Hot upsetting process for cast ingot with large height to diameter ratio for ultra large ring forging

A super-large ring, high-diameter ratio technology, applied in metal processing equipment and other directions, can solve the problems of uneven distribution, excessive stress in the ingot, instability of the ingot, etc., to achieve uniform strain distribution, uniform internal structure, good quality performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (this example is illustrated with 42CrMo material):

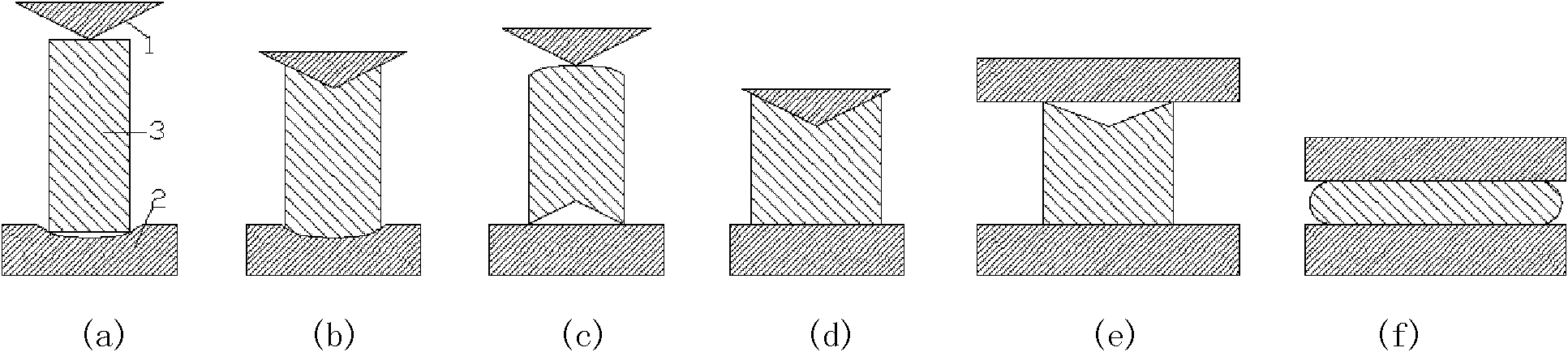

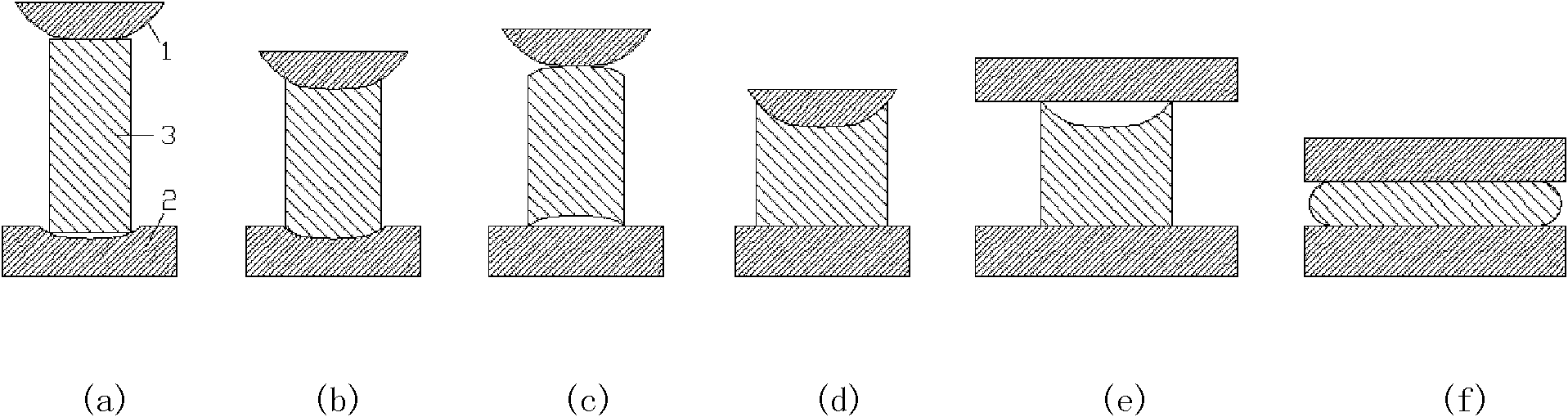

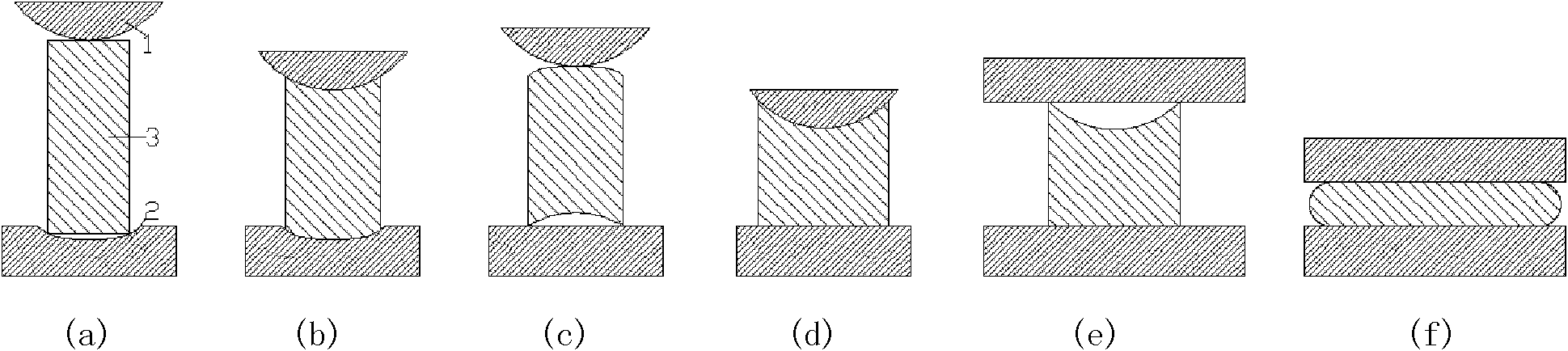

[0037] Such as figure 1 , Figure 4 , Figure 7 As shown, the hot upsetting process of super-large ring forgings with large aspect ratio ingots includes the following steps:

[0038] 1) The height-to-diameter ratio H / D of the 42CrMo round ingot is 3.0, the height of the 42CrMo round ingot is 3000mm, and the diameter is 1000mm. The 42CrMo round ingot is heated to the initial forging temperature of 1150°C, and the heated high-height-diameter ratio is The high-temperature ingot (42CrMo round ingot) is hung on the lower concave mold 2 to ensure that the centerlines of the ingot and the lower concave mold coincide, and the ingot and the lower concave mold are transported through the workbench and enter the press;

[0039] 2) Adjust the position of the upper convex mold 1 to ensure that the centerline of the upper convex mold coincides with the centerline of the ingot and the lower concave mold 2; at this t...

Embodiment 2

[0047] It is basically the same as Example 1, except that the material of the ingot is TA2, the height-to-diameter ratio H / D of the ingot is 3, and the initial forging temperature of the ingot is 980°C; the upper convex die adopts figure 2 , Figure 5 Structure.

Embodiment 3

[0049] It is basically the same as Example 1, except that the material of the ingot is GCr15, the height-to-diameter ratio H / D of the ingot is 3, and the initial forging temperature of the ingot is 1050-1100°C; the upper convex die adopts image 3 , Figure 6 Structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com