Single-roller extrusion type coconut shell-flesh separator

A shell and meat separation and extrusion technology, applied in the field of agricultural machinery, can solve problems such as inconvenience in taking coconut meat, and achieve the effects of improving service life, improving production efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe in detail the technical content, structural features, objectives and effects of a single-roll extrusion type coconut husk meat separator of the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

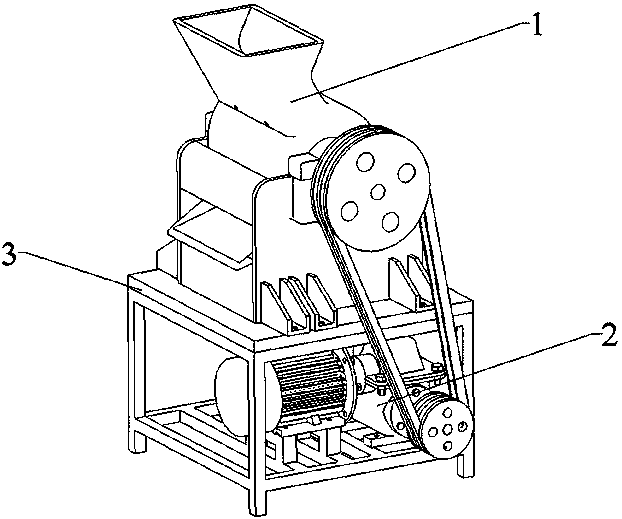

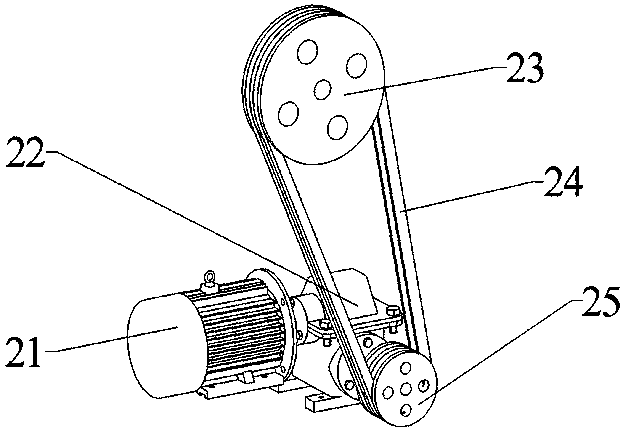

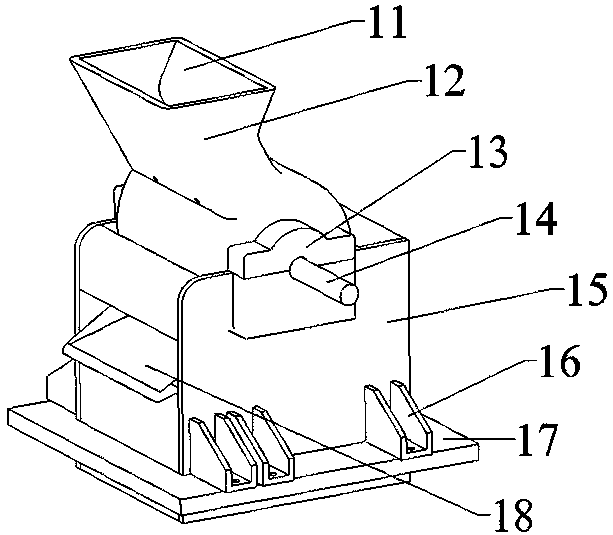

[0020] Such as figure 1 , 2 , 3, 4, 5, and 6, a single-roller extrusion type coconut shell meat separator is characterized in that it mainly includes a shell meat separation system 1, a transmission system 2, and a frame 3, and the shell meat separation system 1 includes feeding port 11, toothed roller extrusion shell 12, toothed roller bearing 13, toothed roller shaft 14, side plate 15, foot 16, support 17, discharge port 18, extrusion teeth 19, cleaning board 110, toothed roller 111; the transmission system 2 includes a motor 21, a reducer 22, a pulley I (23), a belt 24, and a pulley II (25).

[0021] The inside of the toothed roller extruding shell 12 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com