogen moleculeSilicon dioxide

A method is provided for producing a silica container arranged with a substrate, having a rotational symmetry, comprised of mainly a silica, and containing gaseous bubbles at least in its peripheral part, and an inner layer, formed on an inner surface of the substrate and comprised of a transparent silica glass; wherein a powdered silica, having particle diameter of 10 to 1000 μm, containing Ca, Sr, and Ba with the total concentration of 50 to 5000 ppm by weight, and releasing hydrogen molecules with the amount of 3×1016 to 3×1019 molecules / g upon heating at 1000° C. under vacuum, is prepared at least as a powdered raw material for forming the inner layer, and then the inner layer is formed from the powdered silica as the powdered raw material for forming the inner layer.

Owner:SHIN ETABU QUARTZ PRODS

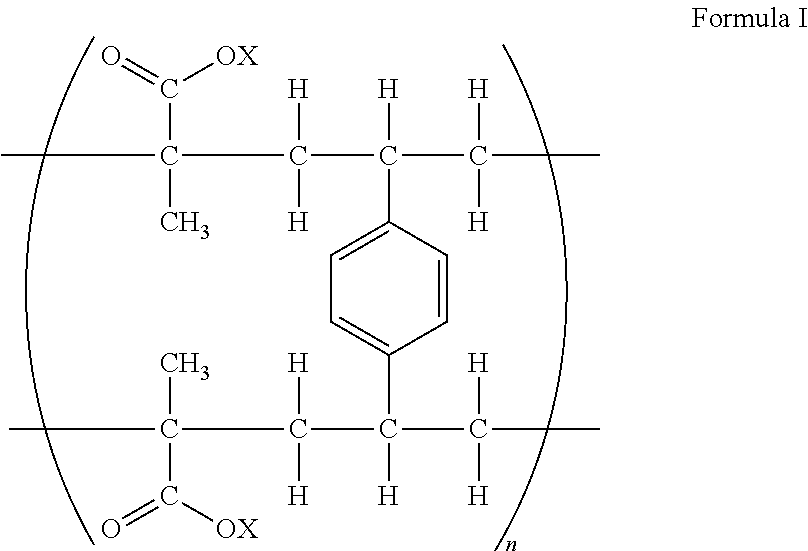

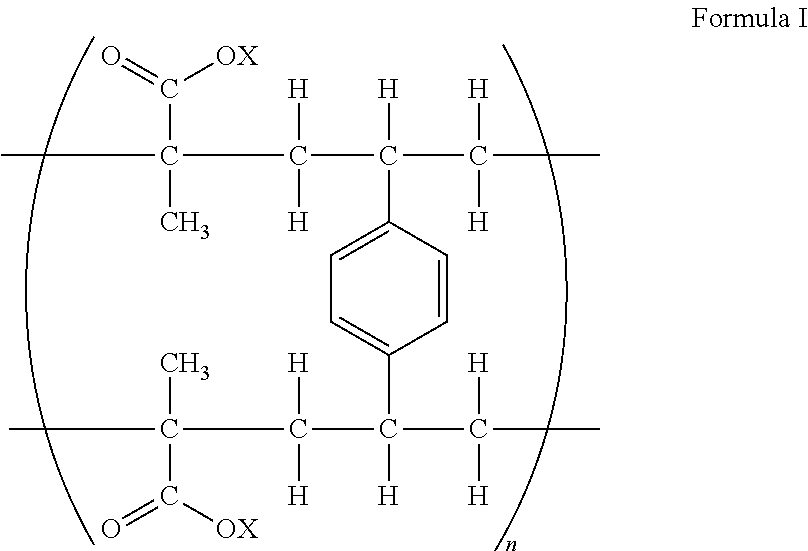

Annular belt made of polyimide and a production method thereof

ActiveUS8470232B2Increase production capacityEnsuring sufficient uniformityHollow filament manufactureLaminationImidePolymer science

Owner:KONICA MINOLTA BUSINESS TECH INC

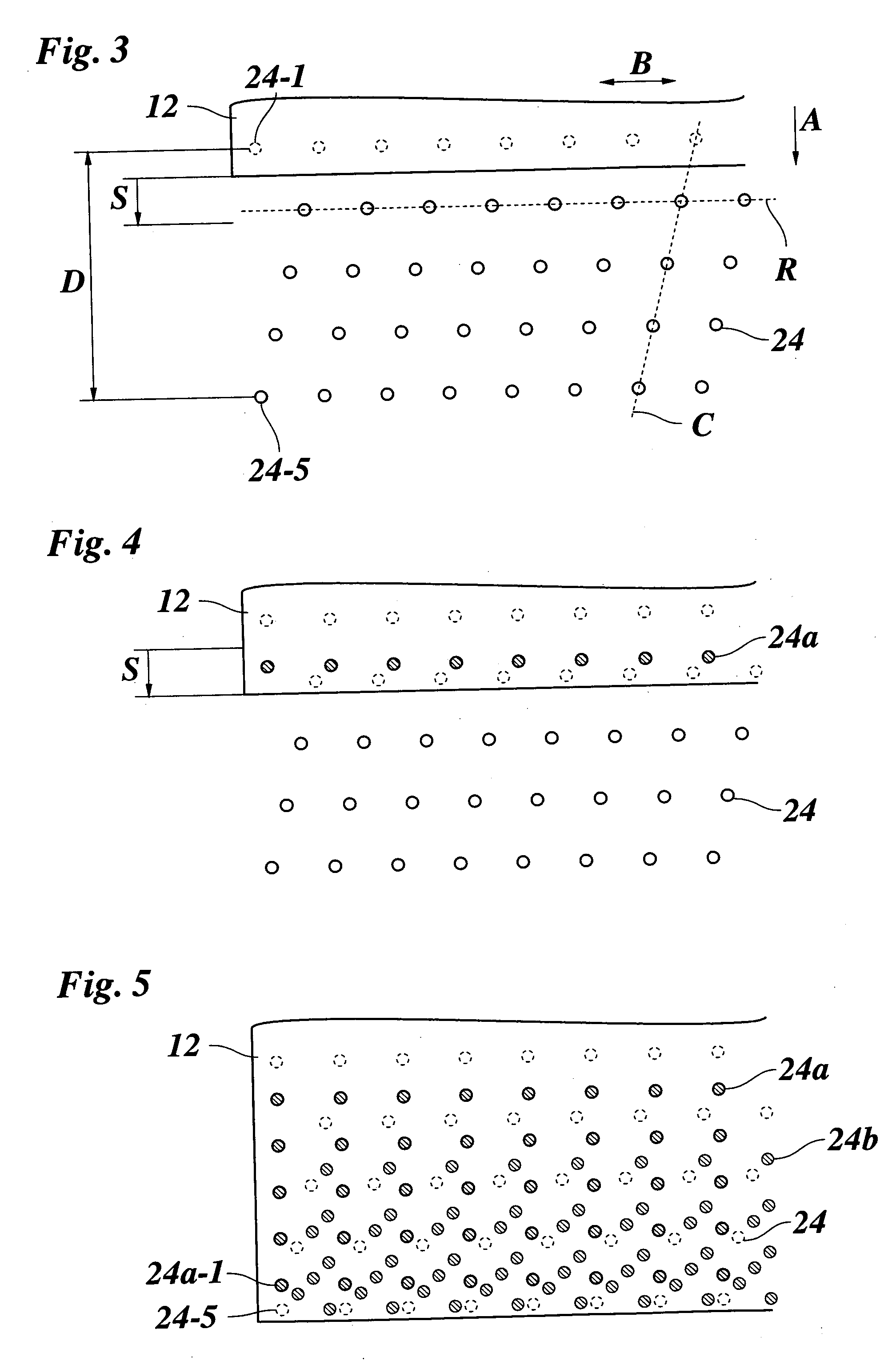

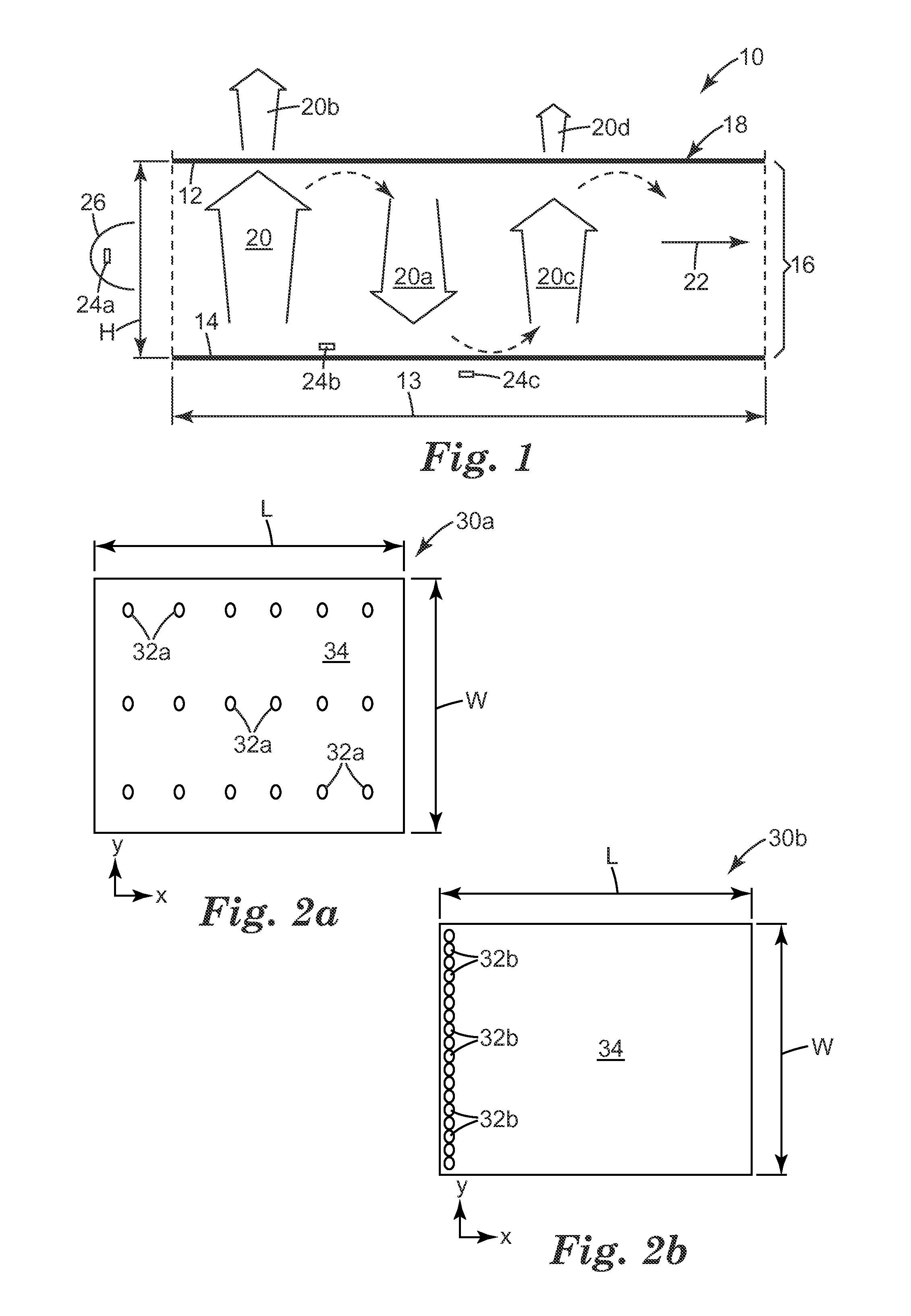

Ink jet printer

InactiveUS20060181016A1Improve image qualityReduce heat dissipationOther printing apparatusArticle feedersComputer printingInk printer

An ink jet printer including: a sheet support plate having suction holes formed in a sheet support surface thereof; a sheet advance mechanism adapted to advance a sheet step-wise in a sheet advance direction over the sheet support surface; and an imaging system adapted to form an image by depositing liquid ink on the sheet, the ink being allowed to dry-out while the sheet is advanced over the sheet support plate, wherein the suction holes are arranged such that their influence on the ink drying process is essentially uniform over the whole area of the image.

Owner:OCE TECH

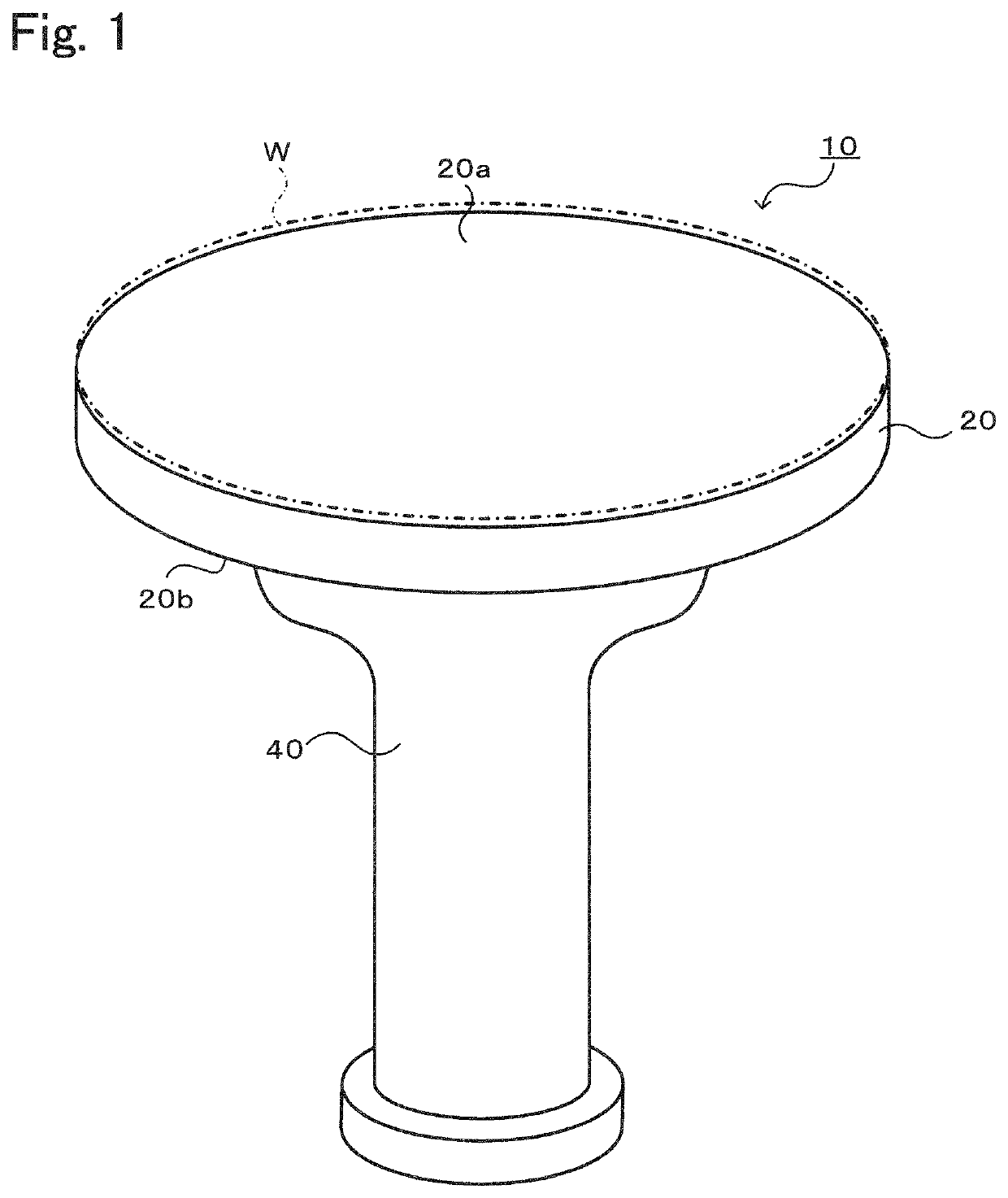

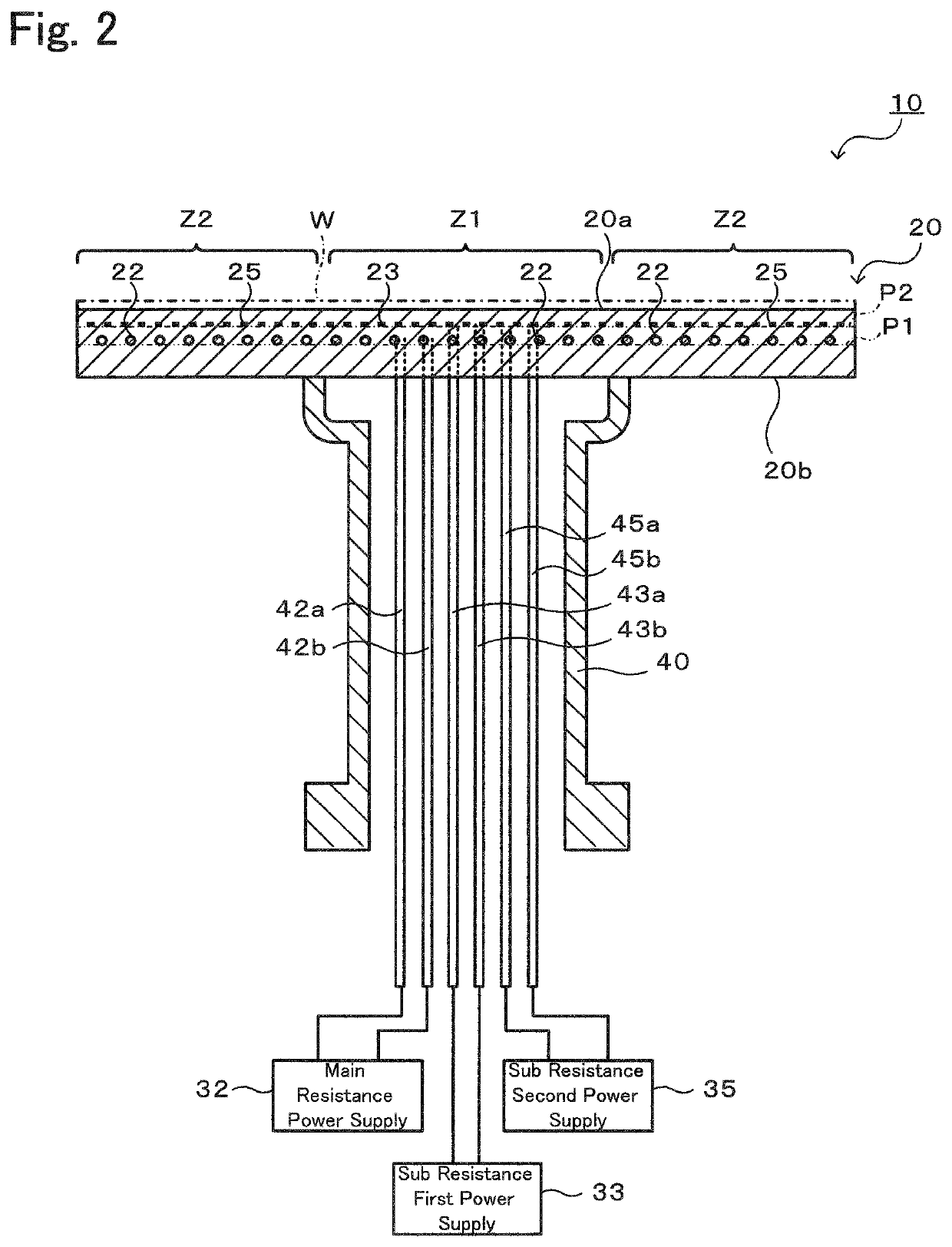

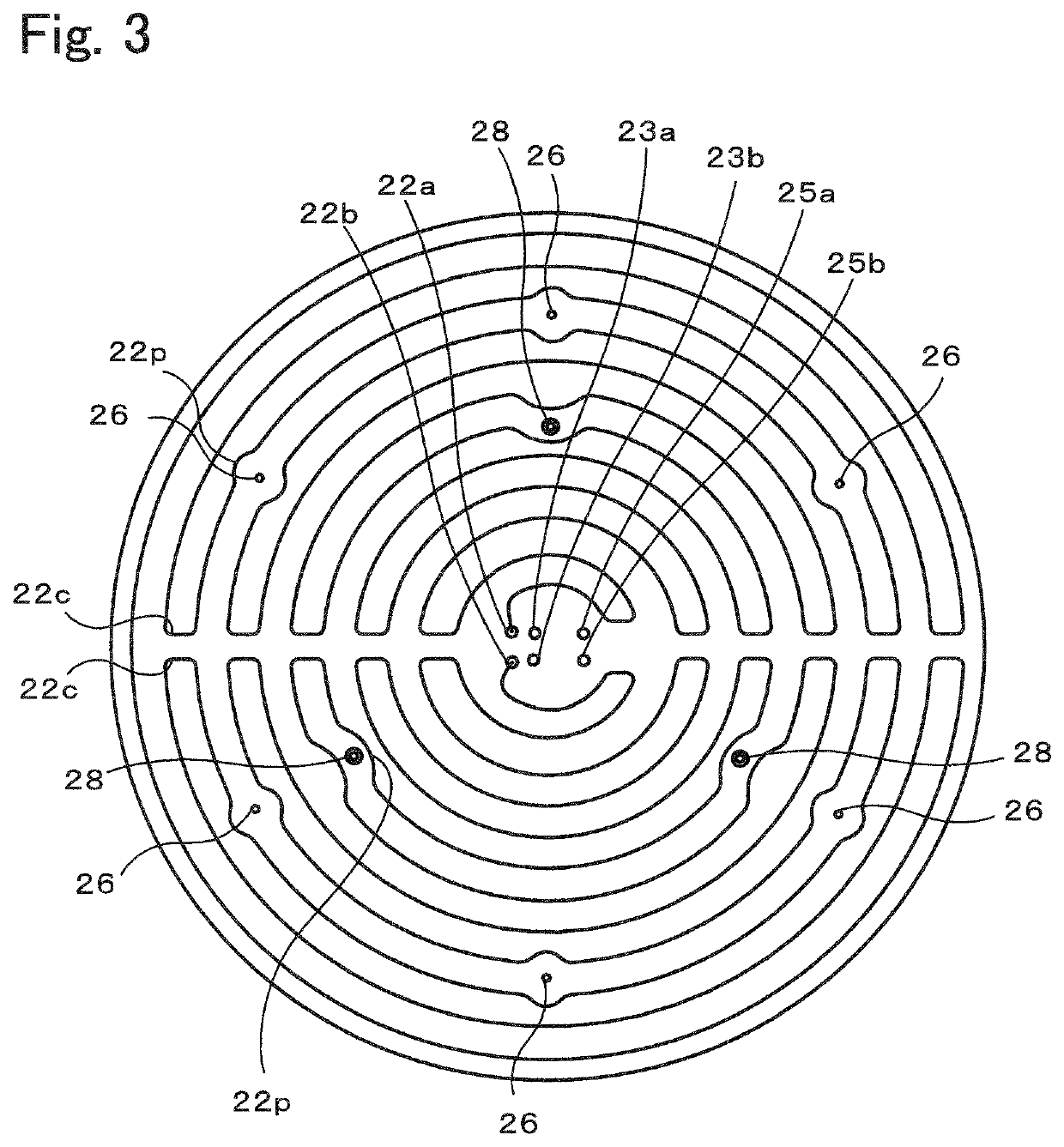

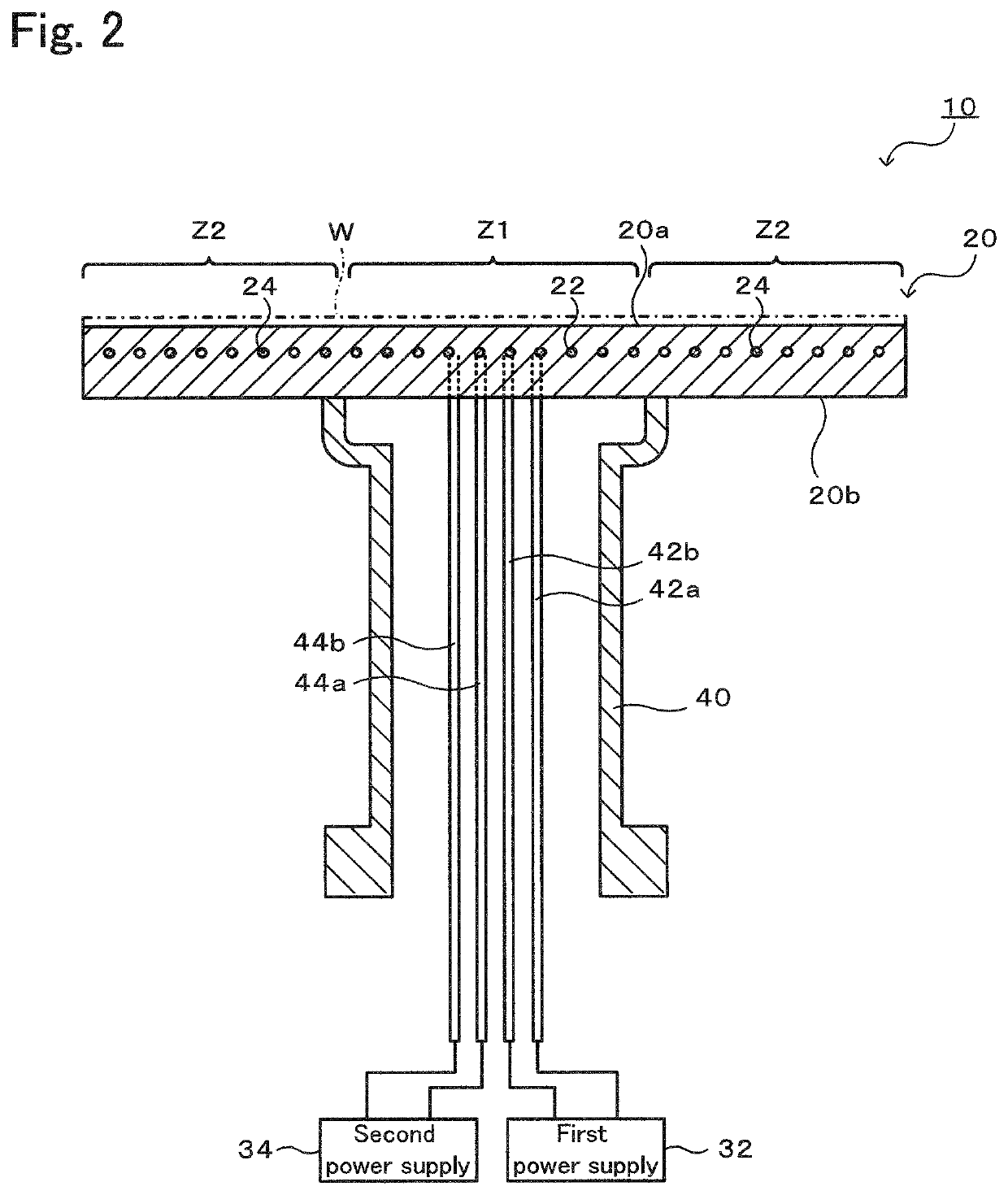

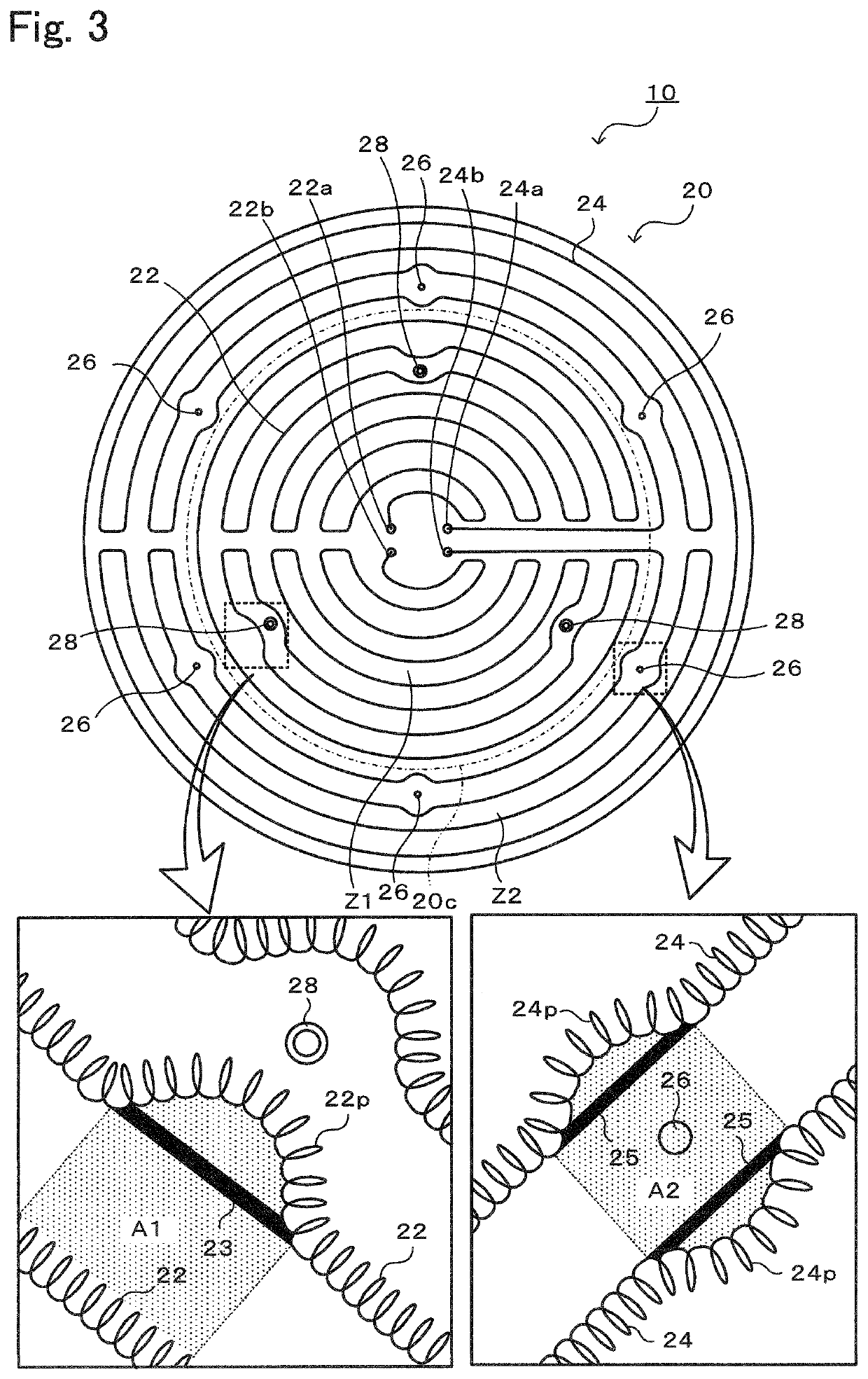

Ceramic heater

PendingUS20210243850A1Easy to adjustDifficult to adjustSemiconductor/solid-state device manufacturingHot plates heating arrangementsWaferingHeating element

A ceramic heater includes a ceramic plate, a main resistance heating element, and sub resistance heating elements. The main resistance heating element is a heating element that is disposed on a first plane parallel with a wafer placement surface in the ceramic plate and that has a coil shape. The sub resistance heating elements are heating elements that are disposed on a second plane parallel with the first plane in the ceramic plate between the first plane and the wafer placement surface, that complement heating with the main resistance heating element, and that have a two-dimensional shape.

Owner:NGK INSULATORS LTD

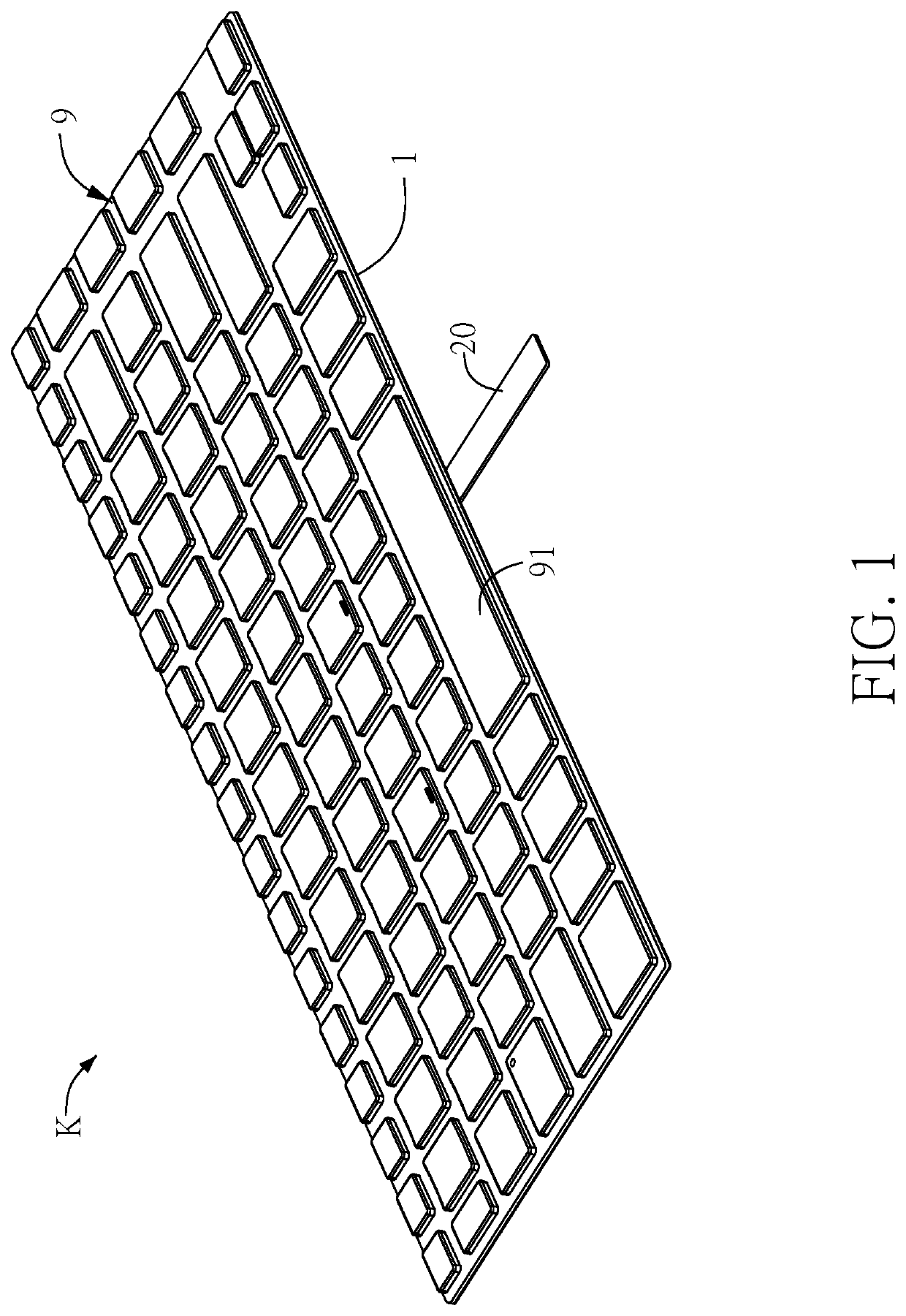

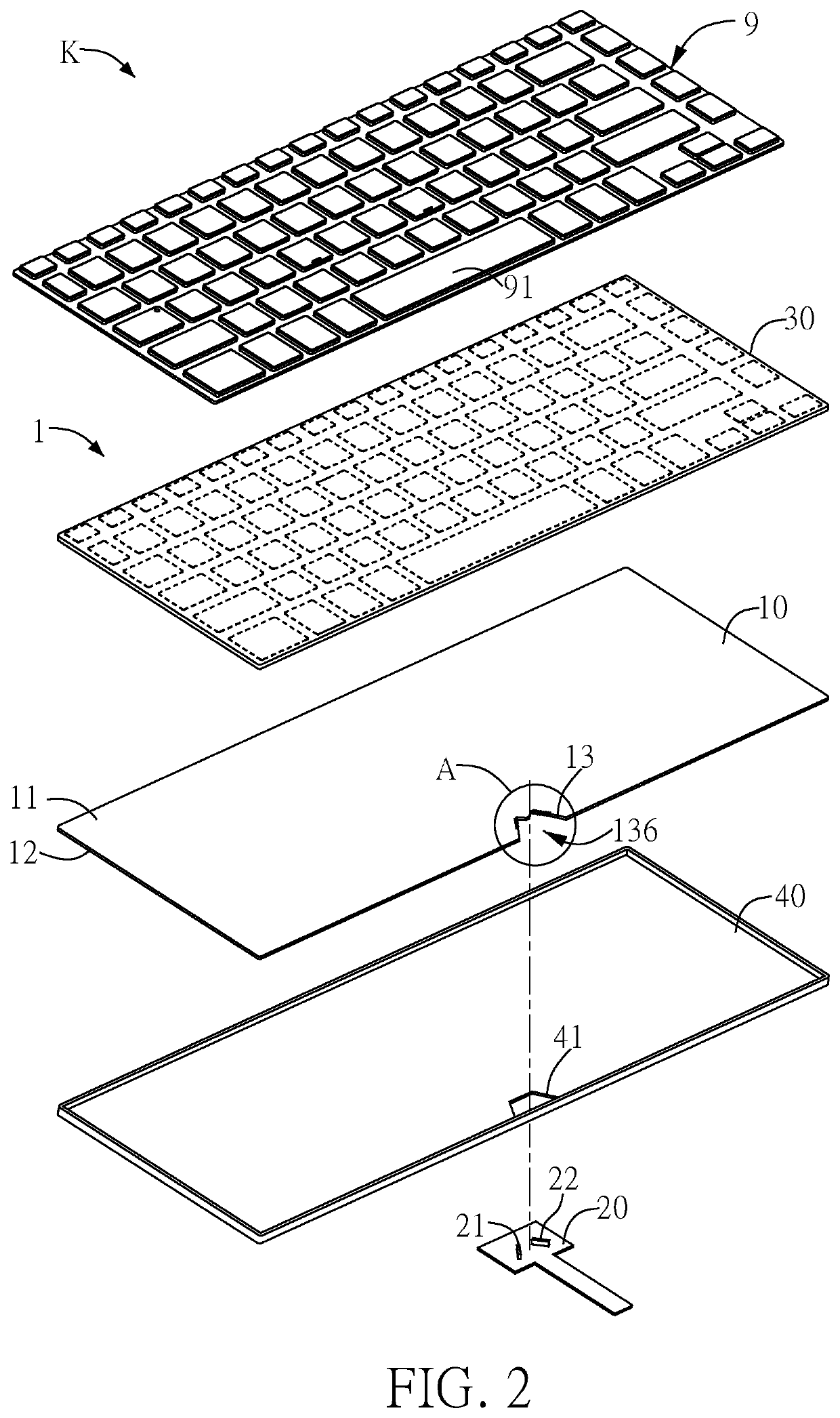

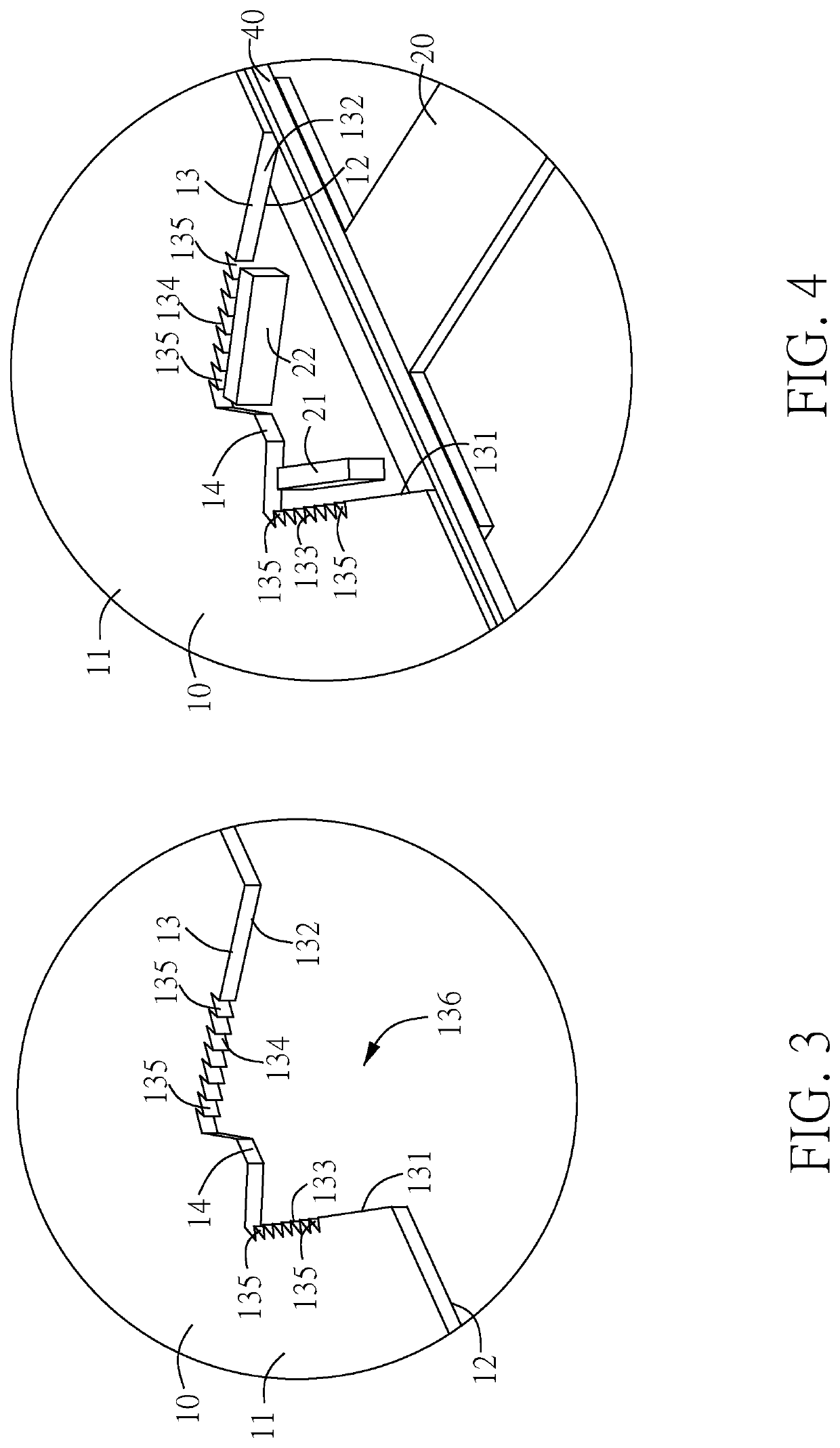

Illuminating keyboard and light emitting module thereof

ActiveUS10593492B1Solve the real problemImprove divergence angleInput/output for user-computer interactionLegendsLight guideLight beam

The present disclosure discloses an illuminating keyboard including a keyboard module and a light emitting module. The keyboard module has an opaque region. The light emitting module includes a light guiding plate, a first light emitting component and a second light emitting component. The light guiding plate includes an accommodating groove corresponding to the opaque region. The accommodating groove has a first sidewall, a second sidewall, a first light divergence segment and a second light divergence segment. The first light divergence segment and the second light divergence segment are disposed on the first sidewall and the second sidewall, respectively. The first light emitting component and the second light emitting component are located in the accommodating groove and are disposed toward the first sidewall and the second sidewall, respectively. The light beams are injected into the light guiding plate via the first and the second light divergence segment.

Owner:CHICONY POWER TECH CO LTD

Ceramic heater

PendingUS20210235548A1Avoid singularitiesIncrease freedomSemiconductor/solid-state device manufacturingHeating element materialsHeating elementCeramic materials

A ceramic heater includes a ceramic plate, a main resistance heating element, and a sub resistance heating element. The main resistance heating element is a coil that is disposed in the ceramic plate, that is wired from one of a pair of main terminals in a one-stroke pattern, and that reaches the other of the pair of the main terminals. The sub resistance heating element is a heating element that is disposed in the ceramic plate, that complements heating with the main resistance heating element, and that has a two-dimensional shape.

Owner:NGK INSULATORS LTD

Silica container and method for producing the same

ActiveUS20130248408A1High inhibiting effect of impurity diffusionIncreased durabilityAfter-treatment apparatusPolycrystalline material growthTransmittanceLength wave

Owner:SHIN ETABU QUARTZ PRODS

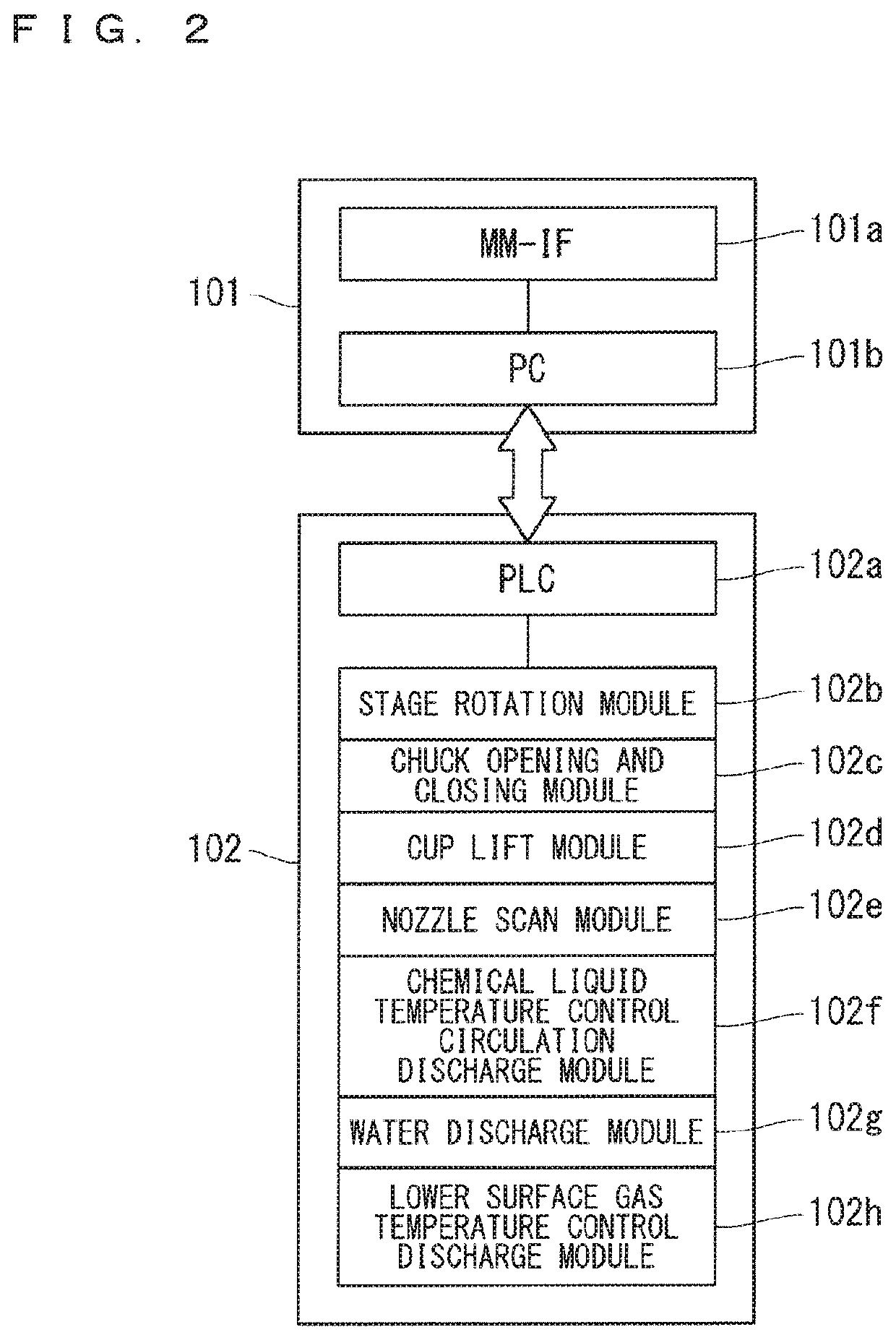

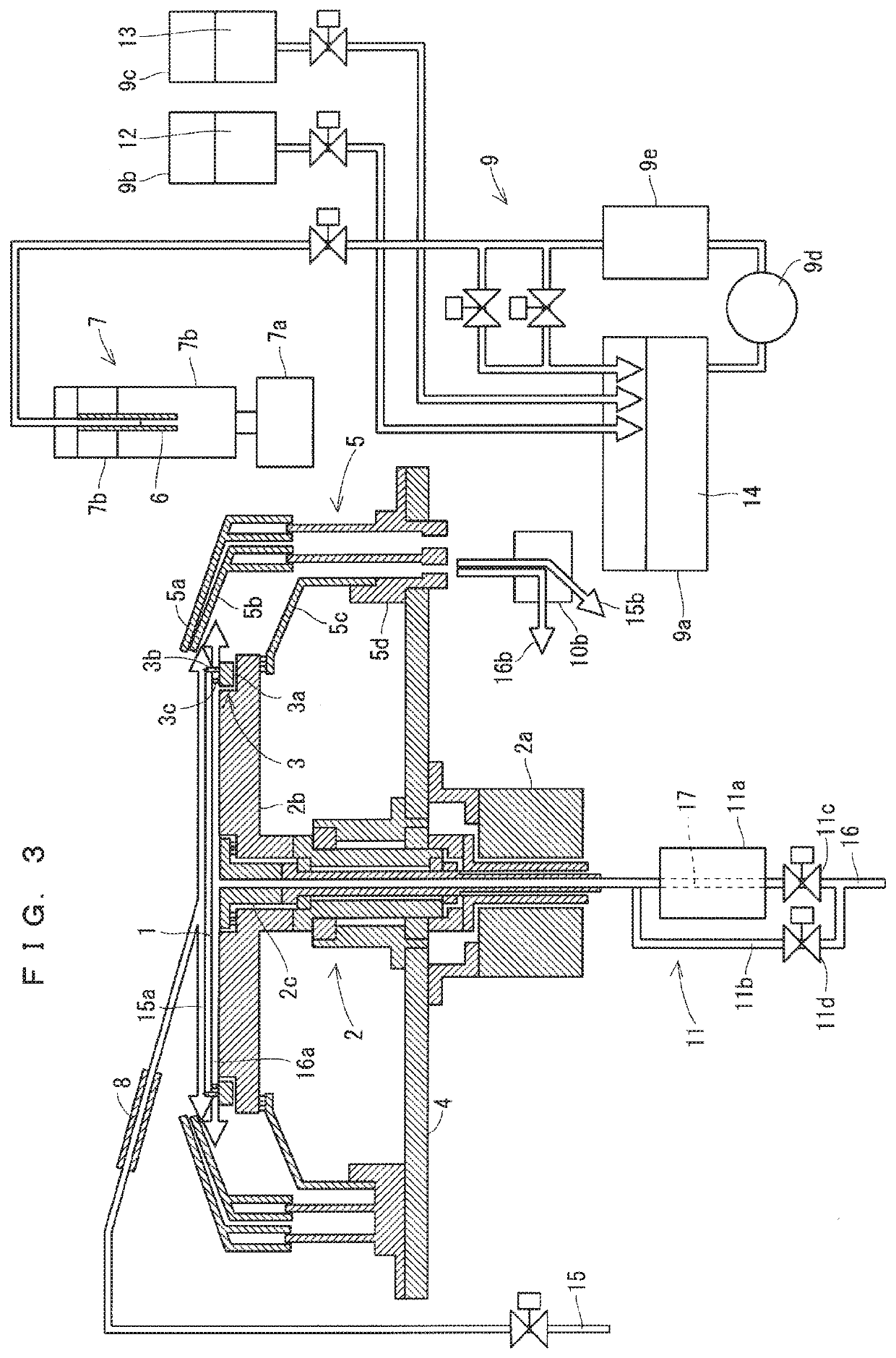

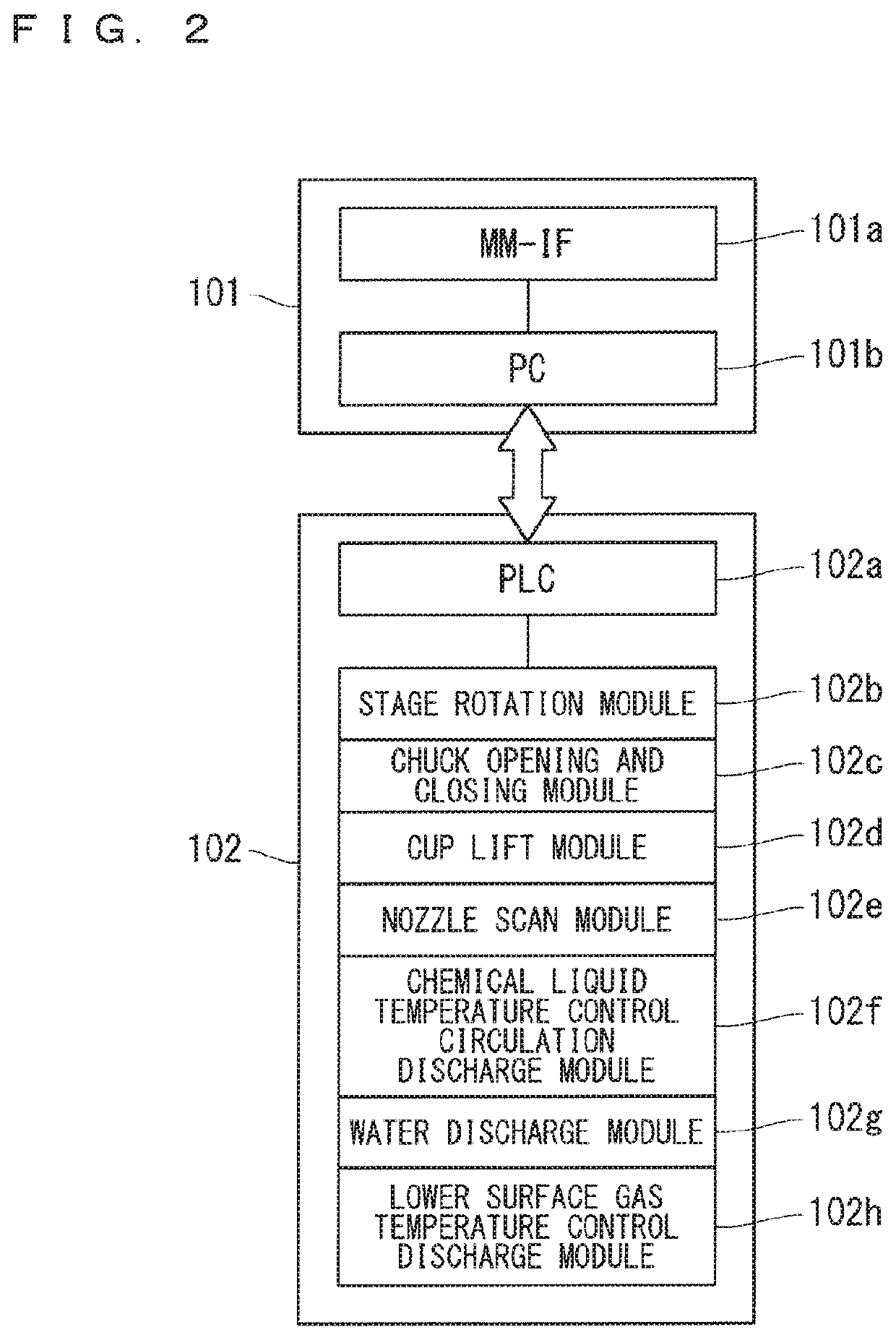

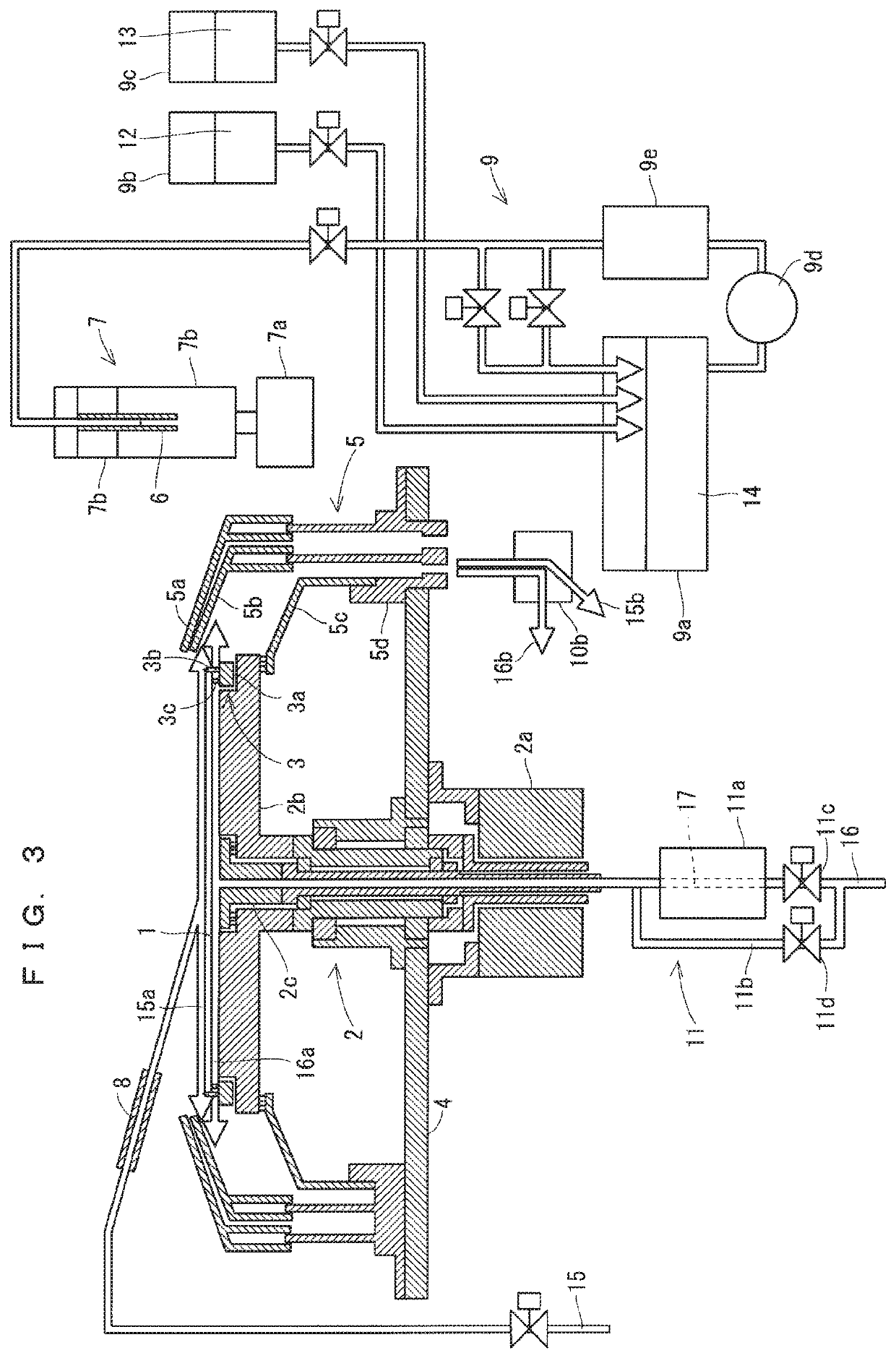

Semiconductor manufacturing apparatus and semiconductor manufacturing method

ActiveUS20200135448A1Sufficient in-plane uniformityIncrease the diameterSemiconductor/solid-state device manufacturingCleaning using liquidsGas passingEngineering

A semiconductor manufacturing apparatus includes a chuck stage, a stage rotation mechanism, a chemical liquid nozzle, a chemical liquid nozzle scan mechanism, a lower surface gas nozzle, a gas temperature controller configured to control a temperature of gas to be supplied to the lower surface gas nozzle, a gas bypass pipe configured to allow the gas to be supplied to the lower surface gas nozzle without causing the gas to pass through the gas temperature controller, and first and second on-off valves configured to open and shut to allow either of the gas whose temperature has been controlled by the gas temperature controller and the gas passing through the gas bypass pipe to be supplied to the lower surface gas nozzle. Actuation of the first and second on-off valves allows a temperature of the gas passing through the lower surface gas nozzle to be changed.

Owner:MITSUBISHI ELECTRIC CORP

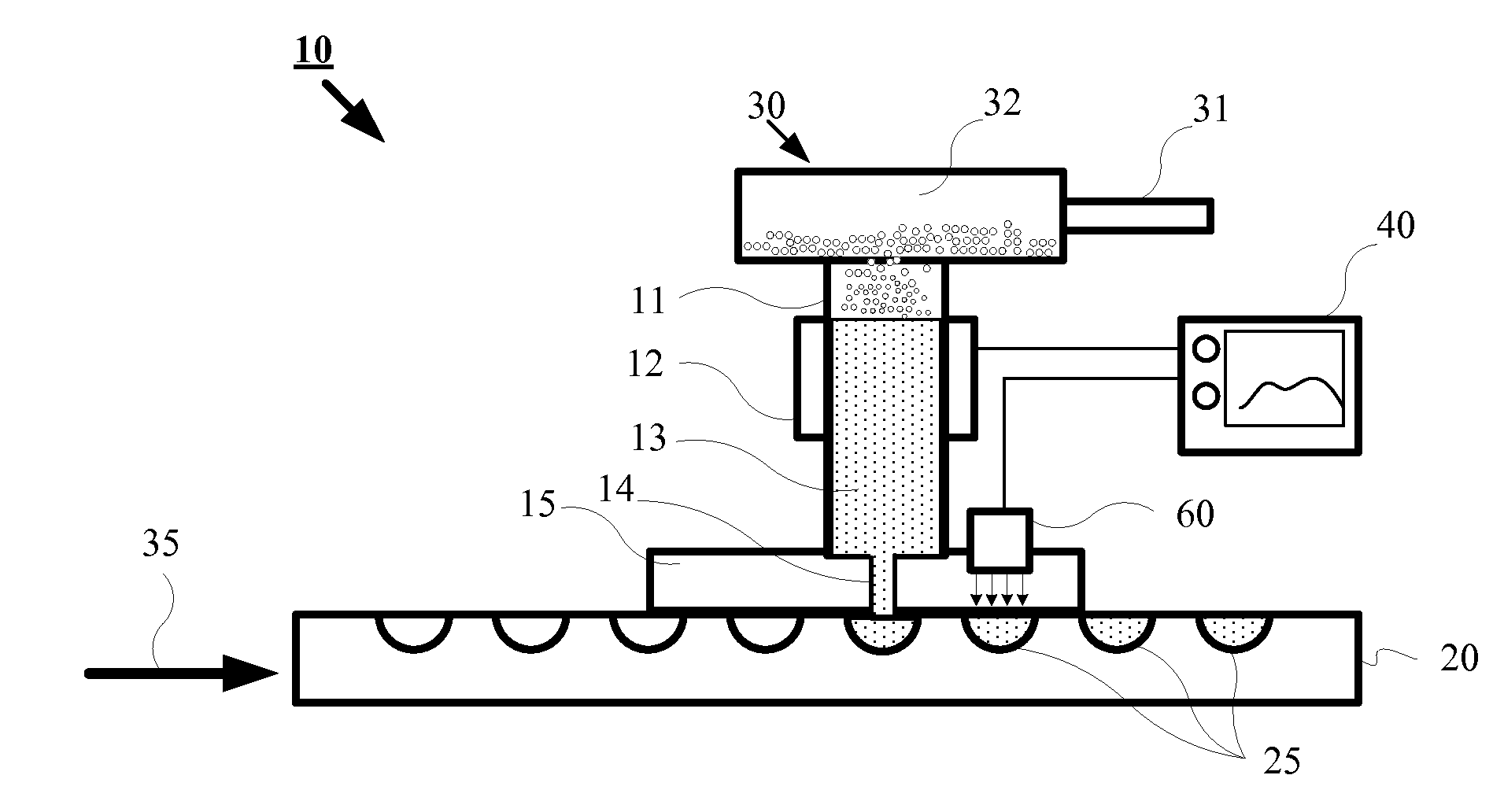

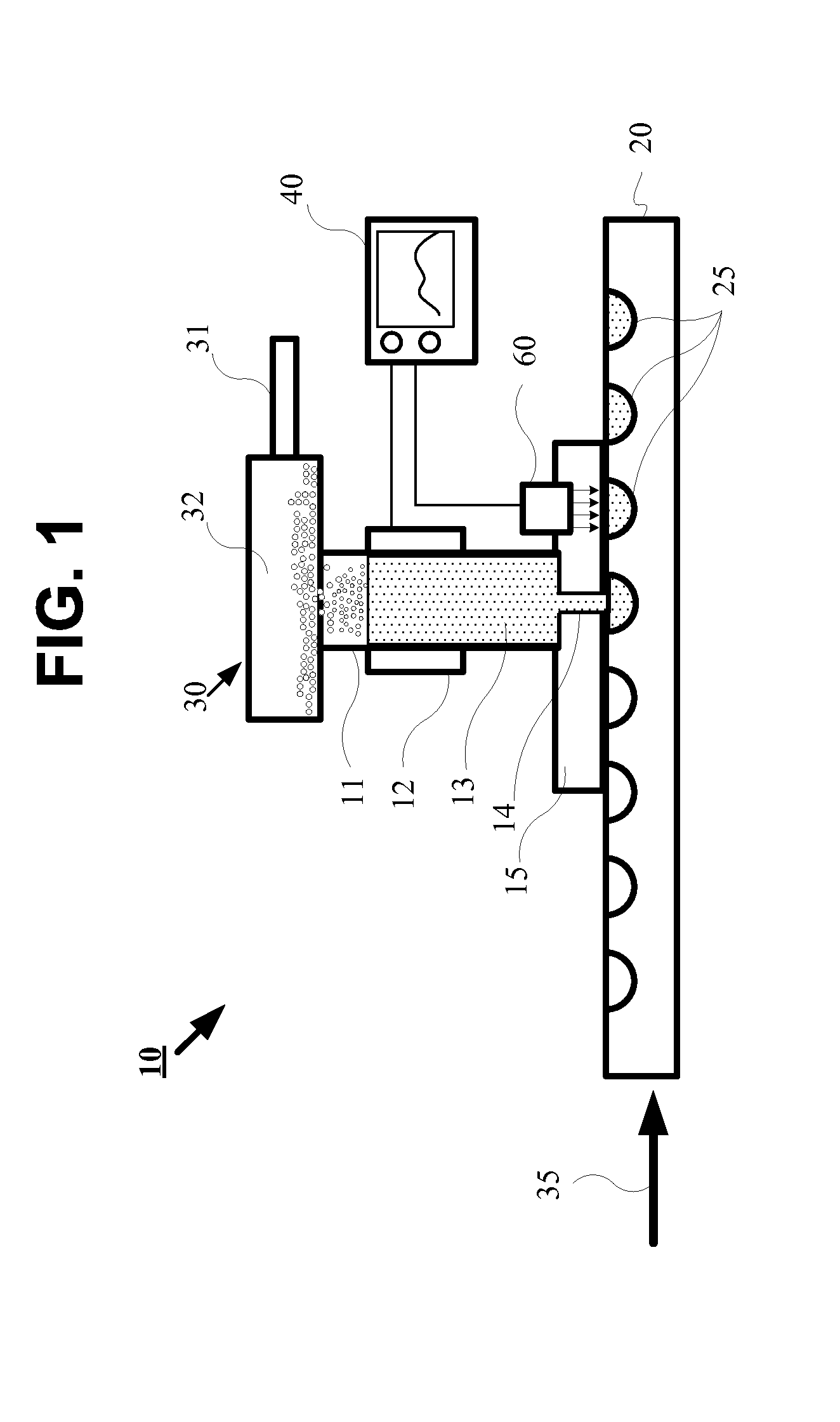

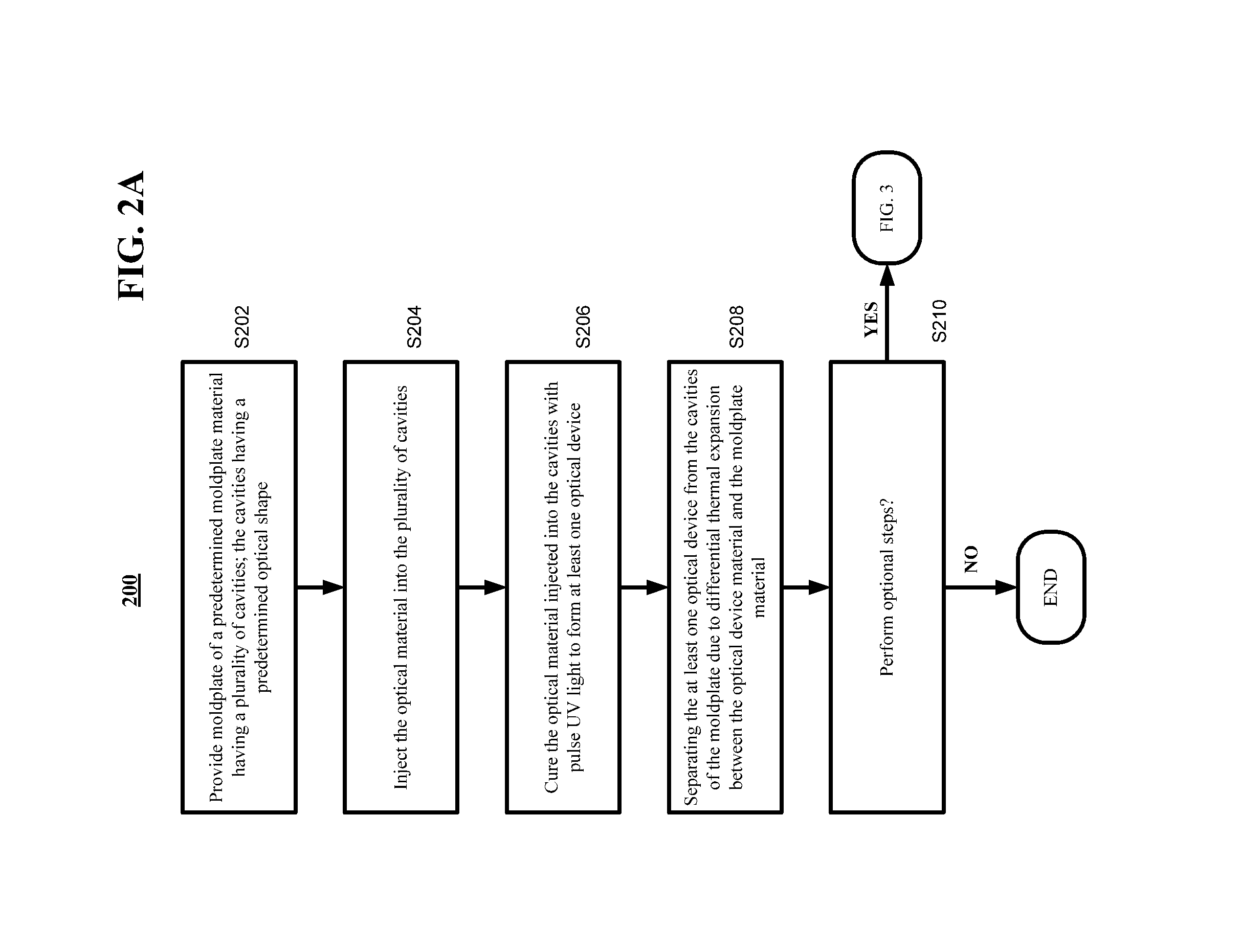

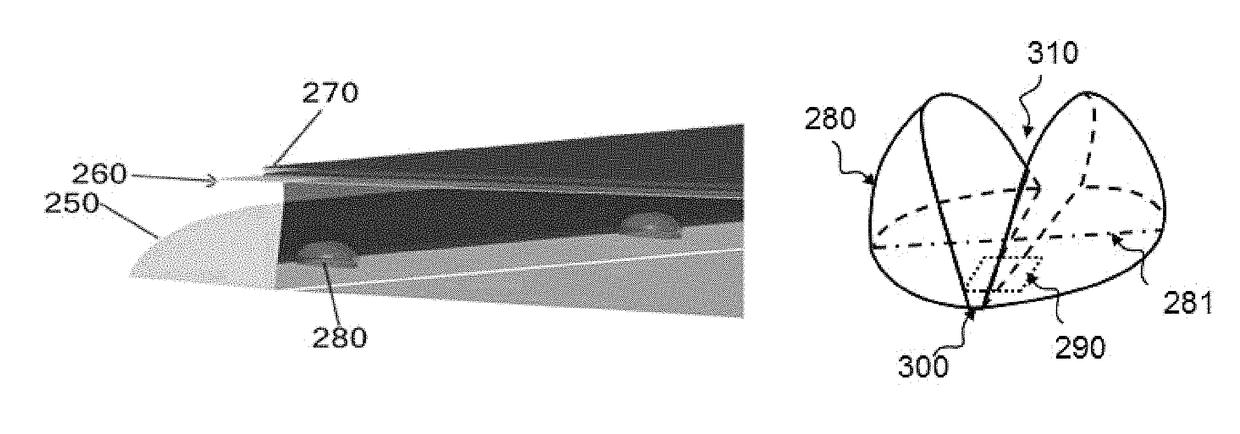

Enhanced separation of injection molded microlenses for high volume manufacturing

InactiveUS20120207868A1Quick evacuationMaterial becomes quickOptical articlesAuxillary shaping apparatusHigh volume manufacturingDevice material

A method and system for enhanced demolding of injection molded optical devices are disclosed. In one embodiment the system includes a metal moldplate without a coat of release layer and a curing device that generates high intensity pulses of UV light. The method includes: providing a moldplate made of a predetermined moldplate material; directly injecting optical material into cavities of a moldplate without a release layer; rapidly curing the injected optical material with high intensity pulses of UV light such that a predetermined optical device is formed; and separating the thus formed optical device from the cavities of the moldplate due to a differential thermal expansion between the optical device material and the moldplate material.

Owner:IBM CORP

Air cavity LED backlight unit

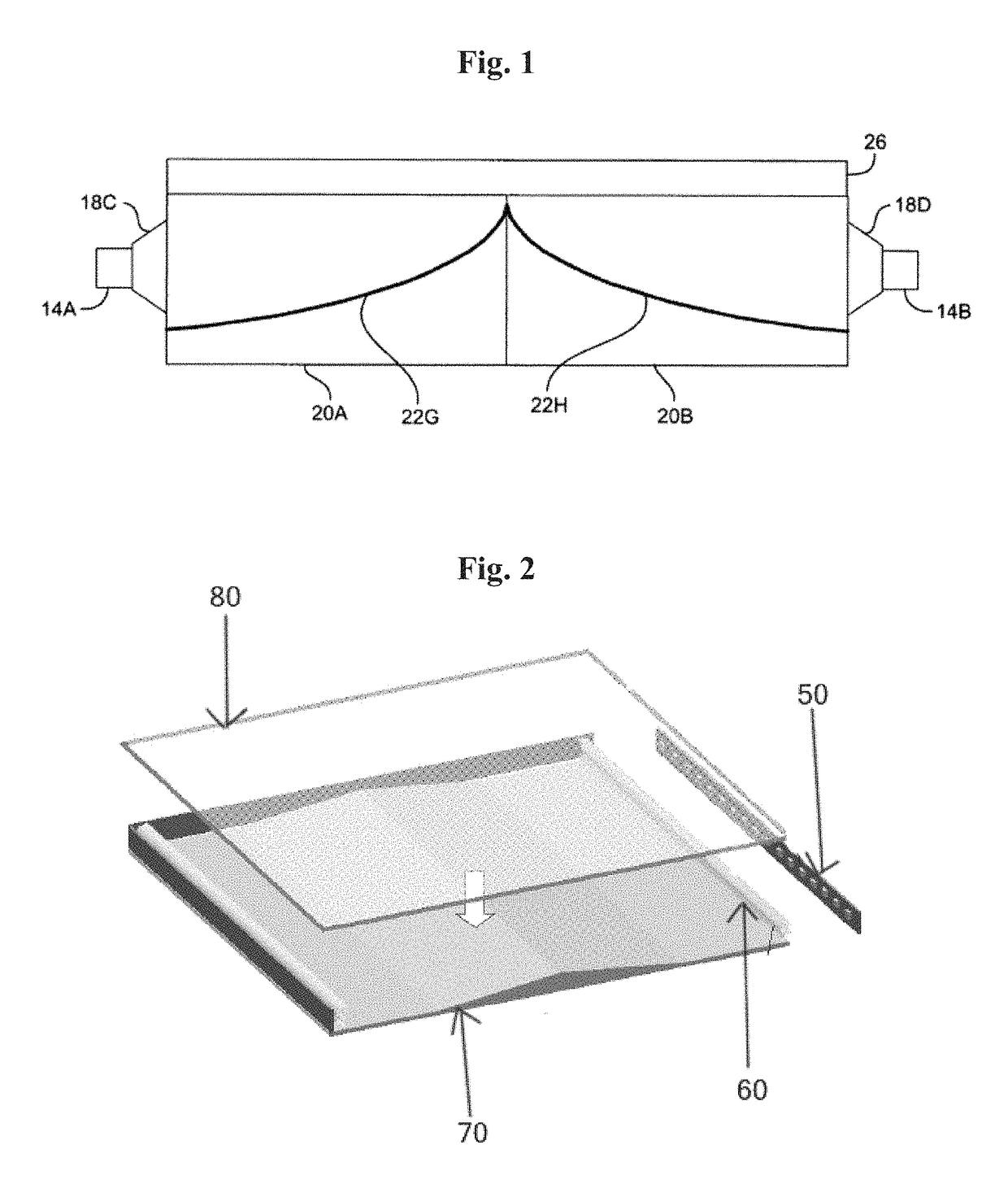

ActiveUS9690041B2Accurate displayEnsuring sufficient uniformityMechanical apparatusHollow light guidesBack reflectorMirror image

A light-emitting diode (LED) backlight unit includes first and second curved bottom floor reflectors exhibiting mirror image symmetry along a center line extending in a latitudinal direction, first and second sides disposed along a longitudinal direction, the first and second bottom floor reflectors disposed therebetween, first and second back reflectors disposed on distal ends of the first and second bottom floor reflectors, respectively, away from the center line, and LEDs disposed in or adjacent to the first and second back reflectors. A curvature of the first and second bottom floor reflectors respectively reach a maximum near the center line.

Owner:SEOUL SEMICONDUCTOR

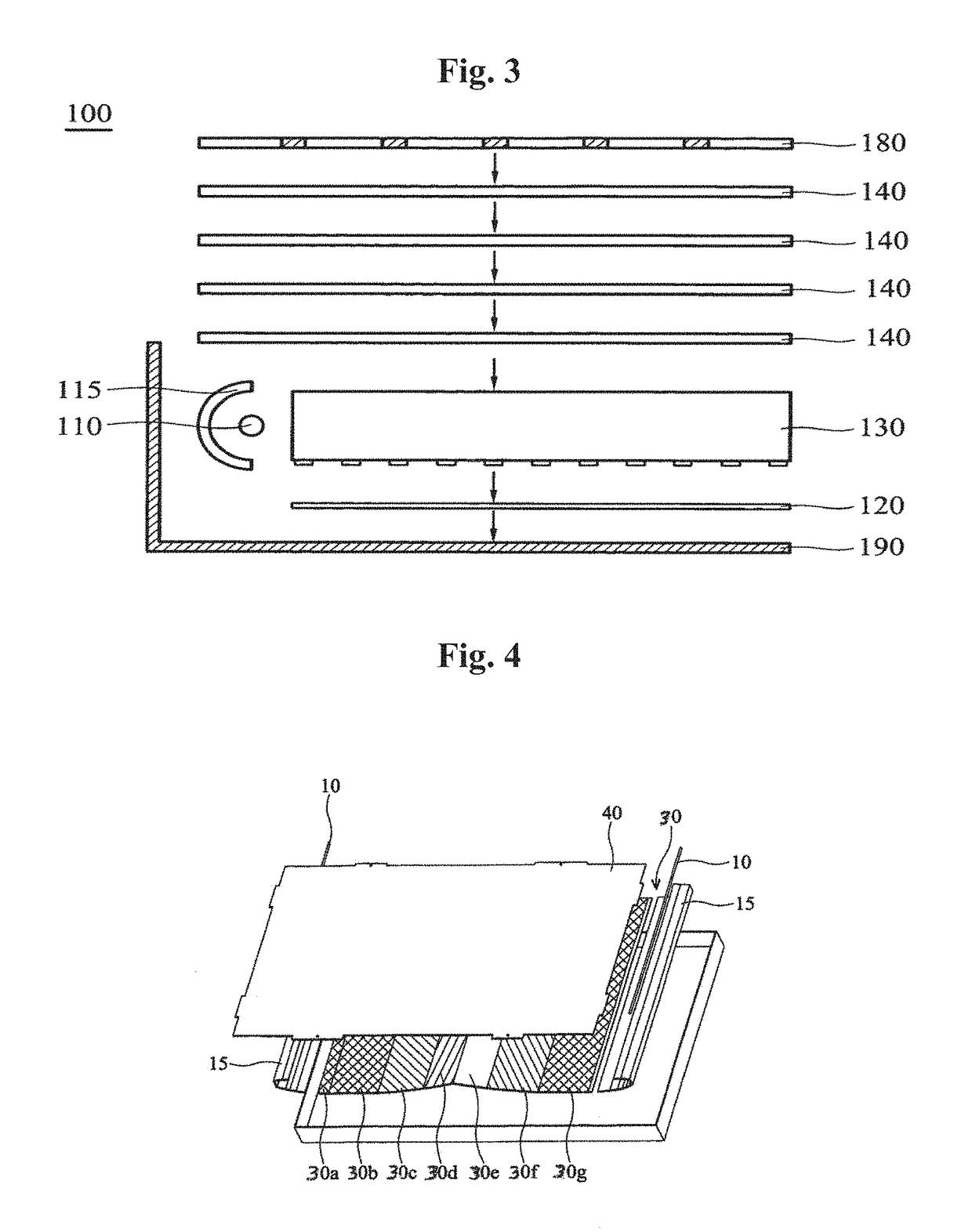

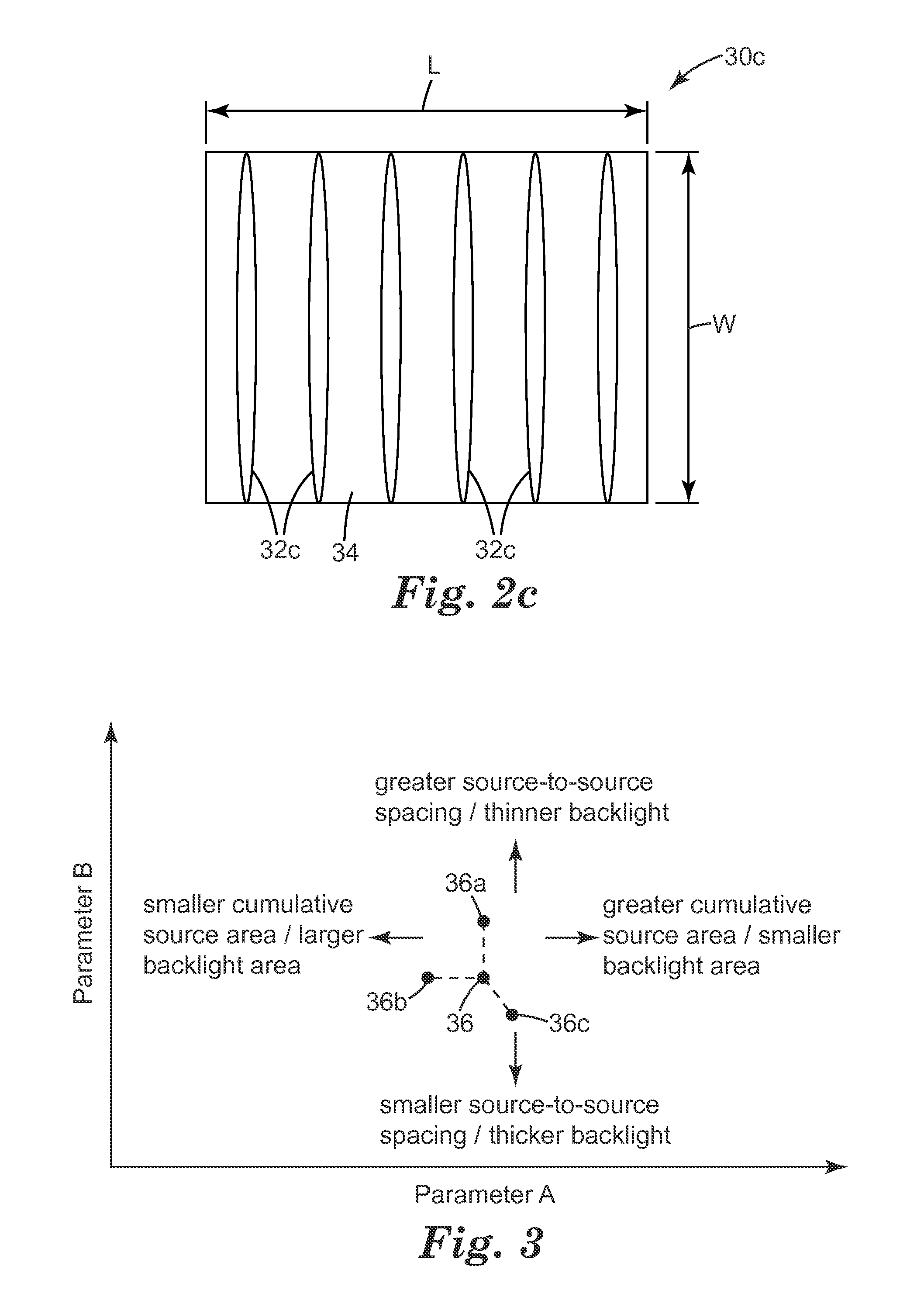

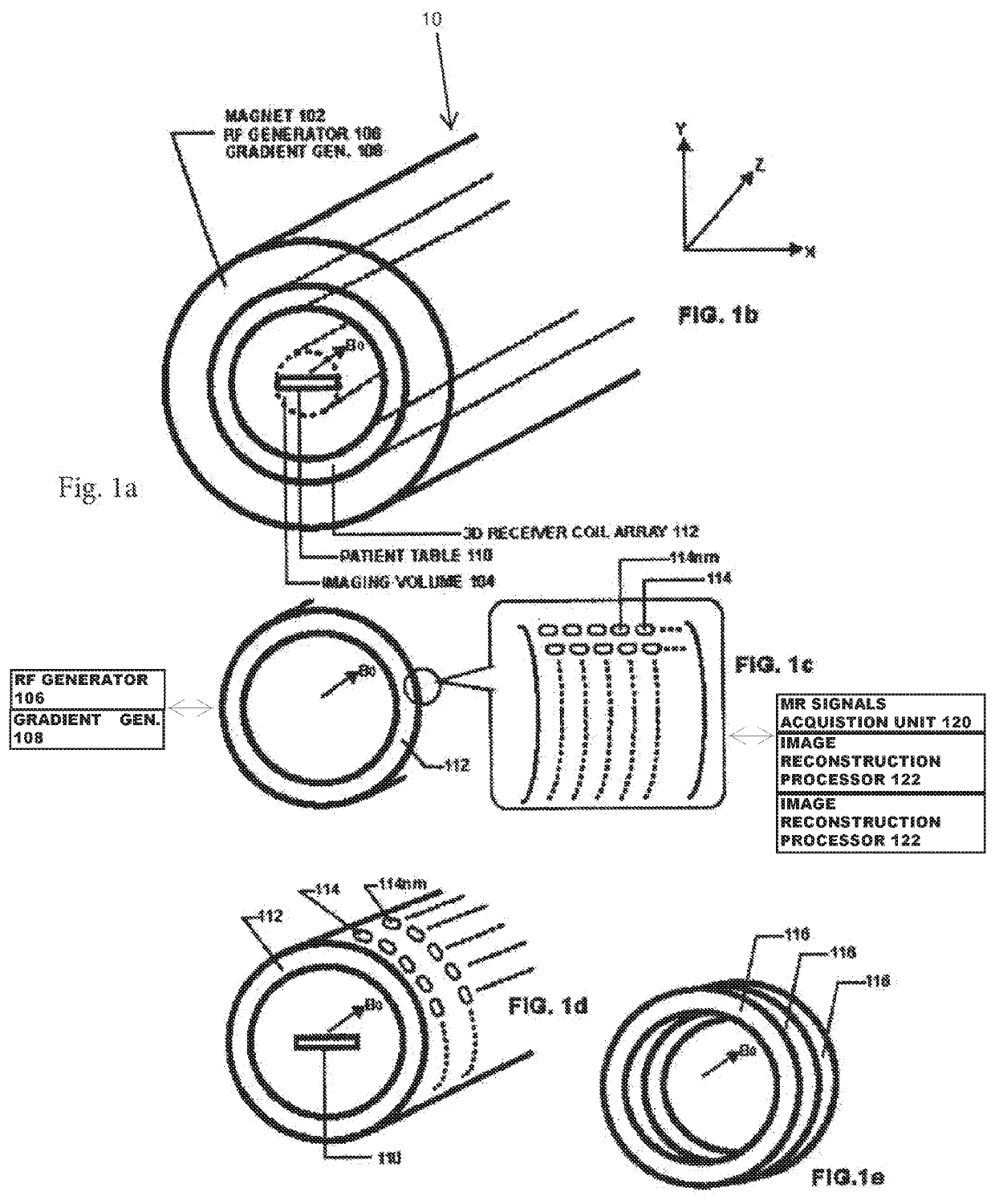

Thin hollow backlights with beneficial design characteristics

InactiveUS20140009963A1Reduce the total massHighly resistant to source failureHollow light guidesNon-linear opticsBack reflectorOptoelectronics

A front and back reflector are arranged to form a hollow light recycling cavity having an output region, and one or more light sources (e.g. LEDs) are disposed to emit light into the cavity. In one aspect, the back reflector has a design characterized by a first and second parameter. The first design parameter is a ratio of the collective emitting area of the light sources Aemit to the area of the output region Aout, and Aemit / Aout is preferably from 0.0001 to 0.1. The second design parameter is SEP / H, where H is the depth of the recycling cavity, and SEP is an average plan view source separation associated with the light sources. Other aspects of the disclosed extended area light sources are also described.

Owner:3M INNOVATIVE PROPERTIES CO

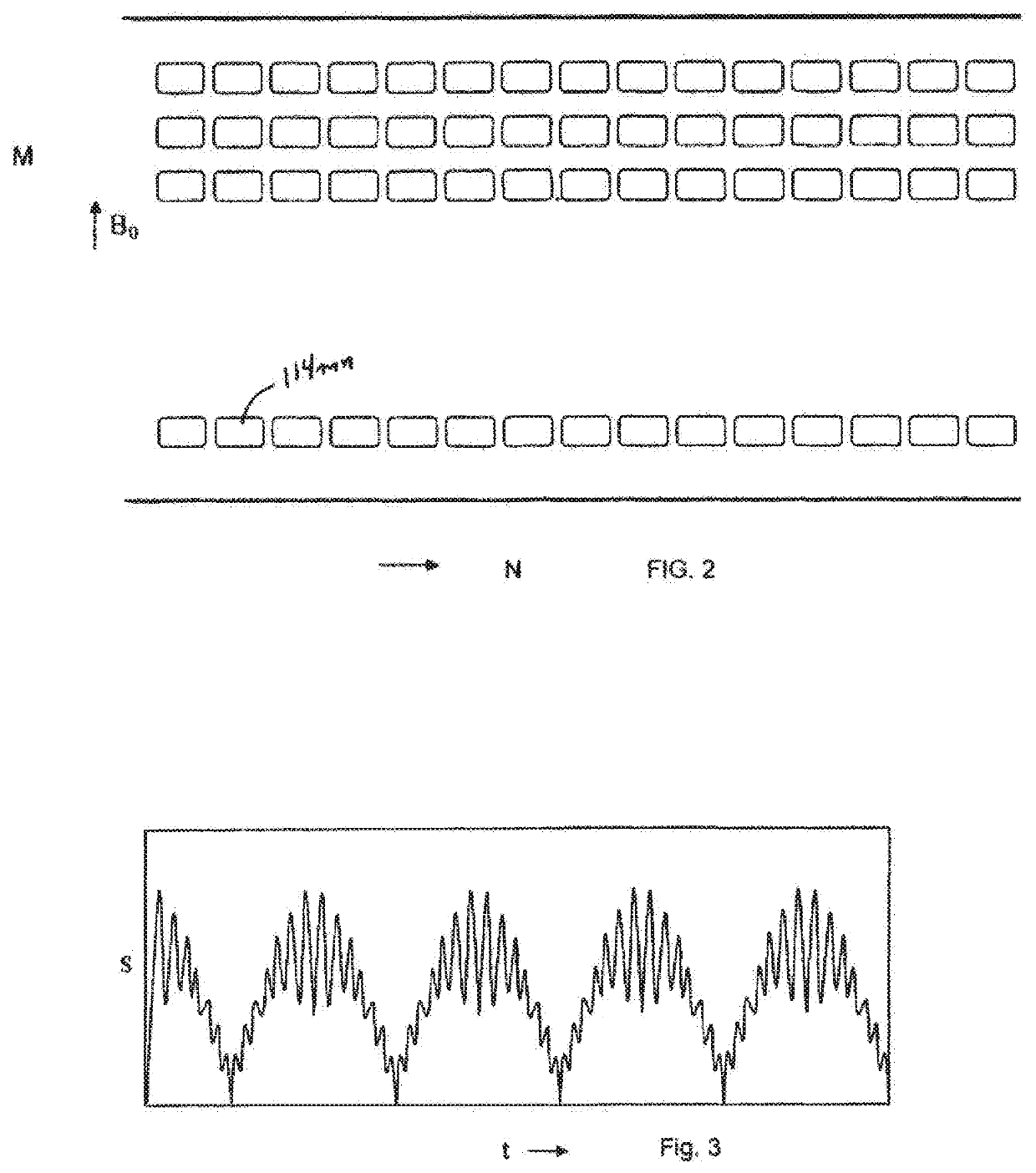

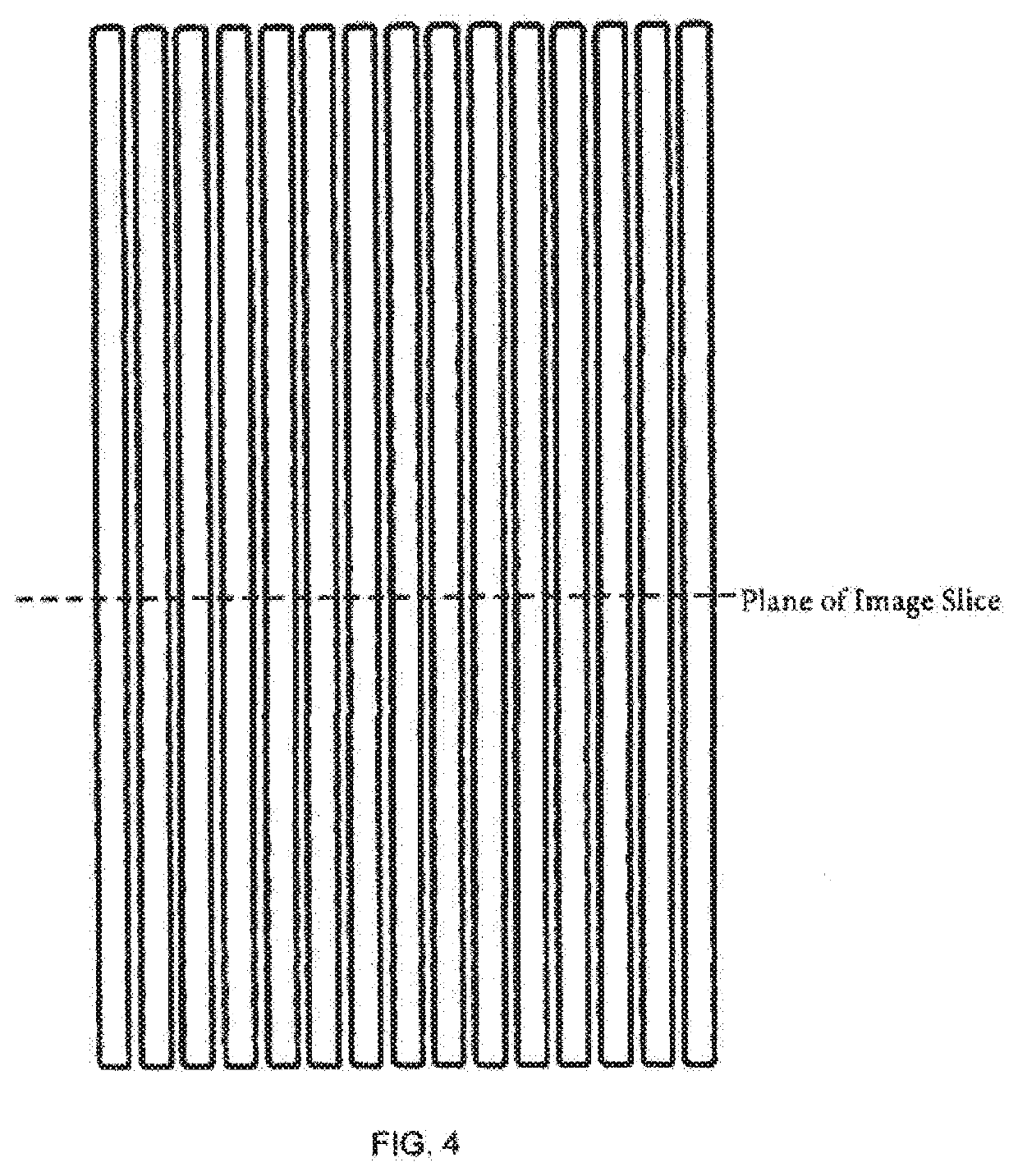

Ultrafast MRI System and Method

ActiveUS20200081087A1Strength be lowerImprove imagingImage enhancementReconstruction from projectionNuclear physicsRf noise

Magnetic Resonance Imaging (MRI), which is given the acronym ULTRA (Unlimited Trains of Radio Acquisitions), can eliminate magnetic gradient reversals and allow simultaneous MR signal acquisition from the entire object volume in each of a multitude of very small receiver coils arranged in a 3D array around the imaging volume, except for gradient reversals and / or RF pulses for refocusing spins into echoes. This permits a rate of MR signal acquisition that is greatly increased (e.g. 256 times) compared with existing techniques, with a full 3D image constructed in as little as 1 millisecond. Furthermore, noise—both audible and electrical—is substantially reduced. The advantages over conventional MRI include:1. Clinical imaging can be completed in seconds or less, with good signal-to-noise ratio;2. Signal-to-noise ratio further increased by reducing or eliminating RF noise due to gradient switching;3. Real-time functional MRI on millisecond timescales;4. With single breath holds, high quality imaging of thorax and abdomen.5. Greatly reduced audible noise and vibration.

Owner:HUTCHINSON MICHAEL

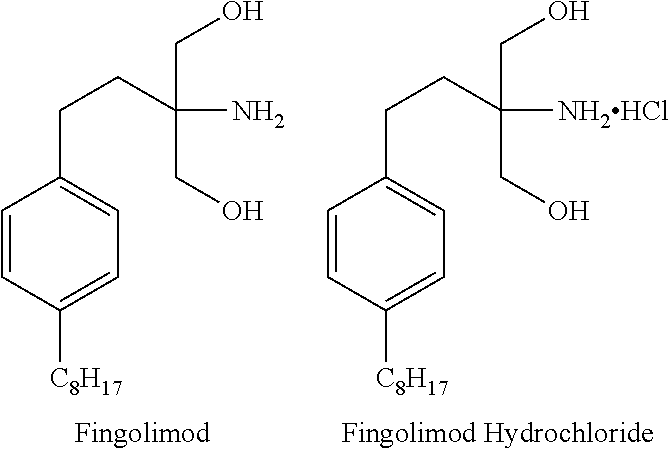

Fingolimod containing stable composition

ActiveUS20150165057A1Adequate rateImprove stabilityBiocideOrganic active ingredientsIon exchangeCombinatorial chemistry

The present invention relates to a pharmaceutical composition comprising fingolimod and a weak acid cation exchange resin in the form of an ion-exchange complex and pharmaceutically acceptable excipients.

Owner:SUN PHARMA INDS

Semiconductor manufacturing apparatus and semiconductor manufacturing method

ActiveUS11227762B2Ensuring sufficient uniformityIncrease the diameterSemiconductor/solid-state device manufacturingCleaning using liquidsGas passingEngineering

A semiconductor manufacturing apparatus includes a chuck stage, a stage rotation mechanism, a chemical liquid nozzle, a chemical liquid nozzle scan mechanism, a lower surface gas nozzle, a gas temperature controller configured to control a temperature of gas to be supplied to the lower surface gas nozzle, a gas bypass pipe configured to allow the gas to be supplied to the lower surface gas nozzle without causing the gas to pass through the gas temperature controller, and first and second on-off valves configured to open and shut to allow either of the gas whose temperature has been controlled by the gas temperature controller and the gas passing through the gas bypass pipe to be supplied to the lower surface gas nozzle. Actuation of the first and second on-off valves allows a temperature of the gas passing through the lower surface gas nozzle to be changed.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com