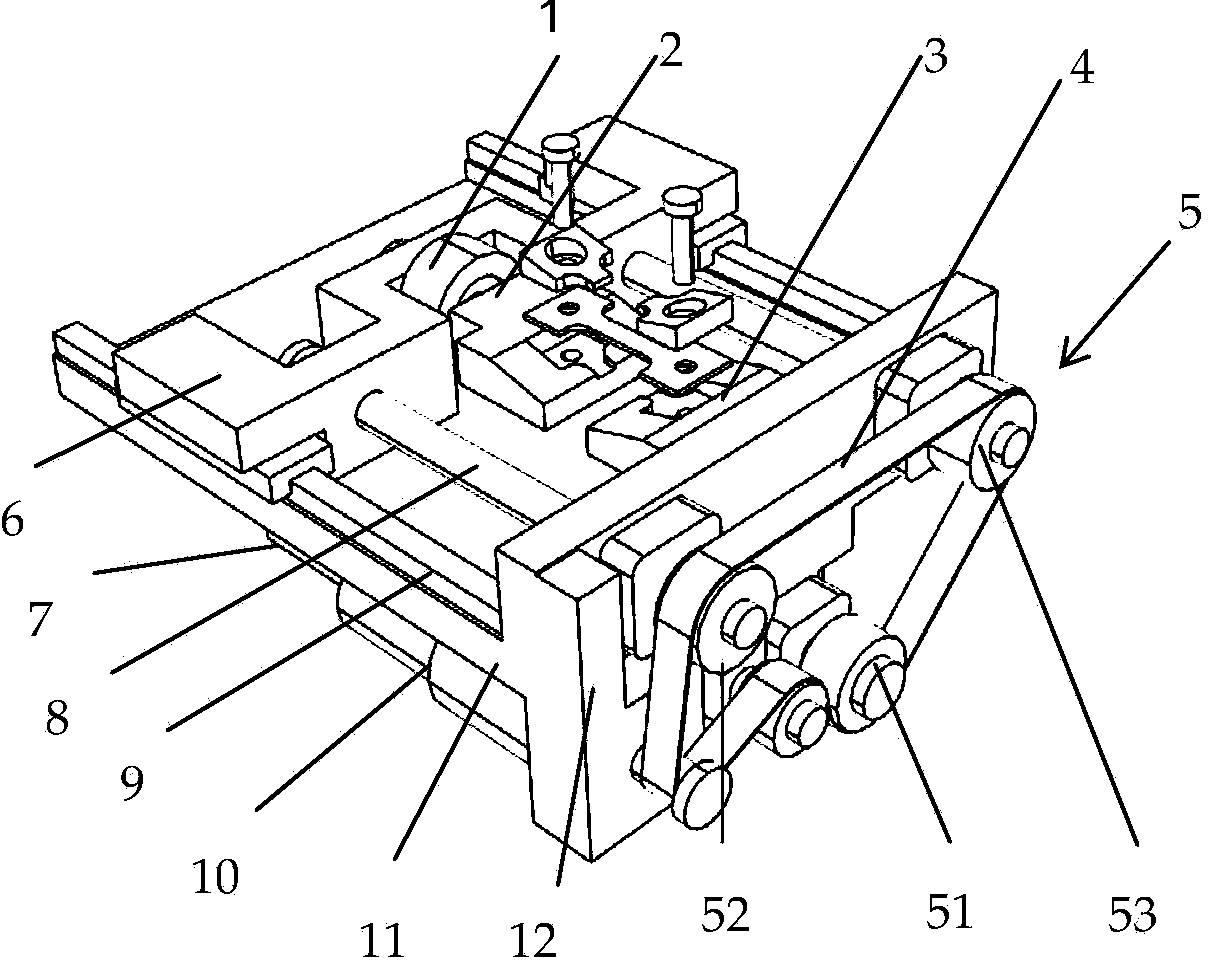

Synchronous radiation X-ray diffraction in-situ stretching device and application method thereof

An in-situ stretching and X-ray technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem that the stretching device cannot be docked with the diffractometer, and achieve accurate and reliable test results. Accurately characterized, stable and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The stretching device of the present invention is on the Huber5021 type six-circle synchrotron radiation X-ray diffractometer, and the measurement method of synchrotron radiation X-ray diffraction in-situ stretching is applied to the Huber5021 type six-circle synchrotron radiation X-ray diffractometer, and the wavelength is 0.12396nm. Equally with Fe-13%Cr-4%Ni (weight percent) martensitic stainless steel as experimental object, this method is carried out as follows:

[0062] 1) The sample is machined into a 14mmX43mmX0.5mm plate-shaped stretched part, the surface of the sample is ground and then mechanically polished, and then electrolytic polishing is performed to eliminate the stress layer on the surface of the stretched part;

[0063] 2) When the rear sample loading jig 2 is adjusted to a distance of 45mm from the front sample fixing jig 3 through the computer operating system, fix the two ends of the tensile sample 18 on the front sample fixing jig 3 and the rear sa...

Embodiment 2

[0071] The laboratory X-ray diffraction in-situ tensile measurement method is applied to the Japanese Rigaku D / max-2500PC X-ray diffractometer. The wavelength of the copper target is selected to be 0.15418nm, and Fe-13%Cr-4%Ni (weight percentage) Ma Tensitic stainless steel is used as the experimental object, and the method is carried out as follows:

[0072] 1) The sample is machined into a 14mmX43mmX0.5mm plate-shaped stretched part, the surface of the sample is ground and then mechanically polished, and then electrolytic polishing is performed to eliminate the stress layer on the surface of the stretched part;

[0073] 2) Start the computer operating system, move the rear sample loading fixture 2, adjust the distance between it and the front sample fixing fixture 3 to be 35 mm, and fix the two ends of the tensile sample 18 on the front sample fixing fixture 3 and the rear sample loading fixture 2. , and press the fixing gasket 17, and lock it with the locking screw 19, at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com