Optical fiber fused taper-based intrinsic Fabry-Perot device and manufacturing method thereof

An intrinsic type, optical fiber technology, applied in the field of optical fiber devices, can solve the problems of incomplete reversibility, long response time, stability and reliability disadvantages, etc., achieve high space selectivity, simple device structure, and improve sensing sensitivity and the effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

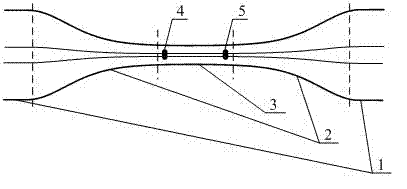

[0026] see figure 1 , the intrinsic type Fabry-Perot device based on the optical fiber fusion cone, including a fiber fusion cone, characterized in that the fiber fusion cone includes two sections of ordinary optical fiber (1), two sections of fiber fusion cone transition zone ( 2), a section of optical fiber fusion cone waist (3), a first optical fiber internal reflection mirror (4) and a second optical fiber internal reflection mirror (5), the optical fiber fusion cone is obtained by melting and drawing an ordinary single-mode optical fiber The first optical fiber internal reflector (4) and the second optical fiber internal reflector (5) are made of femtosecond pulse laser along the radial direction of the inner core (3) of the fiber melting cone waist in the optical fiber The reflective surface formed by changing the refractive index of the optical fiber at the waist of the melting cone; the diameter of the waist of the optical fiber melting cone (3) is 10-50 μm; the inter...

Embodiment 2

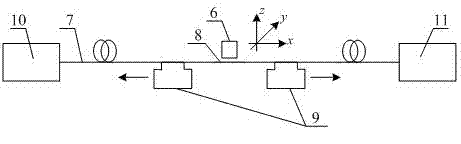

[0028] see figure 2 , the manufacturing method of the intrinsic type Fabry-Perot device based on the optical fiber fusion cone is used to manufacture the optical fiber fusion cone according to the first embodiment. Use the hydrogen-oxygen flame as the heat source (6) for melting and tapering: take a section of single-mode optical fiber (7) about 2 meters long, and peel off the coating layer about 1 cm long in the middle of the single-mode optical fiber, and wipe it clean with alcohol The single-mode optical fiber to be used in the bare fiber part (8) is placed on the fiber holder (9) with a distance of 3 cm. One end of the pigtail is connected to the broadband light source (10), and the other end is connected to the optical power meter (11) for Monitor the loss change of the fused optical fiber during the stretching process, and optimize the settings of parameters such as the stretching speed, stretching length, and hydrogen flow rate of the heat source. The diameter of the ...

Embodiment 3

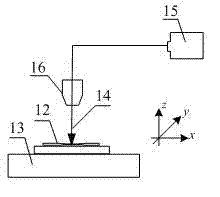

[0030] see image 3 , the manufacturing method of the intrinsic type Fabry-Perot device based on the fiber fusion cone is used to make the optical fiber Fabry-Perot cavity written on the waist of the fiber fusion cone by using the femtosecond laser according to the first embodiment . The prepared optical fiber fusion cone (12) is placed on a three-dimensional mobile platform (13), so that the axis of the optical fiber fusion cone (12) is perpendicular to the transmission direction of the femtosecond pulsed laser beam (14). The femtosecond pulse laser (15) is focused on the center of the fiber fusion cone waist through the objective lens (16) of the microscope, and the three-dimensional mobile platform moves along the transmission direction of the femtosecond pulse laser, so that the focal point of the femtosecond pulse laser scans the fiber radially The waist of the melting cone makes the femtosecond laser writing area cover the core of the fiber melting cone waist area, that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com