Distributive optical fiber detection method for mining overburden rock deformation

A technology of distributed optical fiber and detection method, which is applied in the direction of adopting optical devices, measuring devices, instruments, etc., to achieve the effects of easy installation, wide practicability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Laying of sensing optical fiber 2:

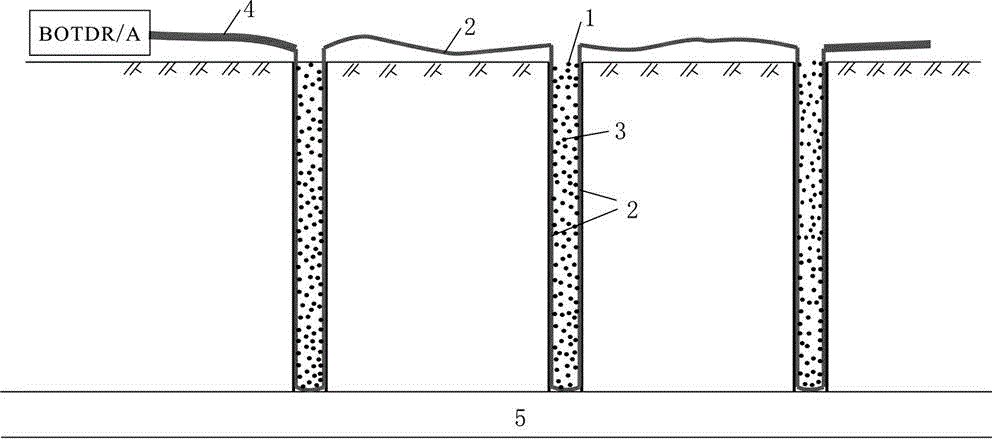

[0042] 1.1) Arrangement of monitoring holes. Boreholes 1 are arranged vertically from top to bottom every 10-50m along the mining direction of the working face. Boreholes 1 are variable-diameter holes whose diameter shrinks from the outside to the inside in stages. 110~200mm;

[0043] 1.2) Laying the sensing optical fiber 2, laying the sensing optical fiber 2 in a U-shape in the monitoring hole, the specific steps are:

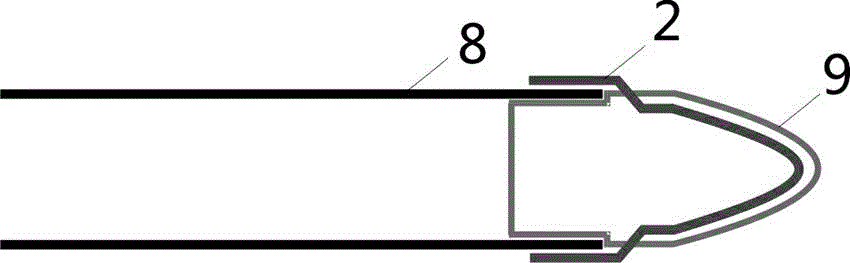

[0044]1.2.1) A counterweight 9 is provided for the drill pipe 8. The longitudinal section of the counterweight 9 is U-shaped, and its top port is provided with a connector that can match the inner diameter of the drill pipe 8. The side wall of the counterweight 9 is symmetrical There is a groove, the width and depth of the groove are 7-8mm respectively;

[0045] 1.2.2) Lay the sensing optical fiber 2 along the groove of the counterweight 9, paste the sensing optical fiber 2 in the counterweight 9 through epoxy r...

Embodiment 2

[0057] 1) Laying of sensing optical fiber 2:

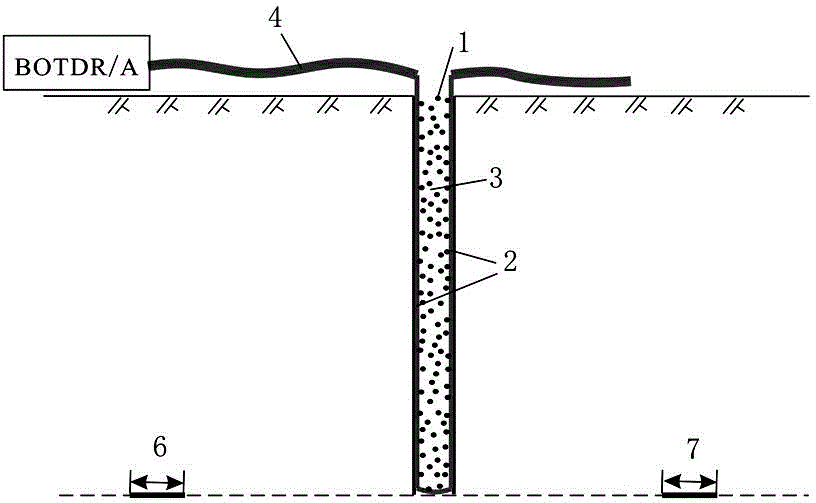

[0058] 1.1) Arrange monitoring holes, drill holes 1 from bottom to top at the roof of air inlet lane 6 and air return lane 7 of mining face 5, and drill holes 1 in the same direction as the vertical line, and arrange vertically from bottom to top every 50m Monitoring hole, the monitoring hole is a variable diameter hole, its diameter shrinks in stages from the outside to the inside, and the range of the hole diameter is 110-200mm;

[0059] 1.2) Laying the sensing optical fiber 2, laying the sensing optical fiber 2 in a U-shape in the monitoring hole, the specific steps are:

[0060] 1.2.1) A counterweight 9 is provided for the drill pipe 8. The longitudinal section of the counterweight 9 is U-shaped, and its top port is provided with a connector that can match the inner diameter of the drill pipe 8. The side wall of the counterweight 9 is symmetrical A groove is provided, and the width and depth of the counterweight 9 are respect...

Embodiment 3

[0073] 1) Laying of sensing optical fiber 2:

[0074] 1.1) Arrange monitoring holes. Drill hole 1 from bottom to top at the roof of air inlet lane 6 and return air lane 7 of mining face 5. The direction of drill hole 1 is at an angle of α with the vertical line. The monitoring holes are arranged in a straight line, and the monitoring holes are variable-diameter holes, whose diameter shrinks from the outside to the inside in stages, and the range of the hole diameter is 110-200mm;

[0075] 1.2) Laying the sensing optical fiber 2, laying the sensing optical fiber 2 in a U-shape in the monitoring hole, the specific steps are:

[0076] 1.2.1) A counterweight 9 is provided for the drill pipe 8. The longitudinal section of the counterweight 9 is U-shaped, and its top port is provided with a connector that can match the inner diameter of the drill pipe 8. The side wall of the counterweight 9 is symmetrical There is a groove, the width and depth of the groove are 7-8mm respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com